Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Development of Pervious Paver Block by Using Rap and Rice Husk Ash

Authors: Shashank Shekhar, Dr. Abhilash Shukla

DOI Link: https://doi.org/10.22214/ijraset.2023.56152

Certificate: View Certificate

Abstract

This specific kind of concrete is characterized by its interconnected pore structure and substantial void content or porosity, often ranging from 15 to 35% in terms of volume. Pervious concrete has the potential to mitigate the risk of floods, decrease storm-water runoff, attenuate noise generated by vehicle tires, and prevent glare and skidding in wet conditions by facilitating the infiltration of water via its porous structure, therefore replenishing the groundwater table. In light of the current state of the adjacent road networks, a conscientious endeavour is undertaken to develop a concrete paver with minimal permeability. Compression strength, void ratio, and infiltration experiments were conducted to evaluate the desired Mix proportions. In the current study, pervious paver blocks with a thickness of 60mm were manufactured using different percentages of RAP aggregate and rice husk ash. These blocks were specifically designed for medium traffic conditions. Consequently, the compressive strength is enhanced. Recycled asphalt pavement (RAP) aggregates provide a viable alternative to natural and synthetic aggregates for use into construction endeavours. The thesis provides an analysis of the potential use of rice husk ash residue. The compressive strength, density test, porosity, permeability, and durability of the paver block were assessed by several research investigations.

Introduction

I. INTRODUCTION

The rapid urbanization and growth in infrastructure development have led to an escalating demand for construction materials, often resulting in the depletion of natural resources. Additionally, the construction industry is one of the significant contributors to landfill waste, which aggregates environmental concerns [5,17]. Thus, there is an increasing need for sustainable alternatives in construction materials that are both economically viable and environmentally friendly. The study aims to address two significant issues: waste management and sustainable construction By utilizing Rice husk ash, a byproduct of the boiler industry, and RAP aggregates, waste from road renovation or construction, the study aims to reduce landfill waste [4,5,9,10,14,16,18]. Secondly, by developing pervious paver blocks, the study aspires to contribute to the sustainability of urban infrastructure by allowing better water management and utilizing waste materials that are usually considered non-recyclable.

Due to its interconnected pore structure, pervious concrete is a high-performance concrete that has a comparatively high-water permeability compared to standard concrete [15,19,20]. Porous concrete and permeable concrete are other names for pervious concrete. It may be made using the standard components for building concrete, such as cement, cement additives, various kinds of coarse and fine aggregates, and water. Fine aggregate without the finest component, binder ingredients, and water are used to make pervious mortar[1,12].

In order to reduce runoff from a site and enable groundwater recharge, pervious concrete is a specific kind of concrete with a high porosity that is used for concrete flatwork applications. Pervious concrete enables water from precipitation and other sources to flow through directly[1,12]. The terms porous concrete, permeable concrete, no fines concrete, and porous pavement are also used to describe it. Large aggregates, with little or no small particles, are used to make pervious concrete. Additionally, roads, footpaths, and pathways with modest loading intensities are excellent places to use pervious concrete. The Environmental Protection Agency (EPA) regards pervious concrete as a means of providing stormwater management, pollution reduction, and appropriate development [17]. It is a composite material made by combining crushed stone, inert sand and gravel, and cement. Because of its light colour and open-cell structure, this concrete does not absorb heat from the sun and does not reflect heat back into the atmosphere, which lowers environmental heating. Installing pervious concrete is inexpensive. Furthermore, it filters storm water, lowering the amount of contaminants that reach rivers and ponds. Additionally, pervious concrete promotes tree growth.

Our project's primary goal is to enhance pervious concrete's strength properties. However, it should be observed that the permeability of pervious concrete will decrease as strength increases. Therefore, because the permeability quality serves a function, the development of strength shouldn't have an impact on it [3].

It has been discovered that pervious concrete, also referred to as no-fines, porous, gap-graded, and permeable concrete, and enhance porosity concrete, is a dependable storm water management strategy. Gravel or granite stone, cement, water, and little to no sand (fine aggregate) are the main components of pervious concrete, according to definition. Storm water may seep through pervious concrete pavements and into the soil’s underneath thanks to the open cell architecture. In other words, pervious concrete contributes to the preservation of the environment and the pavement's surface.

II. DESIGN OF PAVER BLOCK

Unusual uses of waste materials reduce the burden on the environment and available resources. The manufacture of paver blocks may easily make use of a variety of wastes thanks to the repolymerization process, which can lead to the preservation of high-quality resources. Savings and sustainable practices will also result from this. Numerous studies have examined the properties of cement concrete with RAP aggregates; however, in this research, we are mixing two types of waste materials with RAP aggregates and sugarcane bag ash in various proportions.

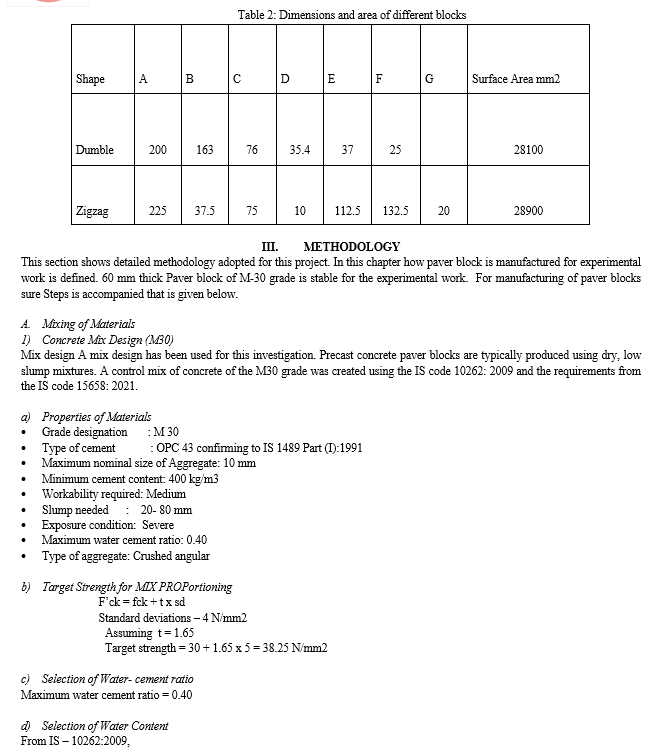

A. Dimension of the Paver Blocks

First, the dimensions for paver block manufacture are chosen in accordance with the producer, as shown beneath:

Shape: I section

Length: 200 mm

Width: 160 mm

Thickness = 80 mm

Aspect ratio (L/T) = 200/80 = 2.5 < 4.0 as in step with IS 15658: 2021

Area shall be calculated by as per IS 15658: 2021 their method and regard is given under.

IV. RESULTS AND DISCUSSION

Pervious paving systems are increasingly recognized as an eco-conscious choice for tackling stormwater management issues. In our research, we focused on creating a permeable paver block formulated with rice husk ash and reclaimed asphalt pavement (RAP) aggregates, evaluating its viability based on various performance metrics.

Incorporating rice husk ash, an often-discarded byproduct of rice milling, presents multiple advantages. For one, rice husk ash serves as a sustainable alternative to conventional cementing agents, helping to divert waste from landfills. Furthermore, the use of RAP aggregates in the mixture contributes to conservation efforts by diminishing the need for new, virgin aggregates. This also results in a reduction of the environmental costs tied to mining and transporting these raw materials. Beyond material recycling, the engineered block exhibits significant stormwater management potential. Its permeable structure allows rainwater to percolate into the soil, thereby decreasing surface runoff and mitigating risks associated with flooding and soil erosion. While the preliminary findings are encouraging, more comprehensive studies are necessary to gauge the material's durability and long-term efficacy under real-world conditions. A financial analysis to assess the economic viability of this innovative material for broader applications is also recommended.

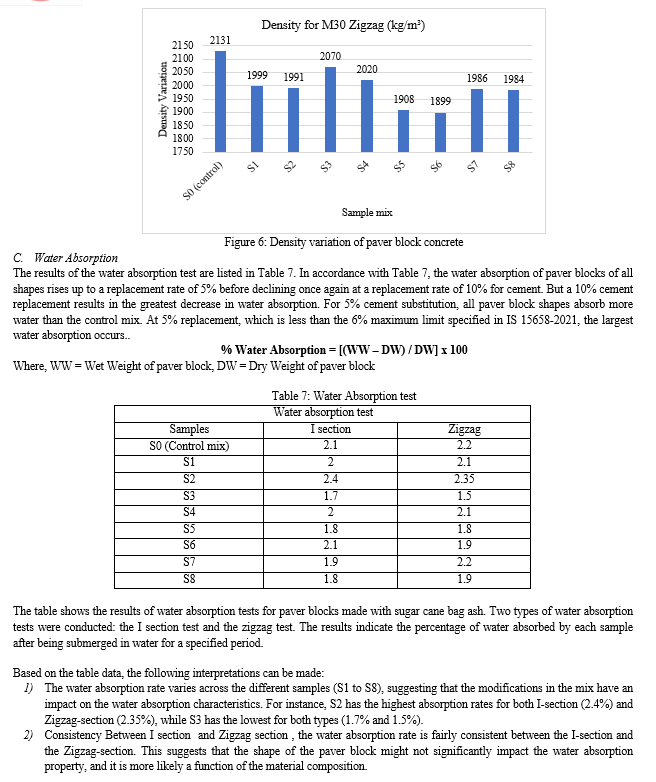

???????A. Workability of Concrete

The result of the slump cone test for each grade of concrete has been tabulated in table 5 for each grade of concrete.

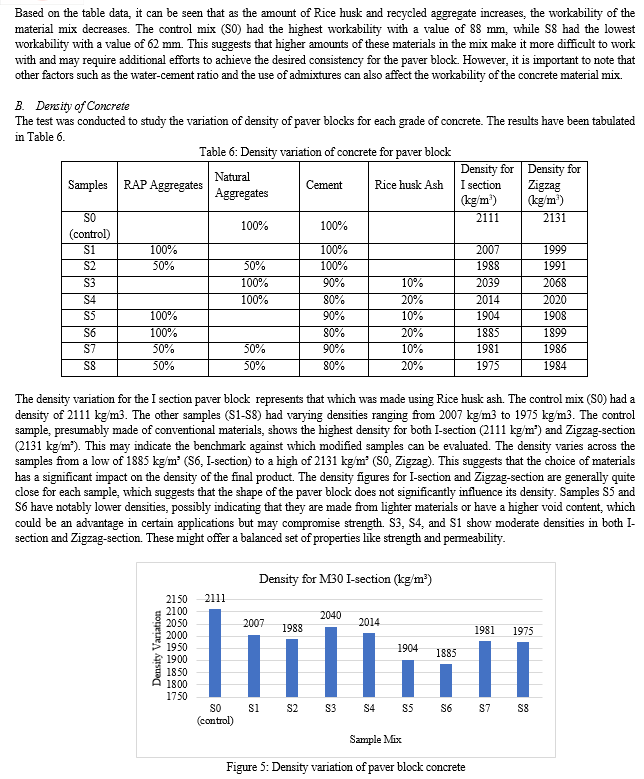

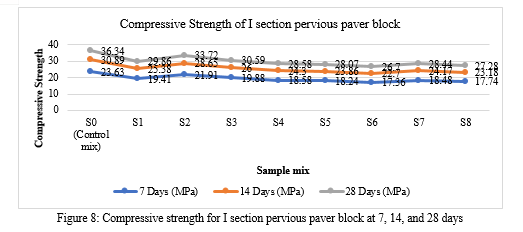

The table provides a comprehensive look at the compressive strength of I-section pervious paver blocks made from various mixes, measured at 7, 14, and 28 days of curing. Overall, the control sample (S0) serves as a high-performance benchmark, showcasing the greatest strength across all time intervals and reaching 36.34 MPa after a 28-day curing period. All the alternative mixes show an upward trend in strength as the curing time increases, which aligns with the typical behavior of concrete materials. However, these mixes also show a trade-off in compressive strength compared to the control, with reductions ranging from minor to significant. For instance, Sample S2 emerges as a relatively strong performer, reaching a 28-day strength of 33.72 MPa, thus presenting itself as a potential alternative for certain applications. Conversely, samples like S6 lag behind, with a 28-day strength of just 26.7 MPa, making them more suited for low-load-bearing applications. The consistency in the increase in strength over time for all samples suggests that the curing conditions were uniform, adding credibility to the data. Overall, the table indicates that while the control mix remains the gold standard in terms of compressive strength, some alternative mixes offer promising, albeit lower, performance levels and could be considered for specific, less demanding applications. In summary, while the control mix offers the highest compressive strength, certain alternative mixes also exhibit promising results, especially after 28 days of curing. However, the reduced strength in most alternative mixes indicates that careful consideration is needed to determine their suitability for specific applications. From a practical standpoint, S0 remains the most desirable mix for long-term strength. The choice between other mixes would depend on specific strength requirements and the timeframe in which those strengths are needed.

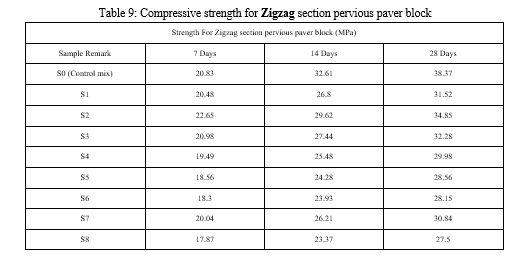

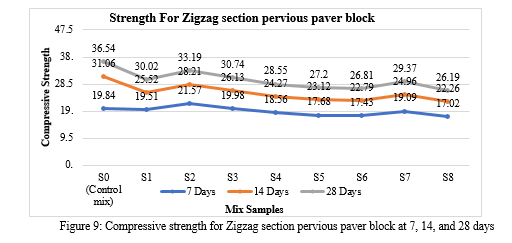

???????E. Compressive Strength of Zigzag section

The table you provided shows the strength values of different mixes of pervious paver blocks at three different time intervals: 7 days, 14 days, and 28 days. This type of testing is often done to see how the strength of a mix matures over time. Here's an interpretation of the data:

The table presents the compressive strength of Zigzag section pervious paver blocks at different curing periods: 7, 14, and 28 days. The control sample (S0) serves as a benchmark with a compressive strength of 20.83 MPa, 32.61 MPa, and 38.37 MPa at 7, 14, and 28 days respectively.

The data indicates that sample S2 outperforms the control mix at all curing stages, reaching a compressive strength of 22.65 MPa at 7 days, 29.62 MPa at 14 days, and 34.85 MPa at 28 days. S3, S1, and S7 also show competitive results but are generally lower in compressive strength compared to the control mix, especially at the 28-day mark.

On the other hand, samples S4, S5, S6, and S8 exhibit relatively lower compressive strengths throughout the curing period. Particularly, S8 lags considerably with a 28-day strength of just 27.5 MPa, indicating that its mix composition may not be as effective for achieving high strength. The table provides valuable insights into the effectiveness of different mix compositions in achieving desired compressive strengths. This information can be crucial for selecting the appropriate mix for specific applications of pervious paver blocks. From an application perspective, the choice of mix would depend on the required final strength and the time within which the strength is desired. For instance, if one needs a strong mix quickly, S2 may be suitable. However, for long-term strength, the control mix (S0) might be the preferred choice.

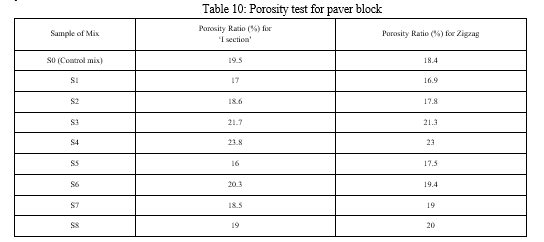

???????F. Porosity Test for Paver Block

The porosity test was carried out in accordance with IS-15658-2021.

The control mix (S0) has porosity ratios of 19.5% for the 'I section' and 18.4% for the Zigzag section. This serves as the baseline for comparing other mixes. S1, with a 17% porosity for 'I section' and 16.9% for Zigzag, exhibits lower porosity compared to the control mix. This could suggest higher material density or fewer voids, possibly leading to less water permeability. S2 and S7 are closer to the control in terms of porosity, which could indicate a more balanced mix of constituents that retain similar permeability characteristics to the control. S3 and S4 show elevated porosity levels, with S4 reaching the highest porosity of 23.8% for 'I section' and 23% for Zigzag. These high ratios likely point to enhanced water permeability but could indicate lower structural strength. On the contrary, S5 has the lowest porosity at 16% and 17.5% for 'I section' and Zigzag, respectively. This could mean a denser, stronger material but at the cost of reduced water permeability. S6 offers a porosity ratio that is slightly higher than the control for both block types, suggesting it might offer a balance between permeability and strength. Finally, S8 has a comparable porosity ratio to the control mix but leans towards higher porosity in the Zigzag configuration.

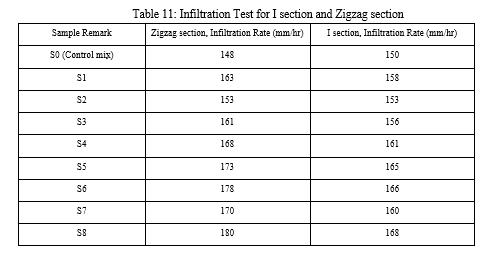

???????G. Infiltration Test

The infiltration test is a method used to determine the rate at which water can infiltrate, or penetrate, into the soil or other porous media. It is a crucial parameter for various engineering applications, especially in hydrology, agriculture, and civil engineering, where understanding water movement is critical.

???????

???????

Conclusion

The study likely discussed the experimental investigation of different mix designs of pervious paver blocks containing Rice husk ash and RAP aggregates, along with conventional materials such as cement and sand. The methodology may include the preparation of different mixes, testing of their physical properties, and measuring their performance in terms of permeability and compressive strength. Based on the findings, the conclusion may suggest that the use of Rice husk ash and RAP aggregates can enhance the permeability of the pervious paver blocks, as well as provide satisfactory compressive strength. The thesis may also suggest that the use of these sustainable materials can contribute to reducing waste and promoting sustainable construction practices. A. Strength Analysis of Paver block for Zigzag shape 1) Benchmark Strength: The control sample (S0) provided a robust benchmark with compressive strengths of 20.83 MPa, 32.61 MPa, and 38.37 MPa at 7, 14, and 28 days, respectively. 2) Strength Improvements: The alternative sample S2 performed remarkably well, with compressive strengths exceeding that of the control sample at each measurement period (7, 14, and 28 days). This indicates that specific alternative mixes have the potential to yield higher compressive strengths than the control. 3) Long-Term Viability: Like with the I-section, the 28-day strength data for most samples were promising. S2, S1, and S3 show 28-day strengths greater than 30 MPa, which is an indicator of their long-term durability and usability in construction applications. 4) Weaker Performers: Samples such as S8 and S6 performed relatively poorly compared to the control, especially at the 28-day mark. This suggests that not all alternative mixes are equally viable for high-strength requirements. 5) Consistent Growth: A general trend of increasing strength from 7 days to 28 days was observed across most samples, indicating the material\'s suitability for long-term applications. In summary, while the control sample gives a strong baseline of performance, certain alternative mixes like S2 show that it\'s feasible to achieve higher compressive strength. These findings offer a path for further optimizing the material composition for achieving a balance of high strength and permeability, which can be critical in certain construction applications. B. Strength Analysis of Paver block for I shape 1) Control Strength: The control sample (S0) sets the standard with compressive strengths of 23.63 MPa, 30.89 MPa, and 36.34 MPa at 7, 14, and 28 days, respectively. This sample serves as the baseline for assessing the performance of alternative mixes. 2) Alternative Mixes: Notably, the alternative mix S2 outperforms the control in compressive strength at all observed time intervals (7, 14, and 28 days), indicating that certain alternative mixes can be formulated to yield greater compressive strengths. 3) Long-Term Strength: The 28-day strengths for most samples were generally promising. Samples S2, S1, and S3, for instance, demonstrated strengths close to or exceeding 30 MPa, highlighting their potential for long-term durability. 4) Weaker Mixes: Some mixes like S6 and S8 lag behind the control sample and other stronger mixes, particularly at the 28-day mark. These compositions might not be suitable for applications requiring high compressive strength. 5) Consistency: The compressive strength generally increased consistently from 7 days to 28 days across all samples, which is a good indicator of the material\'s long-term reliability. In conclusion, while the control sample offers a solid benchmark, alternative mixes such as S2 provide compelling advantages in compressive strength. This suggests that with the right mix formulation, it\'s possible to develop I-section pervious paver blocks that meet or even exceed standard performance metrics. Further research could focus on optimizing these mixes for a balanced performance in terms of both strength and permeability. a) Porosity: Generally, the I-section tends to have slightly higher porosity percentages than the Zigzag section across most sample mixes. Higher porosity would typically lead to better water infiltration and could be advantageous for groundwater recharge. However, this may also indicate a potential compromise in mechanical strength, which needs to be further investigated. b) Infiltration Rate: The infiltration rates for both configurations show that changing the mix composition has a significant impact on water infiltration capability. While both sections exhibit variable rates depending on the sample mix, the I-section generally appears to have comparable or slightly lower infiltration rates than the Zigzag section. In summary, both I-section and Zigzag section pervious paver blocks have their merits and demerits. The optimal choice would depend on the specific requirements of the project, taking into account factors like porosity, infiltration rates, mechanical strength, and cost.

References

[1] Saboo, N., Nirmal Prasad, A., Sukhija, M., Chaudhary, M., & Chandrappa, A. K. (2020). Effect of the use of recycled asphalt pavement (RAP) aggregates on the performance of pervious paver blocks (PPB). Construction and Building Materials, https://doi.org/10.1016/j.conbuildmat.2020.120581 [2] Elavenil, S., & Ramamurthy, K. (2020). Influence of rice husk ash and metakaolin on the mechanical properties and durability of pervious concrete. Journal of Cleaner Production, 259, 120879. [3] Liu, Y., & Shu, X. (2020). Study on the mechanical properties of pervious concrete prepared with different mineral admixtures. Materials Research Express, 6(12), 125502. [4] Ganesh, P., Kannan, P., & Santhanam, M. (2019). Sustainable paving blocks using rice husk ash: A review. Construction and Building Materials, 229, 116890. [5] Goh, S. W., Chai, G. F., & Liu, M. (2016). Sustainable pavement material: Review of recycled concrete aggregates in pervious pavement. Procedia Engineering, 145, 1473-1479. [6] Scholz, M., Grabowiecki, P., & Gersonius, B. (2019). Review of permeable pavement systems. Sustainable Water Resources Management, 5(4), 1895-1919. [7] Wang, K., Shi, X., & Zhu, H. (2015). Pervious concrete pavement: A review. Journal of Civil Engineering and Management, 21(3), 312-326. [8] Kumar, S., & Bhattacharyya, S. K. (2020). Sustainable pervious concrete with improved mechanical and durability properties: A review. Journal of Building Engineering, 32, 101788. [9] Hu, J., & Li, R. (2020). A review of pervious concrete incorporating industrial waste. Sustainability, 12(4), 1631. [10] Shen, D., Li, X., & Zhao, J. (2020). Utilization of recycled waste ceramic powder (RWCP) in pervious concrete. Construction and Building Materials, 234, 117414. [11] Kadir, A. A., & Eida, S. F. (2020). Behavior of pervious concrete with nanosilica under freezing and thawing cycles. Cold Regions Science and Technology, 171, 102903. [12] Zhang, Y., & Shi, C. (2021). A review on sustainability of pervious concrete pavements with an emphasis on materials, mix design, construction, and maintenance. Construction and Building Materials, 278, 122336. [13] Ting Bao a, b , Zhen (Leo) Liu b, * , Xingui Zhang a, **, Yuhui He a (2019). A drainable water-retaining paver block for runoff reduction and evaporation cooling https://doi.org/10.1016/j.jclepro.2019.04.142 [14] Mohd Zulqar Nain, Senthil Kasilingam (2023), Influence of rice husk ash and bagasse ash on durability of concrete https://doi.org/10.1016/j.matpr.2023.06.464 [15] R. Dharmaraj a, M. Dinesh a, Saranya Sampathkumar b, M. Haripprasath a, V. Chandraprakash (2023) High performance concrete using rice husk ash https://doi.org/10.1016/j.matpr.2023.04.104 [16] Nelson R. Camargo-Pérez, Joaquín Abellán-García, Luis Fuentes (2023) Use of rice husk ash as a supplementary cementitious material in concrete mix for road pavements https://doi.org/10.1016/j.jmrt.2023.07.033 [17] Joaquin Abellan-Garcia a, Daniela M. Martinez a, M. Iqbal Khan b, Yassir M. Abbas b, Francisco Pellicer-Martínez (2023) Environmentally friendly use of rice husk ash and recycled glass waste to produce ultra-high-performance concrete https://doi.org/10.1016/j.jmrt.2023.06.041 [18] Arshdeep Singh a, Ran Bir Singh b, Bhupinder Singh (2023) Thixotropic evaluation of a highly-workable and a flowable concrete made with Rice Husk Ash https://doi.org/10.1016/j.jobe.2023.105990 [19] Helena Lunkes Strieder, Vanessa Fátima Pasa Dutra, Ângela Gaio Graeff, Washington Peres Núñez, Felipe Raul Meert Merten (2022) Performance evaluation of pervious concrete pavements with recycled concrete aggregate https://doi.org/10.1016/j.conbuildmat.2021.125384 [20] Nian Hu, Jiong Zhang, Shuang Xia, Ruonan Han, Zhaoxia Dai, Rui She, Xinzhuang Cui, Bowen Meng (2020) A field performance evaluation of the periodic maintenance for pervious concrete pavement https://doi.org/10.1016/j.jclepro.2020.121463

Copyright

Copyright © 2023 Shashank Shekhar, Dr. Abhilash Shukla. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET56152

Publish Date : 2023-10-14

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online