Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Development of Pervious Paver Block Using Sugarcane Bagasse Ash & RAP Aggregates

Authors: Shivam Chauhan, Dr. M. K. Trivedi

DOI Link: https://doi.org/10.22214/ijraset.2023.55575

Certificate: View Certificate

Abstract

This particular kind of concrete is distinguished by its interconnected pore structure and significant void content or porosity, which typically varies from 15 to 35% by volume. Pervious concrete may lower the danger of flooding, diminish storm-water runoff, reduce noise when in contact with automobile tires, and avoid glare and skidding during rainy seasons by allowing water to easily infiltrate through its pores and replenish the ground water table. Considering the condition of the neighboring roadways, a modest effort is undertaken to construct the least amount of porous paver concrete. For the planned Mix proportions, compression strength, void ratio, and infiltration tests were conducted. In the current study, 60mm thick pervious paver blocks for medium traffic with different RAP aggregate percentages and sugarcane bag ash are cast. This improves the compressive strength. RAP aggregates are a suitable material that may be utilized in place of natural and artificial aggregates in construction projects. The thesis shows how discarded sugarcane ash may be used again. Several experiments were conducted to evaluate the compressive strength, density test, porosity, and permeability of the planned paver block as well as its durability.

Introduction

I. INTRODUCTION

The rapid urbanization and growth in infrastructure development have led to an escalating demand for construction materials, often resulting in the depletion of natural resources. Additionally, the construction industry is one of the significant contributors to landfill waste, which aggravates environmental concerns. Thus, there is an increasing need for sustainable alternatives in construction materials that are both economically viable and environmentally friendly. The study aims to address two significant issues: waste management and sustainable construction. By utilizing sugarcane bagasse ash, a byproduct of the sugar industry, and RAP aggregates, waste from road renovation or construction, the study aims to reduce landfill waste. Secondly, by developing pervious paver blocks, the study aspires to contribute to the sustainability of urban infrastructure by allowing better water management and utilizing waste materials that are usually considered non-recyclable.

By integrating waste materials into the construction of pervious paver blocks, this study aims to develop a comprehensive solution that addresses both environmental concerns and infrastructural needs. Through rigorous testing and analysis, the study intends to prove the viability of these sustainable construction materials for real-world applications the present study aims to explore sustainable alternatives in construction materials by developing pervious paver blocks using sugarcane bagasse ash and reclaimed asphalt pavement (RAP) aggregates. Sugarcane bagasse ash serves as a partial replacement for cement, while RAP aggregates substitute for traditional aggregates. These blocks are designed to offer efficient water infiltration and thus contribute to groundwater recharge, mitigating surface runoff and reducing the risk of urban flooding. By examining mechanical properties such as compressive strength, water absorption, and permeability, the study evaluates the performance of these sustainable paver blocks against traditional ones. Through this research, we intend to prove the viability of incorporating waste materials into construction, aiming for a comprehensive solution that fulfills both environmental and infrastructural needs.

A. Pervious Concrete Pervious Concrete

A unique kind of concrete called pervious concrete is made of cement, large aggregates, water, and, if necessary, admixtures and other cementitious elements. The concrete matrix's higher void content, which results from the absence of fine particles, enables water to pass more easily through the material's body. Permeable concrete and porous concrete are other names for pervious concrete. The field of pervious concrete is the subject of much study. Due to its porosity and voids, pervious concrete has a lower compressive strength than ordinary concrete. Because of this, even though pervious concrete has several benefits, its use is restricted. A greater range of applications for pervious concrete are possible with enhanced compressive and flexural strengths. Pervious concrete is currently exclusively used on roadways with low traffic volumes.

It may also be utilized for inflexible pavements with medium and high traffic if the characteristics are upgraded. Additionally, pervious concrete prevents storm water runoff from surfaces, enables groundwater recharging, and maximizes the use of land.

Our project's primary goal is to enhance pervious concrete's strength properties. However, it should be observed that the permeability of pervious concrete will decrease as strength increases. Therefore, because the permeability quality serves a function, the development of strength shouldn't have an impact on it.

It has been discovered that pervious concrete, also referred to as no-fines, porous, gap-graded, and permeable concrete, and enhance porosity concrete, is a dependable storm water management strategy. Gravel or granite stone, cement, water, and little to no sand (fine aggregate) are the main components of pervious concrete, according to definition. Storm water may seep through pervious concrete pavements and into the soils underneath thanks to the open cell architecture. In other words, pervious concrete contributes to the preservation of the environment and the pavement's surface.

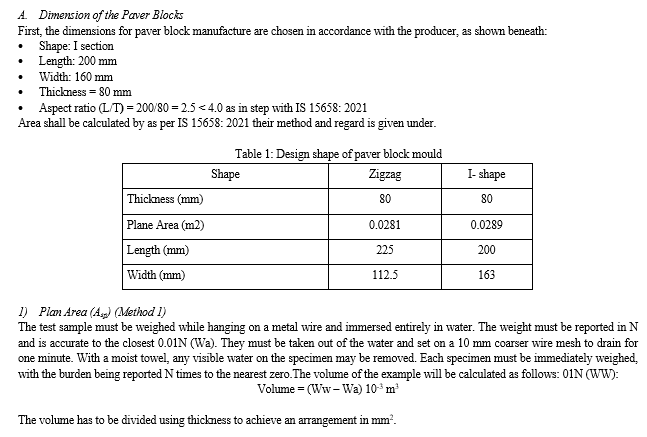

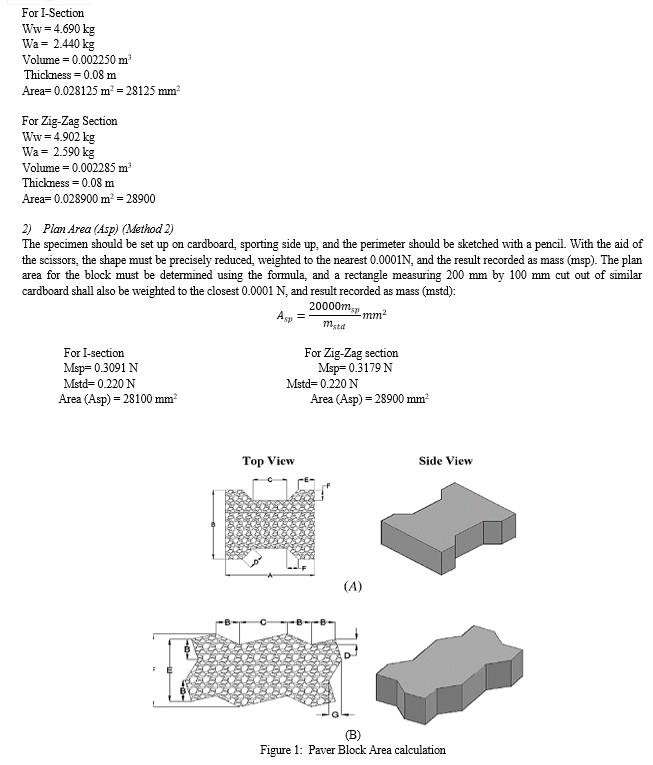

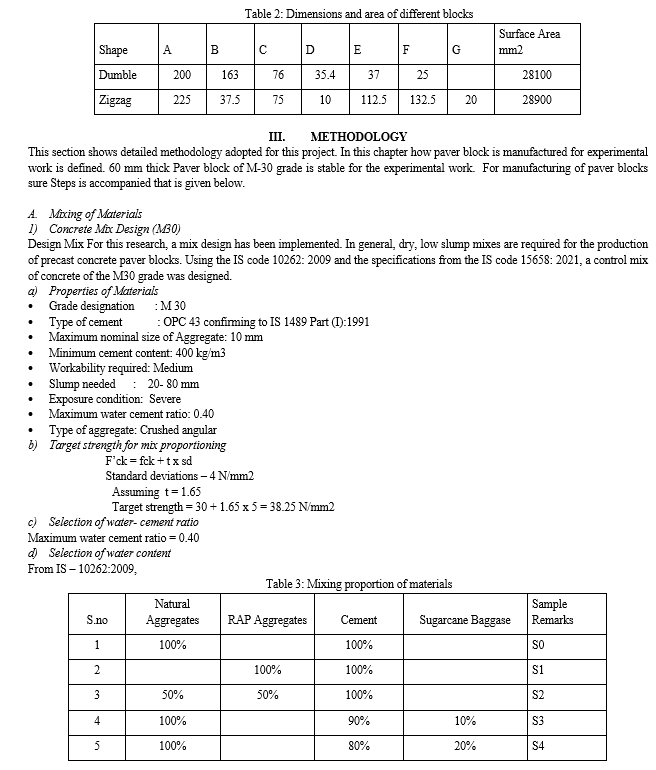

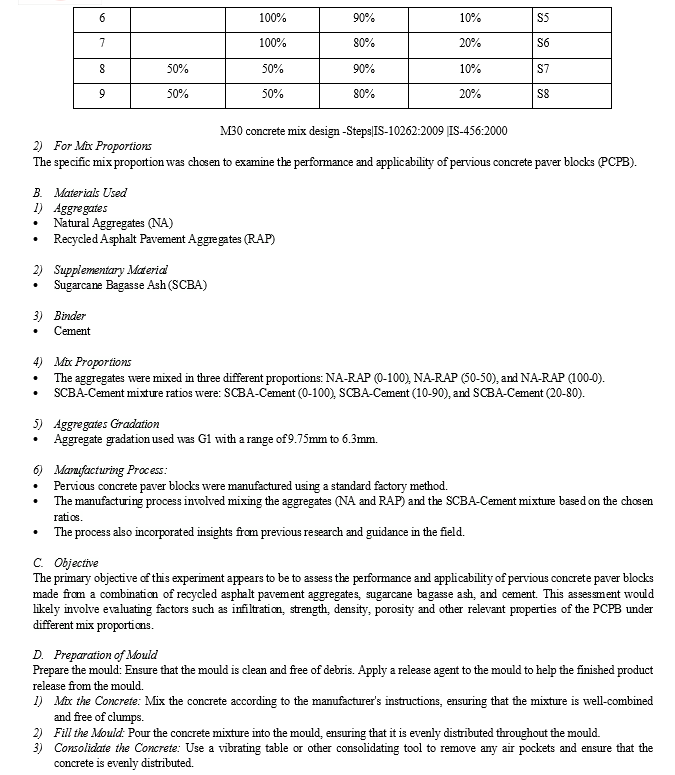

II. DESIGN OF PAVER BLOCK

Utilizing waste products in unconventional ways helps ease the strain on the environment and current resources. The utilization of diverse wastes with the repolymerization process may be readily utilized in the manufacturing of paver blocks, which can result in the preservation of high-quality resources. Additionally, this will lead to savings and sustainable practices. The qualities of cement concrete with RAP aggregates have been the subject of several investigations; however, in this study, we are combining two kinds of waste materials in different proportion combinations with RAP aggregates and sugarcane bag ash.

IV. RESULTS AND DISCUSSION

The use of sugarcane bagasse ash in combination with RAP aggregates offers several potential benefits. Firstly, sugarcane bagasse ash is an industrial waste product that is currently underutilized and can be used as a sustainable alternative to traditional cementitious materials. Secondly, the use of RAP aggregates in the paver block can help reduce the demand for virgin aggregates, thereby reducing the environmental impact associated with their extraction and transportation.

Furthermore, the developed pervious paver block offers potential benefits for stormwater management. The water permeability of the paver block allows rainwater to infiltrate into the ground, reducing the amount of stormwater runoff and helping to prevent flooding and erosion. While the results of our investigation are promising, further research is needed to assess the long-term performance of the pervious paver block in actual field conditions. Additionally, the cost-effectiveness of the developed material should be evaluated to ensure its practical feasibility for widespread use.

In conclusion, our study suggests that the use of sugarcane bagasse ash and RAP aggregates in pervious paver block construction has the potential to offer a sustainable and environmentally friendly solution for managing stormwater runoff in low-traffic pavement applications.

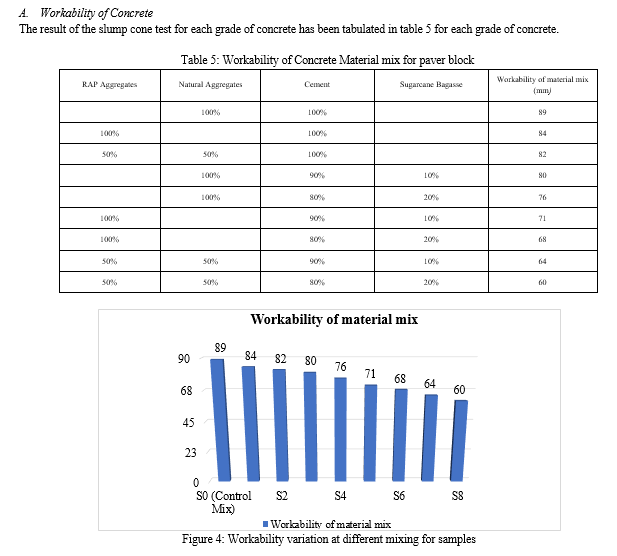

Based on the table data, it can be seen that as the amount of sugarcane bagasse ash and recycled aggregate increases, the workability of the material mix decreases. The control mix (S0) had the highest workability with a value of 89 mm, while S8 had the lowest workability with a value of 60 mm. This suggests that higher amounts of these materials in the mix make it more difficult to work with and may require additional efforts to achieve the desired consistency for the paver block. However, it is important to note that other factors such as the water-cement ratio and the use of admixtures can also affect the workability of the concrete material mix.

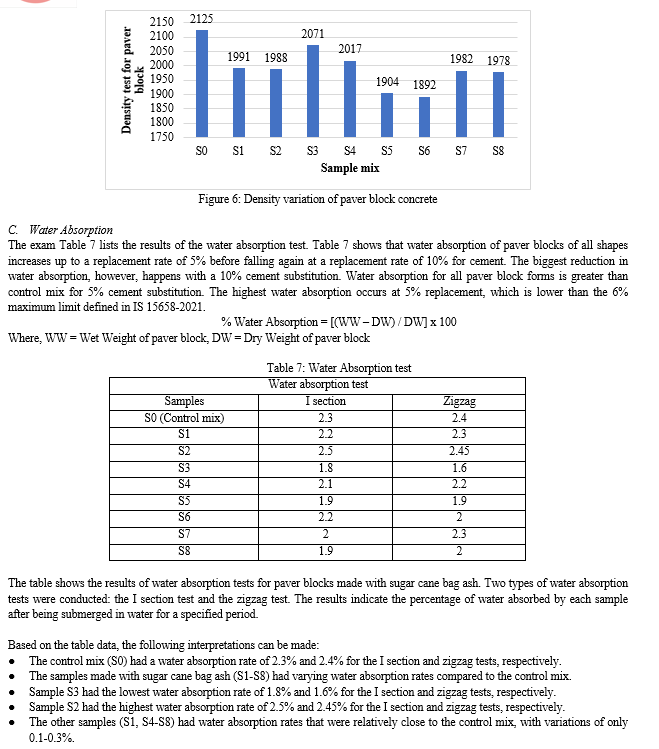

B. Density of Concrete

The test was conducted to study the variation of density of paver blocks for each grade of concrete. The results have been tabulated in Table 6.

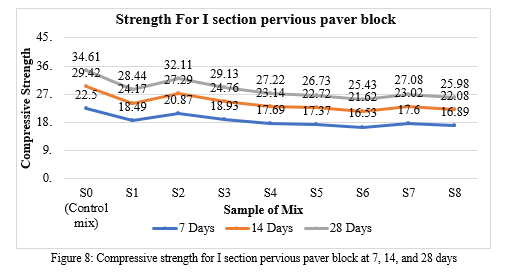

Based on the provided compressive strength data for the "I section pervious paver block" across different curing durations, interpretation of the results are:

The table you provided showcases the strength values of different mixes of I section pervious paver blocks at three different time intervals: 7 days, 14 days, and 28 days. Just like the Zigzag section paver blocks, this type of testing measures how the strength of a mix matures over time. Here's an interpretation of the provided data:

- Control Mix (S0)

- At 7 days, it showcases a strength of 22.50.

- By 14 days, it increased to 29.42.

- At 28 days, the strength matures further to 34.61. This mix serves as the benchmark against which other mixes are evaluated.

a. Mix S1: The strength values at 7, 14, and 28 days are 18.49, 24.17, and 28.44 respectively. S1 consistently shows lower strength values across all the time durations when compared to the control mix (S0).

b. Mix S2: Strength values are 20.87 at 7 days, 27.29 at 14 days, and 32.11 at 28 days. While this mix starts weaker than the control mix at 7 days, it narrows the gap over time but remains weaker than S0 at all stages.

c. Mix S3: This mix demonstrates strengths of 18.93, 24.76, and 29.13 at 7, 14, and 28 days respectively. Like S1, it remains consistently weaker than the control mix across all durations.

d. Mix S4: The strength values for this mix are 17.69 at 7 days, 23.14 at 14 days, and 27.22 at 28 days. It continues to demonstrate lower strengths than both the control mix and most of the prior mixes at all durations.

e. Mix S5: Strengths of 17.37, 22.72, and 26.73 are seen at 7, 14, and 28 days respectively. S5 is relatively weaker across all intervals, only marginally stronger than S6.

f. Mix S6: This mix, with strength values of 16.53, 21.62, and 25.43 at the respective durations, emerges as one of the weakest mixes among all.

g. Mix S7: Strengths are showcased as 17.60 at 7 days, 23.02 at 14 days, and 27.08 at 28 days. S7 exhibits a slight rebound in strength when compared to S6, but it remains weaker than the control mix.

h. Mix S8: With strengths of 16.89, 22.08, and 25.98, this mix is among the weaker ones, especially by the 28-day mark.

2. Summary

a. The Control Mix (S0) is the strongest among all samples by the 28-day interval, having a strength of 34.61.

b. S2 comes close to the control mix but remains weaker throughout the testing period.

c. S6 and S8 appear to be the weakest, especially when the 28-day strength is considered.

d. There's a clear maturity in strength from 7 days to 28 days for all mixes, highlighting the importance of the curing period.

From a practical standpoint, S0 remains the most desirable mix for long-term strength. The choice between other mixes would depend on specific strength requirements and the timeframe in which those strengths are needed.

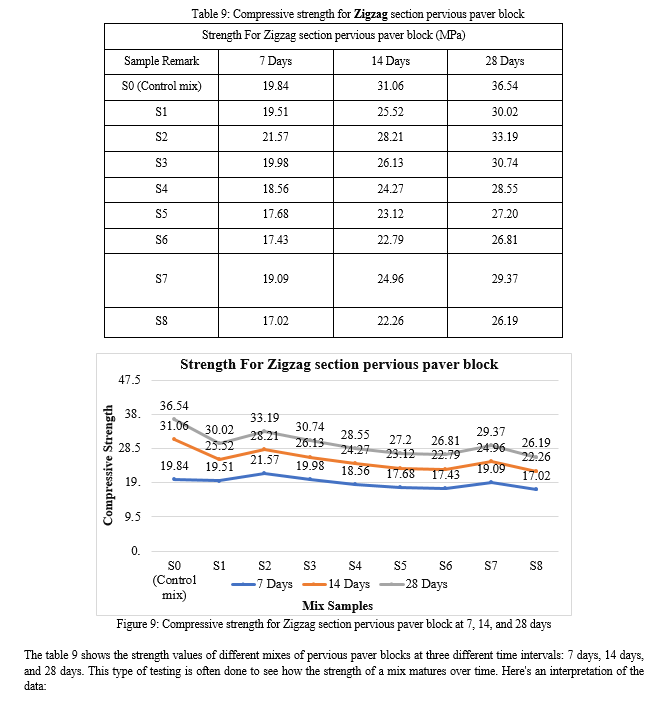

???????E. Compressive Strength of Zigzag section

- Control Mix (S0)

- At 7 days, it has a strength of 19.84.

- By 14 days, it increased to 31.06.

- At 28 days, the strength matured to 36.54. This mix is the standard by which other mixes are compared.

a. Mix S1: The strength values at 7, 14, and 28 days are 19.51, 25.52, and 30.02 respectively. This mix shows lower strength values across all durations compared to the control mix (S0).

b. Mix S2: Strength values are 21.57 (7 days), 28.21 (14 days), and 33.19 (28 days). This mix started stronger than the control mix at 7 days, but ended up weaker by 28 days.

c. Mix S3: This mix has strengths of 19.98, 26.13, and 30.74 at 7, 14, and 28 days respectively. This mix performs similarly to S1, with strengths generally below the control mix but slightly stronger than S1.

d. Mix S4: The strength values for this mix are 18.56 (7 days), 24.27 (14 days), and 28.55 (28 days). This mix is consistently weaker than the control mix and most of the prior mixes at all durations.

e. Mix S5: At 7, 14, and 28 days, the strengths are 17.68, 23.12, and 27.20 respectively. This mix continues the trend of declining strength compared to prior mixes.

f. Mix S6: This mix has strength values of 17.43, 22.79, and 26.81 at the respective durations. It's even weaker than S5 across all intervals.

g. Mix S7: Strengths are 19.09 (7 days), 24.96 (14 days), and 29.37 (28 days). This mix rebounds slightly from the declining trend seen in S5 and S6 but remains below the control mix.

h. Mix S8: With strengths of 17.02, 22.26, and 26.19, this mix is among the weakest, particularly by the 28-day mark.

i. From an application perspective, the choice of mix would depend on the required final strength and the time within which the strength is desired. For instance, if one needs a strong mix quickly, S2 may be suitable. However, for long-term strength, the control mix (S0) might be the preferred choice.

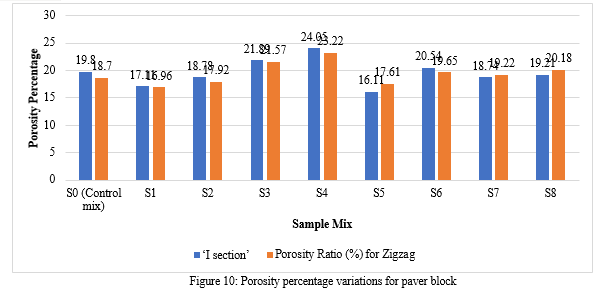

???????F. Porosity Test for Paver Block

The porosity test was carried out in accordance with IS-15658-2021.

Table 10: Porosity test for paver block

|

Sample of Mix |

Porosity Ratio (%) for ‘I section’ |

Porosity Ratio (%) for Zigzag |

|

S0 (Control mix) |

19.8 |

18.7 |

|

S1 |

17.11 |

16.96 |

|

S2 |

18.78 |

17.92 |

|

S3 |

21.89 |

21.57 |

|

S4 |

24.05 |

23.22 |

|

S5 |

16.11 |

17.61 |

|

S6 |

20.54 |

19.65 |

|

S7 |

18.74 |

19.22 |

|

S8 |

19.21 |

20.18 |

The table shows the results of a porosity test for two types of paver blocks: "I section" and "Zigzag". The control mix (S0) had a porosity ratio of 19.8% for I section and 18.7% for Zigzag. The other samples (S1 to S8) had varying porosity ratios for both types of paver blocks. The porosity ratio is the percentage of voids in a material, which indicates its ability to allow water or air to pass through. In this case, the porosity ratio represents the percentage of voids in the paver blocks.

Looking at the data, we can see that the porosity ratio generally increases as the sample number increases, meaning that the blocks become more porous. The S5 sample had the lowest porosity ratio after the control mix, indicating that it is the least porous.

The data suggests that the type of paver block and the mix used can have an impact on the porosity ratio, with some mixes resulting in significantly more porous blocks than others. This information can be useful for determining the best mix to use for a particular application, depending on the desired level of porosity.

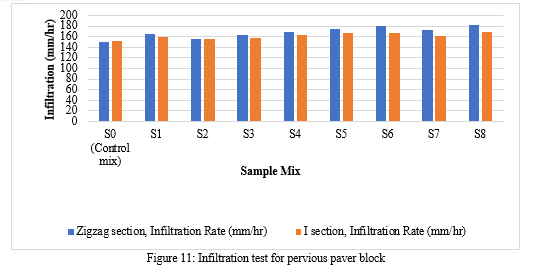

???????G. Infiltration Test

The infiltration test is a method used to determine the rate at which water can infiltrate, or penetrate, into the soil or other porous media. It is a crucial parameter for various engineering applications, especially in hydrology, agriculture, and civil engineering, where understanding water movement is critical.

Table 11: Infiltration Test for I section and Zigzag section

|

Sample Remark |

Zigzag section, Infiltration Rate (mm/hr) |

I section, Infiltration Rate (mm/hr) |

|

S0 (Control mix) |

150 |

152 |

|

S1 |

165 |

160 |

|

S2 |

155 |

155 |

|

S3 |

163 |

158 |

|

S4 |

170 |

163 |

|

S5 |

175 |

167 |

|

S6 |

180 |

168 |

|

S7 |

172 |

162 |

|

S8 |

182 |

170 |

???????

???????

Conclusion

The present study aimed to investigate the viability of using sustainable materials—specifically, sugarcane bagasse ash and recycled asphalt pavement (RAP) aggregates—in the development of pervious paver blocks. A range of mix designs were experimentally analyzed to evaluate their physical properties such as permeability and compressive strength. The study also explored the performance differences between \'I section\' and \'Zigzag section\' paver blocks. The control mixes (S0) for both \'I\' and \'Zigzag\' sections demonstrated the highest compressive strength across all curing times, providing a benchmark for the study. In general, the strength decreased as the proportion of sugarcane bagasse ash and RAP aggregates increased. However, it was observed that the strength reduction was not significant enough to entirely discount these sustainable materials as feasible alternatives for certain applications. A. Comparative Analysis of \'I\' and \'Zigzag\' Sections Both \'I\' and \'Zigzag\' sections demonstrated similar trends concerning compressive strength, though the Zigzag section had a slightly higher maximum compressive strength at 28 days. Specific samples, such as S2 in the \'I\' section and S3 in the \'Zigzag\' section, showed promising results, approaching the compressive strength of their respective control mixes. This suggests potential for optimization. B. Practical Implications 1) Sustainable Construction: Utilizing sugarcane bagasse ash and RAP aggregates in paver blocks not only aligns with eco-friendly construction practices but also aids in waste management. 2) Customization: Different mixes offer varied compressive strength and permeability rates, allowing for customization based on the application\'s specific requirements. 3) Cost-Efficiency: While not directly investigated in this study, using recycled or waste materials could potentially lead to cost savings in large-scale manufacturing. 4) Application-Specific Decision: The study indicates that if compressive strength is a primary concern, the Zigzag section may be more appropriate. However, the \'I\' section should not be discounted, especially when other factors such as aesthetics, ease of installation, and cost are considered.

References

[1] Saboo, N., Nirmal Prasad, A., Sukhija, M., Chaudhary, M., & Chandrappa, A. K. (2020). Effect of the use of recycled asphalt pavement (RAP) aggregates on the performance of pervious paver blocks (PPB). Construction and Building Materials, 262, 120581. doi:10.1016/j.conbuildmat.2020.12 [2] Akshaya Krishna, Anusha Jain, \"Experimental Investigations on Paver Blocks by Partial Replacement of Cement by Lead Slag and Natural Sand by M-sand\", Turkish Journal of Computer and Mathematics Education, Vol.12 No.10, 2021. [3] Rajat Singh Rajput, Prabhat Kumar Tiwari, Abhay Kumar Jha, \"Evolution Properties of Paver Blocks Using Waste Foundry Sand in Concrete\", International Journal of Trend in Scientific Research and Development (IJTSRD) Volume 5 Issue 6, September-October 2021 [4] Hossiney, N., Sepuri, H. K., Mohan, M. K., Chandra K, S., Lakshmish Kumar, S., & H K, T. (2020). Geopolymer concrete paving blocks made with Recycled Asphalt Pavement (RAP) aggregates towards sustainable urban mobility development. Cogent Engineering, 7(1), 1824572. doi:10.1080/23311916.2020.1824572 [5] Hossiney, N., Sepuri, H. K., Krishna Mohan, M., R, A. H., Govindaraju, S., & Chyne, J. (2019). Alkali-activated concrete paver blocks made with recycled asphalt pavement (RAP) aggregates. Case Studies in Construction Materials, e00322. doi:10.1016/j.cscm.2019.e00322 [6] Mr. Laxmikant N. Vairagade, Dr. Jaskiran Sobti, P.K.Sharma, \"Feasibility of Manufacturing Paver Blocks Using Waste Materials\", Test Engineering And Management, 2022. [7] Achchaeylal, Rajan Kumar Paswan, Jitendra Kumar yadav, \"Design of Paver Block using Plastic Waste Material\" International Research Journal of Engineering and Technology, Volume: 07, Issue: 06, June 2020. [8] P. Kirubagharan, R. Gowtham, Albert Duraisingh, Akshai B Nair, \"Experimental Study On Behaviour Of Paver Block Using Crushed Rubber Powder\", International Journal of Civil Engineering and Technology (IJCIET),Volume 8, Issue 3, March 2017, pp. 582–589. [9] Byung-Hyun Ryu, Sojeong Lee, Ilhan Chang, \"Pervious Pavement Blocks Made from Recycled Polyethylene Terephthalate (PET): Fabrication and Engineering Properties\", Sustainability, Volume 12, Issue 16, 10.3390/su12166356. [10] Bhimaji Dashrath Kanawade, Sonali Ratnakar Nawale, \"Strength and Durability of Concrete Paver Block\", Strength and Durability of Concrete Paver Block, Advances in Civil & Structural Engineering, Volume 2, Issue 3, 2017. [11] M. C. Nataraja, Lelin Das,\"A study on the strength properties of paver blocks made from unconventional materials\", IOSR Journal of Mechanical and Civil Engineering, 2014 [12] Chandrashekhar Pandiya, A. K. Saxena, \"Effect of Reclaimed Asphalt Pavement Aggregate on Hardened Properties of Concrete\", International Journal for Research in Applied Science & Engineering Technology, Volume 9 Issue XI Nov 2021. [13] Lillian Gungat, Fulgentius Anthony, Abdul Karim Mirasa, \"Development of Paver Block Containing Recycled Plastic\", Materials Science and Engineering, 2021. [14] Bittencourt, S. V., da Silva Magalhães, M., & da Nóbrega Tavares, M. E. (2021). Mechanical behavior and water infiltration of pervious concrete incorporating recycled asphalt pavement aggregate. Case Studies in Construction Materials, 14, e00473. doi:10.1016/j.cscm.2020.e00473 [15] Manuel Contreras-Llanes, Maximina Romero, Manuel Jesús Gázquez, Juan Pedro Bolívar, \"Recycled Aggregates from Construction and Demolition Waste in the Manufacture of Urban Pavements\", Materials, 2021. [16] Nur Hidayah, Hasanan Md. Nor, \"Porous Concrete Paving Blocks Using Coarse Aggregate\", Applied Mechanics and Materials Vol. 554, 2014, pp 111-115. [17] M.T. Tiza, O.N. Mogbo, E.C. Duweni, \"Recycled Asphalt Pavement: A Systematic Literature Review\", Journal of Modern Technology and Engineering, Vol.5, No.3, 2020, pp.242-254.

Copyright

Copyright © 2023 Shivam Chauhan, Dr. M. K. Trivedi. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET55575

Publish Date : 2023-08-31

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online