Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Performance Evaluation of Plastic Waste as Partial Replacement of Fine Aggregate in Concrete

Authors: Muktta Narayan Shrestha, Jamuna Kandel, Pawan KC, Swastika Poudyal, Ajay Yadav, Ashish Poudel

DOI Link: https://doi.org/10.22214/ijraset.2024.65327

Certificate: View Certificate

Abstract

Plastic pollution is a significant environmental problem caused by the accumulation of plastic waste in the environment, particularly in oceans, rivers, and terrestrial ecosystems. It is a global issue with far-reaching consequences for ecosystems, wildlife, and human health. Thus, it is indispensable to reduce the use of plastics by recycling or reusing them. Utilizing waste plastic in the concrete mix is one of the methods of recycling it.In this study, the fine aggregate in the concrete mix is partially replaced by multi-layer plastic with a size of 5-7 mm. M20 concrete cubes were produced using a replacement weight of fine aggregate by plastic 0%, 2%, 4%, and 6%. To determine the strength parameter, 90 cubes were manufactured and put through a compressive strength test. The test result demonstrated that as the fraction of plastic increases, the compressive strength and weight of the concrete cube decreases. By adding admixture, the strength of the concrete increased slightly, but not significantly. When silica and additional additives were added to plastic mix concrete, the compressive strength test result showed an increase in comparison to regular M20 concrete\'s strength. In addition, it is discovered that when compared to 4% and 6%, the 2%plastic substitution yields the best results. The investigation leads to the conclusion that using plastic in concrete helps get rid of plastic trash.

Introduction

I. INTRODUCTION

As the population is growing, waste of various types is being generated, among them plastic waste is non-degradable and can persist in the environment for hundreds of years, causing pollution and harm to ecosystems. Every year more than 500 billion plastic bags are used (nearly 1 million bags per minute) and it takes up to 1000 years to degrade (Raghatate Atul, M., 2012). Only 9% of the produced waste is recycled, and 12% is burned, reflecting that almost 79% of the waste is still uncontrolled and deposited in landfills, oceans, or rivers (da Luz Garcia et al.,2021).

The problem of plastic waste disposal and management has become one of the most serious environmental, economic, and social issues in all countries. Due to the high labor and processing expenses associated with plastic recycling and reuse, only a small amount of plastic is recovered and reused. The excessive production and consumption of plastic has serious consequences on the environment and human health.

The reduction of plastic has therefore become a major global challenge (Heidbreder et al., 2019). Following normal population growth, the amount and type of waste materials have increased accordingly. Since the rate of plastic production is projected to double every ten years, a more sustainable and safer way is needed to be taken (Prasanth et al.,2022).

Addressing the issue of plastic waste requires a comprehensive approach, including reducing plastic consumption, improving waste management and recycling infrastructure, promoting alternative materials, and raising awareness about the importance of sustainable practices. From different perspectives, waste reuse is important because it helps to recycle and conserve energy in the production process, reduce environmental pollution, and helps to conserve non-renewable natural resources. To enhance the best environmental alternative for solving the problem of plastic waste disposal, recycling plastic waste into convenient products would be the better option. As the development is increasing day by day there is an increase in construction and maintenance work of structures. Using waste plastic in concrete has become a major research subject in recent years.

So, we are looking for a new concept of using waste plastic by partially substituting it with the fine aggregates in cement concrete mix. The use of waste plastic in concrete can reduce the disposal problems and other environmental problems that we are facing due to the increase in the usage of plastics. To minimize the proportion of landfills used, using plastic waste in the material industry is an environmental solution. It is an innovative approach to reduce plastic pollution while enhancing the properties of concrete.

Plastic was used as a partial replacement of fine aggregates in varying proportions and then studies were conducted where they concluded that the addition of plastic in concrete reduces the strength of concrete and this is continued as we increased the amount of plastic (Elziny et al. (2023), Pushpa Lumina et al. (2022), Amula R.G et al.(2016), Youcef Ghernouti et al. (2014), Ismail et al. (2007)).

Plastic bag fibers of two types were used in concrete: one hand cut (60mm*3mm) and the other shredded, and it was discovered that the combination of shredded fibers worked fairly well but the strength of concrete was lower than that of standard concrete (Bhogayata et al. (2012)).

Plastic was used as a substitute for coarse aggregates in concrete at various proportions and concluded that the compressive strength of concrete was decreased with subsequent additions of plastic. The admixture used had a significant impact on the strength of the concrete, implying that careful additive selection and dosage can be used to optimize concrete properties (Azad Khajuria et al. (2019)).

II. METHODOLOGY

A. Materials

Concrete is a composite material composed of aggregate bonded together with a fluid cement that cures over time. Plastic concrete is a mixture of cement (43-grade Sagarmatha OPC), sand from Narayani River (pass through 4.75mm and be retained on a 0.075 mm sieve), clean water, and crushed aggregate from Narayani River (pass from a 20 mm sieve) in appropriate proportion. Additionally, admixture ("Brocrete S888”), multi-layer plastics (5 to 7mm), and silica of fine quality are used in this project.

B. Methods

To achieve the objectives of the study a distinct methodology is a must. For the same purpose, the methodology for this study has been summarized below.

- Collection, cleaning, drying, and crushing of waste plastic: The discarded plastics are gathered from landfills where they cannot be recycled or used again. Those plastics are cleaned in clean water and dried artificially or mechanically before shredding in a size of 5mm to 7mm which is further cleaned by fresh water to remove any chemical materials in the plastic.

- Performing mix design: In this project, mix design was done to calculate the required proportion of the various ingredients like coarse aggregate, fine aggregate, cement, water, and admixture, based on the IS 456:2000, 10262. batching, mixing, workability check, and casting of concrete

- Batching is done by weight and all the concrete materials are mixed in dry state before wet mix for the homogeneous mixture of plastic in concrete. After that, a workability check is performed and the concrete with suitable workability is typically cast using standardized molds of dimension 15cm*15cm*15cm*15cm. Together 90 cubes were prepared for this project with plastic and without plastic in concrete.

- Curing and compressive strength check: The Oxford Builders Engineering Construction Company, Nawalpur, facilities were used for all production, drying, and curing tasks. The water ponding curing method was adopted for all days of concrete continuously till the time of testing. Concrete cubes are then dried naturally in the presence of the sun or artificially before it goes to the compressive strength check. It can be calculated either in wet condition or dry condition but for this project we seek the maximum compressive strength, so the cube is tested by drying before testing to get the maximum strength of the concrete. The strength of concrete is then calculated as follows.

Compressive strength = Final load / cross-sectional area……………(i)

III. RESULT AND DISCUSSION

A. Plastic in Concrete

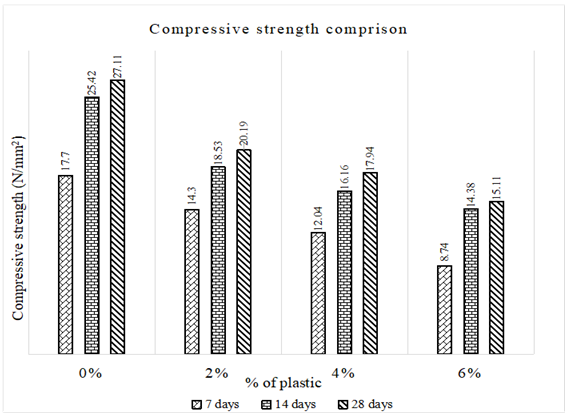

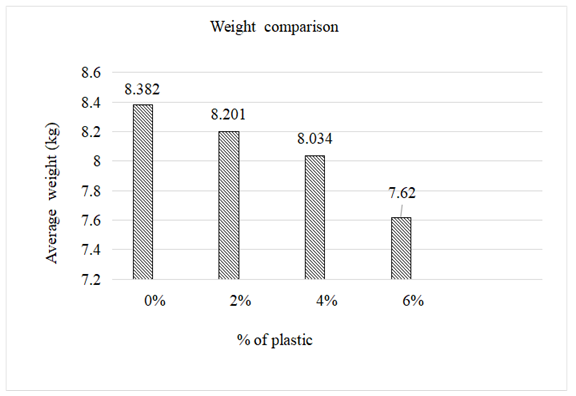

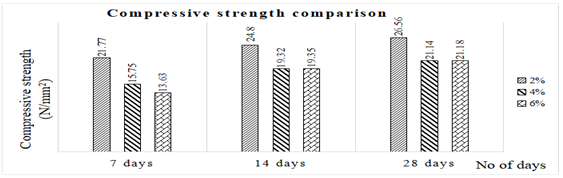

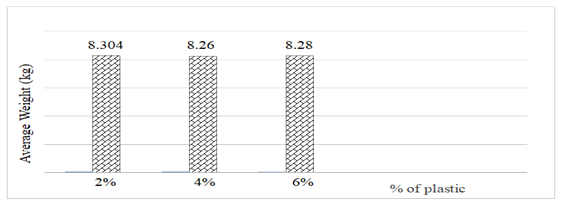

Different amounts of plastic were added to the mixture in partial replacement ratios of 2%, 4%, and 6%, and the effects were observed in the predetermined number of days. The obtained compressive strength and weight of concrete were plotted in Figure 1 and Figure 2 respectively. Compared to normal concrete, the compressive strength decreased by 19.20%, 31.97%, 50.62% on 7th-day, by 27.10%, 36.42%, 41.66% on 14th-day and by 25.52%, 33.82%, 44.26% on 28th-day strength when plastic replaced the fine aggregate by 2%,4% and 6% respectively. Similarly, the weight of concrete decreases as the number of plastic increases. It shows that as the percentage of plastic increases, the cube's compressive strength decreases. And, similar types of results were concluded by many researchers including Pushpa Lumina et al. (2022), Elziny et al. (2023), Youcef Ghernouti et al. (2014), Amula R.G et al.(2016), Bhogayata et al. (2012) and many more.

Figure 1. Bar chart between Compressive strength and varying % of plastic

Figure 1. Graph of the average weight of concrete in addition to plastic

B. Admixture in Concrete with Plastic

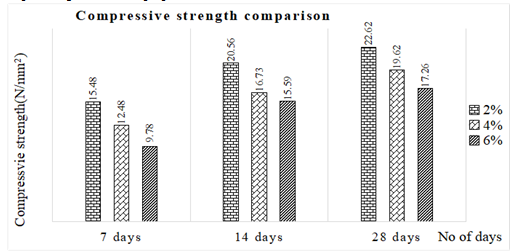

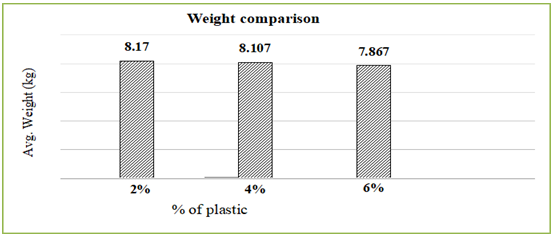

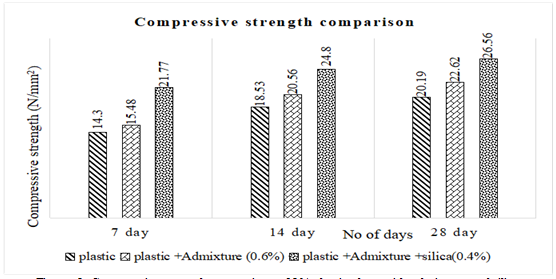

To monitor the outcomes and adjust the amount of plastic added, admixture was added to the concrete mix along with the plastic. Figures 3 and Figure 4 display the bar graph that was plotted by using the observed data. The experiment results show that, with an increase in the proportion of plastic in the admixture used, the cube's compressive strength is dropping along with weight. Compressive strength dropped by 19.37% and 21.63% on the 7th day, by 18.33% and 25.96% on the 14th day, and by 6.498% and 18.39% on the 28th day as the amount of plastic increased from 2% up to 6% in the increment of 2%. With the addition of additives, the concrete cube's strength and weight did not rise considerably, but the sample's workability seemed to be greatly improving. According to the findings, there is a complex link that gets weaker as plastic content increases between compressive strength and weight. By adding an admixture, it was possible to increase the compressive strength and weight of the concrete marginally, but the increase was insufficient. Azad Khajuria et al. (2019) also concluded that the careful additive selection and dosage implication in the concrete are useful in optimizing the concrete properties.

Figure 3. Bar chart between compressive strength of concrete on the addition of admixture with varying % of plastic

Figure 4. Graph between average weights of plastic mix concrete cube on adding admixture

C. Admixture and Silica in Concrete with Plastic

To increase the concrete's strength, which had decreased due to the use of plastic, silica (0.4% of cement) and admixture(0.6% of cement) were added to plastic concrete. As evidenced by figures 5 and 6, when the plastic component was raised from 2% to 4% and 4% to 6%, respectively, the compressive strength decreased by 27.65% and 13.46% on 7th-day, by 22.10% and 24.20% on 14th-day, and by 20.4% and 24.0% on 28th-day, respectively. Although we used additive materials on it, the compressive strength of the concrete decreased continuously as we increased the plastic content. However, the result reveals that there is a significant increase in the strength and weight of concrete cubes than that of the same proportion of plastic concrete only.

Figure 5. Bar chart of compressive strength of plastic mix concrete on addition of admixture and silica

Figure 6. Bar chart of the weight of concrete cube on the addition of admixture and silica

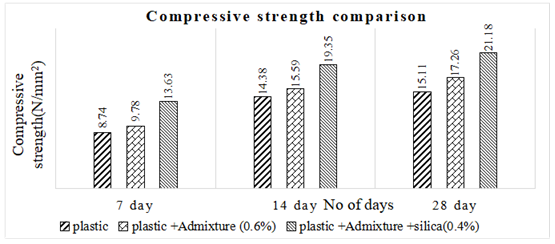

D. Compressive strength comparison in 2% plastic among the plastic concrete, (plastic+admixture) concrete, (plastic+admixture+silica) concrete

Figure 7 illustrates the comparative compressive strength of concrete on using plastic only, on using both plastic and admixture, and on using the plastic, admixture, and silica all together in the concrete mix. In addition to admixture (0.6% of cement content) in the plastic concrete, it was observed that the compressive strength increased by 8.25% on the 7th day, by 10.95% on the 14th day, and by 0.035% on 28th-day than that of plastic mix concrete without the addition of admixture. Furthermore, the addition of silica (0.4% of cement) along with admixture increased the strength by 40.63% on the 7th day, by 20.62% on the 14th day, and by 17.41% on the 28th day than that of concrete with the addition of 2% plastic and admixture only.

Figure 2. Compressive strength comparison of 2% plastic along with admixture and silica

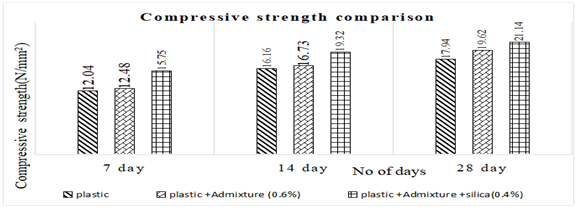

E. Compressive strength comparison in 4% plastic among the plastic concrete, (plastic+admixture) concrete, (plastic+admixture+silica) concrete

The relative compressive strength of concrete on the 4% partial replacement of fine aggregate by plastic was illustrated in Figure 8. Admixture was shown to be somewhat important in increasing the compressive strength of concrete, however, using silica and admixture in combination with plastic concrete resulted in a large increase in concrete strength. The addition of 0.6% admixture of total cement content increased the strength of the concrete by 3.65%, 3.57%, and 9.36% for the 7th, 14th, and 28th days of concrete strength, respectively while silica (0.6 percent of cement) with admixture increased the strength by 30.81%, 19.55%, and 17.83% compared to 4% plastic replacement without that additive.

Figure 8. Compressive strength comparison of 4% plastic along with admixture and silica

F. Compressive strength comparison in 6% plastic among the plastic concrete, (plastic+admixture) concrete, (plastic+admixture+silica) concrete

A significant decrease in the concrete's compressive strength—15.11N/N/mm2 for M20 concrete—was noted in the test results when 6% plastic was substituted with sand. Thus, by adding silica and additives to concrete together with plastic, the effects were examined. According to the experiment, the strength of plastic concrete increases by 11.89%, 8.4%, and 14.22% when admixture is added, and by 55.94%, 34.56%, and 40.17% when silica (0.4% of cement) and admixture (0.6% of cement) are added and tested on the 7th, 14th, and 28th days, respectively.

Figure 9. Compressive strength comparison of 6% plastic along with admixture and silica

Conclusion

The average compressive strength of concrete was found to be 27.11 N/mm2, but when plastic was substituted with 2%, 4%, or 6% of the fine aggregate, the compressive strength decreased to 20.19 N/mm2, 17.94 N/mm2, and 15.11 N/mm2. It demonstrates that only 2% of the plastic addition to concrete achieves the desired level of concrete strength and that additions of 4% and 6% fail to achieve this level. When admixture is added, plastic concrete becomes more workable and has a higher compressive strength (22.62 N/N/mm2, 20.19 N/N/mm2, and 17.26 N/mm2 for plastic content levels of 2%, 4%, and 6%, respectively) than when it is not added. It demonstrates that the required strength of concrete is maintained even in the 4% of plastic replacement of the fine aggregate in the concrete by using the additives. In addition, the compressive strength of concrete with silica and additives improves to 26.56N/mm2, 22.62N/mm2, and 20.19N/mm2 for 2%, 4%, and 6% of plastic concrete, respectively. This shows that the concrete virtually maintained its strength even when 6% of plastic was added in the presence of both admixture and silica. It indicates that the strength of concrete can be increased significantly by using admixture and silica instead of plastic only. Also, it is concluded that the weight of the concrete cube falls as the proportion of plastic increases, resulting in lightweight concrete and it failed to achieve the desired strength in this condition. Although, the cube is unable to attain the desired level of strength when the content of plastic increases, we can effectively utilize this concrete in other nonstructural components where high strength is not compulsory.

References

[1] Milan Kandel; Sandhya Ghimire; Nikita Bhatta; Bijaya Poudel; Isha Adhikari; Aarti Acharya; Ajay Yadav. “An Experimental Study on Concrete Strength Optimization with Surkhi as.” Volume. 9 Issue.11, November-2024 International Journal of Innovative Science and Research Technology (IJISRT), 172-184, https://doi.org/10.38124/ijisrt/IJISRT24NOV566 [2] Sapkota, S.C., Yadav, A., Khatri, A. et al. Explainable hybridizedensemble machine learning for the prognosis of the compressive strength of recycled plastic-based sustainable concrete with experimental validation. Multiscale and Multidiscip. Model. Exp. and Des. 7, 6073–6096 (2024). https://doi.org/10.1007/s41939-024-00567-4 [3] Chhetri Sapkota, Sanjog and Dahal, Dipak and Yadav, Ajay and Dhakal, Dipak and Sharma, Ram Kumar and Saini, Gaurav, A Paradigm Shift in Corrosion Inhibition using Botanical Extracts: From Conventional Methods to Advanced Methods for Reinforcing Steel, https://ssrn.com/abstract=4963462 or http://dx.doi.org/10.2139/ssrn.4963462 [4] Adnan, HamsaMahir, and Abbas Oda Dawood. “Recycling of Plastic Box Waste in the Concrete Mixture as a Percentage of Fine Aggregate.” Construction and Building Materials, vol. 284, May 2021, p. 122666, https://doi.org/10.1016/j.conbuildmat.2021.122666. Accessed 22 Mar. 2021. [5] Batayneh, M., Marie, I. and Asi, I. (2007). Use of selected waste materials in concrete mixes. Waste Management, 27(12), pp.1870–1876. doi:https://doi.org/10.1016/j.wasman.2006.07.026. [6] Bhogayata, A. C., Shah KD, Vyas, B., & Arora, N. K. (2012). Performance of concrete by using Non-recyclable plastic wastes as concrete constituents. 1(4). [7] da Luz GM, Oliveira MR, Silva TN, Castro ACM (2021) Performance of mortars with PET.JMater Cycles Waste Management 23(2):699–706. https://doi.org/10.1007/s10163-020-01160-w [8] Elziny, A. (n.d.). USE OF PLASTIC IN CONCRETE TO IMPROVE ITS PROPERTIES. Www.academia.edu. Retrieved June 7, 2023, from https://www.academia.edu/30615363/USE_OF_PLASTIC_IN_A_CONCRETE_TO_IMPROVE_ITS_PROPERTIES [9] Heidbreder, L.M., Bablok, I., Drews, S. and Menzel, C. (2019). Tackling the plastic problem: A review on perceptions, behaviors, and interventions. Science of The Total Environment, [online] 668(1), pp.1077–1093. doi https://doi.org/10.1016/j.scitotenv.2019.02.437. [10] Ismail, Z. Z., & AL-Hashmi, E. A. (2008b). Use of waste plastic in concrete mixture as aggregate replacement. Waste Management, 28(11), 2041–2047. https://doi.org/10.1016/j.wasman.2007.08.023 [11] Prasanth, R. L., Gopalakrishnan, S., G Thanigainathan, & Kathiravan, A. (2018). Utilization of waste plastics in fly ash bricks. International Journal of Pure and Applied Mathematics. 119(15):1417-1424 [12] Raghatate Atul, M. (2012). Use of plastic in concrete to improve its properties. International journal of advanced engineering research and studies, 1(3), pp.109-111. [13] Utilization of Waste Plastic in Concrete Towards Sustainable Development: A Review Rajat Saxenaa, Abhishek Jaina and Yash Agrawala A (Assistant Professor, Department Of Civil Engineering, Geetanjali Institute Of Technical Studies, Udaipur, [14] Mathew, P., Varghese, S., Paul, T., & Varghese, E. (2013). Recycled Plastics as Coarse Aggregate for Structural Concrete. International Journal of Innovative Research in Science, Engineering, and Technology, 2. http://www.ijirset.com/upload/march/26_Recycled%20Plastics.pdf [15] Vanitha, S., et al. “Utilization of Waste Plastics as a Partial Replacement of Coarse Aggregate in Concrete Blocks.” Indian Journal of Science and Technology, vol. 8, no. 12, 13 July 2015, https://doi.org/10.17485/ijst/2015/v8i12/54462. [16] Youcef Ghernouti, Bahia Rabehi, Safi, B., &RabahChaid. (2014). USE OF RECYCLED PLASTIC BAG WASTE IN THE CONCRETE. 8(1), 480–487. [17] Ashraf, A., Hashim, M., & Professor, A. (2016). USE OF WASTE PLASTIC AS FINE AGGREGATE SUBSTITUTE IN CONCRETE NITHYA KURUP. International Journal of Scientific & Engineering Research, 7(4). https://www.ijser.org/researchpaper/USE-OF-WASTE-PLASTIC-AS-FINE-AGGREGATE-SUBSTITUTE-IN-CONCRETE.pdf [18] Khajuria, A., & Sharma, P. (2019). Use of Plastic Aggregates in Concrete. International Journal of Innovative Technology and Exploring Engineering, 9(1), 4406–4412.https://doi.org/10.35940/ijitee.a5088.119119 [19] Kumar, A. (2018b). STUDY ON PARTIAL REPLACEMENT OF PLASTIC WASTE AS FINE AGGREGATE IN CONCRETE. International Journal of Current Engineering and Scientific Research (IJCESR), 5(5), 2394-0697. https://troindia.in/journal/ijcesr/vol5iss5/1-9.pdf [20] Pushpa Lumina, Pallavi, G. A., Bhavya, C. H., S Vanishree, & Supriya, C. B. (2022). Use of Waste Plastic as Fine Aggregate Substitute in Concrete. IOP Conference Series, 1255(1), 012010–012010.https://doi.org/10.1088/1757-899x/1255/1/012010 [21] Ajay Yadav; Dipak Dahal; Sanjog Chhetri Sapkota; Pawan Dumre; Binay Kumar Sah. “Experimental Study on the Mechanical Properties of Sustainable Concrete using Recycled Plastic and Glass Waste.” Volume. 9 Issue.11, November-2024 International Journal of Innovative Science and Research Technology (IJISRT), 93-101, https://doi.org/10.38124/ijisrt/IJISRT24NOV406

Copyright

Copyright © 2024 Muktta Narayan Shrestha, Jamuna Kandel, Pawan KC, Swastika Poudyal, Ajay Yadav, Ashish Poudel. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET65327

Publish Date : 2024-11-17

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online