Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Polymer in Pharmaceutical Drug Delivery System

Authors: Hase Sagar Madan, Miss. Nakhate S. T., Dr. Hingne L. D.

DOI Link: https://doi.org/10.22214/ijraset.2021.39568

Certificate: View Certificate

Abstract

The current review article focuses on polymers in pharmaceutical drug delivery of therapeutic agents. These dosage forms include tablets, patches, tapes, films, semisolids and powders. Polymers are the backbone of a pharmaceutical drug delivery system as they control the release of the drug from the device. Biodegradable polymers attracts the attention of its use as they can be degraded to non?toxic monomers and most important, a constant rate of drug release can be achieved from a biodegradable polymer based controlled release device. Natural polymers can be used as the means of achieving predetermined rates of drug delivery and their physico?chemical characteristics with the ease of availability provide a platform to use it as a polymer for drug delivery systems. Biodegradable polymers have been widely used in biomedical applications because of their known biocompatibility and biodegradability. In the biomedical area, polymers are generally used as implants and are expected to perform long term service. These improvements contribute to make medical treatment more efficient and to minimize side effects and other types of inconveniences for patients. The main role of polymer is to protect drug from physiological environment and prolong release of drug to improve its stability. The drug is release from polymer by diffusion, degradation and swelling. In addition to this review presents characteristics and behaviours of plant derived and mucoadhesive polymers which are currently used in drug delivery.

Introduction

I. INTRODUCTION

Over the past decades research at the level of molecular biology has unveiled the molecular basis for many diseases. New important technologies and concepts such as recombinant DNA and gene therapy have provided tools for the creation of pharmaceuticals and methods designed to specifically address such diseases.

The pharmaceutical applications of polymers range from their use as binders in tablets to viscosity and flow controlling agents in liquids, suspensions and emulsion however progress towards the application of these medicines outside of the laboratory has been considerably slow principally due to the lack of effective drug delivery systems that is mechanisms that allow the release of the drug into the appropriate body compartment for the appropriate amount of time without seriously disrupting the rest of the organism functionality.

The application of the polymeric materials for medical purposes is growing fast Polymers have found applications in diverse biomedical fields such as drug delivering systems, developing scaffolds in tissue engineering, implantation of medical devices and artificial organs, prosthesis, ophthalmology, dentistry, bone repair, and many other medical fields.

II. HISTORY

The use of polymers in the medical field is not a novelty ? natural polymers have been used as components of bal remedies for centuries When it comes to synthetic polymers however the situation is very different. Because polymer science is a relatively recent area of research synthetic water?soluble polymers as macromolecular drugs or as part of drug delivery systems related to inoculation can be considered a modern achievement.

The first polymer?drug conjugates appeared around 1955, being mescaline?N?vinylpyrolidine conjugate one of the first. In 1994, the first synthetic polymer?drug conjugate (as shown in figure 1b) designed to treat cancer was clinically tested. It consisted on an HPMA (N?(2?hydroxypropyl) methacrylamide) copolymer conjugate of doxorubicin.

III. ROLEOFPOLYMERIN DRUG DELIVARY SYSTEM

A. Immediate Release Dosage forms Tablets

Polymers have been used for many years as excipients in conventional immediate?release oral dosage forms, either to aid in the manufacturing process or to protect the drug from degradation upon storage.

Microcrystalline cellulose is often used as an alternative to carbohydrates as diluents in tablet formulations of highly potent low?dose drugs.

B. Capsules

Capsules are used as an alternative to tablets, for poorly compressible materials, to mask the bitter taste of certain drugs, or sometimes to increase bioavailability.

Many of the polymeric excipients used to “bulk out” capsule fills are the same as those used in immediate?release tablets.

Gelatine has been used almost exclusively as a shell material for hard (two?piece) and soft (one?piece) capsules.

C. Modified release Dosage Forms

It is now generally accepted that for many therapeutic agents drug delivery using immediate release dosage forms results in suboptimal therapy and/or systemic side effect Pharmaceutical scientists have attempted to overcome the limitations of conventional oral dosage forms by developing modified release dosage forms.

D. Extended Release Dosage Forms

The therapeutic effect of drugs that have a short biological half?life may be enhanced by formulating them as extended or sustained release dosage forms.

Extended and sustained release dosage forms prolong the time that systemic drug levels are within the therapeutic range and thus reduce the number of doses the patient must take to maintain a therapeutic effect thereby increasing compliance.

E. Gastroretentive Dosage Forms

Gastroretentive dosage forms offer an alternative strategy for achieving extended release profile, in which the formulation will remain in the stomach for prolonged periods, releasing the drug in situ, which will then dissolve in the liquid contents and slowly pass into the small intestine.

IV. TYPE OF POLYMER DRUG DELIVARY SYSTEM

A. Polymers for Drug Delivery in Tissue Engineering

Several strategies have been developed in order to regenerate functional tissue, the majority of which involve the use of polymer scaffolds specifically designed to direct tissue growth. The cell transplantation method is one of the most commonly used in cartilage and bone formation.20 Polymer matrices both natural and synthetic can play a vital role in the delivery of protein growth factors and cytokines to aid angiogenesis and tissue reconstruction procedure.

B. Poly (lactic co glycolic acid) Microspheres

The term microsphere refers to a small sphere with a porous inner matrix and variable surface from smooth and porous to irregular and nonporous. The drug when encapsulated is dispersed throughout the inner matrix. The size range of microspheres is typically 1 to 500 μm in diameter.

Poly (lactic?co?glycolic acid) microspheres have increasingly become the focus of research efforts in the scientific community and pharmaceutical industry. Their application as drug delivery vehicles has risen in line with the expanding biotechnology sector and the promise of new drugs discovered in the wake of the human genome project and proteomics.

V. POLYMERIC NANOPARTICLES AS DRUG CARRIERS

Certain chemical entities are either rapidly degraded and/or metabolized after administration (peptides, proteins, and nucleic acids). This is the reason the idea that nanotechnologies may be employed to modify or even to control the drug distribution at the tissue, cellular, or sub cellular levels has emerged. Among the technologies utilized for drug targeting are polymerbased nanoparticles, which have been developed since the early 1980s, when progress in polymer chemistry allowed the design of biodegradable and biocompatible materials. Nanoparticles may be defined as being submicron (<1 μm) colloidal systems generally composed of polymers. Thus, nanoparticles are colloidal systems with a size 7 to 70 times smaller than the red cells. They may be administered intravenously without any risk of embolization.

A. Polymeric Micelles as Pharmaceutical Carriers

Polymeric micelles demonstrate many attractive properties as pharmaceutical carriers. They are stable both in vitro and in vivo, can be loaded with a wide variety of poorly soluble pharmaceutical agents, effectively accumulate in pathological body areas with compromised vasculature (infarcts, tumors), and can be targeted by attaching various specific ligands to their surface.

B. Polymeric Vesicles

Polymeric vesicles may be fabricated from a variety of macromolecular amphiphile architectures, which include: block copolymers, random graft copolymers, and polymers bearing hydrophobic low?molecular?weight pendant or terminal groups. These tough particles, which reside in the nanometre and micrometer size domains, may be used for drug targeting, the preparation of responsive release systems, and other drug delivery applications.

C. Polymer Drug Conjugates

Current research in the field of polymer anticancer drug conjugates is directed towards the identification of the mechanism of action of free and polymer?bound drugs at the cellular and subcellular levels. Newer applications for polymer–drug conjugates are also being explored21. Inflammatory diseases are characterized by an increase in the vascular permeability (similar to tumors).

VI. POLYMER IN PHARMACEUTICAL APPLICATION

A. Water Soluble Synthetic Polymers

- Poly (acrylic acid) Cosmetic, pharmaceuticals, immobilization of cationic drugs, base for Carbopol polymers.

- Poly (ethylene oxide) Coagulant, flocculent, very high molecular?weight up to a few millions, swelling agent.

- Poly (vinyl alcohol) Water?soluble packaging, tablet binder, tablet coating.

- Cellulose Based Polymers

a. Carboxymethyl cellulose Super disintegrant, emulsion stabilizer.

b. Hydroxyethyl and hydroxypropyl celluloses Soluble in water and in alcohol for tablet coating.

c. Cellulose acetate phthalate enteric coating.

2. Hydrocolloids

a. Alginic acid Oral and topical pharmaceutical products; thickening and suspending agent in a variety of pastes, creams, and gels, as well as a stabilizing agent for oil?in?water emulsions; binder and disintegrants.

b. Carrageenan Modified release, viscosifier.

B. Water Insoluble Biodegradable Polymers

(Lactide?co?glycolide) polymers Microparticle– nanoparticle for protein delivery.

- Starch Based Polymers

a. Starch Glidant, a diluent in tablets and capsules, a disintegrant in tablets and capsules, a tablet binder.

b. Sodium starch glycolate super disintegrant for Tablets and capsules in oral delivery.

2. Plastics and Rubbers

a. Polyurethane Transdermal patch backing, blood pump, artificial heart, and vascular grafts, foam in biomedical and industrial products.

b. Polyisobutylene Pressure sensitive adhesives fortransdermal delivery.

VII. CLASSIFICATION OF POLYMER

A. Basis on Interaction with Water.

Soluble Polymers:? E.g. HPMC, PEG

B. Based on polymerisation method

Addition Polymers:? E.g. Alkane Polymers

C. Based on polymerization mechanism

- Chain Polymerization

- Step growth Polymerization

D. Based on chemical structure

- Activated C?C Polymer

- Inorganic polymers

- Natural polymers

E. Based on Bio Stability

- Bio?degradable

- Non Bio?degradable

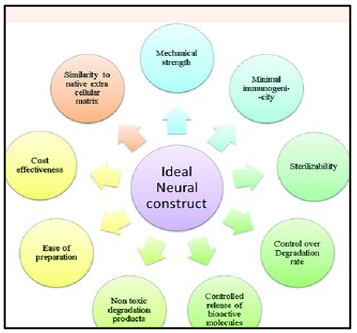

F. Characteristics of an Ideal Polymer

- It should be versatile and possess a wide range of mechanical, physical, chemical properties.

- It should be non?toxic and have good mechanical strength and should be easily administered.

- It should be inexpensive and easy to fabricate.

VIII. POLYMER IN PHARMACEUTICAL DRUG DELIVARY SYSTEM

A. Rosin

Rosin a film?forming biopolymer and its derivatives have been extensively evaluated pharmaceutically as filmcoating and microenc.

B. Chitin and Chitosan

Chitin a naturally abundant muco polysaccharide and consist of 2?acetamido?2? deoxy?b?D?glucose. Chitin can be degraded by chitinase.

C. Zein

Zein an alcohol?soluble protein contained in the endosperm tissue of Zeamais, occurs as a by?product of corn processing.

D. Starches

It is the principal form of carbohydrate reserve in green plants and especially present in seeds and underground organs.

IX. MACHANISMS OF MUCOADHESION

The mucoadhesive must spread over the substrate to initiate close contact and increase surface contact, promoting the diffusion of its chains within the mucus.

Attraction and repulsion forces arise and, for a mucoadhesive to be successful, the attraction forces must dominate.

X. FUTURE TRENDS

Despite the excessive use of synthetic polymers the need for natural biodegradable polymers to deliver drugs continues to be area of active research.

Much of the development of novel materials in controlled drug delivery is focusing on the preparation and use of these responsive polymers with specifically designed macroscopic and microscopic structural and chemical features.

A. Such Systems Include

- Copolymers with desirable hydrophilic/hydrophobic interactions.

- Complexation networks responding via hydrogen or ionic bonding.

- Polymers as nanoparticles for immobilization of enzymes, drugs, peptides, or other biological agents.

- New biodegradable polymers.

- New blends of hydrocolloids and carbohydratebased polymers.

Design and synthesis of novel combinations of polymers will expand the scope of new drug delivery systems in the futures

This will obviously require assimilation of a great deal of emerging information about the chemical nature and physical structure of these new materials.

There is an increasing movement of scientists and engineers who are dedicated to minimizing the environmental impact of polymer composite production.

Life cycle assessment is of paramount importance at every stage of a product's life, from initial synthesis through to final disposal and a sustainable society needs environmentally safe materials and processing methods.

Conclusion

Polymer?based pharmaceuticals are starting to be seen as key elements to treat many lethal diseases that affect a great number of individuals such as cancer or hepatitis. Although excipients have traditionally been included in formulations as inert substances to mainly make up volume and assist in the manufacturing process, they are increasingly included in dosage forms to fulfil specialized functions for improved drug delivery because many new drugs have unfavourable physicochemical and pharmacokinetic properties. The synthetic polymers can be designed or modified as per requirement of the formulation by altering polymer characteristics and on the other hand natural pharmaceutical excipients are biocompatible, non toxic, environment friendly and economical. Several polymers have been successfully used and others are being investigated as excipients in the design of dosage forms for effective drug delivery.

References

[1] Vicky V. Mody, Introduction to Polymeric Drug Delivery, Internet Journal of Medical Update, 5(2): 2010 July;1?2. [2] Omanathanu Pillai, Ramesh, Polymers in drug delivery, Current Opinion in chemical biology, Vol 5, issue 4, 2001, 447?451. [3] Omanathanu Pillai, Ramesh, Polymers in drug delivery, Current Opinion in chemical biology, Vol 5, issue 4, 2001, 447?451. [4] Clochard M, Dinand E, Rankin S, Simic S, Brocchini S, New strategies for polymer development in pharmaceutical science?a short review, J Pharm Pharmacol, 2001, 53(9),1175? 1184. [5] Vyas SP, Khar RK. Controlled Drug Delivery: Concepts and Advances. I st ed. Vallabh prakashan, New Delhi,2002, 156?189.Kathryn E. Uhrich ,Scott M. Cannizzaro , Robert S. Langer, Polymeric Systems for Controlled Drug Release, Chem. Rev, 99, 1999, 3181?3198. [6] Reja M, Quadir MA, Haider SS, Comparative evaluation of plastic, hydrophobic and hydrophilic polymers as matrices 00000for controlledrelease drug delivery, J Pharm Sci 692, 2003, 274?291. [7] Taylor and Francis, Polymers in Drug Delivery System, 2006, 1?236. [8] Hoffman, A.S., Hydrogels for biomedical applications, Adv. Drug Delivery Rev.54, 2002, 3–12. [9] Park, J.H., Ye, M.L., and Park, K., Biodegradable polymers for microencapsulation of drugs, Molecules, 10, 146–161, 2005. [10] Almeida, Biomedical application of polymer based pharmaceuticals, Biomedical Engineering – Group XII,2008. [11] Van Savage, G. and Rhodes, C.T., The sustained release coating of solid dosage forms: a historical review, Drug Dev. [12] Industrial Pharm., 21(1), 1995, 93. [13] Longer, M.A., Ch’ng, H.S., and Robinson, J.R., Bioadhesive polymers as platforms for oral controlled drug delivery III: oral delivery of chlorothiazide using a bioadhesive polymer, J. Pharm. Sci., 74(4), 1985, [14] Park, K. and Robinson, J.R., Bioadhesive polymers as platforms for oral?controlled drug delivery: method to study bioadhesion, Int. J. Pharm., 19, 1984, 107. [15] Chang, H.S., Bioadhesive polymers as platforms for oral controlled drug delivery II: synthesis and evaluation of some swelling, water?insoluble bioadhesive polymers, J. Pharm. Sci., 74(4), 1985, 399. [16] Harris, D., Fell, J.T., Sharma, H.L., and Taylor, D.C., Gastrointestinal transit of potential bioadhesive formulations in man: a scintigraphic study, J. Controlled Release, 12, 1990, 45. [17] Leung, S.?H.S. and Robinson, J.R., Polymer structure features contributing to Mucoadhesion II., J. Controlled Release, 12, 1990, 187. [18] Whitehead, L., Floating dosage forms: an in?vivo study demonstrating prolonged gastric retention, J. Controlled Release, 55, 1998, 3. [19] Marler, J.J., Upton, J., Langer, R., and Vacanti, J.P., Transplantation of cells in matrices for tissue regeneration, Adv. Drug Delivery Rev., 33, 1998, 165. [20] Wang, D., Cathepsin K inhibitor?polymer conjugates: potential drugs for the treatment of osteoporosis and rheumatoid arthritis, Int. J. Pharm., 277(1–2), 2004, 73. [21] Reja M, Quadir MA, Haider SS. Comparative evaluation of plastic, hydrophobic and hydrophilic polymers as matrices for controlled release drug delivery, J Pharm Sci 692, 2003, 274?291. [22] Verhoeven, J, Controlled?release formulations, a hydrophilic matrix containing furosemide, Int. J. Pharm, 45, 1988, 65?69. [23] Ankita Raizada, Polymers In Drug Delivery: A Review, IJPRD, 2(8),2010, 9?20. [24] Nokano M, Ogata A, In vitro release characteristics of matrix tablets, Study of Karaya gum and Guar gum as releasemodulators, Ind. J. Pharm. Sc, 68, 6, 2006, 824?826. [25] Poddar RK, Rakha P, Singh SK, MishraDN, Bioadhesive Polymers as a Platform for Drug Delivery: Possibilities and Future Trends, Research J on Phamacetical Dosage Form and Technology, 2,1,2010, 40?54.

Copyright

Copyright © 2022 Hase Sagar Madan, Miss. Nakhate S. T., Dr. Hingne L. D.. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET39568

Publish Date : 2021-12-21

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online