Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Preparation of Bajra Healthy Wafers

Authors: Akshay Subhash Dhankute, Sachin Hemraj Baghele, Arpit Gajanan Pote, Siddhant Chandrabhan Waghmare, Lilesh Hiwaraj Pustode, Prashant Watkar

DOI Link: https://doi.org/10.22214/ijraset.2024.62212

Certificate: View Certificate

Abstract

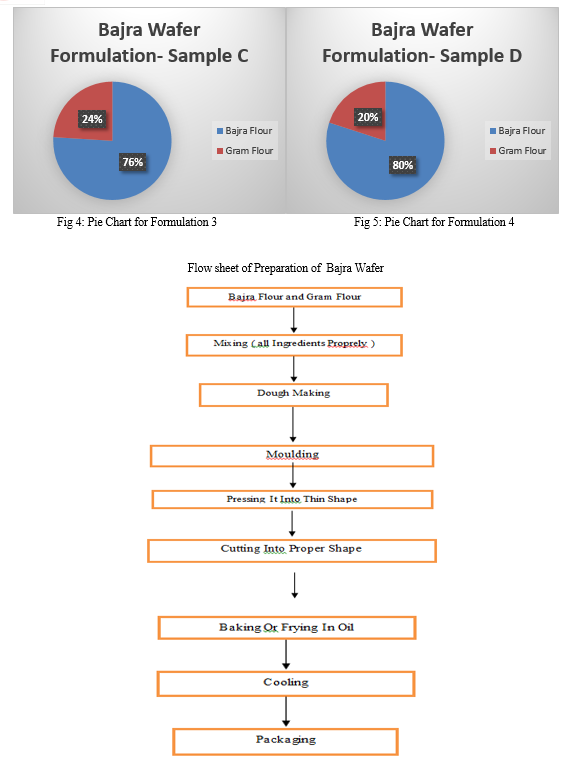

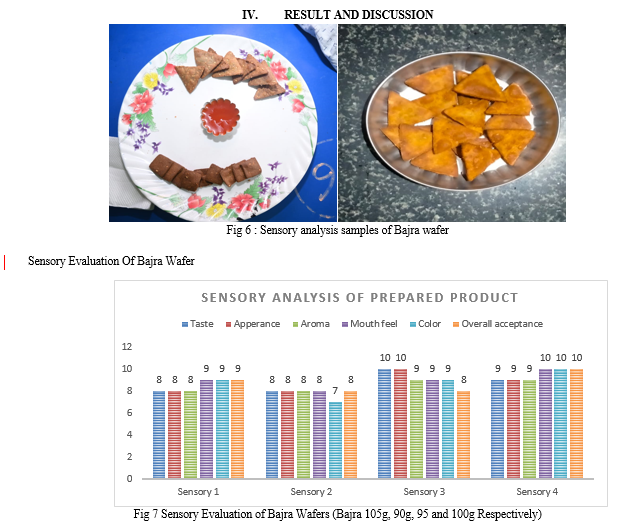

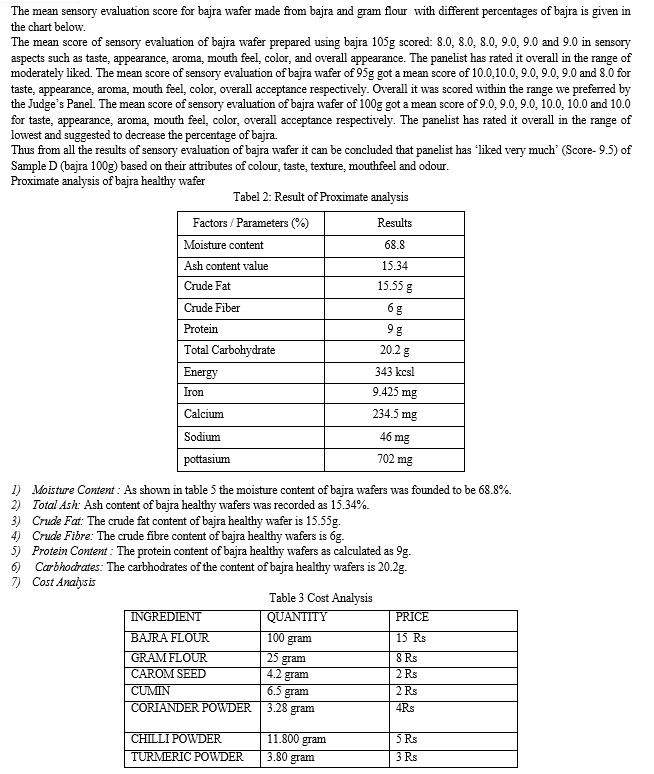

Bajra, also known as pearl millet, is a versatile grain rich in essential nutrients and dietary fiber. The incorporation of bajra into snack production, particularly in the form of wafers, presents a promising avenue for creating healthier snack alternatives. Bajra-based wafers offer a blend of taste, crunchiness, and nutritional benefits, catering to the growing demand for wholesome snacks in today\'s health-conscious society. This abstract explores the development and nutritional aspects of bajra-based wafers, highlighting their potential as a nutritious snack option. The process involves carefully selecting high-quality bajra grains, milling them into flour, and blending them with complementary ingredients to create a crispy, flavorful snack. These wafers not only provide a delightful eating experience but also offer numerous health benefits due to bajra\'s inherent nutritional profile. The nutritional analysis reveals that bajra wafers are an excellent source of complex carbohydrates, dietary fiber, protein, and essential minerals such as iron and magnesium. Additionally, they are gluten-free, making them suitable for individuals with gluten sensitivities or celiac disease. The inclusion of bajra in snack form contributes to a balanced diet, aiding in weight management and promoting digestive health. Sensory and microbial analyses were conducted to evaluate the product\'s attributes and safety. The proximate analysis revealed key nutritional parameters such as moisture content (68.8%), total fats (15.55g/200g), protein (9g/200g), carbohydrates (20.2g/200g), crude fiber (6g/200g), ash content (15.34), calcium (234.5mg/200g), and iron (9.425mg/200g). The microbial load was found to be within acceptable limits. Organoleptic assessment, encompassing attributes like color, flavor, texture, taste, and odor, indicated favorable reception by panelists, garnering a high rating score of 8. A packaging solution was chosen based on considerations of product properties and shelf-life requirements, with the product exhibiting a shelf life of 2 to 3 months from the manufacturing date. In conclusion, the developed product offers a nutrient-rich, fiber- and protein-packed snack alternative, catering to health-conscious consumers.

Introduction

I. INTRODUCTION

Bajra, a traditional Hindi name for the Pennisetum glaucum crop, also referred to as pearl millet, is cultivated primarily in Africa and India, serving as a significant nutritional source. However, it is also grown and consumed in various other regions globally. Bajra, encompassing edible seeds of pearl millet plants, manifests in white, yellow, gray, brown, and bluish-purple hues. Typically, these seeds are cooked as a cereal grain or finely ground into flour. This article provides a comprehensive overview of bajra and its health benefits.Bajra pearl millet represents just one of many millet varieties, including fonio, finger millet (ragi), Job’s tears, foxtail, and kodo millet. Cooked millet serves as a valuable source of protein, carbs, fiber, vitamins, and minerals, constituting a nutritious carbohydrate source. Moreover, millet is gluten-free, suitable for individuals with celiac disease or those adhering to a gluten-free diet, provided they select certified gluten-free products.Bajra boasts high levels of beneficial plant chemicals such as antioxidants, polyphenols, and phytochemicals, contributing to overall human health. However, the presence of polyphenols may hinder the absorption of certain minerals, such as iron and zinc, from bajra.Introduction to Bajra Wafers in Thesis: Bajra, also known as pearl millet, emerges as a versatile and nutritious grain entrenched as a staple in numerous regions worldwide for centuries. Its robust nutritional composition, resilience to adverse environmental conditions, and adaptability render it indispensable in arid and semi-arid regions. In recent times, there has been a burgeoning interest in exploring innovative avenues to incorporate bajra into processed food items, with one notable development being the production of Bajra Wafers.Bajra wafers signify a novel and nutritious snack option harnessing the nutritional merits of bajra while addressing the contemporary demand for healthy and convenient food alternatives. These wafers, typically thin and crispy slices crafted from bajra flour, offer a distinctive departure from conventional potato-based or wheat-based snacks. As consumers increasingly seek healthier snack choices, bajra wafers present an opportunity to cater to this demand by offering a delectable, gluten-free, and nutrient-rich alternative.The production of bajra wafers entails diverse processing techniques, including milling bajra grains into flour, blending with other ingredients, and utilizing advanced technology for shaping and baking. The outcome is a crunchy and flavorful snack that not only tantalizes taste buds but also contributes to a balanced diet.

This thesis endeavors to explore the feasibility, nutritional attributes, and consumer reception of bajra wafers as a prospective snack product. It will delve into processing methods, quality parameters, and sensory attributes of bajra wafers, encompassing factors like texture, taste, and aroma. Furthermore, the thesis will evaluate the potential market for bajra wafers, considering prevailing trends in the food industry and the burgeoning awareness of health benefits linked with ancient grains.Comprehending the production and reception of bajra wafers can furnish invaluable insights to the food industry, agricultural sector, and nutrition science. The findings of this thesis can pave the way for the development of novel bajra-based products, advocate sustainable agriculture, and furnish consumers with a healthier snacking alternative. As the global food landscape evolves, exploring innovative applications for traditional grains like bajra assumes paramount importance, aligning with objectives of advancing food security, sustainability, and public health improvement.

II. MATERIAL AND METHODS

This chapter contains all the materials and methodology followed to prepare and test the product. The test methods for testing raw materials and products are also discussed. New product development work was carried out at the Department of Food Technology, Ballarpur Institute of Technology, Bamni, Ballarpur.

Table 1: Material Required for New Product Development

|

Material Required |

Collection Of Raw Material |

|

Bajra Flour |

Super Market |

|

Gram Flour |

Super Market |

|

Carom Seed |

Home |

|

Cumin |

Home |

|

Coriander Powder |

Home |

|

Chilli Powder |

Home |

|

Tumeric Powder |

Home |

|

Water |

Mineral Water |

|

Oil |

Home |

|

Curd |

Dairy Shop |

|

Salt |

Home |

|

Grinder |

Processing Lab |

|

Weighing Machine |

Processing Lab |

|

Measuring cylinder |

Processing Lab |

|

Ovan/Pan |

Processing Lab |

|

LDPE |

Stationary Shop |

Packaging Material:

Packaging is the science, art and technology of enclosing or protecting products for distribution, storage, sale, and use. The packaging material for the product was selected according to the Food Safety and Standard (Packaging) Regulation, 2018 (schedule IV – List of suggestive packaging material. The packaging of the final product was done in LDPE, a thermoplastic made from monomer ethylene which is a soft, flexible and lightweight. It has high clarity, heat-seal ability, high elongation and softness. This allows the consumer to have a greater experience in seeing the contents and product level as well as holding and squeezing the packaging. LDPE is the most inexpensive material for plastic films. LDPE (resin identification code 4) is recycled in the United States. (Team Xometry April 29, 2022). The above explained were the resons for which LDPE was chosen as a packaging material for the developed bajra wafer

3) Sensory Analysis:

Sensory analysis was conducted in the campus of Ballarpur Institute of Technology by a sensory panel consisting of 10 panelists. The panelist observed color, appearance, flavor, texture, taste and overall acceptability of product and rated them in a scale of 0 to 10 with 0 as the minimum and 10 as the maximum.

4) Proximate Analysis:

a) Estimation of Moisture

Moisture content was determined using the Oven drying method. Approximately 5 grams of the sample were weighed (W2) on pre-weighed petri plates (W1) and placed in an oven at 105º C for 3 hours. After drying, the samples were cooled in airtight desiccators to prevent moisture exchange with the environment. The drying process was considered complete when two consecutive weighings, taken an hour apart, showed variations of no more than 5 mg. Moisture content was calculated by subtracting the dried weight from the initial sample weight and expressed as a percentage. [Adya Yadav, et al, 2016]

% Moisture = (Loss in weight×100)/(Weight of sample)

b) Estimation of Fat

5 gm sample was weighed and packed in a thimble the prepared thimble was weighed to cross- check the weight of the sample. The thimble was then enclosed in a big cellulose thimble and then it was placed in a Soxhlet extraction tube, 250 ml, of petroleum ether, was added to the Soxhlet extraction tube containing the sample. The heating mantle was turned on and the temperature was set at 60°C. Petroleum ether gets evaporated and condensed and falls over the sample drop by drop and the speed of dropping should be 150 drops per minute. When clear color petroleum ether was seen in Soxhlet after 6-12 hours, the assembly was turned off. The round bottom flask containing the solvent was separated from the assembly to recover the solvent. The solvent was recollected by using the downward distillation unit for the next use and the round bottom flask holding the extracted fat sample was dried in a hot air oven at 105 "C until all the solvent was removed after drying the RBF was cooled in a desiccator and the weight was taken until the last three successive reading shows the difference less than 0.001 gm. A 5-gram sample underwent initial weighing and was then enclosed within a thimble. Subsequently, the thimble, now containing the sample, underwent an additional weighing to verify the sample's weight. The thimble, housing the sample, was then inserted into a larger cellulose thimble. This combined setup was carefully positioned within a Soxhlet extraction tube. To facilitate the extraction process, 250 ml of petroleum ether was introduced into the Soxhlet extraction tube containing the sample. Upon activating the heating mantle and setting the temperature to 60°C, the petroleum ether underwent a cycle of evaporation, condensation, and dripping over the sample at a controlled rate of 150 drops per minute. Once the petroleum ether, now visibly clear, was observed in the Soxhlet after 6-12 hours, the entire assembly was deactivated. The round bottom flask, holding the solvent, was then separated from the apparatus to recover the solvent. The reclaimed solvent underwent further processing using a downward distillation unit for subsequent use. Meanwhile, the round bottom flask containing the extracted fat sample underwent a drying process in a hot air oven set at 105°C until all the solvent was completely removed. Following drying, the round bottom flask was cooled in a desiccator, and its weight was measured until three successive readings showed a difference of less than 0.001 grams [AOAC (1995)].

Percent crude fat was calculated as under:

% Crude Fat=(Weight of Fat)/(Weight of sample) ×100

c) Estimation of Protein

The protein content of the samples was determined utilizing the Kjeldahl method. Initially, 2 grams of the sample underwent digestion with 5 grams of a digestion mixture, comprising 10 parts potassium sulfate and 1 part copper sulfate, along with 20 ml of concentrated sulfuric acid. This digestion process continued in a Kjeldahl flask until the contents achieved a state of being carbon-free. The resulting digested sample was then adjusted to a final volume of 100 ml. A 10 ml aliquot of the digested sample was subjected to distillation with 20 ml of 30 percent sodium hydroxide. The liberated ammonia from this process was collected in a solution containing 20 ml of 2 percent boric acid, enriched with 2-3 drops of a mixed indicator. This indicator was a combination of 0.1% methyl red and 0.1% bromo-cresol green, dissolved in 95 percent ethyl alcohol, with a ratio of 1:5, respectively.

The entrapped ammonia was subsequently titrated against 0.1N hydrochloric acid. The nitrogen content in the sample was then calculated using the following expression:

% Nitrogen = (14×N of HCL×Titre value (ml)×Dilution factor×100)/(Weight of sample(g)×1000)

d) Estimation of Total Ash

To determine the ash content, a 2-gram sample was placed in a silica crucible and ignited on a heater. Subsequently, the crucible was transferred to a muffle furnace and maintained at a temperature of 550º C ± 15º C until a clean ash was obtained. The weight of the resulting residue was then recorded, and the percentage of ash was calculated using the following formula:

% Ash = (Weight of residue×100)/(Weight of sample)

e) Estimation of Carbohydrate:

The percent carbohydrates were calculated by subtracting the sum of moisture, protein, fat, ash and fiber from 100.

% CHO = 100 - (% Moisture + % Protein + % Fiber + % + Ash)

5) Microbial Analysis

The Total bacterial count and fungal load was estimated by serial dilution method.

6) Shelf life testing

Shelf life was estimated based on microbial and sensory analysis at intervals of 15 days.

Conclusion

The bajra wafers are prepared by using both oil frying and oven baking. The sample prepared using oil frying gives more crispiness than oven baking method. The sample is assured to withstand its shelf life more than a year due to its complete removal of moisture. On comparison the oil frying is appreciable one than baking. Addition of garlic and ginger tastier product. High dietary fibre and phenolic content makes bajra wafers very beneficial for diabetic patients. Apart from this it also has low glycemic index (GI) that make it an ideal snack to prevent late night thirst and helps to maintain blood sugar at constant ratio. Pearl millet (Pennisetum glaucum), a drought tolerant crop belonging to the family Poaceae is an important type of millet. It is a sturdy plant that can sustain adverse growing conditions. It is rich in vitamins, minerals, oil and phytochemicals. The phytates or phytic acid present acts as antinutritional factor which bind to the proteins and minerals thereby reducing the digestibility and bioavailability of the proteins, carbohydrates and minerals. In the following study, nixtamalization, a process widely used for the treatment of maize, is being used on the millet to lower the antinutritional properties of the millet. The grain was cooked at 95 C with varying lime concentration (0.5%, 1.0%, 1.5%, 2.0%) while keeping the cooking time (30 min) and steeping time (2 hours) constant. Product (crisp fried dough wafers) was made from the milled nixtamalized flour and different physio-chemical parameters and acrylamide content of the crisp fried dough wafer was analysed. The product made from flour treated with 1.5% lime showed the best results and overall acceptability. This research could be beneficial for increasing the utilization of pearl millet in different parts of the world especially in under developed countries as a health food. Also, the phytochemicals of pearl millet have various health benefits and this study can be used to increase their concentration and thereby promote the use of pearl millet for enrichment of various food products.

References

[1] Singh, S., Gahlaut, A. K., & Sharma, S. K. (2019). Development and quality evaluation of pearl millet (bajra) based wafers. Journal of Food Science and Technology, 56(3), 1373-1382. [2] Kaur, M., Sharma, S., & Singh, N. (2015). Development and quality assessment of pearl millet based gluten-free wafers. Journal of Food Science and Technology, 52(7), 4065-4074. [3] Kaur, M., Singh, N., & Sharma, S. (2014). Development and nutritional evaluation of pearl millet based extruded snacks. Journal of Food Science and Technology, 51(12), 3752-3760. [4] Kaur, M., Singh, N., & Sharma, S. (2013). Development of pearl millet based extruded ready-to eat snack.* LWT - Food Science and Technology, 50(2), 535-542. [5] Sharma, S., & Singh, N. (2012). Development and quality evaluation of pearl millet based glutenfree cookies. Journal of Food Science and Technology, 49(4), 445-453. [6] Nutritional and functional properties of bajra (Pennisetum typhoides): a review. Singh, P., Kumar, R., Bhalla, M., & Rani, S. (2019). International Journal of Food Science & Technology, 54(2), 333-342. [7] Development and quality evaluation of bajra based cookies.* Kumari, A., & Rana, K. (2012). Journal of Food Processing & Technology, 3(2), 121. [8] Effect of incorporation of bajra flour on the physicochemical and sensory properties of biscuits.Chauhan, A., & Singh, B. (2013). International Journal of Food and Nutritional Sciences, 2(6), 80. [9] Development and evaluation of extruded snacks using different proportions of bajra flour. Singh, B., & Rana, K. (2012). International Journal of Food Science & Technology, 47(12), 2536-2543. [10] Development and sensory evaluation of cookies from blends of wheat and bajra flours. Kumar, R. A., & Ramesh, B. (2014). International Journal of Agricultural Sciences, 10(2), 532-537.

Copyright

Copyright © 2024 Akshay Subhash Dhankute, Sachin Hemraj Baghele, Arpit Gajanan Pote, Siddhant Chandrabhan Waghmare, Lilesh Hiwaraj Pustode, Prashant Watkar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62212

Publish Date : 2024-05-16

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online