Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Preparation of Multigrain Papdi

Authors: Anushree Pandurang Sawarkar , Pradnya Vilas Urade, Pamu Sevkalal Bisen, Divya Korde, Prashant Watkar

DOI Link: https://doi.org/10.22214/ijraset.2024.62733

Certificate: View Certificate

Abstract

Rice papdi made traditionally by using rice and gram flour, for flavor spices are added after it cut into small circles shapes and for cooking frying is done. modifying this papdi by using sorghum oats and cornflower to increase its nutritional value the nutrients present in this papdi helps in good health as compared to traditional gujarati papdi. Millets are a group of small, round whole grains that belong to the Poaceae family. Proso (Panicum miliaceum) also known as Vari/Chena is a type of millet which has various health benefits. Viruddha Ahara is an important concept in Ayurveda and if consumed it can cause disbalance of dosha leading to many disorders. One such wrong food combination (Viruddha Ahara) has been mentioned in Charaka Samhita that is consumption of proso millet with milk which can cause psoriasis. To test this hypothesis; the pH factor of millets and millet-milk combination as well as the protein and lipid profile of millet, milk and millet-milk combination are taken into consideration. The best method for protein extraction was selected based on the protein yield obtained. For protein profiling, SDS-PAGE was performed and a comparative analysis of proteins in milk and milk-millet combination was done to check for the presence of any extra protein formed in the milletmilk combination. Further confirmatory studies for analyzing the protein profile of millet, milk, and millet milk combination have to be done by HPLC. A peak for eicosanoic acid (also known as arachidic acid) was observed in the GC-MS the for, millet milk combination

Introduction

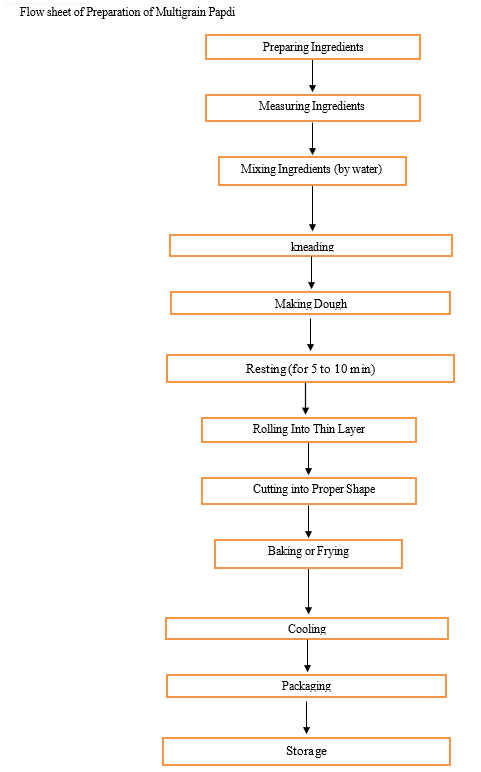

I. INTRODUCTION

Evening time is passed by tea and snack and eating oily junk food it is not good and that is unhealthy from corona everyone wanted to eat nutritional food but snacks are not nutritious so our goal is to make healthy multigrain papdi Using sorghum we are making daily eating snack called gujarati papdi which is normally made by rice maida and spices and cooked by frying by using sorgum oats and corn flour we are making this regular snack healthy and tasty to make ourevening enjoyable and nutritional in multigrain papdi is free from maida .it has verry good in taste multigrain papdi is crispy snacks that contain various from sorghum flour ,oats flour, corn flour and adding some spices to make delicious tasty snacks eat with tea or that can be eaten anytime of the day

A. Sorghum Flour

Sorghum (Sorghum bicolor) is a tropical cereal. Sorghum is a naked grain–that is, during threshing, the glumes are removed from the grain. Thus, there is no husk to remove during milling. The grain is approximately 4 mm in length, and it is more or less spherical in shape but somewhat flattened at the germ end. Sorghum is a major staple crop and food in arid, tropical countries in Africa and India. Sorghum has some valuable nutritional characteristics. It is gluten-free and can contain high levels of phytochemicals, particularly …

Sorghum is a major staple crop and food in arid tropical and subtropical regions of Africa and India. It has some valuable nutritional characteristics—it is gluten free and generally contains high levels of phytochemicals, particularly antioxidant-rich phenolics. There is also evidence that some sorghum foods have slow starch digestibility. Sorghum flour milling technology has not been developed sufficiently. There is a considerable loss of micronutrients and phenolics in the refined flour.

B. Corn Flour

Corn is the cereal with the highest production worldwide and is used for human consumption, livestock feed, and fuel. Various food technologies are currently used for processing industrially produced maize flours and corn meals in different parts of the world to obtain precooked refined maize flour, dehydrated nixtamalized flour, fermented maize flours, and other maize products. These products have different intrinsic vitamin and mineral contents, and their processing follows different pathways from raw grain to the consumer final product, which entail changes in nutrient composition. Dry maize mechanical processing creates whole or fractionated products, separated by anatomical features such as bran, germ, and endosperm

The use of rice flour corn and cassava starch was evaluated in several formulations aiming to find a flour mixture to replace wheat flour in the production of free-gluten white bread. Production parameters were evaluated through sensory analysis. The resulting breads were evaluated taking into account physical parameters (crumb appearance, specific volume and moisture) and sensorial parameters (flavor, appearance, crumb texture, crust color and satisfaction).

C. Oats Flour

The properties of oat flour can be manipulated by processing to suit various consumption and product development needs. In this work, three different processes typically used on oat flour, namely the extrusion, drum drying and enzyme-treatment spray drying process were evaluated with respect to how each process changes the quality of the oat flour. Results showed that the extrusion process produced oat flour with the best flow ability while the enzyme-treated spray drying process led to the lowest flowability. The color of enzymetreated

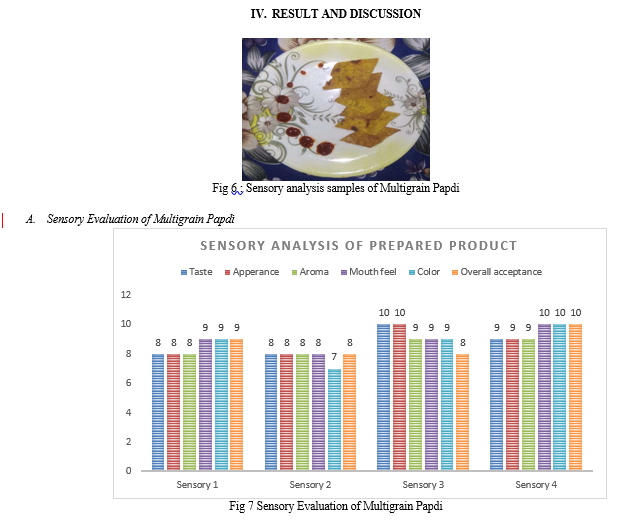

II. MATERIAL AND METHODS

This chapter contains all the materials and methodology followed to prepare and test the product. The test methods for testing raw materials and products are also discussed. New product development work was carried out at the Department of Food Technology, Ballarpur Institute of Technology, Bamni, Ballarpur.

Table 1: Material Required for New Product Development

|

Material Required |

Collection Of Raw Material |

|

Sorghum Flour |

Society |

|

Oats Flour |

Society |

|

Corn Flour |

Society |

|

Spices |

Home |

|

Salt |

Home |

|

Ginger Garlic Powder |

Home |

|

Coriander Leaves |

Home |

|

Oil |

Shop |

|

Weighing Machine |

Processing Lab |

|

Measuring cylinder |

Processing Lab |

|

Pan |

Processing Lab |

|

LDPE |

Stationary Shop |

A. Packaging Material

Packaging is the science, art and technology of enclosing or protecting products for distribution, storage, sale, and use. The packaging material for the product was selected according to the Food Safety and Standard (Packaging) Regulation, 2018 (schedule IV – List of suggestive packaging material. The packaging of the final product was done in LDPE, a thermoplastic made from monomer ethylene which is a soft, flexible and lightweight. It has high clarity, heat-seal ability, high elongation and softness. This allows the consumer to have a greater experience in seeing the contents and product level as well as holding and squeezing the packaging. LDPE is the most inexpensive material for plastic films. LDPE (resin identification code 4) is recycled in the United States. (Team Xometry April 29, 2022). The above explained were the resons for which LDPE was chosen as a packaging material for the developed Multigrain Papdi.

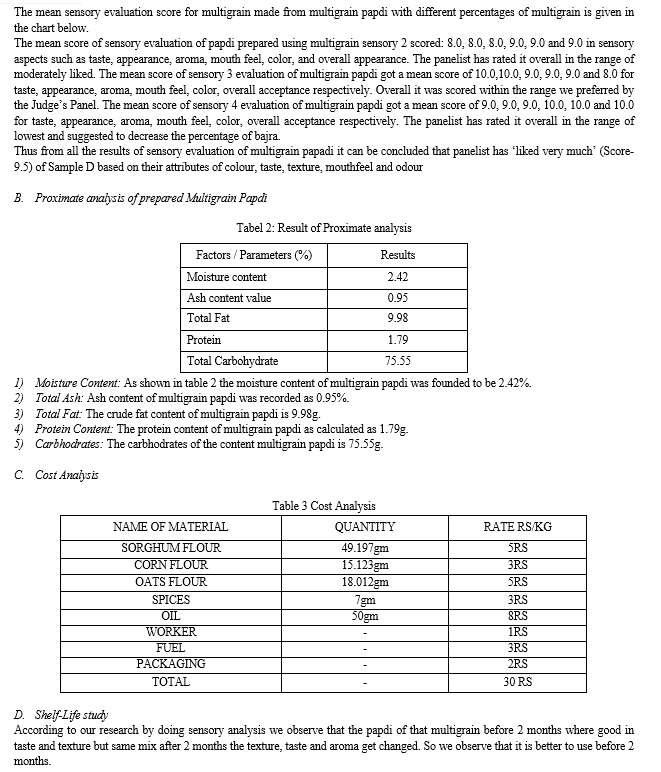

A. sory Analysis

Sensory analysis was conducted in the campus of Ballarpur Institute of Technology by a sensory panel consisting of 10 panelists. The panelist observed color, appearance, flavor, texture, taste and overall acceptability of product and rated them in a scale of 0 to 10 with 0 as the minimum and 10 as the maximum.

B. Proximate Analysis

- Estimation of Moisture

Moisture content was determined using the Oven drying method. Approximately 5 grams of the sample were weighed (W2) on pre-weighed petri plates (W1) and placed in an oven at 105º C for 3 hours. After drying, the samples were cooled in airtight desiccators to prevent moisture exchange with the environment. The drying process was considered complete when two consecutive weighings, taken an hour apart, showed variations of no more than 5 mg. Moisture content was calculated by subtracting the dried weight from the initial sample weight and expressed as a percentage. [Adya Yadav, et al, 2016]

% Moisture = (Loss in weight×100)/(Weight of sample)

2. Estimation of Fat

5 gm sample was weighed and packed in a thimble the prepared thimble was weighed to cross- check the weight of the sample. The thimble was then enclosed in a big cellulose thimble and then it was placed in a Soxhlet extraction tube, 250 ml, of petroleum ether, was added to the Soxhlet extraction tube containing the sample. The heating mantle was turned on and the temperature was set at 60°C. Petroleum ether gets evaporated and condensed and falls over the sample drop by drop and the speed of dropping should be 150 drops per minute. When clear color petroleum ether was seen in Soxhlet after 6-12 hours, the assembly was turned off. The round bottom flask containing the solvent was separated from the assembly to recover the solvent. The solvent was recollected by using the downward distillation unit for the next use and the round bottom flask holding the extracted fat sample was dried in a hot air oven at 105 "C until all the solvent was removed after drying the RBF was cooled in a desiccator and the weight was taken until the last three successive reading shows the difference less than 0.001 gm. A 5-gram sample underwent initial weighing and was then enclosed within a thimble. Subsequently, the thimble, now containing the sample, underwent an additional weighing to verify the sample's weight. The thimble, housing the sample, was then inserted into a larger cellulose thimble. This combined setup was carefully positioned within a Soxhlet extraction tube. To facilitate the extraction process, 250 ml of petroleum ether was introduced into the Soxhlet extraction tube containing the sample. Upon activating the heating mantle and setting the temperature to 60°C, the petroleum ether underwent a cycle of evaporation, condensation, and dripping over the sample at a controlled rate of 150 drops per minute. Once the petroleum ether, now visibly clear, was observed in the Soxhlet after 6-12 hours, the entire assembly was deactivated. The round bottom flask, holding the solvent, was then separated from the apparatus to recover the solvent. The reclaimed solvent underwent further processing using a downward distillation unit for subsequent use. Meanwhile, the round bottom flask containing the extracted fat sample underwent a drying process in a hot air oven set at 105°C until all the solvent was completely removed. Following drying, the round bottom flask was cooled in a desiccator, and its weight was measured until three successive readings showed a difference of less than 0.001 grams [AOAC (1995)].

Percent crude fat was calculated as under:

% Crude Fat=(Weight of Fat)/(Weight of sample) ×100

3. Estimation of Protein

The protein content of the samples was determined utilizing the Kjeldahl method. Initially, 2 grams of the sample underwent digestion with 5 grams of a digestion mixture, comprising 10 parts potassium sulfate and 1 part copper sulfate, along with 20 ml of concentrated sulfuric acid. This digestion process continued in a Kjeldahl flask until the contents achieved a state of being carbon-free. The resulting digested sample was then adjusted to a final volume of 100 ml. A 10 ml aliquot of the digested sample was subjected to distillation with 20 ml of 30 percent sodium hydroxide. The liberated ammonia from this process was collected in a solution containing 20 ml of 2 percent boric acid, enriched with 2-3 drops of a mixed indicator. This indicator was a combination of 0.1% methyl red and 0.1% bromo-cresol green, dissolved in 95 percent ethyl alcohol, with a ratio of 1:5, respectively.

The entrapped ammonia was subsequently titrated against 0.1N hydrochloric acid. The nitrogen content in the sample was then calculated using the following expression:

% Nitrogen = (14×N of HCL×Titre value (ml)×Dilution factor×100)/(Weight of sample(g)×1000)

4. Estimation of Total Ash

To determine the ash content, a 2-gram sample was placed in a silica crucible and ignited on a heater. Subsequently, the crucible was transferred to a muffle furnace and maintained at a temperature of 550º C ± 15º C until a clean ash was obtained. The weight of the resulting residue was then recorded, and the percentage of ash was calculated using the following formula:

% Ash = (Weight of residue×100)/(Weight of sample)

5. Estimation of Carbohydrate

The percent carbohydrates were calculated by subtracting the sum of moisture, protein, fat, ash and fiber from 100.

% CHO = 100 - (% Moisture + % Protein + % Fiber + % + Ash)

???????

???????

Conclusion

The multigrain property is prepared by frying and baking the thin layer poppy is more effective when it’s fried as compared to baking. The sorghum flours gluten content is low that’s why it takes time to bind perfectly to form thin layer. Corn flour and oats help to bind strongly for forming a thin layer. The nutritional value of sorghum oats and corn flour is made papdi more health beneficial. It is consumed as snack at evening or it can be used as raw material to make Bhel or chiwda. Because it is used as a snack consumption of papaya is depending upon its taste It’s the taste is very good and spices used in Papdi make multigrain papdi more delicious.

References

[1] Lloyd W Rooney, Sergio Othón Serna-Saldivar Handbook of Cereal Science and Technology, Revised and Expanded, 149-175, 2000 [2] WR Young, GL Teetes Annual Review of Entomology 22 (1), 193-218, 1977 [3] Donghao Zhang, Yuhui Zhang, Xin Pan, Lin Yuan, Yanpei Cai, Fei Lao, Jihong Wu Journal of Cereal Science 113, 103742, 2023 Jeffrey A Gwirtz, Maria Nieves Garcia Casal Annals of the New York Academy of Sciences 1312 (1), 66-75, 2014 [4] Jeffrey A Gwirtz, Maria Nieves Garcia Casal Annals of the New York Academy of Sciences 1312 (1), 66-75, 2014 [5] Phillip Makhumula, Omar Dary, Monica Guamuch, Carol Tom, Ronald Afidra, Zo Rambeloson Annals of the New York Academy of Sciences 1312 (1), 91-104, 2014 [6] Elijah Edache Ehoche, Akanya Oluwafunmi, Adefolalu Folasade Oluwafunmilola Jurnal Teknologi Laboratorium 8 (1), 23-35, 2019 [7] Ali Khoddami, Valeria Messina, Komala Vadabalija Venkata, Asgar Farahnaky, Christopher L Blanchard, Thomas H Roberts Critical Reviews in Food Science and Nutrition 63 (9), 1170-1186, 2023 [8] Mamoudou H Dicko, Harry Gruppen, Alfred S Traoré, Willem JH van Berkel, Alphons GJ Voragen Journal of agricultural and food chemistry 53 (7), 2581-2588, 2005 [9] Oi-Wah Lau, Siu-Kay Wong Journal of chromatography A 882 (1-2), 255-270, 2000 [10] Anour Shebani, Abdalah Klash, Rabea Elhabishi, Shalh Abdsalam, Hassan Elbreki, Wael Elhrari Res. Dev. Mater. Sci 7 (5), 791-797, 2018 [11] Millets 50 Properties, Processing, and Health Benefits Issue 27 of FAO food and nutrition series, ISSN 1014-3181 [12] Volume 27 of Food and Agriculture Organization: FAO food and nutrition series Author- Food and Agriculture Organization of the United Nations Publisher Food & Agriculture Org., 1995 Oats Nutrition and Technology Hardcover – Illustrated, 27 December 2013 by YiFang Chu Chemical composition of finger millet (Eleusine coracana) flour October 2018 [13] 3) John RN Taylor, Joseph O Anyango Flour and breads and their fortification in health and disease prevention, 127-139, 2011 [14] Jeffrey A Gwirtz, Maria Nieves Garcia Casal Annals of the New York Academy of Sciences 1312 (1), 66-75, 2014 [15] Chengxin He, Jun Zheng, Fengjie Liu, Meng Wai Woo, Hua Xiong, Qiang Zhao Journal of Cereal Science 96, 103123, 2020 [16] AS Oladapo, AB Adepeju, AA Akinyele, DM Adepeju International Journal of Scientific Engineering and Science 1 (2), 23-26, 2017 [17] Bala, R.S., Swain, S., Sengotuvel, D. and Parida, N.R. (2010). Nutritious millets for enhancing income and improved nutrition: A case study from Tamilnadu and Orissa. Miner millets in South India. [18] Bamboriya, S.D., Bana, R.S., Pooniya, V., Rana, K.S. and Singh. Y.V. (2017). Planting density and nitrogen management effects on productivity, quality and water-use efficiency of rainfed pearlmillet (Pennisetum glaucum) under conservation agriculture. Indian Journal of Agronomy, 62(3): 363-366. [19] Bana, R.S., Rana, K.S., Dass, A., Choudhary, A.K., Pooniya, V., Vyas, A.K., Kaur, R., Sepat, S. and Rana, D.S. (2013). A Manual on Dryland Farming and Watershed Management. India. IARI, New Delhi, p. 104. [20] Bana, R.S. (2014). Agrotechniques for conserving water and sustaining production in rainfed agriculture. Indian Farming, 63(10): 30-35. [5] Bana, R.S., Pooniya, V., Choudhary, A.K., Rana, K.S. and Tyagi, V.K. (2016). [21] Influence of organic nutrient sources and moisture management on productivity, biofortification and soil health in pearlmillet (Pennisetum glaucu? 4) RN Taylor, Joseph O Anyango Flour and breads and their fortification in health and disease prevention, 127-139, 2011 [22] Jeffrey A Gwirtz, Maria Nieves Garcia?Casal Annals of the New York Academy of Sciences 1312 (1), 66-75, 2014 [23] Chengxin He, Jun Zheng, Fengjie Liu, Meng Wai Woo, Hua Xiong, Qiang Zhao Journal of Cereal Science 96, 103123, 2020 [24] AS Oladapo, AB Adepeju, AA Akinyele, DM Adepeju Intrnational Journal of Scientific Engineering and Science 1 (2), 23-26, 2017

Copyright

Copyright © 2024 Anushree Pandurang Sawarkar , Pradnya Vilas Urade, Pamu Sevkalal Bisen, Divya Korde, Prashant Watkar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62733

Publish Date : 2024-05-26

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online