Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Preparation of Pista Rabadi by Rabadi Instant Mix

Authors: Shruti Ramteke, Gayatri Lonare, Vijaykumar Karmankar, Pratik Shamkure, Divya Korde, Prashant Watkar

DOI Link: https://doi.org/10.22214/ijraset.2024.62339

Certificate: View Certificate

Abstract

From the young to the old, Rabdi is an Indian delicacy that is loved by all. Infused with cardamoms, saffron, almonds and pistachios - this milk-based dessert is a delight for your taste buds. Instant Pista Rabdi Dessert Mix is a 100% vegetarian, preservative-free, artificial colour and flavour-free dish. Benefits of Pista Rabadi Instant Mix is Ready in 3 easy steps in just 15 minutes, Flavoured with nuts and spices. Simple and quick to make Indian dessert mix for special occasions, makes 500ml of tasty Rabdi. Surprisingly, you only need 6 ingredients to craft these delectable treats, and they\'re not just delicious they\'re gluten free too. Elevate your taste experience with this health conscious and satisfying Pista Rabdi creation. A Pista Rabdi Instant Mix was prepared by mixing ingredient such as SMP 25%, Sugar20%, Corn Flour 15%, Pista 12%, Citric Acid 7%, Saffron 0.43%. After that mix the Pista Instant Mix with 500ml lukewarm milk and bring it to boil by stirring continuously or till the desired consistency and then serve chilled.

Introduction

I. INTRODUCTION

Instant Rabdi mix refers to a blend of ingredients which are necessary to prepare an Indian sweet called rabadi. Rabadi is a sweet dish made by reducing the mild by 50-60% and sweetening it with sugar. It can be flavored by various things like saffron, cardamom, rose water, kewda water, nutmeg etc. The instant rabadi mix comprises of skimmed milk powder, preservatives and spices like cardamom, etc. They are available in the market under many brand names. The existing method for the preparation of rabadi is suitable at cottage scale. The preparation of rabdi requires boling whole fat milk for a long duration, upto 15-20 minutes to bring the rabadi to the desired thick consistency. Pista Rabdi also known as Rabdi is a North Indian traditional sweet dish made with full fat milk, sugar, cardamoms and nuts. It is served as a dessert or along with Malpua, Gulab Jamun, Jalebi and Poori. Rabri tastes very delicious, creamy and is full of flavors from the cardamoms and saffron.

II. MATERIALS AND METHODOLOGY

This chapter contains all the materials and methodology followed to prepare and test the product. The test method for testing raw materials and product are also discussed. New product development work was carried out at the Department of Food Technology, Ballarpur Institute of Technology, Bamni, Ballarpur.

Table 1: Material Required for New Product Development

|

Material Required |

Collection of Raw Material |

|

Corn Flour |

Super Market |

|

SMP |

Super Market |

|

Sugar Powder |

Super Market |

|

Citric Acid |

Super Market |

|

Pistachio Chips |

Super Market |

|

Cardamom |

Super Market |

|

Almond |

Super Market |

|

Saffron |

Super Market |

|

Refrigerator |

Processing lab |

|

Measuring cups |

Processing lab |

|

Induction |

Processing lab |

|

Spatula |

Processing lab |

|

Weighing Machine |

Processing lab |

|

Knife |

Processing lab |

|

Non-stick pan |

Processing lab |

A. Packaging Material

The packaging of the final product was done in PET/MET-PET/LDPE, three layered packaging material. PET (polyethylene terephthalate) is the chemical name for polyester. It is clear, strong, light weight plastic that is widely used for packaging foods. It is durable, heat resistant film with very good oxygen barrier property.

MET is nothing but PET film laminated with metal foil. It increases film’s oxygen-water barrier and blocks out UV rays. LDPE (low density polyethylene) is a thermoplastic made from monomer ethylene which is a soft, flexible and lightweight. It has high clarity, heat-seal ability, high elongation and softness.

Low-density polyethylene (LDPE) is a thermoplastic made from the monomer ethylene. The EPA estimates 5.7% of LDPE (resin identification code 4) is recycled in the United States.

Despite competition from more modern polymers, LDPE continues to be an important plastic grade. LDPE has SPI resin ID code 4. Low Density Polyethylene is made through a process known as free radical polymerization. This process requires heat (420-570 degrees K) and a lot of pressure (1000-3000 atm), so it is commonly conducted in an autoclave or tubular reactor in large batches. The image below shows the molecular structure of polyethylene and ethylene. Natural LDPE is very flexible and translucent in appearance.

It's a soft, flexible, lightweight plastic material, noted for its low temperature flexibility, toughness, and corrosion resistance. This allows the consumer to have a greater experience in seeing the contents and product level as well as holding and squeezing the packaging.

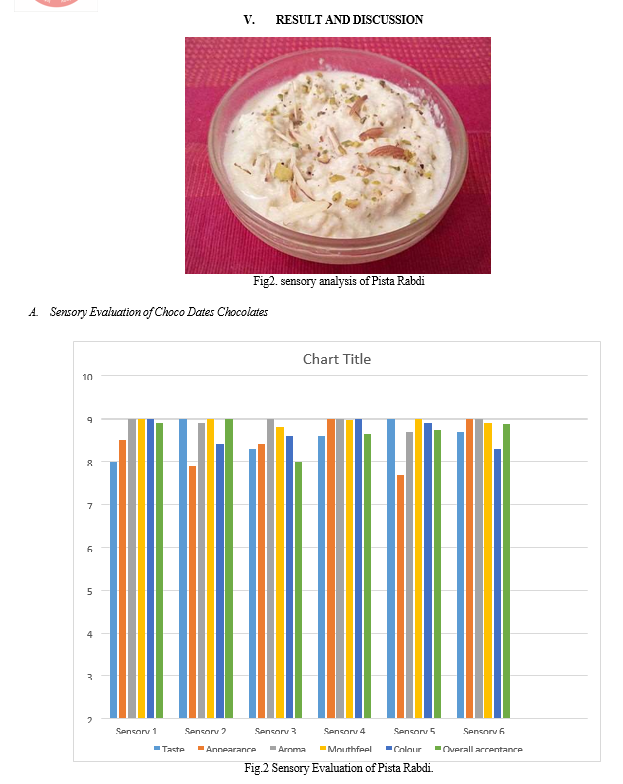

III. METHODOLOGY

A. Ingredient Selection

High quality Corn Flour, SMP, Sugar Powder and Pista along with complementary ingredients such as Cardamom, Almond, Citric acid and Saffron to achieve optimal taste.

Flow sheet of preparation of Pista Rabadi by Rabadi Instant Mix:

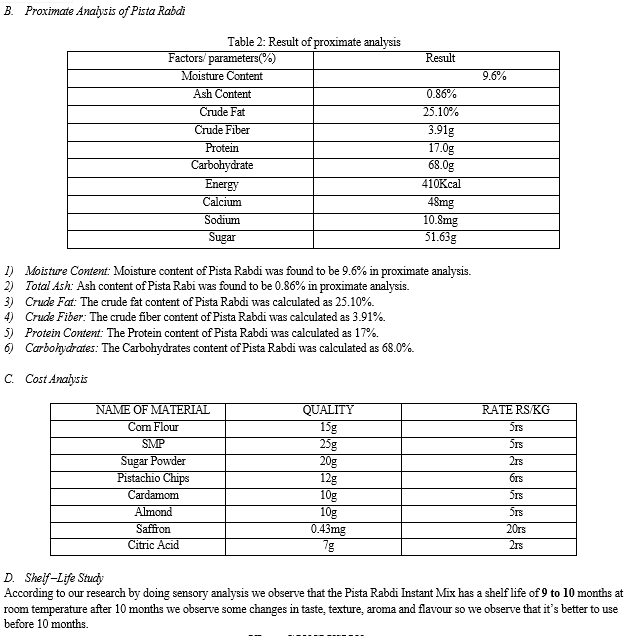

B. Sensory Analysis

Sensory analysis was conducted in the campus of Ballarpur Institute of Technology by a sensory panel consisting of 10 panelists. The panelist observed color, appearance, flavor, texture, taste and overall acceptability of product and rated them in a scale of 0 to 10 with 0 as the minimum and 10 as the maximum.

IV. PROXIMATE ANALYSIS

A. Estimation of Moisture

Moisture content was determined using the Oven drying method. Approximately 5 grams of the sample were weighed (W2) on pre-weighed petri plates (WI) and placed in an oven 105" C for 3 hours. After drying, the samples were cooled in airtight desiccators to prevent moisture exchange with the environment. The drying process was considered complete when two consecutive weighing, taken an hour apart, showed variations of no more than 5 mg. Moisture content was calculated by subtracting the dried weight from the initial sample weight and expressed as a percentage.

%Moisture= (Loss in weight x 100)/ (weight of sample)

B. Estimation of Fat

5 gm sample was weighed and packed in a thimble the prepared thimble was weighed to cross check the weight of the sample. The thimble was then enclosed in a big cellulose thimble and then it was placed in a Soxhlet extraction tube, 250 ml, of petroleum ether, was added to the Soxhlet extraction tube containing the sample. The heating mantle was turned on and the temperature was set at 60°C. Petroleum ether gets evaporated and condensed and falls over the sample drop by drop and the speed of dropping should be 150 drops per minute. When clear color petroleum ether seen in Soxhlet after 6-12 hours, the assembly was turned off. The round bottom flask containing the solvent was separated from the assembly to recover the solvent. The solvent was recollected by using the downward distillation unit for the next use and the round bottom flask holding the extracted fat sample was dried in a hut air oven at 105 "C until all the solvent was removed after drying the RBF was cooled in a desiccator and the weight was taken until the last three successive reading shows the difference less than 0.001 gm.. A 5-gram sample underwent initial weighing and was then enclosed within a thimble. Subsequently, the thimble, now containing the sample, underwent an additional weighing to verify the sample's weight. The thimble, housing the sample, was then inserted into a larger cellulose thimble. This combined setup was carefully positioned within a Soxhlet extraction tube. To facilitate the e extraction process, 250 ml of petroleum ether introduced into the Soxhlet extraction tube containing the sample. Upon activating the heating mantle and setting the temperature to 60°C, the petroleum ether underwent a cycle of evaporation, condensation, and dripping over the sample at a controlled rate of 150 drops per min Once the petroleum ether, now visibly clear, was observed in the Soxhlet after 6-12 hours, the entire assembly was deactivated. The round bottom flask, holding the solvent, was then separated from the apparatus to recover the solvent.

The reclaimed solvent underwent further processing using a downward distillation unit for subsequent use. Meanwhile, the round bottom flask containing the extracted fat sample underwent a drying process in a hot air oven set at 105°C until all the solvent was completely removed. Following drying, the round bottom flask was cooled in a desiccator, and its weight was measured until three successive readings showed a difference of less than 0.001 grams [AOAC(1995)]. Percent crude fat calculated as under:

% Crude Fat= (weight of fat)/(weight of sample) x100

C. Estimation of Protein

The protein content of the samples was determined utilizing the Kjeldahl method. Initially, 2 grams of the sample underwent digestion with 5 grams of a digestion mixture, comprising 10 parts potassium sulfate and I part copper sulfate, along with 20 ml of concentrated sulfuric acid. This digestion process continued in a Kjeldahl flask until the contents achieved a state of being carbon- free. The resulting digested sample was then adjusted to a final volume of 100 ml. A 10 ml aliquot of the digested sample was subjected to distillation with 20 ml of 30 percent sodium hydroxide. The liberated ammonia from this process was collected in a solution containing 20 ml of 2 percent boric acid, enriched with 2- 3 drops of a mixed indicator. This indicator was a combination of 0.1% methyl red and 0.1% bromo-cresol green, dissolved in 95 percent ethyl alcohol, with a ratio of 1:5, respectively.

The entrapped ammonia was subsequently titrated against 0.IN hydrochloric acid. The nitrogen content in the sample was then calculated using the following expression:

% Nitrogen (14xN of HCL x Titre value (ml)× Dilution factorx100)/(Weight of sample (g)x100)

D. Estimation of Total Ash

To determine the ash content, a 2-gram sample was placed in a silica crucible and ignited on a heater. Subsequently, the crucible was transferred to a muftle furnace and maintained at a temperature of 550° C 15° C until a clean ash was obtained. The weight of the resulting residue was then recorded, and the percentage of ash was calculated using the following formula:

%Ash = (weight of residue x 100)/(weight of sample)

E. Estimation of Carbohydrates

The percent carbohydrates were calculated by subtracting the sum of moisture, protein, fat, ash and fiber from 100.

% CHO 100-(% Moisture +% Protein+% Fiber+%+ Ash

F. Microbial Analysis

The Total bacterial count and fungal load was estimated by serial dilution method.

G. Shelf life testing

Shelf life was estimated based on microbial and sensory analysis at intervals of 10 months.

Conclusion

Pista Rabdi is essentially a condensed milk-based sweet treat. The primary ingredients include milk, sugar, and sometimes flavorings like cardamom, saffron, or nuts. To make rabdi, milk is simmered for an extended period, allowing it to reduce and thicken gradually. As it does, the milk solids separate, creating a creamy, granular texture. The addition of sugar, along with aromatic spices and garnishes, enhances the flavor profile, making rabdi a dessert fit for royalty. The history of rabdi can be traced to the Mughal period in India, which spanned from the 16th to the 18th century. The Mughal emperors were renowned for their extravagant lifestyles and love for rich, decadent cuisine. Rabdi, with its opulent, velvety texture and sumptuous taste, quickly became a staple in their royal kitchens. It was often served at grand feasts and banquets, where it was relished by the nobility.

References

[1] https://www.indianhealthyrecipes.com/rabri-recipe- video/#:~:text=Rabdi%20is%20a%20traditional%20North,gulab%20jamun%2C%20jalebi%20or%20malpua. [2] https://www.aqua-calc.com/page/density-table/substance/cornstarch [3] http://www.merriam-webster.com/dictionary/cornstarch [4] Gremse, D.A.; Bucuvalas, J. C.; Balistreri, W. F. (October 1990). \"Efficacy of cornstarch therapy in type III glycogen-storage disease\". The American Journal of Clinical Nutrition. 52 (4): 671–674. doi:10.1093/ajcn/52.4.671. ISSN 0002-9165. PMID 2403059. [5] ^ \"How to: make a liquid that\'s also a solid\". bbc.co.uk. August 5, 2013. Archived from the original on December 12, 2016. Retrieved December 3, 2016. [6] ^ Paisley.org.uk - Brown & Polson, Paisley - From Boom to Bust [7] ^ Grace\'s Guide To British Industrial History - Brown and Polson [8] ^ \"Cornstarch is a Powerful Tool That Must be Used Responsibly\". January 28, 2020. [9] ^ \"Ingredient Substitution\". JoyofBaking.com. September 11, 2007. Archived from the original on May 10, 2011. Retrieved June 12, 2011. [10] ^ \"High-Tech Shortcut To Greek Yogurt Leaves Purists Fuming\". NPR.org. Retrieved January 11, 2018. [11] Bilge Altunaker; Sepil Sahin; Gulum Sumnu (March 2004). \"Functionality of batters containing different starch types for deep-fat frying of chicken nuggets\". European Food Research and Technology. 218 (4): 318–322. doi:10.1007/s00217-003-0854-5. S2CID 93841327. [12] ^ Manley, Duncan (1998). Biscuit, cookie and cracker manufacturing manuals – Manual 1 – Ingredients. Cambridge, England: Woodhead Publishing Limited. p. 34. ISBN 1-85573- 292-0. [13] ^ \"What They Don\'t Tell You About 3D Printing PLA\". Engineering.com. Retrieved April 30, 2023. [14] ^ \"Women\'s health concerns prompt condom makers to stop using talc\". The Free Lance- Star. January 11, 1996. p. D3. Retrieved May 14, 2016 – via Google News Archive Search. [15] ^ \"Medical Glove Powder Report\". Fda.gov. Archived from the original on May 12, 2016. Retrieved May 14, 2016.

Copyright

Copyright © 2024 Shruti Ramteke, Gayatri Lonare, Vijaykumar Karmankar, Pratik Shamkure, Divya Korde, Prashant Watkar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62339

Publish Date : 2024-05-19

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online