Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Printed Circuit Board (PCB) Fault Detection

Authors: Rahul Lambture , Suyog Mahajan, Kiran Patil, Nestor J. Philips

DOI Link: https://doi.org/10.22214/ijraset.2024.63142

Certificate: View Certificate

Abstract

Nowadays many industries heavily depend on devices, those, with printed circuit boards (PCBs) to function properly. However issues like connections, damaged components or short circuits can cause malfunctions that result in downtime and financial losses. It is crucial to identify and resolve these PCB faults to maintain the operation of electronic systems. On average businesses experience a 23% decrease in productivity due to PCB faults. One of the contributors to this problem is the lack of detection and resolution. To tackle this issue we propose an approach using machine learning techniques for PCB fault detection. Our solution harnesses the power of Web Machine Learning to implement a real time model for detecting PCB faults. By utilizing TensorFlow.js – a JavaScript library for training and deploying machine learning models in web browsers – we can provide instant feedback on the health of PCBs. The foundation of our system lies in leveraging TensorFlow.jss capabilities while incorporating a model designed specifically for detecting PCB faults. This model examines the positions of components identifies anomalies in circuitry. Provides immediate feedback, on potential faults. With a web based interface that allows users to access this tool from devices our approach ensures efficient and user friendly PCB fault detection. There are benefits, to using our PCB fault detection system. It helps minimize downtime by identifying and resolving faults, which in turn saves costs by preventing damage, to electronic components. Moreover it encourages maintenance reducing the chances of failures and improving the overall reliability of the system.

Introduction

I. INTRODUCTION

A. Overview

In todays evolving world, where technology continues to shape aspects of our daily lives there is significant potential, in integrating technology with quality control processes particularly in the manufacturing industry. This project focuses on the intersection of technology and quality control by using intelligence (AI) and machine learning (ML) techniques to detect faults in Printed Circuit Boards (PCBs). The reliability and functionality of devices heavily rely on the integrity of their PCBs. However traditional manual inspection methods are prone to error. Require a lot of labor. The proposed solution aims to revolutionize quality control by introducing an approach that harnesses the power of AI and ML. To accomplish this we will gather a dataset consisting of labeled PCB images that cover various types of faults. We will preprocess this dataset to ensure analysis. The project will explore trained models for image classification within popular frameworks like TensorFlow or PyTorch adapting them specifically for PCB fault detection. Training the model will involve dividing the dataset into training, validation and test sets while continuously monitoring its performance. The deployed system will include a user interface that allows uploading of PCB images, for fault detection. We will carry out real world tests to evaluate the effectiveness of the system making room, for improvements based on evaluations. This innovative application of AI and ML in PCB fault detection not only aims to enhance manufacturing efficiency and reliability but also addresses the challenges associated with human-dependent inspection processes, paving the way for a more robust and automated quality control system.

B. Motivation

The development of the ”Printed Circuit Board (PCB) Fault Detection” system is driven by the need to enhance the reliability of devices, across industries. Traditional methods of inspecting PCBs which’re prone to human errors and require a lot of effort highlight the necessity for an advanced solution. This project aims to overcome these limitations by leveraging cutting edge intelligence (AI). Machine learning (ML) techniques. When it comes to selecting a model to how we choose YOLO for detecting traffic violations this project explores models for classifying images with a particular focus on frame- works like TensorFlow or PyTorch. The goal is to adapt and fine tune these models according to the requirements of PCB fault detection covering types of defects such, as deformations, track discontinuities, crossover paths and improper soldering.

C. Objective

The main goals of the ”Printed Circuit Board (PCB) Fault Detection” project are carefully planned to tackle areas, in PCB manufacturing with the aim of ensuring the production of quality electronic devices.

D. Specific Goals

- Collecting and Preparing the Dataset: Gather a ranging and comprehensive dataset consisting of PCB images with labeling to cover various types of faults such as deformation, track interruptions, crossover paths and incorrect soldering. Make sure to standardize the images in terms of size orientation and format, for analysis.

- Customizing the Model: First we need to explore and choose trained models suitable, for image classification, such as TensorFlow or PyTorch frameworks. Once we have a model in mind we’ll adapt it to meet the requirements of PCB fault detection. Our focus will be on handling types of defects by tuning the model for accurate identification and classification.

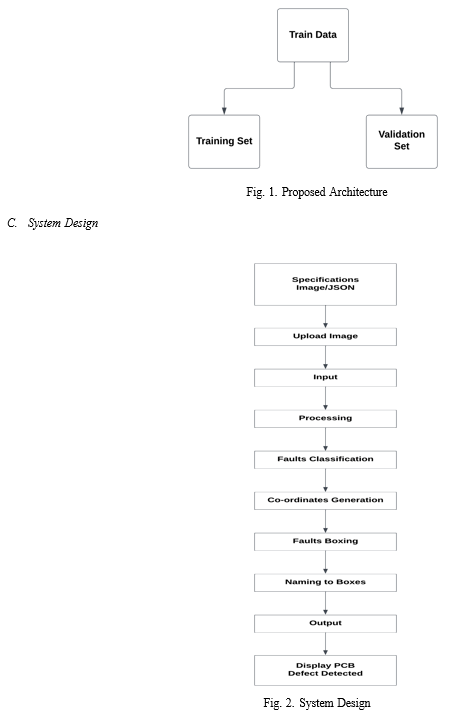

- Training and Evaluation Process: To ensure a training process we’ll divide our dataset into three parts; training set, validation set and test set. The adapted model will be trained using the training set while closely monitoring its performance on the validation set. To evaluate its effectiveness in detecting faults we’ll utilize metrics, like accuracy, precision and recall on the test set.

- Deployment and Interface Development: Creating a user interface, for navigation is an aspect of this project. We want users to have the ability to upload images of printed circuit boards (PCBs) and obtain results for detecting faults. It would be beneficial to explore the possibility of deploying the model as a web service using frameworks like Flask or Django as this would improve accessibility and user friendliness.

- Real-world Testing and Enhancement: To ensure that our system is reliable and accurate, in detecting faults it is necessary to test it with real world scenarios involving PCB images from manufacturing environments. By doing we can evaluate its effectiveness. Make any necessary adjustments or refinements to enhance its performance. This iterative process may involve tweaking hyperparameters incorporating data augmentation techniques or fine tuning the model architecture. Ultimately our goal is to create a system that performs optimally in real world situations.

By achieving these goals the project aims to make a contribution, to automating the detection of faults in PCBs. This will enhance manufacturing efficiency minimize the need, for inspections and ultimately guarantee the production of notch electronic devices.

II. LITERATURE SURVEY

A. Survey of Existing Systems

In [1] In the stage of manufacturing known as detection, in process (DIP) a team of researchers has created a system that’s capable of identifying imperfections in printed circuit boards (PCBs). The study, published in the IEEE Transactions on Components, Packaging and Manufacturing Technology introduces a self adjusting approach to detecting defects. Their models ability to adapt to defect patterns is demonstrated through its utilization of a technique. The findings highlight the systems effectiveness, in pinpointing flaws during this phase of the manufacturing process.

In[2] This paper share findings on detecting surface defects, on printed circuit boards in the 2021 IEEE International Conference on Big Data, Artificial Intelligence and the Internet of Things Engineering. Researchers improved upon the used YOLOv4 algorithm to identify and address intricate surface defects. Their approach proved effective in overcoming chal- lenges related to defect detection offering a solution for quality control, in real world PCB manufacturing.

In[3] In this article published in IEEE Access, Hu, Bing and Jianhui Wang introduced a technique to identify surface flaws, on Printed Circuit Boards (PCBs). Their approach combines the advantages of Faster RCNN (Region Convolutional Neural Network) and Feature Pyramid Network (FPN) resulting in an enhanced ability to detect defects on PCB surfaces. By integrating these architectures they demonstrate a dedication, to improving accuracy and efficiency in identifying PCB flaws.

In[4] Saeed Khalilian, Yeganeh Hallaj and Arian Balouchestani have put forward a proposal that introduces a cutting edge method, for detecting defects in PCBs. In their paper they describe how they utilize denoising autoencoders to not identify defects but also pinpoint their locations on the PCBs.

What is truly impressive, about this approach is its accuracy rate of 97.5% surpassing the performance of existing methods that were considered state of the art. This unique capability to not detect defects. Also take corrective actions sets this method apart offering a comprehensive solution to enhance the overall quality of PCBs.

B. Limitation of Existing Systems

Finding issues, in printed circuit boards (PCBs) is current systems for detecting faults in them have their fair share of challenges. These tools, meant to spot flaws and abnormalities, in PCBs come across obstacles that hinder their performance. By recognizing these challenges we can look into ways to enhance and innovate PCB fault detection technology.

- Limited Fault Coverage: Many current PCB fault detection systems are set up to identify types of faults or have restrictions, in spotting a spectrum of fault types. This restriction may lead to missing out on newer fault trends, which could diminish the systems overall efficiency.

- High False Positive Rates: Numerous systems have a tendency to mistakenly classify PCBs as faulty resulting in rework or rejection of PCBs leading to increased production expenses and wastage.

- Limited Scalability: Current PCB fault detection systems face difficulties in terms of scalability those relying on image processing methods or rule based algorithms. These systems may encounter issues in handling volumes of data or adjusting to variations, in production levels and line setups.

- Inability to Detect Subtle Faults: Some systems might struggle to identify faults, in PCBs that’re not immediately visible. This issue could lead to defects passing through inspections potentially impacting product quality and dependability.

- High Cost of Implementation: Setting up and managing PCB fault detection systems can be expensive for smaller manufacturers with limited resources. The upfront costs for equipment, software, training and ongoing maintenance may present challenges, for adoption.

III. PROPOSED SYSTEM

A. Problem Statement

The reliability and consistency of devices and networks are, at risk due to imperfections and shortcomings discovered in printed circuit boards (PCBs). Existing approaches for identifying faults frequently face difficulties in detecting and fixing these problems resulting in delays in production and increased costs. To tackle this issue it is essential to establish a fault detection system, for PCBs that makes use of technologies and approaches. This system should integrate detection techniques into a structure that guarantees recognition of PCB faults ultimately improving quality control and product dependability.

B. Proposed Methodology / Techniques

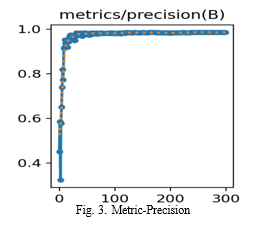

This project presents a system aimed at transforming the way we detect and fix PCB faults effectively. Essentially our method combines strategies, from computer vision and machine learning specifically customized to tackle the hurdles in fault detection. Our suggested approach includes elements all working together to enhance the systems ability to spot and rectify PCB faults promptly.

- Advanced Object Detection with YOLO v8: In our project we use the YOLO v8 algorithm to spot defects, in printed circuit boards. This algorithm is recognized for its quick and accurate object recognition abilities. It’s a component of our system that helps us identify faults and abnormalities on PCBs. The swift processing power of YOLO v8 with PCB images allows for the detection and classification of faults enhancing quality control and defect analysis, in manufacturing processes.

- Resizing: To maintain consistency in the size of input data and make processing more efficient we adjust the resolution of PCB images to a format before inputting them into the machine learning model. This initial step, in preprocessing simplifies the detection process and enhances model precision by minimizing differences, in image sizes.

- Normalization: We use normalization methods to make the pixel values, in PCB images consistent. By adjusting the intensity of pixels to a scale normalization helps the machine learning model better understand the characteristics and designs present, in the images. This standardization procedure improves the models capacity to adapt across datasets and lighting scenarios.

- Augmentation: We use augmentation methods to expand the variety of the training dataset. By employing data augmentation we incorporate changes, like rotation, translation, flipping and adjustments in brightness to the PCB images. This approach to augmentation aids in avoiding overfitting and enhances the models capacity to adapt to data. Moreover it boosts the models resilience by introducing it to a spectrum of situations and variations, in PCB layouts.

- Assessment and Ongoing Enhancement: To verify the efficacy of our proposed approach we intend to conduct testing using real world PCB models. This evaluation will focus on evaluating the systems accuracy in detecting defects the reliability of identifying faults and its performance in conditions.

D. Details of Hardware and Software Requirements

- Software Requirements

Web Hosting Software: Website Hosting Application; A necessity for hosting the user interface that enables users to access and engage with the PCB fault detection system. This application should be in line with industry standards offering secure and scalable web hosting features to ensure access, to the system across devices and locations.

2. Hardware Requirements:

Industrial-Grade Cameras: High quality Cameras, for Industry Use; Utilizing cameras with resolution to capture intricate images of printed circuit boards (PCBs). These cameras must adhere to industry norms for image clarity and dependability to guarantee fault detection.

IV. RESULTS AND DISCUSSION

A. Implementation Details

Our dedication, to improving fault detection in manufacturing processes is showcased through the introduction of the PCB fault detection system, which effectively utilizes machine learning models. This outline demonstrates how different software components have been seamlessly integrated for PCB fault detection eliminating the requirement, for database management.

- Deployment of Software and Model Integration: Our project began with establishing a foundation using an operating system such, as Linux and incorporating libraries like TensorFlow and OpenCV. The primary objective was to develop machine learning models specifically designed for identifying defects in PCBs. We invested effort, in training these models with a variety of PCB images to enable them to distinguish between various types of faults as they manifest.

- Effective Utilization of Machine Learning Models: Our system depends entirely on machine learning models that are trained to identify fault patterns, in PCB images. By utilizing deep learning algorithms we guarantee that our fault detection system functions smoothly, without requiring management of databases. Of saving PCB images and associated data our method involves utilizing the API of the trained machine learning model to categorize faults instantly in real time.

- Real-Time Fault Identification: In order to showcase how our system works we carried out tests using PCB inspection data. Our system analyzed PCB images in time spotting issues according to specific criteria. The detected faults were then recorded along, with information like the nature of the fault and where it was located on the PCB. This ability to identify faults, in real time highlights how our system can be applied practically in manufacturing settings without requiring an amount of data storage.

- Challenges faced and Solutions Implemented: During the execution phase we faced difficulties associated with differences, in PCB images and the intricacy of fault patterns. To tackle these obstacles we improved our machine learning algorithms and integrated preprocessing methods to strengthen the systems resilience and flexibility. By concentrating on enhancing the efficiency of our machine learning models we successfully navigated through these hurdles. Guaranteed fault identification, in practical settings.

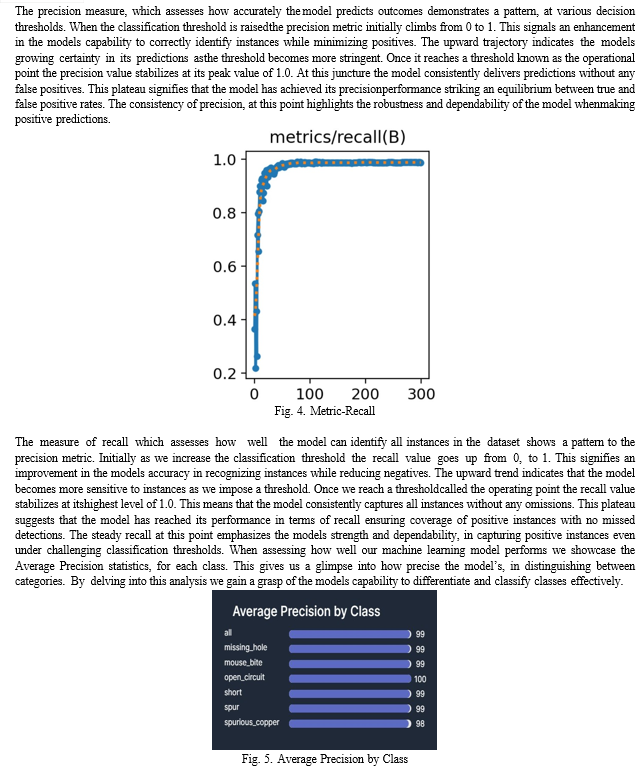

B. Result Analysis

Conclusion

A. Conclusion A new model created to spot flaws, in printed circuit boards appears to be making progress in tackling the growing challenges related to identifying and fixing faults. By blending methods and approaches this strategy offers an accurate solution for pinpointing and dealing with PCB issues. The hybrid model designed for detecting faults in PCBs offers advantages. Improved Precision; By using detection methods this hybrid approach surpasses fault detection methods by decreasing both positives and false negatives ensuring precise fault diagnosis. Adaptability; As patterns of PCB faults change over time the hybrid model can adapt to types of faults and obstacles in detection enhancing its resilience and effectiveness. Scalability; This model can easily expand to match manufacturing environments and production scales catering to both small scale operations and large facilities. Prompt Response; By employing a mix of detection methods the hybrid model can quickly. Address PCB faults, minimizing disruptions in production processes for resolutions. Efficient Resource Usage; Through optimized usage of resources this hybrid model offers a cost solution for fault detection while improving efficiency. Improved Quality Control; Integration of detection techniques serves as a defense mechanism, against PCB faults enhancing product quality and reliability while reducing risks of manufacturing defects. B. Future Work When looking into ways to improve the detection of faults, in PCBs using models there are paths to explore for progress. One key area involves refining algorithms for fault analysis to identify and classify types of faults in PCBs. This includes developing algorithms that can accurately distinguish between patterns of faults and normal variations in PCB designs. Another interesting aspect worth exploring is creating models that can adjust their fault detection methods over time based on feedback from manufacturing processes. These initiatives could lead to the development of techniques that continuously learn and enhance their ability to detect faults ultimately improving accuracy over time. Additionally integrating hybrid PCB fault detection models with cloud based platforms presents an opportunity. By utilizing the scalability and computational power offered by cloud environments we could strengthen fault detection capabilities. Efficiently handle amounts of PCB data. Moreover advancements in AI and machine learning approaches show potential in speeding up the performance, precision and effectiveness of hybrid PCB fault detection models. Research efforts in this area may involve designing algorithms that use data to improve accuracy in fault detection and adaptability as PCB manufacturing techniques. As the landscape of PCB manufacturing evolves it becomes essential to prioritize strategies for addressing emerging challenges, in fault detection while maintaining the quality standards of PCBs.

References

[1] Yu-Ting Li,Paul Kuo and Jiun-In Guo, “Automatic Industry PCB Board DIP Process Defect Detection System Based on Deep Ensemble Self-Adaption Method”,IEEE TRANSACTIONS ON COMPONENTS, PACKAGING AND MANUFACTURING TECHNOLOGY, VOL. 11, NO. 2, FEBRUARY 2021 [2] Haofei Xielst,Xingchen Li3rd, Yuan Li2nd, Li He4th , “Circuit Board Based on Improved YOLOv4 ”, 2021 IEEE 2nd International Conference on Big Data, Artificial Intelligence and Internet of Things Engineering (ICBAIE 2021) [3] BING HU, JIANHUI WAN, “Detection of PCB Surface Defects with Improved Faster-RCNN and Feature Pyramid Network ”, IEEE Access 2021 [4] Saeed Khalilian, Yeganeh Hallaj, Arian Balouchestani , “PCB Defect Detection Using Denoising Convolutional Autoencoders ”, 2020 Inter- national Conference on Machine Vision and Image Processing (MVIP) Faculty of Engineering, College of Farabi, University of Tehran, Iran, 19 20 Feb. 2020 [5] Chen, Xing, Yonglei Wu, Xingyou He, and Wuyi Ming. ”A Compre- hensive Review of Deep Learning-Based PCB Defect Detection.” IEEE Access (2023). [6] Ling, Qin, and Nor Ashidi Mat Isa. ”Printed Circuit Board Defect Detection Methods Based on Image Processing, Machine Learning and Deep Learning: A Survey.” IEEE Access (2023). [7] Kolachi, Karim, Malhar Khan, Shahjahan Alias Sarang, and Aaqib Raza. ”Fault Detection and Quality Inspection of Printed Circuit Board Using Yolo-v7 Algorithm of Deep Learning.” In 2023 7th International Multi- Topic ICT Conference (IMTIC), pp. 1-7. IEEE, 2023. [8] Chen, I-Chun, Rey-Chue Hwang, and Huang-Chu Huang. ”PCB Defect Detection Based on Deep Learning Algorithm.” Processes 11, no. 3 (2023): 775. [9] Nayak, Jithendra PR, K. Anitha, B. D. Parameshachari, Reshma Banu, and P. Rashmi. ”PCB Fault detection using Image processing.” In IOP Conference Series: Materials Science and Engineering, vol. 225, no. 1, p. 012244. IOP Publishing, 2017. [10] Zhou, Yongbing, Minghao Yuan, Jian Zhang, Guofu Ding, and Shengfeng Qin. ”Review of vision-based defect detection research and its perspectives for printed circuit board.” Journal of Manufacturing Systems 70 (2023): 557-578.

Copyright

Copyright © 2024 Rahul Lambture , Suyog Mahajan, Kiran Patil, Nestor J. Philips. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63142

Publish Date : 2024-06-06

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online