Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Proactive System Maintenance: Machine Learning Models for Predicting and Preventing Potential System Failures

Authors: Shivam Kumar, Tanveer Naushad, Dr. Prakash Singh Tanwar

DOI Link: https://doi.org/10.22214/ijraset.2024.61922

Certificate: View Certificate

Abstract

In modern industrial systems, the prevention of failures and downtime is of paramount importance for ensuring efficiency and productivity. Proactive system maintenance approaches leverage machine learning (ML) models to predict potential failures before they occur, enabling pre-emptive actions to be taken [1]. In this paper, we present a comprehensive review of existing research on proactive system maintenance, focusing on the development and application of ML algorithms for fault prediction and prevention. We discuss various machine learning techniques, data sources, feature engineering methods, and evaluation metrics employed in this domain [8]. Furthermore, we propose novel algorithms and strategies for enhancing the effectiveness of proactive maintenance systems. Through experimentation and case studies, we demonstrate the feasibility and benefits of utilizing machine learning for proactive maintenance in diverse industrial settings.

Introduction

I. INTRODUCTION

A. Background

The increasing complexity and interconnectivity of modern industrial systems have heightened the need for effective maintenance strategies to prevent costly downtime and failures. Traditional reactive maintenance approaches, where repairs are performed only after equipment failure, are no longer sufficient to meet the demands of today’s dynamic environments. Proactive maintenance, which involves the use of predictive analytics and advanced technologies to anticipate and prevent failures, has emerged as a promising solution to address these challenges [1].

B. Motivation

Proactive maintenance offers several advantages over reactive approaches, including reduced downtime, lower maintenance costs, and improved asset reliability. By leveraging machine learning algorithms, it becomes possible to analyse large volumes of sensor data, identify patterns indicative of impending failures, and take pre-emptive action to mitigate Risks. However, the development and deployment of effective proactive maintenance systems require careful consideration of various factors, including data quality, model accuracy, and scalability [7] [8].

C. Objectives

To propose this paper, we aim to explore the application of machine learning models for proactive system maintenance. Specifically, we will

- Review existing research on proactive maintenance and fault prediction techniques

- Investigate different machine learning algorithms and methodologies used in this domain.

- Propose novel algorithms and strategies to enhance the effectiveness of proactive maintenance systems.

- Evaluate the performance of these algorithms through experimentation and case studies in real-world industrial set-tings.

II. LITERATURE REVIEW

- Traditional Maintenance Approaches: Traditional maintenance strategies encompass reactive, preventive, and predictive maintenance methodologies [2]. Reactive maintenance involves addressing equipment issues only upon failure, often resulting in unplanned downtime and significant repair costs. Conversely, preventive maintenance relies on scheduled inspections and upkeep to forestall failures [4]. While effective in reducing unexpected breakdowns, it may lead to excessive maintenance activities and associated expenses. Predictive maintenance seeks to transcend the limitations of reactive and preventive approaches by employing data-driven techniques to forecast failures and proactively schedule maintenance tasks [6].

- Proactive Maintenance Paradigm: Proactive maintenance signifies a departure from reactive and preventive strategies towards a data centric and predictive approach. Through continuous monitoring and analysis of equipment, proactive Maintenance systems discern anomalies and patterns indicative of potential failures, enabling pre-emptive intervention by maintenance teams. This proactive stance minimizes down-time, curtails maintenance costs, and prolongs the operational lifespan of critical assets [1].

- Machine Learning in Proactive Maintenance

a. Supervised Learning Techniques: Supervised learning techniques, including classification and regression, are extensively applied in fault prediction within proactive maintenance systems. These methods necessitate labelled training data, associating each instance with a class label (in classification tasks) or a continuous target variable (in regression tasks). By training models on historical data, the supervised learning algorithms can learn the relationship between input features and the corresponding output, allowing them to make pre-dictions on new, unseen data. In fault prediction for proactive maintenance, classification models can be employed to categorize equipment behaviour into different fault classes, while regression models can be utilized to predict continuous variables related to equipment performance or degradation. The accuracy and effectiveness of these models heavily rely on the quality and representation of the labelled training data, as well as the selection of appropriate features and model architecture. Furthermore, ongoing validation and refinement of the models based on real time data can enhance their predictive capabilities and contribute to more proactive and effective maintenance strategies [9].

b. Unsupervised Learning: In proactive maintenance, such as clustering and anomaly detection, play a critical role in analysing sensor data streams to detect abnormal patterns that may signal potential faults or deviations from normal operating conditions. By flagging anomalies for further investigation, maintenance teams can prioritize their attention on areas that show signs of irregular behaviour, allowing for proactive intervention to prevent equipment failures or downtime. This data driven approach enables maintenance personnel to take preventative actions based on early suggestions of potential issues, ultimately improving equipment reliability, reducing maintenance costs, and optimizing asset performance [9].

c. Hybrid Approaches: Hybrid approaches amalgamate supervised and unsupervised learning techniques to capitalize on the strengths of both paradigms. For instance, a hybrid model may employ unsupervised anomaly detection to pre-process sensor data and identify potential outliers, followed by supervised classification to categorize anomalies into different fault classes. Through the integration of multiple data driven techniques, hybrid models can effectively leverage the comprehensive insights provided by unsupervised learning to pre-process and identify anomalies, and then utilize the labelled data and structured approach of supervised learning to accurately categorize these anomalies. By integrating multiple methodologies, hybrid approaches in proactive maintenance can enhance the overall predictive capabilities, providing a more comprehensive understanding of potential faults and deviations within industrial equipment. This holistic approach Contributes to improved decision making for maintenance interventions and resource allocation, ultimately leading to optimized operational efficiency and reduced downtime [4].

4. Data Sources and Feature Engineering: The efficacy of machine learning models for proactive maintenance hinges on the quality and relevance of input data. Common data sources in proactive maintenance systems encompass sensor data from industrial equipment, maintenance logs, operational parameters, and environmental variables. Feature engineering assumes a pivotal role in enhancing the predictive capabilities of these models by extracting and selecting the most relevant information from the raw data sources. Feature engineering involves transforming the raw data into meaningful features that capture essential patterns and relationships within the data, allowing the machine learning models to make accurate predictions and identify potential maintenance issues. By care-fully engineering features from diverse data sources, proactive maintenance systems can better capture the complex interplay of factors that influence equipment performance and health, ultimately leading to more accurate and actionable insights for maintenance planning and decision making.

III. METHODOLOGY

A. Data Collection

The first step in developing a proactive maintenance system is to collect relevant data from various sources within the industrial environment. This may include sensor data streams, historical maintenance records, equipment stipulations, and environmental variables. Care should be taken to ensure that the collected data is representative of diverse operating scenarios and conditions to encompass a wide range of potential factors influencing equipment performance and health.

By capturing data that spans different operational state and environmental influences, the proactive maintenance sys-tem can effectively analyse and anticipate diverse maintenance needs and potential failure modes, leading to more accurate predictive models and targeted maintenance interventions [7] [9].

B. Pre-processing and Feature Selection.

Upon completion of the data collection phase, it becomes imperative to engage in meticulous pre-processing to render the data suitable for training machine learning models. This intricate process encompasses purging the data of missing values and outliers, standardizing or normalizing numerical features, encoding categorical variables, and managing temporal data. Furthermore, the application of feature selection techniques assumes paramount importance to curtail dataset dimensionality and eliminate irrelevant or redundant features. Noteworthy methodologies in feature selection include filter methods, wrapper methods, and embedded methods. The significance of rigorous pre-processing and feature selection cannot be overstated in setting the groundwork for model development, thereby bolstering the efficacy and efficiency of the proactive maintenance system [8] [9].

C. Model Development

With pre-processed data and selected features, 11the next step is to develop machine learning models for fault extrapolation and proactive maintenance. Various algorithms can be employed for this purpose, including decision trees, random forests, support vector machines (SVM), k-nearest neighbours (KNN), neural networks, and ensemble methods. The choice of algorithm depends on factors such as the nature and complexity of the problem, the size and quality of the avail-able data, computational requirements, interpretability of the model, and specific performance requirements. Each algorithm has its strengths and limitations, and the selection should be informed by the unique characteristics and needs of the proactive maintenance system, ensuring that the chosen models align with the overarching objectives while delivering accurate and actionable insights for fault prediction and preventive maintenance operations [7] [9] [10].

D. Model Evaluation

Once the models have been trained, they must be evaluated using appropriate performance metrics to assess their predictive accuracy and generalization ability [7]. This typically involves splitting the data into training and testing sets, training the models on the training data, and evaluating their performance on the unseen testing data. Cross-validation techniques, such as k-fold cross-validation, can also be used to validate the robustness and generalization of the models.

IV. PROPOSED ALGORITHMS

A. Hybrid Deep Learning Models

Hybrid Deep Learning Models Neural networks, particularly deep learning models, have showcased remarkable effectiveness across a spectrum of predictive maintenance scenarios. In the domain of proactive maintenance, the integration of diverse neural network architectures such as convolutional neural networks (CNNs) and recurrent neural networks (RNNs) presents a promising avenue for enhancing predictive capabilities within maintenance systems. By leveraging the unique strengths of these architectures, hybrid deep learning models emerge as powerful tools proficient in capturing both spatial intricacies and temporal dynamics inherent in the data [4].

In the proactive maintenance context, these hybrid models transcend traditional boundaries by seamlessly blending CNNs’ expertise in spatial pattern recognition with RNNs’ sequential memory capabilities. This fusion enables the models to conduct intricate analyses of complex industrial data, thereby enabling more accurate fault predictions and faster identification of maintenance requirements [1].

Moreover, by leveraging ensemble techniques such as AdaBoost, these hybrid deep learning models can further enhance their predictive prowess. AdaBoost, with its iterative approach of training weak learners sequentially and focusing on misclassified samples, complements the inherent strengths of deep learning architectures. Through iterative refinement and integration of diverse weak learners, AdaBoost augments the robustness and generalization ability of hybrid deep learning models, thus fortifying their predictive accuracy and reliability in proactive maintenance applications [4].

Consequently, the utilization of hybrid deep learning models, enriched with ensemble techniques like AdaBoost, signifies a pivotal advancement in proactive maintenance strategies. These synergistic frameworks not only elevate the efficiency and effectiveness of maintenance interventions but also pave the way for proactive measures that pre-emptively safeguard industrial systems against potential failures [4] [9].

B. Ensemble Techniques

Ensemble learning techniques, such as bagging, boosting, and stacking, can improve the robustness and generalization performance of proactive maintenance models [1]. By combining multiple base learners into a single composite model, ensembles can leverage the diverse strengths and perspectives of individual models to collectively make more accurate and re-liable predictions. Through techniques like bagging, boosting, and stacking, ensemble methods can mitigate the limitations of individual models and enhance the overall predictive power of the proactive maintenance system. By aggregating the predictions of multiple models, ensembles are better equipped to handle complex patterns in the data, leading to more robust fault predictions and improved maintenance strategies in industrial environments [9].

C. Transfer Learning Strategies

Transfer learning is a machine learning technique where knowledge gained from training one model on a specific task is transferred and applied to a related but different task. In the context of proactive maintenance, transfer learning can be used to transfer the knowledge and patterns acquired from models trained on similar industrial maintenance tasks to enhance the learning and performance of proactive maintenance models in new or related environments. By leveraging transfer learning, the proactive maintenance system can benefit from pre-existing knowledge and model architectures, thereby reducing the need for extensive training on limited data and expediting the development of effective fault prediction models for diverse industrial settings. This approach ultimately enables more efficient and accurate proactive maintenance strategies by capitalizing on the collective intelligence of related tasks and domains [11].

V. CASE STUDIES

- In the context of predictive maintenance in manufacturing, the implementation of machine learning models revolutionizes the approach to equipment maintenance and reliability. By systematically gathering sensor data from production equipment and harnessing machine learning algorithms, the potential for forecasting and pre-empting mechanical issues before they transpire becomes attainable. The seamless deployment of these predictive models within real-time monitoring systems instigates tangible enhancements in equipment uptime and operational efficiency. Consequently, the consequential impact encompasses substantial cost savings and heightened productivity, thereby positioning the manufacturing milieu at the forefront of operational excellence and sustainable competitive edge. Ultimately, this amalgamation of advanced technology and proactive maintenance strategies brings about a pivotal shift in the industry’s maintenance paradigm, cultivating an environment of optimized performance and seamless operational continuity [2] [8] [1].

- Fault Detection in Power Systems Power systems are critical infrastructure components that require continuous monitoring to ensure reliability and stability. In this case study, we develop machine learning algorithms to detect faults and anomalies in power grids using historical sensor data and operational parameters. By accurately identifying potential is-sues, we enable proactive maintenance interventions to prevent costly outages or disruptions in power supply. Machine learning algorithms, we can analyse historical sensor data and operational parameters to detect patterns indicative of potential faults or anomalies within the power grid. By promptly identifying these issues, proactive maintenance intrusions can be implemented to address potential problems before they escalate, thereby ensuring the stability and reliability of the power system. This proactive approach not only helps prevent disruptions in power supply but also contributes to minimizing downtime, reducing maintenance costs, and ultimately enhancing the overall resilience and performance of the power grid [2] [3].

- Proactive Maintenance in Transportation systems, including fleets of vehicles and infrastructure components, face unique maintenance challenges due to their dynamic and distributed nature. In this case study, we explore the application of machine learning techniques for proactive maintenance in transportation networks [1]. By analysing sensor data from vehicles, tracking systems, and infrastructure modules, we can develop predictive maintenance models using machine learning techniques. This involves analysing a myriad of data sources such as sensor data from vehicles, tracking systems, and infrastructure to anticipate maintenance needs before they escalate into critical issues [4]. By leveraging machine learning algorithms to sift through this data, transportation networks can implement proactive maintenance strategies to optimize fleet performance, minimize downtime, and enhance safety. The insights gained from predictive maintenance can lead to more efficient allocation of resources, reduced maintenance costs, and improved overall operational efficiency in transportation systems. This approach not only ensures the reliability of vehicles and infrastructure but also contributes to enhanced service delivery and customer satisfaction in an ever-evolving transportation landscape[1] [3] [4].

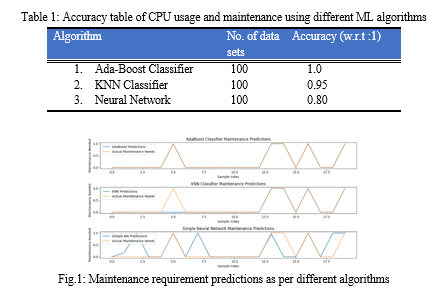

VI. EXPERIMENTAL RESULTS

- Performance Evaluation Metrics we evaluate the performance of our proposed algorithms using a variety of metrics, including accuracy, precision. These metrics provide insights into the predictive capabilities, robustness, and generalization ability of the models across different datasets and scenarios. These performance evaluation metrics offer a comprehensive understanding of how well the proposed algorithms are performing in terms of accuracy, precision, recall. Accuracy measures the overall correctness of the predictions, while precision and recall assess the trade-off between the positive predictions and the actual positives. We can thoroughly assess the effectiveness and adaptability of the models to various datasets and real-world scenarios. These measurements play a crucial role in validating the predictive capabilities and robustness of the models in predictive maintenance applications.

- Real-world Deployment Considerations In addition to evaluating model performance in controlled environments, we consider the practical challenges and considerations involved in deploying proactive maintenance systems in real-world industrial settings. These include data integration, scalability, computational resources, model interpretability, regulatory compliance, and user requirements. Ensuring seamless data integration across disparate sources, scalability to handle large volumes of data, efficient utilization of computational resources, and model interpretability are crucial factors in the successful deployment of proactive maintenance systems. Moreover, compliance with regulatory standards and industry-specific guidelines is essential to guarantee the legality and ethical use of the deployed models in industrial settings. By addressing these real-world deployment considerations, we can orchestrate a smooth transition from model development to operational implementation, maximizing the impact of proactive maintenance systems on enhancing operational efficiency, reducing downtime, and optimizing maintenance strategies in industrial environments.

VII. DISCUSSION

- Challenges and Limitations: Despite the promising results achieved with proactive maintenance systems, several challenges and limitations remain. These include data quality issues, model interpretability, scalability concerns, regulatory constraints, and ethical considerations related to privacy and security [1]. Data quality issues can affect the accuracy and reliability of maintenance predictions, while model interpretability is vital for understanding and trusting the decisions made by the proactive maintenance systems. Scalability concerns encompass the ability of the systems to handle increasing volumes of data and expanding operational demands. Regulatory constraints dictate compliance with industry standards and legal frameworks, while ethical considerations surrounding privacy and security entail safeguarding sensitive data and ensuring transparent and responsible use of predictive maintenance technologies. Addressing these challenges and limitations is crucial for the continued advancement and successful implementation of proactive maintenance systems in real-world industrial environments.

- Future Directions: looking ahead, there are several avenues for future research and development in proactive maintenance. These include the exploration of advanced machine learning techniques, such as deep reinforcement learning and generative adversarial networks, for more complex predictive tasks. Additionally, the integration of sensor fusion technologies for enhanced data collection and analysis, the implementation of edge computing to enable real time decision making at the source, and the adoption of predictive maintenance as a service models to facilitate cost-effective and Scalable maintenance solutions [3][4]. Furthermore, researching explainable AI methodologies to improve model interpretability and transparency in decision-making processes while exploring the potential applications of distributed ledger technologies such as block chain for secure and immutable maintenance records could be promising directions. Overall, embracing these advancements and innovations is key to further enhancing the effectiveness, efficiency, and sustainability of proactive maintenance practices in a rapidly evolving industrial landscape.

- Ethical Considerations: As proactive maintenance systems become increasingly prevalent in industrial environments, it is essential to consider the ethical implications of these technologies [1]. This includes ensuring transparency and accountability in decision-making processes, protecting sensitive data and privacy rights, and mitigating the potential impact on the workforce. Maintaining transparency and accountability in decision making processes is crucial to fostering trust in the use of proactive maintenance systems. Additionally, protecting sensitive data and privacy rights through robust security measures and ethical data handling practices is imperative. Mitigating any potential impact on the workforce, such as displacement or reconfiguration of job roles, should also be a key ethical consideration. It is essential to prioritize ethical principles and stakeholder well-being in the development and deployment of proactive maintenance systems.

Conclusion

In conclusion, proactive maintenance represents a paradigm shift towards more efficient, cost-effective, and reliable maintenance strategies in industrial systems. By leveraging ma-chine learning algorithms, predictive analytics, and advanced technologies, proactive maintenance systems can anticipate and prevent potential failures before they occur, thereby minimizing downtime, reducing costs, and maximizing operational efficiency. However, the successful development and deployment of proactive maintenance systems require careful Consideration of various factors, including data quality, model accuracy, scalability, and ethical considerations. Through experimentation, case studies, and real-world deployment, we have demonstrated the feasibility and benefits of proactive maintenance in diverse industrial settings. Moving forward, continued research and innovation in this field will be essential to unlocking the full potential of proactive maintenance and ensuring the reliability and resilience of critical infrastructure components.

References

[1] R. Ahmad, S. Kamaruddin An overview of time-based and condition-based maintenance in industrial application In: Computers & Industrial Engineering, 63 (1) (2012), pp. 135-149 [2] Developing hybrid machine learning models to assign health score to railcar fleets for optimal decision making [3] K. Exner, C. Schnürmacher, S. Adolphy, and R. Stark, \"Proactive maintenance as a success factor for use-oriented Product-Service Systems,\" 2017, pp. 330-335. [4] R. Kothamasu, S.H. Huang, and W.H. VerDuin, \"System health monitoring and prognostics — a review of current paradigms and practices,\" Int. J. Adv. Manuf. Technol., vol. 28, no. 9-10, pp.1012-1024, 2006. [5] Johal, H. S., Singh, B., Nagpal, A., & Krishan, K. (2011). Dynamically Controlling Retransmission Mechanism for Analysing QoS Parameters of IEEE 802.11 Networks. In Computers, Networks, Systems, and Industrial Engineering 2011 (pp. 11-23). Springer, Berlin, Heidelberg [6] S. Sankararaman, \"Significance, interpretation, and quantification of uncertainty in prognostics and remaining useful life prediction,\" Mechanical Systems and Signal Processing, vol. 52-53, pp. 228-247, 2015. [7] R. S. Upadhyay and P. S. Tanwar, \"A Review on Bone Fracture Detection Techniques using Image Processing,\" in 2019 International Conference on Intelligent Computing and Control Systems (ICCS), pp. 287-292, IEEE, May 15, 2019. [8] A.K.S. Jardine, D. Lin, and D. Banjevic, \"A review on machinery diagnostics and prognostics implementing condition-based maintenance,\" Mechanical Systems and Signal Processing, vol. 20, no. 7, pp. 1483-1510, 2006. [9] Ahmad R, Kamaruddin S. An overview of time-based and condition- based maintenance in industrial application. In: Computers & Industrial Engineering 2012;63(1):135-149. [10] Singh, B., & Verma, H. K. (2022). Application of Hadoop in Data Science. Machine Learning and Data Science: Fundamentals and Applications, 147-167 [11] R. Sathya and A. Abraham, \"Comparison of Supervised and Unsupervised Learning Algorithms for Pattern Classification,\" 2013, vol. 2, pp. 2013.020206. [12] J. S. Raikwal and K. Saxena, \"Performance Evaluation of SVM and K-Nearest Neighbor Algorithm over Medical Dataset,\" 2012, vol. 50, no. 14, pp. 35-39. [13] Singh, B., & Verma, H. K. (2022). Dawn of Big Data with Hadoop and Machine Learning. Machine Learning and Data Science: Fundamentals and Applications, 47-65

Copyright

Copyright © 2024 Shivam Kumar, Tanveer Naushad, Dr. Prakash Singh Tanwar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET61922

Publish Date : 2024-05-10

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online