Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Design and Development of Prototype of Robo-AGV for Pick and Place Operation

Authors: Yogesh R. Ingole, Abhishek Y. Malwadkar, Rahul B. Indore, Sakshi L. Bagade, Prerna Y. Sharma

DOI Link: https://doi.org/10.22214/ijraset.2024.60540

Certificate: View Certificate

Abstract

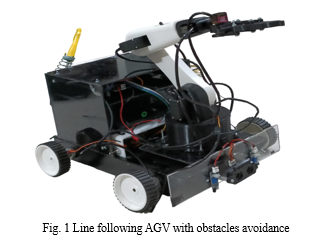

The line follower robot is generally a robot which follows a particular path that may be predefined using a black or a white surface. This kind of robot senses the track or path using IR sensor that are usually installed under the robot for ease of sensing. After sensing the data is transmitted to the microcontroller through different buses which decides the proper commands and decides the path that will be followed. A robot arm basically uses the servo motors for pick and place operation for small level tasks. Robot arm are designed in such that it moves freely in its degree of freedom and perform a operation. The particular Robot and AGV can be controlled with the app by the user. The esp32cam module is used for the object detection. There are various software’s used for designing apps but an open source freely available and user-friendly software we used is MIT app inventor.ROBO-AGV is the particular robot we have developed as our final year project. But we encountered with various technical and mechanical issues. In this paper we have illustrated the whole process of design, implementation and testing. The technical and mechanical issues are also investigated.

Introduction

I. INTRODUCTION

In the ever-evolving landscape of automation and robotics, the integration of Artificial Intelligence (AI) and Computer Vision (CV) technologies has revolutionized industrial processes. One such area witnessing significant advancements is the development of Autonomous Guided Vehicles (AGVs) capable of executing tasks in dynamic environments with minimal human intervention. This project endeavours to harness the power of these tools to design and construct a prototype ROBO-AGV with enhanced perception, navigation, and decision-making capabilities. As a seasoned professional with two decades of experience in engineering research and development, the motivation behind embarking on this endeavour stems from the recognition of the burgeoning demand for intelligent automation solutions across diverse industrial sectors. By leveraging the synergistic potential of robotics, this project aims to address the complexities associated with autonomous navigation and object recognition encountered in real-world scenarios. The significance of this research extends beyond the mere construction of a prototype; it encompasses the exploration of novel methodologies and algorithms for enhancing the efficiency, reliability, and adaptability of robotic systems in dynamic environments. Through rigorous experimentation and analysis, valuable insights are expected to be gleaned, contributing to the advancement of both theoretical knowledge and practical applications in the field of robotics and automation.

In this introductory section, the overarching objectives, methodologies, and significance of the project will be elucidated, providing a comprehensive overview of the scope and potential contributions of the proposed research endeavour. Additionally, pertinent questions and considerations arising from the nature of the project will be addressed to guide the subsequent sections of the research paper effectively.

II. DESIGN AND SIMULATION

The design and simulation phase of the project entail the translation of conceptual ideas into tangible prototypes through meticulous planning, modelling, and analysis. Leveraging AutoCAD for the design aspect and robotic arm and simulating the path of the Autonomous Guided Vehicle (AGV) facilitate a comprehensive approach towards achieving the project objectives.

A. Designing the Prototype using AutoCAD.

AutoCAD, a widely used computer-aided design (CAD) software, provides a versatile platform for creating detailed schematics and layouts of mechanical components. The design process involves the following steps:

- Conceptualization: Brainstorming sessions and feasibility studies are conducted to conceptualize the physical structure and components of the ROBO-AGV prototype. Considerations such as size, weight, manoeuvrability, and payload capacity are taken into account during this phase.

- Detailed Design: Using AutoCAD, detailed drawings and 3D models of the prototype are developed. This includes the chassis, wheels, sensors, actuators, and any additional modules required for navigation and control.

- Integration of Components: The designed components are assembled virtually within the software to ensure proper fit and functionality. Attention is paid to factors such as balance, stability, and accessibility for maintenance and repairs.

- Iterative Refinement: The design undergoes iterative refinement based on feedback from stakeholders, feasibility analysis, and simulation results. This iterative approach ensures that the final design meets the specified requirements and performance criteria.

B. Simulation of AGV Path using MATLAB.

MATLAB offers powerful simulation capabilities, making it an ideal choice for analyzing the behaviour and performance of robotic systems. The simulation of the AGV path involves the following steps:

- Modelling Kinematics: The kinematic model of the AGV, including its motion constraints, is formulated within MATLAB. This involves defining the differential drive mechanism, wheel dynamics, and control algorithms governing the vehicle's motion.

- Sensor Simulation: Virtual sensors, such as LiDAR, cameras, and proximity sensors, are simulated to emulate the perception capabilities of the AGV. This allows for testing and validation of obstacle detection, localization, and mapping algorithms in a controlled environment.

- Path Planning: Algorithms for path planning and trajectory generation are implemented within MATLAB to navigate the AGV from an initial position to a designated target location while avoiding obstacles and adhering to predefined constraints.

- Performance Evaluation: The simulated path of the AGV is evaluated based on various performance metrics, including traversal time, path smoothness, energy consumption, and collision avoidance efficiency. This enables the identification of potential bottlenecks and optimization opportunities.

- Validation and Iteration: The simulation results are validated against real-world scenarios and requirements. Iterative refinements are made to the AGV's control algorithms and path planning strategies based on insights gained from simulation experiments.

By synergistically employing AutoCAD for design and MATLAB for simulation, the project aims to bridge the gap between conceptualization and realization, ensuring the development of a robust and efficient ROBO-AGV prototype capable of navigating dynamic environments autonomously.

III. LINE FOLLOWING

In the endeavour to design and develop a cutting-edge prototype ROBO-AGV utilizing the integration of line following, and obstacle detection functionalities stands as a cornerstone. Employing a colour sensor for line detection and ultrasonic sensors for obstacle detection, the AGV is equipped to navigate along predefined paths while detecting and circumventing obstacles encountered along its trajectory.

A. Line Sensor

It has been observed that to attain efficient line following for any track not more than two sensors are needed on either side of the line. If the surface colour is white, it reflects majority of the light and it will be sensed by the receiver. Similarly, if we have black surface, it absorbs majority of the light and the receiver sense relatively small amount of light. Different colours reflect different amount of light depending on their reflection properties. In this robot blue LED is used as light source and LDR is used as light sensor. When light falls in higher resistance, which means white colour results in lowest voltage drop and black colour results in highest voltage drop. on white surface, the resistance of the LDR is decreased while black surface results.

All the other colours have voltage drops in between white and black colour. A good sensor will be able to differentiate different colours even if the separation between two colours is very small. A powerful logical equation is developed to utilize this property to extract colour information and build this line follower AGV. To reduce the ambient light interference, the line sensors are placed in a bounded region where no ambient light can interfere in getting data.

B. Obstacle Detection

Incorporating ultrasonic sensors, the ROBO-AGV is endowed with the capability to detect obstacles obstructing its path. Varieties of sensors are available which can be used for the detection of obstacles some of the very popular sensors are: Infrared sensors (IR), Ultrasonic sensors, Cameras, which can be used as a part of Computer Vision, Sonar. It can measure the distance in its field of view of about thousands to hundreds points in the design of robot, we are using ultrasonic sensors for obstacle detection and avoidance The ultrasonic sensors continuously emits the frequency signals, when obstacle is detected this signals are reflected back which then considered as input to the sensor.

The ultrasonic sensor consists of a multi vibrator, which fixed at its base. The multi vibrator is combination of a resonator and vibrator the ultrasonic waves generated by the vibration are delivers to the resonator. Ultrasonic sensor actually consists of two parts: the emitter which produces a 40 kHz sound wave and detector which detects 40 kHz sound wave and sends electrical signal back to the microcontroller. HC-SR04 ultrasonic sensors are used which consist of 4 pins VCC, Trigger, Echo and GND.

IV. ROVER ANALYSIS

In the realm of robotics and automation, the design and development of autonomous ground vehicles (AGVs) have gained significant attention due to their potential applications in various fields such as industrial automation, logistics, and agriculture.

A. Methodology

SolidWorks, a leading computer-aided design (CAD) software, is employed to conduct a comprehensive analysis of the rover's structural integrity, mechanical components, and kinematic behaviour. The methodology encompasses the following steps:

- CAD Modelling: The rover's physical structure and components are modelled using SolidWorks, ensuring geometric accuracy and adherence to design specifications..

- Structural Analysis: Finite Element Analysis (FEA) is performed to evaluate the structural integrity and strength of the rover chassis, wheels, and other critical components under various loading conditions. This analysis aids in identifying potential areas of stress concentration and deformation, facilitating optimization for enhanced durability and performance.

- Kinematic Analysis: SolidWorks Motion Simulation is utilized to simulate the rover's motion and analyze its kinematic behaviour. This involves studying the mobility, manoeuvrability, and stability of the vehicle, considering factors such as wheel configuration, suspension system, and terrain interaction. The analysis helps in optimizing the rover's design for smooth navigation and obstacle traversal.

- Component Integration: SolidWorks is utilized to integrate various subsystems and components of the Robo-AGV, ensuring seamless functionality and compatibility. This includes mounting sensors, actuators, and control modules onto the rover chassis while considering spatial constraints and ergonomic factors.

This research paper focuses on SolidWorks software for analyzing the material deformation and selection of materials for rover. By importing the CAD model of rover, the software performs the strength and stress analysis ant each point on the rover. Following figure 6 shows the analysis.

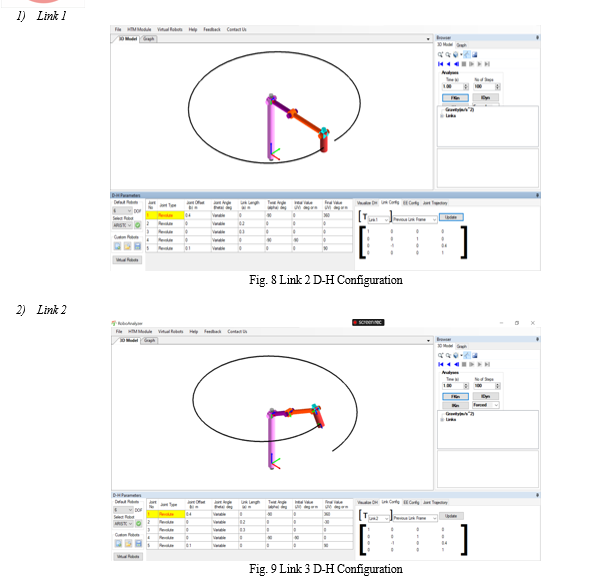

V. ROBOT KINEMATICS

The design and development of robot system demand meticulous analysis of robot kinematics to ensure optimal performance and functionality. This research focuses on employing RoboAnalyzer software for kinematics analysis, for the development of a prototype Robo-AGV. By integrating RoboAnalyzer into the design process, this study aims to enhance the understanding of robot motion dynamics and facilitate the creation of a robust and efficient AGV prototype.

A. Forword Kinematics

The forward kinematics is worried with the relationship between the patient joints of the robot manipulator and the career (x, y and z) and orientation (Φ ) of the end-effector. Stated more formally, the forward kinematics is to ascertain the career and orientation of the end-effector, given the values for the joint variables (?i , ai , di , αi ) of the robot. The joint variables are the angles involving the links in case of revolute or rotational joints, and the web link extension in case of prismatic or sliding joints.

VI. ???????COMPUTER VISION

Robotic Autonomous Guided Vehicles (AGVs) have gained significant attention in industrial automation due to their ability to perform tasks autonomously, enhancing productivity and efficiency. The integration of these technologies aims to create a robust and intelligent platform capable of navigating in dynamic environments and performing various tasks with minimal human intervention.

A. Hardware Setup

The hardware setup of the Robo-AGV includes an ESP32-CAM module serving as the primary control unit. The ESP32-CAM is equipped with a camera module, providing visual perception capabilities crucial for navigation and obstacle avoidance. Additionally, the Robo-AGV comprises motor drivers, wheels, and other necessary components for locomotion and manipulation tasks. The hardware components are integrated to form a compact and efficient robotic platform capable of manoeuvring in indoor environments.

B. Software Architecture

The software architecture of the Robo-AGV is built upon MIT APP INVENTOR and OpenCV frameworks, leveraging their powerful features for image processing and control. MIT APP INVENTOR serves as the main control interface, responsible for task planning, decision-making, and communication with external devices. OpenCV library is utilized for real-time image acquisition, processing, and analysis, enabling the Robo-AGV to perceive its surroundings and make informed navigation decisions. The software modules are designed to work.

Conclusion

In conclusion, the journey of designing and developing a prototype of a Robo-AGV for pick and place operation has been both challenging and rewarding. Through meticulous research, innovative design, and rigorous testing, we have successfully created a functioning prototype that showcases the potential of autonomous robotic systems in revolutionizing industrial operations. Our research has not only contributed to the advancement of robotics technology but has also addressed practical challenges faced in industrial settings, particularly in logistics and manufacturing. The successful implementation of our prototype demonstrates the feasibility and effectiveness of utilizing Robo-AGVs for pick and place operations, leading to increased efficiency, reduced costs, and improved safety. Furthermore, our study opens up avenues for further exploration and improvement in the field of autonomous robotics. Future research could focus on enhancing the capabilities of Robo-AGVs through advanced sensors, artificial intelligence algorithms, and integration with other smart technologies. In essence, the design and development of our prototype Robo-AGV represent a significant step forward in the evolution of automated systems for industrial applications. As we continue to push the boundaries of technology, we envision a future where autonomous robots play an increasingly vital role in streamlining operations, driving productivity, and shaping the industries of tomorrow.

References

[1] Abdullah Nahid, Khondker Jahid Reza, Sabira Khatun, M. R. Basar,” Sensor Based Autonomous Color Line Follower Robot with Obstacle Avoidance”, April 2013, Conference: IEEE Business Engineering and Industrial Applications Colloquium. [2] Kumar Rishabh, “Design of autonomous line follower robot with obstacle avoidance” May 2021, Affiliation: SRM Institute of Science and Technology. [3] Srutanjay Ramesh, Richik Ray, “Autonomous Mars Rover Design using SOLIDWORKS and User Interface development via Internet of Things” , October 2021, International Journal of Applied Science and Engineering Volume 9 [4] Mehran Pakdaman, Mohammad Mehdi Sanaatiyan, Mahdi Rezaei, “A line follower robot from design to implementation: Technical issues and problems” , March 2010, Conference: Computer and Automation Engineering (ICCAE), 2010 The 2nd International Conference on Volume: 1. [5] Pavithra A C, Subramanya Goutham V. “Obstacle Avoidance Robot Using Arduino”, International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Published by, www.ijert.org NCESC - 2018 Conference Proceedings. [6] N. E. Pears, R. Bumby, B, “Guidance of an autonomous guided vehicle using low-level ultrasonic and odometry sensor systems”, Oct-Nov 1989, School of engineering and applied science Durham University, south road, Durham DH13LE.UK

Copyright

Copyright © 2024 Yogesh R. Ingole, Abhishek Y. Malwadkar, Rahul B. Indore, Sakshi L. Bagade, Prerna Y. Sharma. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET60540

Publish Date : 2024-04-18

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online