Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Real Time Monitoring of Temperature And Humidity Using LabVIEW and ML

Authors: Kulkarni Sheetal Vijay , Saahieel Sasane, Mrunali Bajare, Rahul Deshmukh

DOI Link: https://doi.org/10.22214/ijraset.2024.62675

Certificate: View Certificate

Abstract

This project presents a Real-Time Temperature and Humidity Monitoring System built on LabVIEW, featuring ML predictive analytics. It facilitates real-time data collection from diverse sensors, ensuring precise environmental monitoring. The ML algorithms within the system forecast future temperature and humidity trends, aiding proactive decision-making. Users enjoy an intuitive graphical interface for visualizing data, analysing historical trends, and receiving alerts for threshold variations. Additionally, the system provides remote monitoring, data logging, and reporting, enhancing its usability and accessibility. This integrated solution caters to the crucial requirement for accurate environmental monitoring, with applications spanning industries like manufacturing, agriculture, and climate control, ultimately enhancing efficiency and decision-making in these sectors.

Introduction

I. INTRODUCTION

In today's context, keeping a close eye on environmental factors like temperature and humidity is essential across different sectors like industry, agriculture, and climate management. This project introduces a thorough solution using LabVIEW for real-time monitoring of these parameters, bolstered by machine learning algorithms for predictive analysis. Our system relies on LabVIEW as the main software, offering a user-friendly graphical interface for tasks like data acquisition, processing, and display. Real-time data on temperature and humidity are gathered from diverse sensors and devices, ensuring precise and current information.

In this post, we aim to provide a brief overview of the applications of data capture, primarily centered around temperature and humidity data, utilizing LabVIEW. Drawing from a combination of literature, including books, internet sources, and references to 40 research articles from diverse journals, our focus lies on LabVIEW's role in data acquisition. We have included a comprehensive table in our literature review, offering readers insights into various applications for temperature data collection using LabVIEW. Additionally, we provide further details on LabVIEW's utilization across different domains.

II. THE KEY COMPONENTS OF OUR SYSTEM INCLUDES

- Sensor Integration: Various temperature and humidity sensors, such as thermocouples, thermistors, and humidity sensors, are seamlessly incorporated into the LabVIEW environment and strategically positioned within the target area to capture pertinent data.

- Real-Time Data Acquisition: LabVIEW is configured to continually gather data from these sensors, ensuring that temperature and humidity levels are consistently monitored and recorded in real-time.

- Data Visualization: The acquired data is presented through an intuitive graphical interface, enabling users to easily monitor current environmental conditions. Additionally, historical data is accessible for trend analysis purposes.

- ML-Based Predictive Analytics: To enhance system functionality, ML algorithms are integrated to conduct predictive analytics. By training machine learning models on historical data, the system can forecast future temperature and humidity trends, enabling users to make proactive decisions to maintain optimal conditions.

- Alerts and Notifications: The system includes alert mechanisms to promptly notify users of any deviations from predefined temperature or humidity thresholds, facilitating timely responses to environmental changes.

- Data Logging and Reporting: All collected data, including real-time measurements and AI predictions, is logged for further analysis. Detailed reports can be generated to summarize trends and anomalies observed over time.

- Remote Monitoring: The LabVIEW system can be configured for remote monitoring, allowing users to access real-time data and predictions from any location with internet connectivity.

This integration of LabVIEW with AI-based predictive analytics offers a comprehensive solution for temperature and humidity monitoring, empowering users to uphold optimal environmental conditions, mitigate potential issues, and enhance overall operational efficiency across various applications.

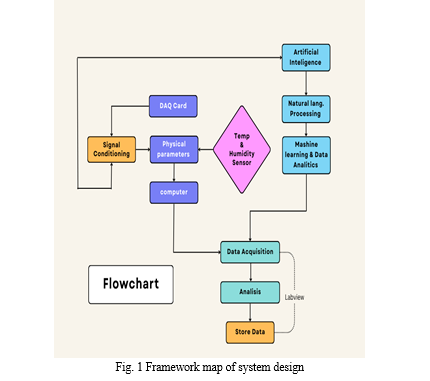

III. SYSTEM DESIGN

Figure 1 illustrates the system architecture, encompassing components like the NI MYDAQ card, environmental variables such as temperature and humidity, data capture and storage mechanisms, and AI and machine learning for data processing. The NI MYDAQ card acts as the intermediary linking LabVIEW software to system hardware, including temperature and humidity sensors like the DHT11 sensor utilized in our setup. This sensor monitors its surroundings, gathering data subsequently processed by the NI MYDAQ card. The card converts raw data into a format interpretable by computers. This processed data is then transmitted to the host computer, where effective interfacing occurs between the computer and NI MYDAQ card via serial transmission, ensuring seamless communication between hardware and software components.

The system proceeds to analyze this data according to the programmed instructions and initiates the necessary actions. Additionally, AI techniques are employed to analyze the provided data, generating pertinent predictions and insights for future system actions and enhancements.

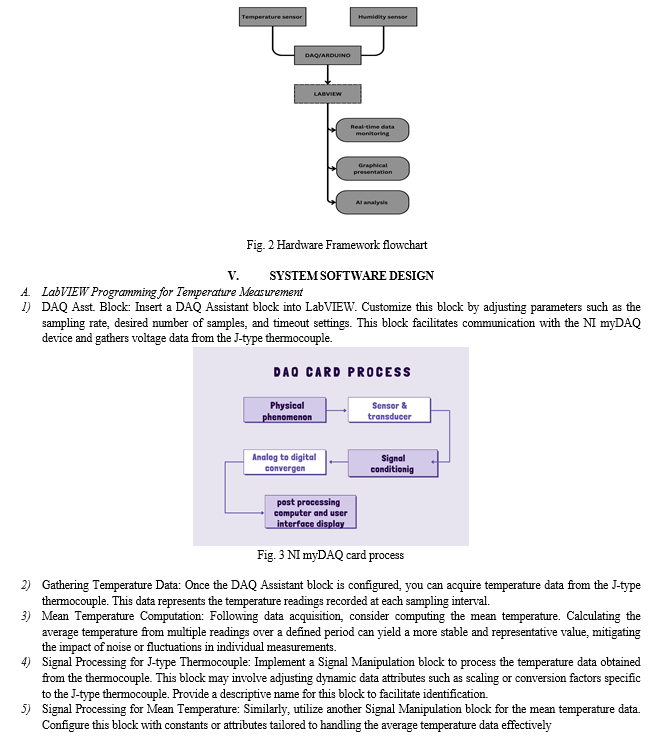

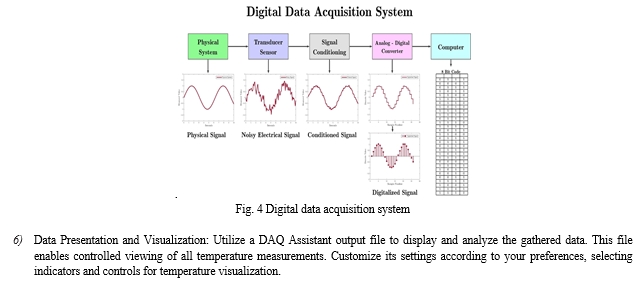

IV. SYSTEM HARDWARE DESIGN AND IMPLEMENTATION CONNECTION OF TEMPERATURE SENSOR(THERMOCOUPLE) WITH NI MYDAQ CARD

The J-type thermocouple is connected to the NI myDAQ card device via two wires, with one wire linked to the AI0+ (analog input 0 positive terminal) and the other to AI0- (analog input 0 negative terminal). This configuration allows the myDAQ device to gauge the voltage generated by the J-type thermocouple in response to temperature changes. Subsequently, this voltage can be read using LabVIEW or compatible software. To obtain accurate temperature data, calibration equations specific to the J-type thermocouple are applied to convert the voltage measurements into precise temperature values.

B. Important Blocks in LabVIEW Programming

The use of mean temperature computation and signal processing blocks improves the reliability and usability of the data.

Mean Temperature Calculation: By averaging many readings, it helps to reduce the inherent mistakes or variations in individual observations, resulting in a more consistent representation of the total temperature.

Signal Manipulation Blocks: These blocks aid in the preprocessing and conditioning of raw temperature data. For thermocouples, this might require using calibration algorithms, scaling factors, or particular conversions to accurately transform voltage data into temperatures.

This systematic technique in LabVIEW allows for exact data gathering, processing, and display of temperature values obtained from the J-type thermocouple connected to the NI myDAQ device.

VI. LITERATURE SURVEY

S. Kalaiarasi, Shubham Gautam (2020) The research employs IoT technology to oversee and control the temperature and humidity during oyster mushroom cultivation. Within the setup, a DHT22 sensor gathers temperature and humidity readings from the growth environment, which are then processed by a Raspberry Pi. Additionally, the system utilizes the Cayenne API to relay this data to farmers. The paper titled "Arduino Based Temperature and Humidity Sensor," authored by S. Kalaiarasi, Shubham Gautam, Anshuman Behera, and Mansi Mewara from the SRM Institute of Science & Technology in Chennai, Tamil Nadu, India, was published in the Journal of Network Communications and Emerging Technologies (JNCET) in April 2018.

The article introduces a temperature and humidity monitoring and transmission system employing Sensirion's DHT11 and DHT22 sensors. This technology addresses drawbacks of traditional systems using analog humidity sensors, such as poor linearity, inaccurate transmission, and complex operation, leading to more precise temperature and humidity measurements.

Hong Zhang, Fan Zhang (2020)[4], This article describes the design and implementation of a greenhouse environmental monitoring system in LabVIEW with extra hardware. The system feeds data from sensors monitoring temperature, humidity, CO2 concentration, and soil pH to a computer via a data acquisition card. A user-friendly interface enables for real-time parameter monitoring and recording, as well as alarms when restrictions are exceeded. The system software is organized into four modules: login, monitoring, data gathering, and alert. The system's installation provides a low-cost and efficient method of monitoring and managing greenhouse crop output. Various sensors in the greenhouse environmental monitoring system collect data on temperature, humidity, CO2 concentration, and soil pH. These sensors communicate with the NI 9201 data acquisition card. This card collects signals from sensors and transmits them to a computer. The data collection card connects to the computer via a USB port. The system's software, created with LabVIEW, allows for real-time monitoring and analysis of the gathered data.

It provides a simple interface for showing real-time information and preserving old data. This data collecting and transmission technique allows for better monitoring and management of the greenhouse environment.

C. A. Belhadj, W. M. Hamanah, M. Kassas. This study describes and evaluates the performance, monitoring, and analysis of a heating, ventilation, and air conditioning (HVAC) system installed in a Saudi Arabian house. The installed air conditioning (A/C) system works in harsh and severe weather conditions. The surrounding area is distinguished by high ambient temperatures, irradiation, humidity, and frequent dust storms. The laboratory virtual instrument engineering workbench (LabVIEW) interface capabilities addressed various goals, including system parameter measurements and performance evaluation of the A/C unit. The created LabVIEW engine shows environmental metrics and electrical variables such as in-house air temperature at different places, air flow, pressure, humidity, outside temperature, irradiation, wind speed, voltage, current, and power, The interface's front panel panes are displayed continually. LabVIEW has demonstrated strong performance while connecting with several devices at the same time, as well as the ability to display the behaviour of various variables in real time. The developed virtual instrument (VI) filters completed several duties in a priority order. The online data presentation in a multi-scale window frame is both instructive and educational. Online efficiency evaluations are important for system operation and analysis.

Norma Latif Fitriyani, Muhammad Syafrudin, Ganjar Alfian, and Jongtae Rhee (2018), The article discusses the performance analysis of an IoT-based sensor, big data processing, and machine learning model are used to create a real-time monitoring system for car production. The proposed system utilizes IoT sensors to collect data, which is processed and stored using Apache Kafka, Apache Storm, and MongoDB. A hybrid prediction model is used to identify and remove outliers and detect faults in the manufacturing process. The system improves decision-making and prevents unexpected losses in the automotive manufacturing industry. The purpose of the proposed monitoring system in automotive manufacturing is to provide real-time monitoring and improve decision-making for managers. The system utilizes IoT-based sensors to collect data on environmental conditions and the manufacturing process. It employs big data processing techniques to handle and store the large amounts of sensor data generated. The system also incorporates a hybrid prediction model. By leveraging IoT sensors, big data processing, and machine learning, the system aims to support management in maintaining an optimum working environment, preventing errors, improving operation control, and ensuring product quality. The proposed system helps managers make informed decisions and prevents unexpected losses caused by faults in the automotive manufacturing process.

Muhammad Sani Danladi , Muhammad Baykar, The paper describes the design and implementation of a Temperature and humidity monitoring system (THMS) based on LPWAN technology, especially LoRa and LoRaWAN. To monitor temperature and humidity, the system uses a Raspberry Pi 3 B+ gateway and an Arduino UNO end device equipped with a DHT11 sensor. LoRa and LoRaWAN are used to transfer sensor data to The Things Network's application server. The results show that the system is successful at communicating sensor readings over extended distances while consuming minimum power, making it a low-cost and efficient alternative for temperature and humidity monitoring. The temperature and humidity monitoring system (THMS) described in this article is based on LPWAN (Low Power Wide Area Network) technologies, notably LoRa (Long Range) and LoRaWAN.

These LPWAN technologies were chosen for their low cost, low power consumption, and long-range data transmission capabilities. The system includes a LoRa-based THMS, a Raspberry Pi 3 B+ gateway, and an Arduino UNO end device equipped with a DHT11 sensor. The sensor data are successfully communicated over long distances utilizing LoRa and LoRaWAN with little power consumption, making it an ideal option for temperature and humidity monitoring.

Ong Wee Chuan, Siti Hawa Ruslan. A medical warehouse serves as a dedicated space for storing various types of medical products, which must be kept under strict conditions to preserve their quality. The environmental conditions within a medical warehouse, particularly temperature and humidity, are crucial as they can impact the purity, quality, and safety of the stored medical items. It is essential to maintain storage areas for medicines within prescribed temperature and humidity limits, with special conditions specified by the manufacturer. Precautionary measures need to be in place to prevent any medical product from being compromised due to deviations from specified conditions. Overall, this project has successfully achieved its objectives and operates as intended.

The results of the circuit implementation, software development, and hardware assembly show that the circuit was successfully developed. This project required the creation of a monitoring and control system for a medical warehouse using LabVIEW. The system connects LabVIEW and Raspberry Pi wirelessly over Wi-Fi, and Raspberry Pi is serially linked to Arduino to control input and output devices. Before attempting to execute this project, you must have a thorough grasp of LabVIEW software, networking systems, TCP/IP theory, Raspberry Pi, and Arduino. TCP facilitates reliable data transfer over networks, guaranteeing that data is delivered and received in the correct order, with no mistakes or loss.

Raspberry Pi functions as a wireless bridge to Arduino, which runs the LabVIEW LINX application. In conclusion, this monitoring and control system was successfully developed. Despite minor flaws, the system effectively meets the specified objectives.

Rohit Agrawal, Saumitra Mohan, The study discusses the significance of controlling humidity and temperature in manufacturing facilities, especially in electronic assemblies. Lack of control over these elements may have an adverse effect on parts, machinery, procedures, and operator comfort, which could ultimately result in production losses1. The Wireless Sensor Network Module by National Instruments will be used to remotely monitor the temperature and humidity levels in various plant locations. The system provides and is based on the LabVIEW software platform. The main advantages of LabVIEW software in this application are its simplicity of graphical programming, which enables for effective user interface creation through numerous designs. LabVIEW also provides a large selection of toolkits with hardware support for nearly all types of applications, making it a suitable software platform for designing industrial solutions such as temperature and humidity monitoring systems. The availability of a wide variety of toolkits reduces the requirement for low-level hardware and software development, allowing developers to concentrate on application bottlenecks. LabVIEW also has features such as secure login, easy reconfiguration, an alert system for over-limit scenarios, and data logging for subsequent analysis. These characteristics make LabVIEW ideal for creating extensive industrial applications.

VII. EXPERIMENTAL RESULTS

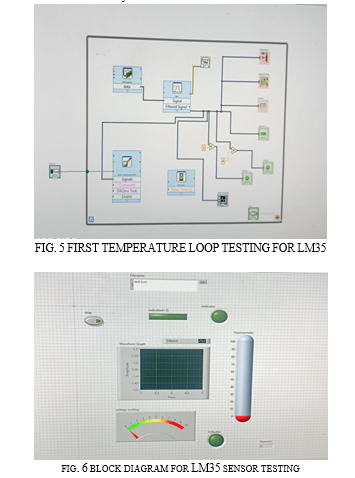

Different tests are carried out with the system at high and low temperatures to test and evaluate the effectiveness of the temperature measurement system proposed in this work.

The following are the experimental outcomes of our system.

VIII. ACKNOWLEDGMENT

DAQ CARD (Hardware)AICTE MODROB Scheme - File no. 9- 167/RIFD/MODROB/Policy – 1/2017-2018.

LabVIEW (Software) – AICTE MODROB Scheme – File no. 9 – 230/RIFD/MODROB/Policy – 1/2018-201

Conclusion

In this review paper, we present an extensive investigation into the design and implementation of a temperature sensor system based on LabVIEW. The main goal of this study was to create a temperature measurement system that is both accurate and dependable, suitable for a wide range of applications. Through a systematic approach, we have achieved several key outcomes: 1) Design and Development: We have successfully created a LabVIEW-based temperature sensor system that integrates hardware components, such as temperature sensors and data acquisition devices, with LabVIEW software. 2) Applications: We have explored potential applications for the LabVIEW-based temperature sensor system, including industrial processes, environmental monitoring, and research laboratories. The versatility of LabVIEW allows for seamless adaptation to various usage scenarios. 3) Future Work: While our research has established a solid foundation for LabVIEW-based temperature sensing, there are opportunities for further enhancements and expansions. Future endeavors could focus on improving the system\'s resilience, investigating additional sensor types, or incorporating machine learning algorithms for predictive analysis.

References

[1] R. Agrawal, Complete Industrial Solution for Automation in Temperature and Humidity Monitoring using LabVIEW, Vellore, India: School of Electronics Engineering. [2] S. H. R. Ong Wee Chuan, Medical Warehouse Monitoring and Control System Using LabVIEW, Johor, Malaysia: Faculty of Electrical and Electronic Engineering,Universiti Tun Hussein Onn Malaysia, 2016. [3] A. F. D. A. M. H. Whisnumurti Adhiwibowo, Temperature and Humidity Monitoring Using DHT22 Sensor and Cayenne API, Soekarno Hatta, Tlogosari, Semarang: University Semarang, 2020. [4] F. Z. Hong Zhang, A kind of Design of Greenhouse Environment Monitoring System Based on LabVIEW, Wuhu, Anhui, China : Electrical Engineering School, Anhui Polytechnic Science and Technology Research Office, Anhui Xinhua, 2020. [5] S. G. A. B. M. M. S. Kalaiarasi, Arduino Based Temprature and Humidity Sensor, Chennai: Assistant Professor, SRM Institute of Science & Technology, Chennai, Tamil Nadu, India., 2018. [6] M.S Danladi* , M. Baykara, Design and Implementation of Temperature and Humidity Monitoring System Using LPWAN Technology Department of Software Engineering, Faculty of Technology, F?rat University, Elaz?? 23119, Turke.,2022 [7] W. M. H. M. K. C. A. Belhadj, LabVIEW Based Real time Monitoring of HVAC System for Residential Load, Dhahran 31261, Saudi Arabia : Electrical Engineering Department King Fahd University of Petroleum and Minerals, 2017. [8] W.-T. H. ,. C.-C. W. a. T.-Y. C. Kai-Chao Yao, Establishing an AI Model on Data Sensing and Prediction for Smart Home Environment Control Based on LabVIEW, Changhua City, Taiwan: Department of Industrial Education and Technology, National Changhua University of Education, No. 2 Shi-Da Road,Changhua City, Taiwan, 2021. [9] Y. S. Qian Zhang, An Intelligent System To Automate Humidity Monitoring And Humidifier Control Using Internet-Of-Things (Iot) And Artificial Intelligence, California: Jserra High School, San Juan Capistrano, CA 92675, California State Polytechnic University, Pomona, CA, 91768. 021. DOI: 10.5121/csit.2021.111711, 2021. [10] S. M. S. A. M. P. M. Olivier Debauchea, Edge Computing and Artificial Intelligence for Real-time Poultry Monitoring, Belgium: Elsevier B.V, 2020. [11] G. A. N. L. F. Muhammad Syafrudin, Performance Analysis of IoT-Based Sensor, Big Data Processing, and Machine Learning Model for Real-Time Monitoring System in Automotive Manufacturing, Seoul 100-715, Korea: Department of Industrial and Systems Engineering, Dongguk University, doi:10.3390/s18092946, 2018. [12] A. D. N. T. Ianire Taboada, Artificial Intelligence Enabled Project Management: A Systematic Literature Review, Melbourne 3011, Australia: Victoria University Business School, Victoria University. 5014. DOI 10.3390, 2023. [13] K. C. Azharul Islam, Real-Time AI-Based Informational Decision-Making Support System Utilizing Dynamic Text Sources, Incheon 22212, Korea: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. DOI. 10.3390, 2021. [14] K. N. A.-K. a. A. M. H. Abdulaziz Aldoseri, Re-Thinking Data Strategy and Integration for Artificial Intelligence: Concepts, Opportunities, and Challenges, Doha P.O. Box 2713, Qatar: Engineering Management Program, College of Engineering, Qatar University.DOI. 10.3390, 2023. [15] I. H. Sarker, Data Science and Analytics: An Overview from Data Driven Smart Computing, Decision Making and Applications Perspective, Melbourne, VIC 3122,Austrilia: Springer Nature Singapore Pte Ltd 2021, 2021. [16] K. A. A. Muhammad Hisham Salleh, Artificial Intelligence Augmented Project Management, Selangor, Malaysia: Faculty of Management, Multimedia University, , 2022. [17] Z. Z. J. G. A. C. X. ZHENYU LIU, Forecast Methods for Time Series Data: A Survey, Hohhot 010018, China: College of Computer and Information Engineering, Inner Mongolia Agricultural University, Digital Object Identifier 10.1109, 2021. [18] M. P. M. P. C. F. D. M. Alexandra Moraru, Using Machine Learning, Ljubljana, Slovenia: Jozef Stefan Institute, MOBITEL Telecommunication Services Inc. DOI: 10.2498, 2010. [19] B. N. N. V. S. Srikanth Namudur, Review—Deep Learning Methods for Sensor Based Predictive Maintenance and Future Perspectives for Electrochemical Sensors, Florida, USA: The Electrochemical Society by IOP Publishing Limited. DOI: 10.1149, 2020. [20] P. C. D. V. B. S. Vaibhav M. Davande, Real Time Temperature Monitoring Using LABVIEW and Arduino, Ichalkaranji, Maharashtra, India: International Journal of Innovative Research in Computer and Communication Engineering. DOI: 10.15680, 2016. [21] Mrs. Kulkarni Sheetal V.,Shambhuraj Mane,Pranay Mankar,Faizan Sayed, “A Systematic Review of LabVIEW Applications in Acquisition of Sensor Data” International Journal of Creative Research Thoughts (IJCRT) Volume X, Issue X Month Year | ISSN: 2320-2882, pp 1-6 [22] Mrs. Kulkarni Sheetal Vijay, Ms. Jijnyasa Joshi, Ms. Aditi Wathe, Ms. Snehal Chandgude, “Biomedical Sensors Data Acquisition with Labview Using Machine Learning: A Review” International Journal for Research in Applied Science & Engineering Technology (IJRASET), ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 7.538 Volume 11 Issue V May 2023. [23] Gauri Bhosale, Shreya Ghosalkar, Deepankar Bhat3 ,Prof. Sheetal Kulkarni, “Review Of Biobench For Various Applications”, International Journal Of Advance Scientific Research And Engineering Trends, Volume 6,Issue 12,II,December 2021, ISSN (Online) 2456-0774, pp 82-86. Author Sensor, controller and Software used LabVIEW application References Rohit Agrawal and Saumitra Mohan Temperature and humidity sensor, Complete Industrial Solution for Automation in Temperature and Humidity Monitoring using LabVIEW 1 Ong Wee Chuan and Siti Hawa Ruslan Arduino, LabVIEW Software, Temperature and humidity sensor Medical Warehouse Monitoring and Control System Using LabVIEW 2 Whisnumurti Adhiwibowo, April Firman Daru, and Alauddin Maulana Hirzan DHT22 Sensor and Cayenne API Temperature and Humidity Monitoring Using DHT22 Sensor and Cayenne API 3 Hong Zhang, Fan Zhang Temperature and humidity sensor A Kind of Design of Greenhouse Environment Monitoring System Based on LabVIEW 4 S. Kalaiarasi 1, Shubham Gautam2, Anshuman Behera 3, Mansi Mewara 4 Arduino, Temperature and humidity sensor Arduino based temperature and humidity sensor 5 Muhammad Sani Danladi Muhammad Baykar Raspberry Pi 3 B+ gateway, DHT11 sensor, Humidity sensor Design and Implementation of Temperature and Humidity Monitoring System Using LPWAN Technology 6 C. A. Belhadj, W. M. Hamanah, M. Kassas Electrical Engineering Department King LabVIEW Software, temperature sensor, Humidity sensor LabVIEW Based Real time Monitoring of HVAC System for Residential Load 7 Kai-Chao Yao, Wei-Tzer Huang, Cheng-Chun Wu, and Teng-Yu Chen LabVIEW software, temperature sensor, Humidity sensor, AI algorithm Establishing an AI Model on Data Sensing and Prediction for Smart Home Environment Control Based on LabVIEW 8 Y. S. Qian Zhang, temperature sensor, Humidity sensor, AI algorithm An Intelligent System to Automate Humidity Monitoring and Humidifier Control Using Internet-of-Things (IoT) and Artificial Intelligence 9 Olivier Debauche, Sad Mahmoudi, Sidi Ahmed Mahmoudi, Pierre Manneback, Jérôme Bindelle, and Frédéric Lebeau. Wireless temperature and Humidity sensor, AI algorithm Edge Computing and Artificial Intelligence for Real-time Poultry Monitoring 10 Muhammad Syafrudin, Ganjar Alfian, Norma Latif Fitriyani, Jongtae Rhee AI algorithm, IoT based sensor Performance Analysis of IoT-Based Sensor, Big Data Processing, and Machine Learning Model for Real-Time Monitoring System in Automotive Manufacturing 11 Tharaka de Vass, Ianire Taboada, Abouzar Daneshpajouh, and Nerea Toledo. AI algorithm Artificial Intelligence Enabled Project Management 12 KyungHi Chang and Azharul Islam AI algorithm Real-Time AI-Based Informational Decision-Making Support System Utilizing Dynamic Text Sources\" 13 Abdulaziz Aldoseri, Khalifa N. Al-Khalifa, and Abdel Magid Hamouda AI algorithm Re-Thinking Data Strategy and Integration for Artificial Intelligence Concepts, 14 Iqbal H. Sarker AI algorithm Data Science and Analytics: An Overview from Data-Driven Smart Computing, Decision- Making and Applications Perspective 15 Muhammad Hisham Salleh and Kamarulzaman Ab. Aziz AI algorithm Artificial Intelligence Augmented Project Management\" 16 Zhenyu Liu, Zhengtong Zhu, Jing Gao, and Cheng Xu AI algorithm Forecast Methods for Time Series Data: A Survey 17 Alexandra Moraru, Marko Pesko, Maria Porcius, Carolina Fortuna, and Dunja Mladenic temperature sensor, Humidity sensor, AI algorithm Using Machine Learning on Sensor Data 18 Swapnil Pradip Patil, Shailaja C. Patil Wireless temperature and Humidity sensor, AI algorithm A Real Time Sensor Data Monitoring System for Wireless Sensor Network 19 Srikanth Namuduri, Barath Narayanan, Venkata Salini Priyamvada Davuluru, Lamar Burton, and Shekhar Bhansali. AI algorithms Deep Learning Methods for Sensor Based Predictive Maintenance and Future Perspectives for Electrochemical Sensors” 20

Copyright

Copyright © 2024 Kulkarni Sheetal Vijay , Saahieel Sasane, Mrunali Bajare, Rahul Deshmukh. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62675

Publish Date : 2024-05-24

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online