Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Experimental Study of Reinforced Concrete using red mud and Lime as Partial Replacement to Cement and Bamboo to Steel

Authors: Boda Ramya, B. Dharmabiksham

DOI Link: https://doi.org/10.22214/ijraset.2023.56169

Certificate: View Certificate

Abstract

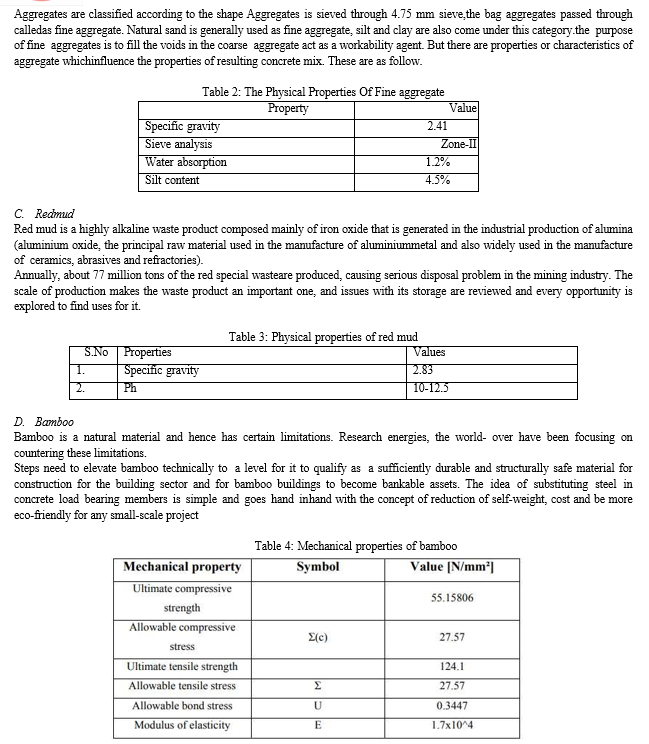

Red mud is an industrial waste material generated during production of alumina from bauxite by Bayer process Nowadays, the wastes are not having any industrial applications, so it can be innovatively using these wastes as a raw material in the civil engineering field. Availability of raw material required for manufacturing of cement and production of concrete are limited in nature. So as to overcome this problem it is very much essential to utilize the industrial waste materials and by- products generated in manufacturing of cement and in concrete construction. Experiments Investigation have been conducted under laboratory condition to assess the strength characteristics of the aluminium red mud. The project work focuses on the suitability of red mud obtained for construction. 5 test groups were constituted with the replacement percentages 0%, 5%, 10%, 15%, 20% of red mud and 5% of hydrated lime with cement in each series. To achieve Pozzolanic property of red mud, hydrated lime was added. The job focuses on the practicality of red mud gotten for structure. 5 assessment groups were consisted of with the replacement percents 0%, 5%, 10%, 15%, 20% of red mud along with 5% of moisturized lime with concrete in each collection in M20 quality concrete. To acquire Pozzolanic house of red mud, moisturized lime was included. This paper points out another enticing direction for the proper usage of red mud.

Introduction

I. INTRODUCTION

One of the real difficulties before the handling and assembling ventures is transfer of the leftover waste items. Out of aggregate Aluminum creation India contributes just around 3% of world's generation. Red mud is one of the bi-items gotten amid refining procedure of Bauxite (mineral of Aluminum Al2O3), at present it is evaluated to be 2.7 billion tons with a yearly development rate of more than 120 million tons. Because of nearness of scathing pop the Red mud has high pH more prominent than 11. Its transfer is tricky and it is unsafe to condition. Keeping in mind the end goal to beat this issue it must be reused in different fields like horticultural, gas medications and structural designing, for example, Bricks planning, Road asphalts, Embankments and for Landfill liners. utilized the Red mud for blocks planning by balancing out with lime and checked the wet and dry compressive qualities at 28 days curing period, got most extreme qualities for 5% lime and8% lime separately. They have done a venture deal with practicality of lime and Red mud settled Red mud blends in street development arranged bond Red mud solid utilizing Red mud. The compressive and flexural quality of this sort of cement is near or much higher than that of customary solid, meeting the prerequisite of bond cement utilized for asphalt materials (the 28-day compressive quality is around 30–40 MPa; the 28-day flexural quality is around 4.5–5.5 MPa). examined slag and Red mud initiated by a composite strong soluble activator, and created antacid slag Red mud bond which has the properties of more prominent early quality (the underlying and last setting is independently 62 min and 95 min), high compressive quality (the 28-day compressive quality can be up to 125 MPa) and brilliant imperiousness to erosion, using 30% of the Red mud. Reported that the use of impact heater slag, phosphor gypsum, flyash, Red mud, squander tea, and so on are utilized as development materials and the ecological effect of such techniques have been considered for a long time., utilized Red mud as a concrete stabilizer and study the impacts of Red mud on the unconfined compressive quality, pressure driven conductivity, and swelling rate of compacted earth liners as water powered obstruction. The test outcomes demonstrate that compacted mud tests containing Red mud and cement–Red mud added substances have a high compressive quality and diminished water driven conductivity and swelling rate when contrasted with normal earth tests. Thusly, it is presumed that Red mud and cement–Red mud materials can be effectively utilized for the adjustment of dirt liners in geotechnical applications.

Has concentrated the planning of conventional Portland concrete from Red mud, lime and freestone, and the 28-day compressive quality of the bond quality can achieve 63MPa utilizing Red mud in fluctuating rates 0%, 5%, 10%, 15%, 20%, these barrels were water cured for 28days and tried. He presumed that expansion in Red mud content abatement the compressive and in addition elasticity of solid, Optimum rate of the substitution of bond by weight is observed to be 25%, Concrete arranged by utilizing Red mud is reasonable in elaborate works and gives stylishly wonderful appearance and workability of cement may get influenced with increment of Red mud yet it can be enhanced by including super plasticizers. In the present review OPC 53 concrete decided for adjustment of Red mud. The Red mud test gathered from NALCO which is situated at Daman Jodi in Orissa. At first the Red mud, bond are tried for their individual attributes and Geotechnical properties. After that the Red mud blended with bond to get ideal blends. The ideal blends were chosen in view of the estimations of compaction attributes. The tests unconfined compressive quality and split rigidity were led at various curing periods to discover the qualities at various curing periods.

Red mud or red slop is an exceptionally soluble waste item made for the most part out of iron oxide that is created in the mechanical generation of aluminum. With around 77 million tons of this unsafe material being created every year, red mud represents a genuine transfer issue in the mining business.

Many researchers have actually utilized Bamboo as an option of enhancing steel in concrete and also chose it really great deals effective. I intend to use bamboo as a substitute of enhancing steel in dust concrete (concrete made with changing cement with red dirt and fly ash). In this way I may be using waste products (pink dust as well as fly ash), whilst on the equivalent time efficiently lowering making use of cement and also reinforcing metal make the bamboo enhanced dust concrete a feasible and also surroundings pleasant opportunity.

II. LITERATURE REVIEW

P. Ashok, M.P. Suresh Kumar[2015]: experimental studies on current utilizing red mud and hydrated lime as a partial replacement of cement M30 grade. The percentage of red mud partial replacement of cement are, 0%, 5%,10%, 15%, 20%, and 25% and 5% hydrated lime partial replacement of cement. From the experimental studies 15% partial replacement of cement with red mud and 5% hydrated lime improved cement concrete properties

Sucharitha patal, B.K.pal [2016] : Current status on industrial waste red mud on overview have made investigated on the amount of the red mud generated per ton of the alumina processed, various greatly with the type of the bauxite ore used. Due to this hazardous nature it is a great challange to researcher to develop new methods for the application of red mud. Various research work going on for storage, disposal and utilization of the red mud in all over the world. Were studied this reviews the current status and future trend of the red mud characterization, disposal, various neutralization methods and utilization in world as well as in Indian context.

M.P.Suresh Kumar, S.K. Gowtham[2015]: were studied the potential utilization of industrial waste (red mud) in concrete. Have made investigation on partial replacement of cement with red mud for studying mechanical properties of concrete. The percentage of red mud partial replacement of concrete are, 0%, 5%, 10%, 15%, and 20% for M20 grade concrete. From the experimental studies 10% partial replacement of cement with red mud improved hardened concrete properties.

Ramarao Chimata, VenkateswaraRao.J[2014] :have made investigated on partial replacement of sand with quarry dust and glass fibers for studying mechanical properties of rigid pavements. The percentage of quarry partial replacement of sand in concrete are, 0%, 10%, 15%, 20%, 30% and 40% and 0.2% glass fibers for M40grade concrete. For experimental studies 30% of partial replacement of sand with quarry dust &glass fibers improved hardened concrete properties.

III. METHODOLOGY AND MATERIALS

Concrete is made up of components sachets, aggregation of stones, which we called as aggregate, embedded in cement mortar that is cement-sand mortar, in his hardened state concrete is aggregation of stones or similar hard material embedded in what we call cement- mortar. The aggregates, aggregates in normal concrete form this skeleton matrix; it is about 60 to 65 percent by volume and rest all is 25 percent is past.

Now paste means cement and water that combines to paste. Concrete’s versatility, durability, sustainability, and economy have made it the world’s most widely used construction material. About 4 tons of concrete are produced per person per year worldwide and about 1.7 tons per person in the United States.

The term concrete refers to a mixture of aggregates, usually sand, and either gravel or crushed stone, held together by a binder of cementitious paste. The paste is typically made up of Portland cement and water and may also contain supplementary cementing materials (SCMs), such as fly ash, rice husk ash, saw dust, glass powder.

- Powerful utilize containing industrial uses up flourishing place epithelial common place commodities can help to diminish powerful noisemaker furthermore besides preserve even our own resource.

- The general development going from cyclic low-priced plus seismically appropriate building materials cherish agricultural as well as industrial consumes is definitely an secondary concern.

- It as well makes a specialty of sensational fast palmy sensational requested as well as spin-off in reference to cementum.

- To discover the general better thanks to step up features going from lumber the as reinforcement booming caked structures.

Conclusion

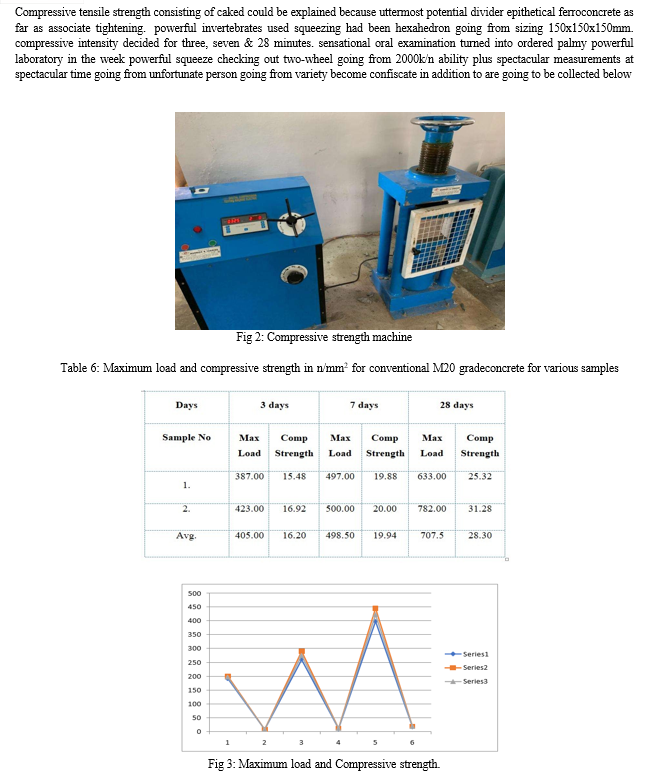

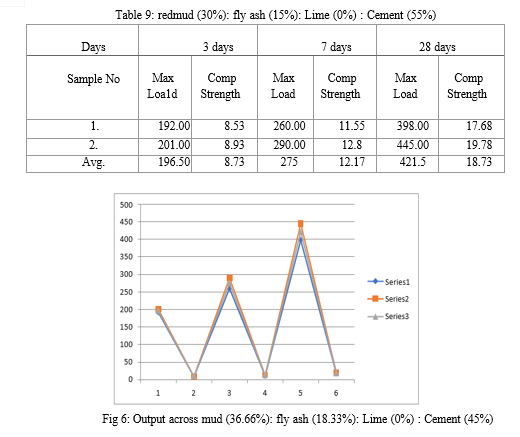

From this research the following final thoughts are: The downturn really really worth is growing with upward push in the percentage of pink dust in concrete for 5% moisturized lime. As a result of boom at a loss dust reasons lower in the quantity of concrete outcomes in increase inside the workability of concrete. 1) The compressive sturdiness of M20 for 28 days at 0%,5%,10%,15%,20% is 51kN/m2, 53 kN/m2, 55 kN/m2,44 kN/m2, 38 kN/m2 in particular. 2) The compressive durability of M20with 5% hydrate lime for 28 days at 0%,5%,10%,15%, and additionally 20% is 51kN/m2, 54 kN/m2, 56 kN/m2, 48 kN/m2, 42 kN/m2respectively. 3) The maximum fee of the compressive stamina of red dirt concrete for 7 days treating come to be determined at 10% red mud opportunity. As well as moreover for 28 days compressive durability located at 10% pink dust substitute.The compressive stamina of concrete using 5% moisturized lime is more compared to the concrete without moisturized lime. 4) The greatest fee of break up tensile electricity with the useful resource of using hydrated lime and additionally with out utilizing moisturized lime are discovered at 10% red dust alternative. As properly as additionally divided tensile toughness is immoderate for 5% hydrated lime concrete. 5) The choicest actually really worth of flexural power become determined at 0% substitute of pink dust concrete for every utilizing moisturized lime and additionally without the use of hydrated lime at 28days of treating. The portion monetary situation is raised with the enhance inside the fine of concrete however at the same time there is a discount in the proportion upward thrust in the Compressive Stamina. 6) Red mud may be efficaciously made use of as alternative product for concrete and alternative makes it viable for the massive use of waste object. Red dust did now not effect of the cement homes, as an alternative advanced the concrete top wonderful by using way of approach reducing the setup time & more appropriate compressive durability.

References

[1] M.P.Suresh Kumar, S.K. Gowtham,‘Potential utilization of industrial waste red mud in concrete’ published in 2015. [2] Sucharithapatal, B.K.pal, ‘Experimental study on the effect of cement and sand replacement with red mud and quarry dust in cement concrete pavements’ published in 2016 [3] M.P.Suresh Kumar, S.K. Gowtham,‘Potential utilization of industrial waste red mud in concrete’ published in 2015. [4] Ramarao Chimata, VenkateswaraRao.J,‘use of quartzite rock dust and effect of glass fiber’ published in 2014. [5] Abdullah Anwar,‘Compressive strength of concrete by partial replacement of cement with high volume fly ash’ published in 2014. [6] Rama Raju, ‘Use of quarry dust and fly ash as partial replacement for sand’ published in 2010. [7] Jayeshkumar Pitroda,‘Experimental Investigations on partial replacement of cement with fly ash in design mix concrete’ published in 2011. [8] Swapnil Dange, Smita V. Pataskar Cost and Design Analysis of Steel and Bamboo Reinforcement International Journal of Innovative Research in Science, Engineering and Technology ISSN (Online): 2319-8753 Vol. 6, Issue 12, December 2017 [9] Prieto, S., et.al., (2002) Manual for earthquake-resistant construction of one and two storey houses with cemented bahareque. Proceedings of the International workshop on the role of bamboo in disaster avoidance Guayaquil, Ecuadaor, 6-8 August 2001, pp.140- 148. [10] Ahmad Shakeel, Raza Altamash and Gupta Hina Mechanical properties of bamboo fibre reinforced concrete, 2nd International Conference on Research in Science, Engineering and Technology (ICRSET’2014), Dubai (UAE), 162-166(2014). [11] Amada, S., Ichikawa, Y., Munekata, T., Nagase, Y. and Shimizu, H., Fiber texture and mechanical graded structure of bamboo, Composites Part B: Engineering, 28(1-2), 13-20(1997). [12] Ghavami, K. Ultimate load behavior of bamboo- reinforced lightweight concrete beams, Cement and concrete composites, 17(4), 281-288(1995).

Copyright

Copyright © 2023 Boda Ramya, B. Dharmabiksham . This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET56169

Publish Date : 2023-10-16

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online