Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Repair & Rehabilitation of Rigid Pavement: A Case Study

Authors: Satendra Rai , Prof. R. K. Yadav

DOI Link: https://doi.org/10.22214/ijraset.2025.66220

Certificate: View Certificate

Abstract

Transportation infrastructure is crucial for a nation\'s development. This paper aims to investigate the various types of rigid pavement failures and to identify the most effective maintenance strategies to address these issues on the Jabalpur-Mandla highway, formerly designated as NH 30 (previously NH 12A). An examination of the roadway between the 3 km to 40 km markers reveals a range of pavement failures, including longitudinal cracks, raveling, rutting, and shear failure. The predominant causes of these rigid pavement failures include excessive loads, inadequate drainage systems, and significant rainfall. Such pavement deteriorations not only hinder the daily lives of residents but also escalate maintenance costs. This study outlines repair techniques for several prevalent crack types that may occur during the construction phase, in the post-construction period, and throughout the pavement\'s service life. The present studies identifies that the classifications of common defects and distresses in rigid pavements with their source along with the way to correct it with associated maintenance procedure.

Introduction

I. INTRODUCTION

National Highway (NH 30) starts from the Sitarganj in Uttrakhand to Ibrahimpatnam, Vijayawada in Andhra Pradesh. The total length of this highway is 1984.30 km. It passes from Jabalpur runs via Barela, Udaipur, Bijadandi, Mandla, Madhopur, Anjania and Bichhiya in Madhya Pradesh. Its connect NH-34, NH-45 and NH-543. The road also passes through Kanha National Park, which is the Famous National park in India. Development of Surface Cracks in rigid pavement are due to temperature difference, late joint cutting, and defective curing of rigid pavement .The cracks will allow water / mud /debris going into the cracks and widens them further. Shrinkage is another common reason for cracking. As concrete hardens and dries it shrinks. The chemical reaction, which causes concrete to go from the liquid or plastic state (or a solid state), requires water. This chemical reaction, or hydration, continues to occur for days and weeks after you pour the concrete. Longitudinal cracks, transverse cracks, diagonal crack, pumping, faulting, spalling, shrinkage, punch out, deterioration of joint load transfer system, linear cracking, durability cracking, corner break, alkali-aggregate reaction, pop-outs and blow-ups are some of failure of rigid pavements. Crack filling, Crack sealing, Stitching, Diamond grinding, Dowel bar retrofitting, Joint repair, Partial-depth repair and Full-depth repairs are the most common techniques used for restoration of rigid pavements .

II. LITERATURE REVIEW

Suja A.C.A. Marliyas M.M (2016) -. Presented failure types as identified with the help of literature survey and the exerted reasons on the failures were studied. Altogether 10 types of various failures were identified in randomly selected all rigid pavements, and 5 major types of failures were focused and stated in this paper. Polished aggregate was the most common problem among the identified failures followed by scaling and transverse cracking. The reasons and solutions were given to those problems by observing those failures and discussing with the responsible road owning authorities. Some solutions were given in order to prevent failures of newly constructed rigid pavement in future. Gurpreet Mains, Er. Neeraj Kumar, Dr. Rakesh Gupta (2019) – Evaluated different types of defects e.g. scaling of cement concrete, shrinkage cracks, joint spalling, warping cracks, pumping. & evaluate causes of defects affecting failures. Dr. B. Prasad, K.Nagateja, Sulakshana Natuva, Bathini Jayanth (2024) -. Studied defects and their causes is the reduction in serviceability brought on by the development of various types of deterioration on the flexible pavement, such as cracks, surface defects, disintegration, etc. The breakdown of bituminous pavement can have numerous causes.

III. OBJECTIVE

The objectives of studying rigid pavement failure aim to categorize and identify different types of rigid pavement failures, such as cracking, faulting, spalling, and joint deterioration, to better understand their characteristics and to develop effective maintenance and rehabilitation strategies that can extend the life of rigid pavements and reduce the frequency and severity of failures.

A. Factor Affecting & Causes of Pavement Failure

- Poor quality of material used in the Pavement construction.

- Defects in quality control and construction method.

- Improper drainage system.

- Movement of heavy load vehicles or increase in load repetition because of increase in traffic volume.

- Improper compaction of pavement layer during early stages of construction.

- Factors such as rainfall, increase in water table etc

B. Classification of Structural Cracks

The structural cracks are classified according to crack width are as follows :-

- Narrow Cracks – If the width of crack is 0.5mm it is considered as narrow crack. It is assumed that there is full aggregates interlock and full load transfer is taking place within the slab at the crack.

- Medium Crack – If the width of crack is 0.5 -1.5mm it is considered as medium crack. It is assumed that there is partial aggregates interlock and partial load transfer is taking place within the slab at the crack. These types of cracks permit of water.

- Wide Crack – If the width of the crack is greater than 1.5 mm it is considered as wide crack. It is assumed that there is no aggregates interlock and no load transfer is taking place within the slab at the crack. These types of cracks permit of water and fine particles.

C. Type of Maintenance

Type of maintenance for rigid pavements are as follows:

- Routine Maintenance or preventive pavement maintenance: This treatment to pavement functioning properly. Routine maintenance includes crack sealing, pothole repair, joint sealing in the rigid pavement.

- Programmed Maintenance: It restore the deterioration to its original condition. Programmed Maintenance includes cross-stitching, partial depth repairs, full depth and diamond grinding to remove faults.

- Rehabilitation and Strengthening: Increase design life for future expected traffic loads. It includes diamond grooving for restoring surface texture, retrofitting of dowel bars, slab stabilization, reconstruction or application of an overlay.

- Emergency Repairs: these repairs are quick, temporary fixe to potholes and cracks that are done to keep driver safe.

D. Types of failure

Types of Failures, their causes and remedies in Rigid Pavement are presented in table 1.

TABLE 1- types of failure , their causes and remedies

|

S.No. |

Types of Failures |

Description & Causes |

Remedies |

|

1. |

Plastic Shrinkage Cracking

|

These are hairline cracks that are less than 2m in length. They do not cross the entire slab. The setting and curing process of the concrete slab results in such cracks.

|

|

|

2. |

Edge Crack?ng |

Curved shaped cracks or cont?nuous cracks that ?ntersect the pavement edge and are located w?th?n 0.5m of the pavement edge, adjacent to shoulder.

|

|

|

3. |

Corner Break |

Corner break is a diagonal crack in a rigid pavement that intersects a joint near the corner of the slab.

|

|

|

4. |

Transverse Cracking |

Transverse cracking in rigid pavement is a type of crack that runs perpendicular to the pavement center line direction.

|

|

|

5. |

Diagonal Crack

|

A diagonal crack in a rigid pavement can be caused by a number of factors including: Shear stress, Flexure at mid span

|

|

|

6. |

Longitudinal Crack or Linear Cracking |

Longitudinal cracks in rigid pavement run parallel to the pavement centerline and can be straight or in the shape of an arc. They can occur in a lane about 3 to 5 cm from the pavement edge.

|

|

|

7. |

Fatigue Cracking or Aligator Cracking |

Fatigue cracking or crocodile cracking is type of damage that occurs in concrete pavement when it repeatedly subjected to traffic loading and environmental conditions

|

|

|

8. |

Ravelling Scaling

|

Loss of fine aggregates from mix of cement paste laittance from the surface through abrasion that may or may not have been previously cracked.

|

|

|

9. |

Polished surface or Glazing or Smooth Surface |

Polished aggregate is a pavement defect that occurs when the aggregate surface is worn down by traffic. It can be identified by looking at the aggregate that is above the asphalt, which may be very small or have no rough particles to provide skid resistance.

|

|

|

10. |

Spalling at Cracks or Joints |

Excessive compressive stress causes deterioration in the joints or crack. This may be related to joint infiltration or the growth of pavement that are caused by the reactive aggregates..

|

|

IV. METHODOLOGY

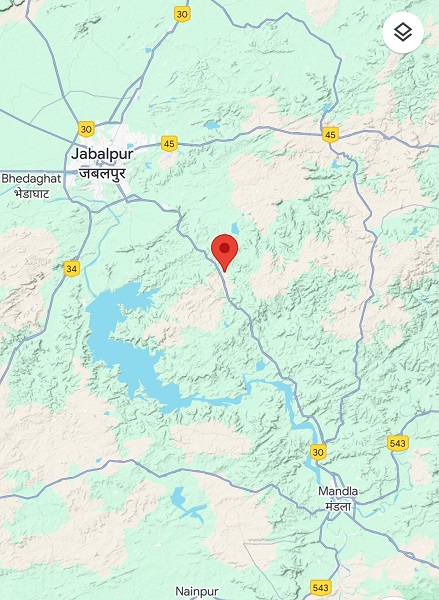

Two Lane with paved shoulders for rehabilitation and up-gradation of Jabalpur-Mandla Section from Design Chainage is Km. 3+200 to km 85+400 to Km of NH-12A (New NH-30) in the state of Madhya Pradesh under NHDP-IV. A survey of 37 km is done the Chainage Km. 3+200 to km 40+300 for determining the various types of failure that are present in pavement and their maintenance procedure to overcome it.

Fig 1. Map of NH 30 Jabalpur to Mandla

Location and types of cracks & other serious defects in rigid pavement Jabalpur to Mandla NH 30 is 2 Lane rigid pavement from distance 3 km to 40 km Barela to Narayanganj run along via Barela, Kalgodi, Dobhi, Udaipur, kudamaili, Bijadandi,Kalpi, Tikariya, Narayanganj in Madhya Pradesh. The various defects found in the pavement and their probable remedies are summarized in table 2.

TABLE 2 Distress observed & remedies measure

|

S.No. |

Location Mark |

Chainage |

Length |

Near Location around Defect |

Types of Cracks |

Remedies |

|

1 |

L1 |

3+200 to 3+300 |

100m |

Barela |

Joint Spalling |

Full Depth Repairing |

|

2 |

L2 |

3+800 to 4+000 |

200m |

Sharda Mandir |

Longitudinal Crack, Plastic Shrinkage Crack |

Cross Stitching Epoxy grouting |

|

3 |

L3 |

5+000 to 5+100 |

100m |

Ghat End |

Plastic Shrinkage Crack |

Epoxy grouting |

|

4 |

L4 |

6+700 to 6+800 |

100m |

Kalgodi |

Longitudinal Crack, Plastic Shrinkage Crack |

Cross Stitching Epoxy grouting |

|

5 |

L5 |

7+200 to 7+300 |

100m |

La Belle Restaurant |

Diagonal of Crack |

Cross Stitching |

|

6 |

L6 |

9+000 to 9+100 |

100m |

Dobhi Location 1 |

Transverse Crack, Reveling of Surface |

Cross Stitching |

|

7 |

L7 |

10+200 to 10+300 |

100m |

Dobhi Location 2 |

Diagonal of Crack , Corner Break, Joint Spalling |

Cross Stitching,Full Depth Repairing |

|

8 |

L8 |

11+300 to 11+400 |

100m |

Baiga Tola |

Diagonal of Crack, Pot hole |

Cross Stitching |

|

9 |

L9 |

12+000 to 12+100 |

100m |

Udaipur |

Multiple Structural Crack, Joint Separation |

Full Depth Repairing |

|

10 |

L10 |

13+000 to 13+050 |

50m |

Chauki |

Transverse Crack |

Cross Stitching, Overlay |

|

11 |

L11 |

14+300 to 14+400 |

100m |

Govt Primary School, Moiyanala

|

Diagonal of Crack, Joint Spalling, Corner Break |

Full Depth Repairing, Cross Stitching, Overlay |

|

12 |

L12 |

18+700 to 18+800 |

100m |

Kachwaha Hotel |

Longitudinal Crack |

Cross Stitching |

|

13 |

L13 |

20+400 to 20+500 |

100m |

Forest Place |

Transverse Crack |

Cross Stitching Full |

|

14 |

L14 |

22+600 to 22+700 |

100m |

Magradha Road |

Longitudinal Crack, Transverse Crack |

Cross Stitching Full |

|

15 |

L15 |

25+000 to 25+150 |

150m |

Bijadandi |

Longitudinal Crack, Corner Break, Joint Spalling |

Cross Stitching Full Depth Repairing |

|

16 |

L16 |

28+500 to 28+600 |

100m |

Dhanwahi |

Multiple Structural Crack, Pop-Out, Polished Surface |

Full Depth Repairing ,Epoxy Mortar |

|

17 |

L17 |

30+200 to 30+300 |

100m |

Ballar Baba Bus Stand |

Longitudinal Crack, Corner Break |

Cross Stitching |

|

18 |

L18 |

33+000 to 33+100 |

100m |

Kalpi Niwas Road |

Diagonal of Crack, Longitudinal Crack |

Cross Stitching |

|

19 |

L19 |

37+100 to 37+150 |

50m |

Kudamaili Bhawal |

Corner Break, Joint Separation |

Cross Stitching |

|

20 |

L20 |

37+600 to 37+700 |

100m |

Boriya |

Corner Break, Longitudinal Crack |

Cross Stitching |

|

21 |

L21 |

37+900 to 37+950 |

50m |

Tikariya |

Plastic Shrinkage crack, Polished Surface |

Epoxy grouting, Epoxy Mortar |

|

22 |

L22 |

40+200 to 40+300 |

100m |

Narayanganj |

Diagonal of Crack, Corner Break |

Cross Stitching |

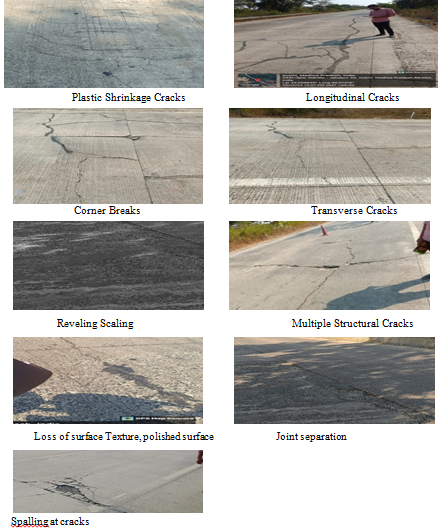

Distress observed in site from Jabalpur to Mandla NH-30 some selected photographs are as under:

Fig.2 Distress observed at site

V. RESULTS AND ANALYSIS

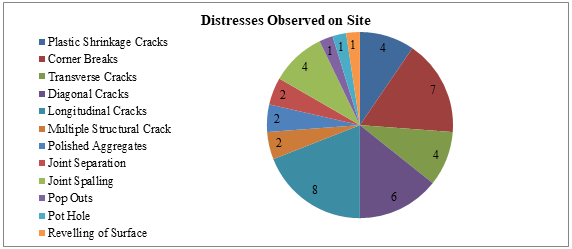

All the maintenance processes are sorted in the maintenance categories of various form of failures the data obtained from study area of observed chainage Km. 3+200 to km 40+300

Fig. 3 Number of distress

Hence maximum number of crack is longitudinal crack, corner break, joint spalling and minimum number of crack is pop out & pot hole. Overall this study to observed cross stitching with epoxy fill in the joint , some place of this pavement full depth repaired treatment is done & hot mix ashphalt as overlay applied to surface treatment

VI. REPAIR & RESTORATION OF RIGID PAVEMENTS

Types of Techniques to Repair Defects:

A. Crack filling

It is the process of filling crack filler into non-working cracks to substantially reduce the intrusion of incompressible material and the infiltration of moisture in the pavement. Usually cracks less than 2 mm and are non-working require crack filling.

Low viscosity epoxy and polymer- modified asphalt are used as crack filler.

Fig.4 Filling of joints using bitumen sealant

B. Stitching

It is a repair technique to maintain aggregate interlock at the point of cracking and to provide added reinforcement and strength to the pavement. Stitching is carried out for strengthening longitudinal cracks in slabs. Stitching is also adopted to alleviate the problems of omission of tie bars during construction, to tie roadway lanes and centerline longitudinal joints of pavements.

There are three types of stitching used; cross-stitching, slot-stitching, and U-bar stitching.

C. Partial depth repairs

Partial depth repairs can be used for repair of Pot holes, Pop outs, Corner cracking, edge cracking, joint spalling type of surface defect which may be repair in rigid pavements.

The process involves the following steps:

- Identification & marking of repair part

- Removal of affected concrete

- Cleaning & preparation of patch

- Application of primer or bonding agent

- Placing of concrete & finishing surface

- Curing of repair patch

- Allowance of traffic

This technique is used to repair joint and crack deterioration and surface distress, popouts and potholes.

D. Flexible overlay

For location L-10 chainage to L-11 chainage flexible overlay over rigid pavement for increase the life of pavement

Fig. 5 Overlays at L-10 location

E. Full depth repairs FDR

Full-depth repair, also known as a whole section substitution, is a method for fixing a full-depth crack in a rigid pavement. This technique used to restore the structural integrity and rideability of rigid pavement, and to extend its service life. It used to repair isolated areas of deterioration, such as cracks, corner breaks, and deteriorated joints.

The process involves the following steps:

- Identification & marking of repair part

- Removal of affected concrete

- Cleaning & preparation of patch

- Application of primer or bonding agent

- Placing of concrete & finishing surface

- Curing of repair patch

- Allowance of traffic

This technique is used to repair full depth cracks, corner crack and joint deterioration & repair punchouts

F. Diamond grinding

Diamond grinding is a pavement preservation technique that uses diamond-tipped saw blades to remove hardened concrete from a pavement's surface. It's often used on concrete pavements, but can also be used on asphalt concrete pavements.

Diamond grinding can improve -

- Improve ride quality: Remove bumps and scallops that can make the pavement uncomfortable to drive on

- Improve surface texture: Create a longitudinal, continuous texture with ridges and corrugations

- Increase friction: Reduce the chance of hydroplaning

- Reduce accident rates: Diamond-ground surfaces have been shown to have up to 60% fewer accidents than non-ground surfaces

- This technique is used as specialized technique used to extend serviceability, improve ride and skid resistance

Conclusion

1) Jabalpur – Mandla highway NH 30 observation between 3 km to 40 km maximum type of crack were found as longitudinal crack, corner crack ,multiple structure failure the suggested reame measure as Full Depth Repair , Stitching , Crack filling by epoxy. 2) At some location as summarized in table 2 bituminous overlay is also suggested. 3) Many type of cracks such as uncontrolled transverse full depth cracks, plastic shrinkage cracks, full depth cracks near slab, cracks over dowel bars etc. have been observed on the concrete road . The probable solution is also suggested. 4) The sealing of all kind of cracks in rigid pavement must be done with approved material to avoid the further development. At some location full panel replacement is required, it should be done along with sub-base, to avoid the chances of re-occurrence of cracks. 5) This distress is in the form of cracks, revelling, joint spalling settlement etc. are observed & the solution for rehabilitation and repair was suggested.

References

[1] IRC:SP:83-2018 Guidelines For Maintenance, Repair And Rehabilitation Of Cement Concrete Pavements (First Revision) [2] IRC-58-2011 Guidelines for the design of plain jointed rigid pavements for highways. [3] S.K. Khanna –C.E.G Justo , book of highway engineering . [4] Bhatty, J I, Miller, F M and Kosmatka, S H Innovations in Portland Cement Manufacturing, (SP400) PCA, Skokie, Illinois, 2004. [5] Sprinkel, M M ‘Very-Early-Strength Latex-Modified Concrete Overlay’, Transportation Research Record, No. 1668, 1999, pp.18–23. [6] Guide for Selecting and Specifying Materials for Repair of Concrete Surfaces, International Concrete Repair Institute. January 1996 [7] Guide for Selecting and Specifying Materials for Repair of Concrete Surfaces, International Concrete Repair Institute.January 1996. [8] IRC:43 - “Recommended Practice for Plants, Tools and Equipment RequiredforConstruction and Maintaince of Concrete Roads” [9] Gurpreet Mains , Er. Neeraj Kumar , Dr. Rakesh Gupta A Review Paper on Evaluation of Rigid Pavement Failures International Journal for Research in Applied Science & Engineering Technology (IJRASET) ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887 Volume 7 Issue IV, Apr 2019 [10] Raghvendra Katarpawar Vijay Kumar Pandey, Shashikant Srivastava(2021) A Detailed Case Study on Construction and Maintenance of Rigid Pavement International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 08 Issue: 07 | July 2021 [11] Suthathip Suanmali, Veeris Ammarapala “Maintenance budget planning: A case study for rigid pavement maintenance system in Thailand” IEEE,June 2010 [12] Mankar Nikhil C., Prof. Nichat K. P. “ Study On All Types Of Failures In Rigid Pavement “International Research Journal of Modernization in Engineering Technology and Science e-ISSN: 2582-5208 /Volume:02/Issue:06/June -2020 [13] Suja A.C.A. , Marliyas M.M. “Identification of Problems In Rigid Pavements In Ampara District And Proposed Solutions “Research Gate December 2016. [14] Dr. B. Prasad , K. Nagateja, Sulakshana Natuva, Bathini Jayanth” Case Study on Pavement Failures & Its Maintenance”

Copyright

Copyright © 2025 Satendra Rai , Prof. R. K. Yadav. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET66220

Publish Date : 2024-12-31

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online