Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Research on An IOT Based Smart E-Fuel Station using ESP-32

Authors: B. Amulya, Deekonda Bhargavi , Noone Ankita, Rayapudi Gopi Lavan

DOI Link: https://doi.org/10.22214/ijraset.2024.62729

Certificate: View Certificate

Abstract

The Internet of Things (IoT) is altering traditional fuel stations in the fast-changing energy and transportation landscape. The ESP32 microcontroller\'s capabilities are utilized in the design and implementation of an Internet of Things (IoT) smart e-fuel station shown in this research. By adding real-time monitoring, automation, and data analytics, the system seeks to improve the effectiveness, security, and user experience of traditional filling stations. Actuators for controlling pumps and queuing traffic are important parts of the proposed system, along with sensor networks for tracking fuel levels, traffic movement, and environmental conditions. The central center for data processing, aggregation, and communication is the ESP32 microcontroller, which makes it easier for different subsystems to work together seamlessly.

Introduction

I. INTRODUCTION

The creation of smart e-fuel stations is one example of how the integration of Internet of Things (IoT) technology has changed numerous industries. These stations make use of the Internet of Things (IoT) to build an integrated network that improves customer satisfaction and operational efficiency. One such device is the ESP32 microcontroller. The core of this system is the ESP32, which has integrated Bluetooth and Wi-Fi. This allows for smooth communication between different parts of the system, including fuel pumps, payment terminals, environmental sensors, and centralized management systems. These intelligent e-fueling stations can maximize fuel inventory management, automate maintenance activities, guarantee regulatory compliance, and provide customized services to consumers by utilizing real-time data analytics and remote monitoring capabilities.

II. RELATED WORK

In this article, the literature on IoT-based smart e-fuel station is to integrate cutting-edge technology to improve user experience, expedite processes, and encourage sustainability. ESP32 microcontrollers act as the central processing units in this configuration, allowing real-time data interchange and easing connectivity between different components. Effective administration of the gasoline dispensing operations is one of this system's main features. ESP32 controllers can track usage trends, keep an eye on gasoline levels in storage tanks, and automatically order replacements when needed thanks to IoT connectivity. In addition to guaranteeing a steady supply of fuel, this improves inventory control and lowers waste and related expenses.

Additionally, sensors can be interfaced with ESP32 modules to track environmental parameters like humidity, temperature, and air quality. Analysis of this data is possible to verify compliance. The ESP32 microcontroller is a complex tool that can be used to modernize conventional fuelling infrastructure and integrate cutting-edge technologies for improved efficiency, safety, and user experience in an IoT-based smart E-fuel station. To seamlessly coordinate several components, this inventive system uses the ESP32 microcontroller, which is well-known for its adaptability and durability in Internet of Things applications, as the central control unit. Numerous sensors connected to the ESP32 enable real-time data collecting and monitoring, which is at the core of this smart E-fuel station. These sensors have a wide range of functions, such as pressure sensing, temperature monitoring, fuel level detection, and environmental parameter assessment. The station's activities may be remotely monitored and managed thanks to the ESP32, which gathers data from various sensors and wirelessly delivers it to a cloud-based platform.

A network of sensors coupled with the ESP32 forms the core of the smart E-fuel station and is intended to gather data in real-time on temperature, pressure, fuel levels, and other vital indicators. By ensuring precise tracking of fuel inventory and machine status, these sensors reduce downtime and enable proactive maintenance. The intelligent E-fuel station can send this data to a cloud platform or centralized control system for in-depth analysis and remote monitoring thanks to the ESP32's networking capabilities. Station managers can use this to better understand gasoline consumption trends, predict changes in demand, and manage inventories. In addition, the ESP32 enables secure communication protocols that guarantee data integrity and guard against manipulation or unwanted access. Major advancements have been made in IoT-based smart e-fuel stations that use ESP32 microcontrollers.

These stations showcase creative ways to improve fuel management systems' sustainability, safety, and efficiency. Numerous facets of IoT integration, such as automated refueling procedures, predictive maintenance, and remote monitoring, have been studied by researchers. Research has looked into the use of sensor networks, for example, to keep an eye on fuel levels, find leaks, and make sure safety regulations are being followed. Proactive maintenance can save downtime and guarantee continuous service with features like automated alerts and remote diagnostics. Additionally, smooth transactions are made possible by ESP32's integration with smart payment systems, which improves customer convenience and security. Ultimately, updating fuelling infrastructure, increasing operational effectiveness, and raising customer happiness can all be accomplished by utilizing ESP32 in an Internet of Things.

III. PROPOSED METHODOLOGY

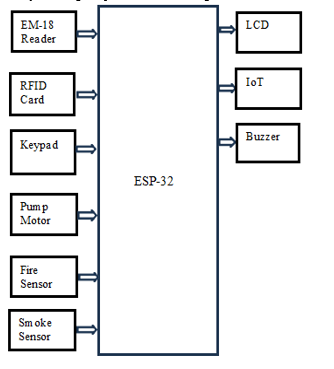

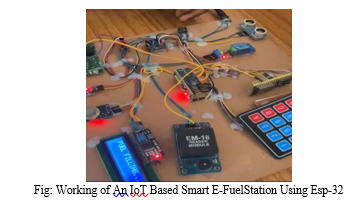

CNN models The ESP32 microcontroller-powered IoT-based smart e-fuel station provides a complete solution for improving customer satisfaction, operational effectiveness, and environmental sustainability. Critical components of the gasoline station are monitored and controlled in real-time by the system through the integration of many sensors, actuators, and communication modules. The ESP32 microcontroller, which is at the heart of the system, is renowned for its great performance, low power consumption, and integrated Bluetooth and Wi-Fi connection. The primary processing unit of the fuel station is this microcontroller, which gathers data from the sensors positioned all over the place. Monitor fuel levels, identify leaks, and guarantee that equipment is operating properly, sensors such as flow meters, pressure sensors, and level sensors are positioned strategically. These sensors provide the ESP32 with data continually, enabling the quick detection of irregularities.

Fundamentally, the ESP32 microcontroller functions as the central processing unit that manages the station's operations. Real-time data on fuel levels, flow rates, and system pressure can be continually monitored by integrating sensors such as flow meters, level sensors, and pressure sensors. For additional processing and analysis, this data is then wirelessly transferred to a central server or cloud platform using Wi-Fi or other communication protocols that the ESP32 supports. Additionally, the ESP32 allows for remote control of actuators such as pumps and solenoid valves, enabling automated gasoline delivery and guaranteeing accurate fuel management. Additionally, by utilizing IoT capabilities, the system may optimize fuel inventory management, improve operating efficiency through remote monitoring and control, and deliver predictive maintenance alerts based on sensor data analysis.

Additionally, the ESP32 microcontroller can support authentication and security access control systems, guaranteeing that only authorized individuals have access to vital infrastructure and fuel distribution devices. This improves security and keeps anybody from breaking in or interfering with the running of the gas station. Customers can also use their computers or smartphones to discover nearby stations, start fueling transactions, and remotely check fuel prices thanks to the ESP32's capabilities for integration with mobile applications and web-based interfaces.

Overall, the suggested smart E-fuel station methodology offers a complete solution for modernizing fueling operations, increasing operational efficiency, enhancing security, and offering a seamless user experience for fuel station operators and customers by utilizing the capabilities of ESP32 microcontrollers and IoT technologies. In order to remotely monitor and control vital station components, the system integrates a number of sensors and communication modules with the ESP32 platform. The technology can optimize fueling operations, detect anomalies like leaks or overflows, and guarantee prompt maintenance through real-time data collecting and analysis. Through a web interface or mobile application, users may communicate with the station and access functions including fueling session reservations, payment processing, and usage data. Additionally, the incorporation of IoT technology promotes interoperability and scalability by enabling smooth connectivity with other smart devices and systems. In addition to lowering operating expenses, the smart e-fuel station advances environmental objectives by utilizing renewable energy sources and energy- efficient parts. All things considered; the suggested methodology provides a thorough way to update traditional fueling.

The ESP32 microcontroller would function as the main processing unit, coordinating the other components' interactions. The station would have sensors installed to keep an eye on things like pressure, temperature, fuel levels, and ambient variables. These sensors would gather data continuously, sending it to the ESP32 via Bluetooth or Wi-Fi. Real-time data processing by the ESP32 would allow the station to detect anomalies, optimize fuel management, and, if needed, initiate automated replies or alerts. Furthermore, the ESP32 might make it easier to communicate with a cloud platform or centralized management system, enabling remote data processing, maintenance scheduling, and monitoring. Additionally, the ESP32 could communicate with actuators to regulate several stations. In a similar vein, actuators can receive commands from the server that cause activities to happen, such turning on fuel dispensers or changing environmental settings.

IV. LITERATURE SURVEY

A detailed literature study is conducted based on the goals outlined for the work done, and the key findings are provided in this parts. V. Sagar and others [1] The study investigates outlet automation using an Internet of Things-based petrol station retail automation and alarm system. Hourly stock and sales updates are sent to outlet dealers by the system. One of the outlet's biggest problems is that customers get the same quantity of fuel for their money. Staff members occasionally become sidetracked when dealing with users and refill their tanks without resetting the dispenser's nozzle. Punit Gupta et al.'s work [2] aims to design and implement a smart gas pump in which the station's fuel quantity is measured and the value is transmitted. The research A gadget that can be inserted in a vehicle's tank is used by Jadhav et al.

to ensure that customers are not misled about the amount of fuel. The fuel tank surface is where the ultrasonic range finder is installed, and it is set up to emit eight pulses over the course of ten microseconds. The ultrasonic range finder measures the time it takes to receive these pulses. The gasoline level's distance from the ultrasonic range finder is measured. When the gadget is turned on, an LCD display interfaced with a microcontroller shows the fuel value as of right now. We have covered the numerous noteworthy research that have been linked to in relation to our findings in this publication.

V. HISTORICAL PERSPECTIVE

The automotive industry has witnessed a shift due to the development of Internet of Things (IoT) technologies. The advent of smart fuel stations, which make use of Internet of Things gadgets like the ESP32 microcontroller for improved functionality and efficiency, is one noteworthy development in this field. These stations offer a combination of automation, connection, and data-driven insights, marking a substantial divergence from conventional fuel stations. In the past, fuel stations have mostly run on manual systems, requiring human involvement for operations like inventory control, payment processing, and fuel dispensing. But as IoT technology has emerged, gas stations have experienced a significant metamorphosis. Real-time monitoring and control of several station operations elements have been made possible by the integration of sensors, actuators, and modules. The development of ESP32 microcontroller- powered smart e-fuel stations for the Internet of Things represents a breakthrough in sustainability and energy management.

Historically, the growth of transportation infrastructure and the increasing need for quick recharging options have been directly correlated with the evolution of gas stations. Beyond simple pump automation and payment systems, traditional fuel stations mainly relied on manual operations with minimal technological integration. But when IoT (Internet of Things) technology advanced, the environment started to change. Real-time monitoring and management of multiple features within fuel stations was made possible by the integration of sensors, actuators, and communication solutions. More sustainability, safety, and efficiency were made possible by this change. The creation of ESP32- powered IoT-based smart e-fuel stations is a result of the coming together of environmental awareness and technology progress. Conventional fuel stations have long been a vital component of the transportation network, but they also greatly increase pollution and carbon emissions. Understanding this, creative thinkers have looked for methods to update existing stations so they meet sustainability targets and increase operational effectiveness. The introduction of IoT technology, which transformed device connectivity and data exchange, marks the beginning of the historical trajectory. The idea of "smart infrastructure," in which sensors and actuators are placed to remotely monitor and manage various systems, was made possible by this technical advancement. In the meantime, the development of microcontroller platforms such as ESP32 offered affordable and adaptable solutions for Internet of Things applications. The Internet of Things (IoT)-based smart E-Fuel station would provide a number of advantages with successful deployment, such as increased operational effectiveness, lower maintenance costs, better inventory control, and customized client experiences.

VI. MAJOR CONTRIBUTIONS

One notable development in the field of fuelling infrastructure is the ESP32-based IoT-based smart e-fuel station, which combines advanced technology with traditional systems. This creative approach has significantly changed the way gas stations are positioned in the market. First off, real-time monitoring and control are made possible by the integration of ESP32 microcontrollers, which promotes smooth communication and data interchange between the station's numerous components. These microcontrollers are the brains of the system; they are incredibly efficient at coordinating tasks like fuel delivery, payment processing, and environmental monitoring. Second, the e-fuel station may be remotely managed and monitored thanks to the integration of IoT technology. Operators with an internet connection can obtain critical data like fuel levels, equipment status, and transaction logs from any location. This remote accessibility promotes prompt decision-making and increases operational flexibility.

VII. RESULTS

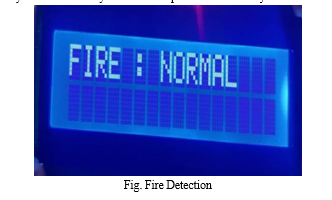

The ESP32 Microcontroller's interface with all the all-sensor data are transmitted to the ESP32 microcontroller. The ESP32- based IoT-based smart fuel station was implemented, and the results were remarkable. The station's efficiency and user experience were improved by achieving real-time monitoring and control capabilities through the integration of sensors and actuators with the ESP32 microcontroller. The station's numerous components were able to communicate with each other more easily thanks to the ESP32, which made it possible to remotely monitor the fuel levels, equipment status, and weather. Furthermore, the Internet of Things' capabilities made it possible to gather and analyse data, giving station operators the ability to better manage fuel, anticipate maintenance requirements, and guarantee that environmental laws are followed. All things considered, the deployment showed how ESP32-based IoT solutions have the power to completely transform the way gas stations operate, providing enhanced sustainability, dependability, and customer convenience. This lowers the need for manual intervention, lowers the possibility of mistakes, and guarantees prompt service delivery. IoT connectivity also makes it possible to remotely monitor and

???????

???????

Conclusion

In this study, by reducing labour costs, capital requirements, and enabling intelligent transactions, the IoT-based smart fuel station system we developed to accomplish this work\'s primary goal will assist in modernizing the traditional gas station. In the future, the system can be enhanced by adding a bill printer, a density tester, and a touch screen display to give the user an intuitive interface. With just one RFID/Wi-Fi card, clients can obtain gasoline at all gas stations and take advantage of the prepaid card recharge feature offered by this system. In the future, the system can be enhanced by adding a density checker, bill printer, and touch screen display to provide the user with an intelligent interface. Reducing corruption can be achieved by using the technique of differentiating between regular card users and government card users. By implementing this project in retail locations, the amount of time spent monitoring the depth of gasoline in tanks—which was previously verified by hand using a large gauging scale, measuring the density and heat of gasoline, stock totalling, can be decreased. increasing the fuel pump\'s lifespan by activating an alert system in the case of a trip or an overload. Additionally, this system requires extremely little and easy maintenance. When there are volume losses in hot weather and volume gains in cold weather of gasoline owing to thermal expansion, measuring the temperature of the weather is very helpful.

References

[1] IoT-based smart fuel pump (Gupta P, Pat Odiya S, Singh D, Chhabra J, Shukla A). Vol. 2016, IEEE, Waknaghat, India, Fourth International Conference on Parallel Distributed and Grid Computing, 2016, pp. 28–32. [2] Gowri Shankar EMR, Baskaran D. Petrol bunk automation with petrol card and biotelemetry system. Engineering Research & Technology International Journal. 2016 [3] Pathan Saddam I, Pawar H, Patel Tosif N, and Waverer Asrar a automatic gas pump with RFID technology. 2016; 4:1333– 1334 in International Journal for Scientific Research & Development. [4] Kumaresan P, Babu Sundaresan Y. Fuel station automation and alarm system automation with Internet of Things. In: IOP Conference Series: Materials Science and Engineering Conference Series, 2017. 042072 [5] Akarsh J, Burugupalli PKK, Chandana K, and Chirag M. Refuelling RFID smart cards with a Raspberry Pi. [6] Haidar B., Makdessi C. using microcontrollers and SCADA to automate and monitor gas station tanks. International Journal of General Science and Engineering Research. 2017 [7] Divya R, Deepu N, Debashree B, and Deepa D. RFID pre- paid cards are used in an automated, multipurpose fuel dispensing system. In: Bangalore, India, during the 2018 International Conference on Design Innovations for 3Cs Compute Communicate Control (ICDI3C). IEEE, 2018. 69– 74 pages. [8] Rahman MM, Pratto MB. An automated gasoline refilling and alerting system that uses RFID authentication and telematics notification for vehicle fuel monitoring and management. Held in Bali, Indonesia at the 2019 International Conference on Advanced Computer Science and Information Systems (ICACSIS). 2019 IEEE, pp. 477–482. [9] Atmajaya H, Sembodo BP. Arduino and the internet of things were used in the design of the smart fuel station and administration system. [10] An innovative smart railway platform assist in domestic railway stations is presented by D. R. Bolla, D. R. Rajesh, Shivashankar, M. Abhiram, B. K. C.S., and M. K. B. V. at the 2018 IEEE 3rd International Conference on Recent Trends in Electronics, Information & Communication Technology (RTEICT), Bangalore, India, 2018, pp. 2608–2612, doi: 10.1109/RTEICT42901.2018.9012272. [11] In the 2nd IEEE International Conference on Recent Trends in Electronics, Information & Communication Technology (RTEICT), Bangalore, 2017 (pp. 2247–2251), D. R. Bolla and Shivashankar present \"An efficient protocol for reducing channel interference and access delay in CRNs\" (doi: 10.1109/RTEICT.2017.8257000). [12] The paper \"Reconfiguring CPLD to perform operations based on sequence detection condition\" was written by M. Penna, J. J. Jijesh, D. R. Bolla, M. S. Pramod, and P. Satya Srikanth in 2012. Bangalore, India, June 16, 2016 IEEE International Conference on Recent Trends in Electronics, Information, and Communication Technology (RTEICT)

Copyright

Copyright © 2024 B. Amulya, Deekonda Bhargavi , Noone Ankita, Rayapudi Gopi Lavan. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62729

Publish Date : 2024-05-26

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online