Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Research on IoT Based Industrial Monitoring and Protection System

Authors: Sirin Kumari M, Tejasree A, Sahithi K, Sai Kiran G

DOI Link: https://doi.org/10.22214/ijraset.2024.62987

Certificate: View Certificate

Abstract

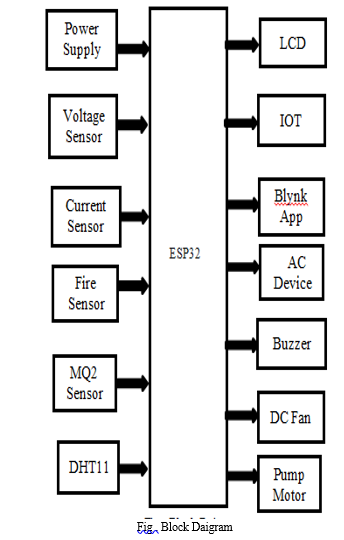

ESP32 microcontroller integration is used in an Internet of Things system created for industrial monitoring and security. The device has multiple sensors built in system to collect critical environmental and operating data, such as voltage, current, fire, MQ2 gas, and DHT11 temperature and humidity sensors. For remote monitoring and analysis, an IoT platform hosted in the cloud can process and transmit data more easily thanks to the ESP32 microcontroller. Industrial parameters can be managed and visualized in real time using the Blynk application as an interface. A DC fan, pump motor, buzzer, LCD display, and AC device control are examples of output actuators included in the system. Through using these actuators, industrial environments can be made safer and more efficiently run by enabling automated responses to recognized anomalies or predefined thresholds.

Introduction

I. INTRODUCTION

IoT technology integration has completely changed how firms monitor and secure their operations in today's industrial world. In order to improve productivity as well as guarantee safety, this introduction provides a thorough overview of an Internet of Things-based industrial monitoring and protection system. Numerous sensors are included in the system, such as temperature and humidity sensors DHT11, fire, voltage, current, and MQ2 gas sensors. An ESP32 microcontroller is accustomed to link these sensors and collect data. The sensor data is transferred to the cloud for real-time monitoring and analysis by utilizing IoT connection and platforms like Blynk. An LCD display, buzzer, AC device control, DC fan, pump motor, and other actuators are among the actuators in the system that allow for automated reactions to anomalies or predetermined thresholds. In industrial settings, this integration of sensors and actuators facilitates proactive monitoring, quick response, and intelligent decision-making, which eventually improves operating efficiency and strengthens safety procedures.

II. RELATED WORK

- Shashank Kumar draws attention to the rise of Industry 4.0, a term that came from the German context and has become well- known since it was first used in 2011 at the Hannover Trade Fair. It is an example of cooperation between the public, private, and academic sectors with the intention of increasing German industry's competitiveness. The idea was welcomed by the German federal government, which included it in their "High- Tech Strategy for Germany 2020" project. Germany's commitment to enhancing industrial capacities and promoting economic growth is emphasized by this policy, which seeks to establish the country as a global leader in technical innovation.

- Beata ?lusarczyk's article explores the utilization of cyber- physical systems (CPS) and smart items in advanced shop floor design and manufacturing industry production processes. Things connected to the Internet (IoT) and its ramifications are the subject of several articles in this field. In particular, S. Wang et al. (2015) describe a smart object-based shop floor that uses sophisticated tools and smart agents to convert simple systems into self-organizing ones. All tools and machines are made intelligent through the application of IoT and CPS, and different agents are categorized to make data collecting and coordination easier. To improve coordination, Wang et al. also present an intelligent bargaining system. Furthermore, virtual engineering object (VEO) technology is introduced by S. Shafiq et al. (2015) for enhanced visualization of smart object coordination.

- The idea of Cyber-Physical Systems (CPS), which involves integrating biological and artificial systems to process information, communicate data, and control feedback processes between the physical and cyberspace realms, is covered by Priyanka Verma and Jyoti Kushwaha (Bagheri et al., 2015). Using embedded subsystems, networked systems in CPS monitor and manage physical processes. To create a coherent physical system, these subsystems include a variety of sensors, computers, and wireless communication devices. Devices are identified by their physical attributes or by data sensing systems like as infrared sensors or radio frequency identification (RFID). They are then connected by networking systems, which usually use the Internet.

- Research by Haradhan Kumar Mahajan, Jaime Ventura, and Hans-Joachim Voth suggests that Britain's big borrowing during the Industrial Revolution (IR) helped the textile and iron sectors grow, additionally agricultural reform. Both significant societal shifts and a alteration in trade patterns were sparked by these events. During the Industrial Revolution, Vijaya Singh highlighted the advances in technology brought about by machines [69]. Robert C. claims that when comparing Britain to other continents, earnings were noticeably higher and energy costs were lower. As a result, these economic advancements led to a significant increase in living standards across the board in Britain.

- Using IoT, G. Elumalai, G. Nallavan, and Assistant Professor R. Rama Krishnan suggested a Smart Industry Monitoring and Controlling System. They created an Arduino UNO-based prototype that can detect gas concentrations. The sensor uses a WiFi device (NodeMCU) to provide data to the cloud about characteristics like temperature, humidity, and gas levels. When gas concentrations surpass the standard range, Google Cloud sends out a first alert that shuts off the gas leak. If required, a follow-up notice is then dispatched by Short Message Service (SMS) to initiate remedial measures and guarantee the return of safe limits. Also emphasized is the responsibility of the government, particularly in managing power outages in industrial environments.

III. PROPOSED METHODOLOGY

The idea behind the suggested strategy for the network of things online based industrial monitoring and protection system is to employ a range of instruments and sensors to monitor activities in factories or other industrial settings to act remedially when anything goes wrong. Think about implementing industry-specific sensors, like to those found in smart houses. These sensors are capable of taking temperature readings. And humidity in addition to checking voltage and current, detecting fires, and monitoring gas levels. They all linked to an ESP32, a compact but potent computer that serves as the system's central nervous system.Now that this ESP32 is online, it can transmit all the data it collects to a unique specifically designed web platform for the Internet of Things (IoT). It involves more than just data collection; it also involves texting a central control center from which everyone can monitor the status of any message. It's not just for show, as this platform is linked to the Blynk smartphone app. By using this software, users caN check the status of the message. This platform is connected to a smartphone app named Blynk, so it's not just for show. With this app, users can easily use their cellphones to remotely operate gadgets and keep an eye on things.

The ESP32 does more than simply wait around when it detects an unusual event, like a fire or gas leak. It sets out alerts, shows cautions on a screen (similar to those used in elevators), and has the capacity for switch off equipment or turn on safety features like fans or sprinklers to remove harmful gases. The goal of the entire arrangement is to guarantee the efficient and secure operation of plants. Internet of Things technologies enable you to monitor things from anywhere, even if you're not physically present at the factory. The sensors and other components of the system also allow it to respond to circumstances quickly smart controls in place, which helps to reduce accidents and ensure the safety of personnel and equipment.

The manufacturing and/or industrial sectors are regularly developed to fulfill the needs of numerous industries, including oil, gas, water/wastewater, electricity, and others. Over the past 20 years, the introduction of IP-centric network technology has produced several breakthroughs, including remote information transfer and system control and monitoring. Furthermore, new developments in the integration of IOT smart technology with network-based industrial infrastructures have enabled the system to achieve a several objectives, including improved performance accuracy, system scalability, efficiency, and capital savings.

IV. IMPLEMENTATION AND RESULTS

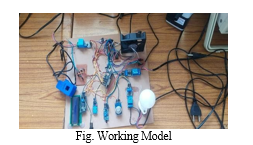

The execution of an IoT-based industrial monitoring and protection system incorporates a suite of sensors and actuators integrated with an ESP32 microcontroller and linked to the Internet through IoT technology. The sensors include voltage, current, fire, MQ2 gas, and DHT11 sensors, which gather crucial data related to the industrial environment The ESP32 microcontroller, which is interfaced with these sensors, functions as a gateway for the data acquired by means of Internet of Things protocols.

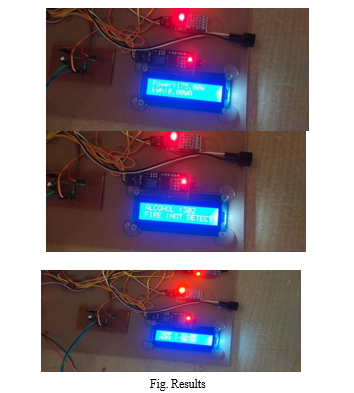

With platforms like Blynk, data can be seen and tracked remotely after it has been transferred to the cloud. Regardless of their physical location, users can stay up to date on the state of industrial operations with the Blynk app's intuitive interface for real-time monitoring of industrial metrics. Because it enables prompt interventions and adjustments based on real-time data, this remote monitoring capacity improves operational efficiency.

A variety of actuators are included in the system for automated reaction and control in addition to monitoring. These actuators consist of a DC fan, pump motor, buzzer, LCD display, and AC device control. After processing the sensor data, the ESP32 microcontroller determines whether to initiate the necessary actions in response to predetermined thresholds or abnormalities. For example, in the event that the fire sensor identifies a fire hazard, the system can sound an alert, show pertinent information on the LCD display, and take action to stop the fire from spreading, such as turning off the AC device.

Additionally, the system has the ability to dynamically modify parameters in response to environmental circumstances that the sensors detect. For instance, to maintain ideal conditions in the industrial setting, the DC fan can be turned on or off based on the temperature and humidity readings from the DHT11 sensor. In a similar vein, to reduce potential risks, the pump motor may turn on in reaction to gas leaks that the MQ2 sensor detects.

The results of implementing such a system are significant regarding enhancing operational efficiency, ensuring safety, and enabling remote management of industrial processes. By leveraging IoT technology, the system provides real-time visibility into the industrial environment, allowing for proactive monitoring and rapid response to potential issues. This proactive strategy reducesdowntime, reduce risks, and optimize resource utilization.

Overall, putting into practice an IoT-based industrial monitoring and protection system represents a significant advancement in industrial automation and safety. By combining sensor data with IoT connectivity and intelligent actuation, the system provides a robust framework for enhancing operational efficiency, ensuring safety, and facilitating remote management of industrial processes.

Conclusion

The IoT-based industrial monitoring and protection system that we have looked at essentially combines IoT technologies, an ESP32 microcontroller, and a sensor network to offer a full industrial safety and efficiency solution. The sensors that collect data from voltage, current, fire, gas, and environmental elements enable the system to provide real-time insights into the operational parameters of industrial operations. This data can be remotely accessed through interaction with platforms such as Blynk, facilitating prompt decision-making and proactive management. Additionally, the system\'s capacity to communicate with actuators—such as buzzers, LCD screens, and other machinery—allows for automated reactions to anomalies that are recognized, guaranteeing prompt interventions when needed. In industrial settings, this integrated approach provides a potent tool for improving safety, streamlining operations, and facilitating remote monitoring.

References

[1] Dai, B. (2019). Design of an intricate parameter control system for wind power generation using embedded control and the internet of things. 17(2), 131–139; Web Intelligence. 10.12323/web-190407 at https://doi.org [2] In 2020, Wang, X., and Cai, S. An IOT Cloud Framework with named data networking that is efficient. 3453–3461 in IEEE Internet of Things Journal, 7(4). 10.1109/jiot.2020.2971009 can be found here. [3] Majumdar, A., and Saha, S. (2017). Cloud-based dashboard with Real-Time Alert System and wireless sensor network based on ESP8266 for data center temperature monitoring. Integrated Circuit Devices, 2017 (DevIC). 10.1109/devic.2017.8073958 is available online. [4] Y. P. Chawla (2022). Wi-Fi Electrical Power Network is strengthened by Wi-Fi Computing Network. Big-Data Analytics in Wireless Ad-Hoc Networks Enhanced by Cloud Computing, 49–64. The doi: 10.1201/9781003206453-4 is available. [5] Lee, H.-S., Kim, S.-K., and C.-H. Lee (2017). An investigation into how dust and wind speed affect the photoelectric smoke detector chamber\'s response characteristics. 31(1), 50–57; Fire Science and Engineering. The article\'s DOI is 10.7731/kifse.2017.31.1.050. [6] Charmongkolpradit, S., and Luampon, R. (2019). Heat and relative humidity have an impact on the cassava pulp\'s equilibrium moisture content. Agricultural Engineering Research, 65(No. 1), 13–19. The publication 10.17221/112/2017-rae [7] Simple-web-server: A quick and adaptable C++ client and server library for HTTP/1.1, by O. Eidheim, Journal of Open Source Software, vol. 4, no. 40, p. 1592, 2019. [8] \"Vessel detection and tracking method based on video surveillance,\" N. Wawrzyniak, T. Hyla, and A. Popik, Sensors, vol. 19, no. 23, p. 5230, 2019. [9] K. Gulati, Big Data, IoT, and Machine Learning, pp. 153–184, 2020; \"Latest Data and Analytics Technology Trends that Will Change Business Perspectives.\"

Copyright

Copyright © 2024 Sirin Kumari M, Tejasree A, Sahithi K, Sai Kiran G. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62987

Publish Date : 2024-05-30

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online