Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Response Optimization of Machining Parameters using MCDA-Vikor Method for Acrylic Glass with AHAJM

Authors: Y. Rameswara Reddy

DOI Link: https://doi.org/10.22214/ijraset.2023.54596

Certificate: View Certificate

Abstract

Abrasive Hot Air Jet Machining (AHJM) is becoming one of the most prominent machining techniques for Polymethyl Methacrylate (PMMA) and other brittle materials. In this attempt has been made to combine abrasive and hot air to form an abrasive hot air jet. Abrasive hot air jet machining can be connected to different tasks, for example, boring, surface scratching, scoring and small scale completing on the glass and its composites. The impact of air temperature on the material expulsion rate connected to the procedure of glass carving and scoring is talked about in this article. The unpleasantness of the machined surface is additionally investigated. It is discovered that the material removal rate (MRR) increments as the temperature of transporter media (air) is expanded. In the present work to be attempt to investigate machining characteristics of PMMA material on hot air abrasive jet machining. In hot air abrasive jet machining(HAJM) abrasive particles stay on abrasive particle stay molten by compacted air in a closed chamber and are intensive over the objective surface over a nozzle the stream of particles coming out of the nozzle through very high velocity’s (175-300m/s) impacts the objective surface and eliminates the material by destruction. The investigation has to be carried on to study the effect of process parameters as material removal rate(MRR) as surface roughness(SR) with different input parameters like Air Pressure, , Size Of Abrasives , Stand-Off Distance ,Temperature Of Carrier Gas. In this experimental process Tungsten carbide coated nozzles were to be used flow of silicon carbide(sic) particles will be used.The Poly(methyl methacrylate) (PMMA), furthermore saw as acrylic glass, acrylic material, or plexiglass as suitably as by using the change names Plexiglas, Crylux, Lucite, Acrylate. PMMA it is an unquestionable thermoplastic .the creation formula of PMMA is (C5O2H8)n it has incredible properties to, for instance, lightweight, 92% Transparent observable light effect inside 3mm of thick material, extraordinary solidarity to consider another polystyrene. it\'s for the most part important in these zones, for instance, Because of its direct properties, lightweight and preferable quality took a gander at over glass, It was broadly used to make aircraft windshields, shades and weapon turrets. After this couple of different business applications were made for PMMA, for instance, glass material, façade arrangement, publicizing, vehicle headlamps, etc.,

Introduction

I. INTRODUCTION

Abrasive Hot Air Jet Machining (AHAJM) is a handling non-conventional machine which works materials without creating stun and heat. AHJM is applied for some, reasons like boring, cutting, cleaning, and drawing activity. In Abrasive stream machining, rough particles are made to encroach on the work material at high speed. A stream of rough particles is conveyed via bearer gas or air. The high-speed stream of abrasives is created by changing over the weight vitality of bearer gas or air to its Kinetic vitality and henceforth the high-speed flight.

Spouts direct grating plane in a controlled way onto work material. The high-speed grating particles expel the material by smaller- scale cutting activity just as fragile break of the work material. Machining, Drilling, Surface Finishing are the Major Processes that can be performed productively.

The procedure parameters are utilized like factors which impact metal evacuation. They are bearer gas, rough, and speed of grating, work material, and spout tip separation (NTD).

Rough stream cutting is utilized in the cutting of materials as different as Titanium, Brass, Aluminium, Stone, Any Steel, Glass, Composites and so on.

II. PRINCIPLE OF WORKING

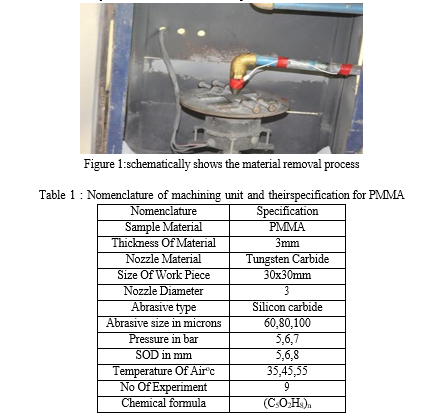

The grinding media can be passed on by a versatile hose to land at the inside, difficult to-land at zones. Second, AHAJM has restricted power and less warmth age than standard machining structures. Unpleasant fly machining (AJM) is seen as one of the most engaging systems that can engraving accurate dimples outwardly of hard and frail materials some judicious employments of AJM have recently shown its high potential as a littler scale machining methodology, for instance, improvement and completing of window glass. At the point when all is said in done, AHAJM is requested as effect wrapping up. The machining framework is perceived from ordinary shot affecting in that it incorporates a precision fly spout of under 1 mm in separation over, through which a controlled mass of fine, hard unpleasant particles is diligently gone for the workpiece surface. Thus, AHAJM can meet the essential for planning of significantly controlled little scale dimples onto the outside of difficult to-machine materials. From another viewpoint, AHAJM is a machining procedure that uses the ordinarily malevolent lead of breaking down, where fine, hard particles ambush the workpiece unremittingly, in a positive way. Material clearing in the AHAJM method is developed by the usage of a consistent fly, which is made by mixing unpleasant particles in with a rapid air stream, which last presents vitality to the grinding particles, enlivening them going before their impingement on the workpiece. The grinding particles serve fundamentally as the harsh medium, giving a different social event of little scale machining instruments supporting material ejection. Extraordinarily bound machining forces and low significance of made warmth are two Additional central purposes of AHAJM. Basically it might be portrayed as the material ejection process where the material is ousted or machined by the impact breaking down of the rapid stream of air or gas and unpleasant mix, which is revolved around to the workpiece. In Abrasive Hot Air Jet Machining (AHAJM), grinding particles are made to infringe on the work material at a fast. The fly of harsh particles is passed on by means of transporter gas or air. The rapid stream of harsh is delivered by changing over the weight imperativeness of the transporter gas or air to its engine essentialness and subsequently fast fly. The spout arranges the unpleasant stream in a controlled manner onto the work material, with the objective that the partition between the spout and the workpiece and the impingement edge can be set alluringly. The fast unpleasant particles oust the material by scaled downscale cutting action similarly as the delicate break of the work material. Fig. 1 underneath schematically shows the material removal process.

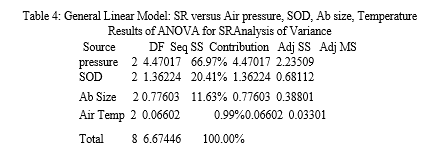

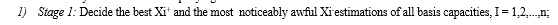

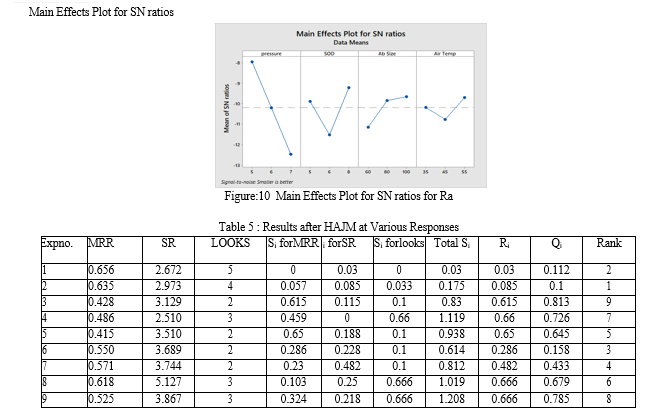

It tends to be seen the least demanding commitment is abrasive size has been done of 47.94% for MRR and pressure has been done 66.97% for SR. The unwinding of the parameters has less responsibilities. It is obvious that Air Pressure is one of the gigantic variables that have more effect than some different components on MRR and Ra regards.

B. Multiple-Criteria Decision Analysis (MCDA)

Procedure streamlining is the control of changing a procedure in order to advance (make the best or best utilization of) some predetermined arrangement of parameters without abusing some requirement. The most well-known objectives are limiting expense and augmenting throughput or potentially effectiveness. This is one of the major quantitative apparatuses in the mechanical making. When enhancing a procedure, the objective is to expand at least one of the procedure details, while keeping all others inside their limitations. This should be possible by utilizing a procedure mining apparatus, finding the basic exercises and bottlenecks, and acting just on them.

The closer to embraced me the plan of down to earth test through the MCDA-VIKOR comparability approach technique extremely valuable getting so great answer for advancement issues underway procedure. Various criteria basic leadership (MCDA) alludes to settling on choices within the sight of numerous, generally clashing, criteria. MCDA issues are normal in regular day to day existence. In close to the home setting, a house or a vehicle one purchases might be portrayed regarding value, size, style, security, comfort, and so forth. In the business setting, MCDA issues are increasingly confounded and more often than not of enormous scale. For instance, numerous organizations in Europe are directing hierarchical self-evaluation utilizing several criteria and sub-criteria set in the EFQM (European Foundation for Quality Management) business greatness model. Acquiring branches of huge organizations regularly need to assess their providers utilizing a scope of criteria in an alternate territory, for example, after-deal administration, quality administration, monetary strength, and so forth.

Despite the fact that MCDA issues are across the board constantly, MCDA as control just has a generally short history of around 30 years.

The improvement of the MCDA control is firmly identified with the headway of PC innovation. In one hand, the quick improvement of PC innovation as of late has made it conceivable to lead an orderly investigation of complex MCDA issues. Then again, the far-reaching utilization of PCs and data innovation has produced a tremendous measure of data, which makes MCDA progressively significant and helpful in supporting business basic leadership.

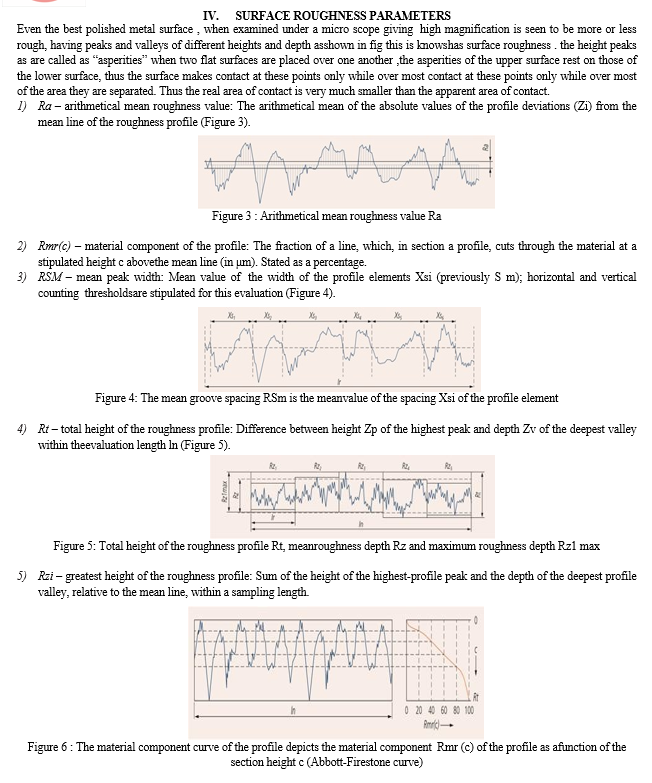

III. METHODOLOGY

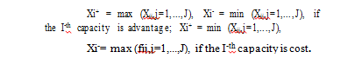

The multiple-criteria decision analysis (MCDA) strategy is well-known procedure broadly applied for deciding the best arrangement among a few choices having different properties or choices. An MCDA issue can be spoken to by a choice network (D) as pursues. The techniques for assessing the best answer for an MCDA issue incorporate registering the utilities of options and positioning these other options. The elective arrangement with the most noteworthy utility is viewed as the ideal arrangement. The accompanying advances are associated with VIKOR strategies.

- The VIKOR system has the accompanying advances:

Conclusion

In the present examination, MCDA-VIKOR is utilized to decide the ideal procedure parameters by utilizing multi-target work for accomplishing better yield reactions. The variety between the VIKOR results and Taguchi results are watched the advancing procedure parameters in AHAJM for better machining reactions indicated Table 5 The impact of the framework parameters viz. pressure, Abrasive size, Standoff segment and air temperature on the work material (PMMA) are examined for their impact on MRR a non-straight condition is being gotten and is indicated graphically and from the condition and the frameworks got two or three terminations are attracted which are as indicated by the going withas follow. It can likewise be reasoned that grating plane machining with silicon carbide rough is appropriate for hard and weak materials like glass, acrylic and fiberglass. It can likewise be reasoned that informs where material expulsion is of prime significance there standoff separation ought to be kept ideal, grating of coarser size ought to be utilized and high weight ought to be utilized. While in situations where surface completion is of prime significance low standoff separation high weight and better grating ought to be utilized. The parameters Pressure, SOD, Ab Size and Air Temperature and their collaborations, influence the deburring procedure. At lower MRR, the deburring time increments with the showdown separation. On account of higher MRR, the deburring time at first diminishes and on arriving at an ideal worth it increments with the SOD.

References

[1] P MUNI PAVAN KUMAR REDDY & Y RAMESWARA REDDY “Experimental Investigation of Machining Parameter for AJM using Nismonic Alloy 75” (IJTIMES),August-2018,(126-135). [2] N. Jagannatha, S.S. Hiremath, “ANALYSIS AND PARAMETRIC OPTIMIZATION OF ABRASIVE HOT AIR JET MACHINING FOR GLASS USING TAGUCHI METHOD AND UTILITY CONCEPT” (IJMME),January 2012,(9-15). [3] N.Jagannatha, S. Hiremath Somashekhar, “MACHINING OF SODA LIME GLASS USING ABRASIVE HOT AIR JET: AN EXPERIMENTAL STUDY” Machining Science and Technology · July 2012,(459-472). [4] Ahmed Nassef1, Ahmed Elkaseer1,2, El ShimaaAbdelnasser, “Abrasive jet drilling of glass sheets: Effect and optimisation of process parameters on kerf tape” Advances in Mechanical Engineering 2018, Vol. 10(1) 1–10. [5] V Srikanth, M. Sreenivasa Ra, “Abrasive Jet Machining- Research Review” International Journal of Advanced Engineering Technologizing J Adv Eng. Tech/Vol. V/Issue II/April-June,2014/18-24. [6] K. Anand Babu1*, P. Venkataramaiah1, and P. Dileep2, “AHP-DENG’S Similarity Based Optimization of WEDM Process Parameters of Al/SiCp Composite” Columbia International Publishing American Journal of Materials Science and Technology (2017) Vol. 6 No. 1 pp. 1-14. [7] Siva prasad PV and noorulHaq,”an entropy-deng’s similarity-based technique for modelling optimization of process variables for laser micro drilling alloy x”(jsandir).aprill-2019 pp(223-230). [8] Madhu.S, “Nozzle Design And Material In Abrasive Jet Machining Process-A Review” International Journal ofApplied Engineering Research, ISSN 0973-4562 Vol. 10 No.33 (2015),(25526-25533). [9] Eshwar Pawar, “A Review Article on Acrylic PMMA” IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE) e-ISSN: 2278-1684,p-ISSN: 2320-334X, Volume 13, Issue 2 Ver. I (Mar. - Apr. 2016), PP 01-04. [10] Bhaskar Chandra&, Jagtar Singh, A Study of effect of Process Parameters of Abrasive jet machining, (IJEST),(504-513) [11] Sudesh Garg, Ravi Kumar Goyal,” A Study of Surface Roughness in Drilling of AISI H11 Die Steel using Face Cantered Design” IJIRST, May 2015,(464-474). [12] Bhaskar Chandra Kandpal1* Naveen Kumar2 Rahul Kuma, “MACHINING OF GLASS AND CERAMIC WITH ALUMINA AND SILICON CARBIDE IN ABRASIVE JET MACHININ” IJAET/Vol.II/ Issue IV/October- December, 2011/251-256. [13] Varun R*, Dr. T S Nanjundeswaraswamy**”A Literature Review on Parameters Influencing Abrasive Jet Machining and Abrasive Water Jet Machining” Journal of Engineering Research and Application. ISSN : 2248-9622 Vol. 9,Issue 1 (Series -I) Jan 2019, pp 24-29 [14] Ahmad JafarnejadChaghooshi, Hossein Janatifar and MaedehDehghan. (2014). An Application of AHP and Similarity-Based Approach to Personnel Selection. International Journal of Business Management and Economics, 1(1), pp. 24-32.

Copyright

Copyright © 2023 Y. Rameswara Reddy. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET54596

Publish Date : 2023-07-03

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online