Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Review of Analytical Studies on The Failure of Granular Anchor Piles in Expansive Soil

Authors: Ashutosh Kumar Singh, Dr. Ashish Gupta

DOI Link: https://doi.org/10.22214/ijraset.2024.65237

Certificate: View Certificate

Abstract

Soft ground, characterized by a high content of clay, silt, peat, and loose sand, is generally unsuitable for constructing large structures due to insufficient stability. Ground improvement techniques, such as the use of stone columns (or granular piles), are often implemented in these areas to enhance load-bearing capacity and minimize settlement. The Granular Anchor Pile (GAP) is an advanced version of the stone column that includes an anchor to boost its tensile load-bearing or pullout capacity. In this study, formulations from various authors regarding the pullout capacity of anchors embedded in clayey soils are analyzed to assess the contributions of pile failure and anchor failure to overall GAP failure. The results indicate that GAP failure occurs due to two main factors: 50%–65% of the anchor length failing, and 35%–50% of the pile length failing. This breakdown helps in understanding the role of each component in the overall pullout capacity of GAP.

Introduction

I. INTRODUCTION

With rapid urbanization worldwide, the demand for land continues to grow, driven by population increases and the need to construct large structures like dams, bridges, and transmission towers. To meet this demand, all available land—including areas with soft soil—needs to be utilized. However, structures built on soft soils are often less stable. To address this, various ground improvement techniques, such as preloading, grouting, electro-osmosis, electrochemical hardening, lime column stabilization, Granular Anchor Piles (GAP), and stone columns, are employed to enhance soil stability.

In clay-rich soft soils, Granular Anchor Piles (GAP) have proven to be a particularly effective ground improvement method, especially for withstanding tensile or pullout loads on foundations. A GAP is essentially a stone column with an anchor added, enhancing its resistance to pullout forces. Compared to concrete piles, GAPs offer higher resistance to uplift loads?4?and are also more cost-effective.

Fig. 1.[7], In their 2009 studies, Madhav and Murali Krishna explored the advantages of using stone columns in regions with a high risk of liquefaction, highlighting their benefits over other ground improvement methods. To assess the pullout capacity of anchors under various soil conditions, they conducted several model tests. B. Raja M. Das [2] proposed an approximate method for estimating the pullout capacity of piles, taking into account the foundation shape (square, circular, or rectangular) and varying soil conditions, including soft clay, medium, and stiff soils. Meyerhof and Adams [10] noted the difficulty in accurately identifying the failure zone profile in soils, making it challenging to develop a pullout capacity theory based on the slip surface. Consequently, Adams (1968) formulated a theory that could be applied to anchors of various shapes, including circular, rectangular, and grouped configurations. .[15] An analytical method has been provided to determine the load-settlement behavior of anchors embedded in cohesive-frictional soils with a low length-to-diameter ratio, employing a nonlinear constitutive model. Jaswant et al. (2019) conducted extensive tests to examine how variations in the pile’s length-to-diameter (L/d) ratio, soil cohesion, and relative density influence the pullout capacity of granular anchor piles. They observed a significant increase in pullout capacity—up to 39%—with a higher L/d ratio, and found that increased relative density also enhanced the pullout capacity. Their research provided an expression to calculate critical and breakout loads for different anchor shapes, including strip, square, and circular anchors. This procedure was then validated against large-scale field and laboratory data to minimize errors. Using experimental results from Vesic [17], Meyerhof [9] developed a relationship for circular and square anchors. Merifield et al. [8] formulated a 3-D numerical method to analyze the effects of anchor shape when positioned horizontally in undrained clays. Laboratory results from soil tests with varying properties were compared with FEM analytical values by Ambily and Gandhi [1], obtained by conducting drained tests.

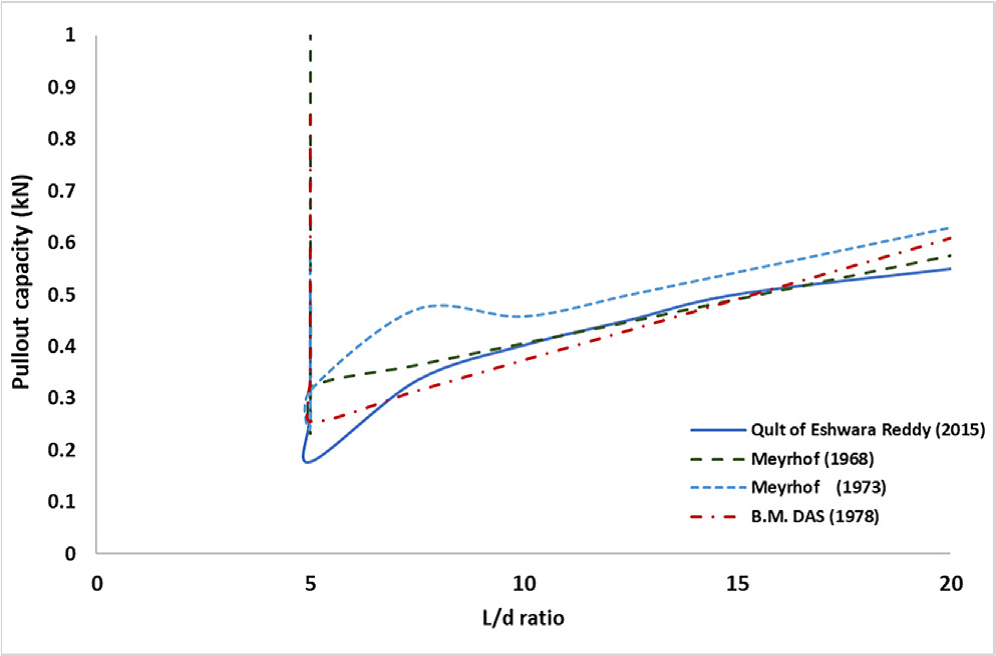

Fig. 1. Ultimate pullout capacity of GAP vs L/d ratio.

elastoplastic analysis using Mohr- Coulomb’s criterion for stones, sands, and soft clays. Shahu [16], Noolu et al. [11], and Krishna et al. [5,6] have introduced an innovative approach to predicting the deformation behavior of granular pile-reinforced soft ground under continuous loading. Reddy [14] carried out laboratory experiments to investigate how undrained shear strength and the pile's length-to-diameter (L/d) ratio influence the pullout capacity performance of granular anchor piles (GAP). Raghuram et al. [13,12] and Krishna et al. [5,6] conducted various laboratory tests on geosynthetic-encased granular anchor piles to improve their performance. Their findings showed a 95% reduction in heave formation in clayey soils. Most research has focused on estimating the pull-out load of piles and anchors separately, considering the impact of physical parameters of the pile (such as length, diameter, and surface area) along with the surrounding soil properties on the performance of granular anchor piles (GAP).

A. Granular Anchor Piles

In geotechnical engineering, granular anchor piles are specialized ground improvement techniques designed to enhance the stability and load-bearing capacity of soils, particularly in challenging conditions such as expansive or weak soils. These piles act as reinforcements to counteract soil movements and improve the overall performance of the soil. Granular anchor piles were developed to address soil-related issues, prevent settlement, and provide strong foundations for various structures.

- Purpose and Functionality: Granular anchor piles are strategically installed in soil to achieve targeted engineering goals. They work by distributing loads more uniformly, enhancing shear strength, and minimizing settlement. Acting as anchors, these piles resist uplift forces, lateral shifts, and general soil instability.

- Materials Used: Typically made from granular materials like crushed stone, gravel, or sand, these anchor piles form a reinforced zone within the soil. The selection of granular material is essential, as it impacts the pile's capacity to offer stable support and endure diverse environmental conditions.

- Installation Process: The installation process involves driving or positioning granular anchor piles into the soil at specific intervals and depths. The layout and spacing of these piles are carefully engineered to match the particular soil conditions and the structural demands of the project.

- Applications: Granular anchor piles are used in a wide range of civil engineering projects, such as providing foundation support for buildings, stabilizing embankments, and addressing settlement issues. They are especially beneficial in areas with expansive soils or regions susceptible to subsidence.

- Advantages:

- Improved load-bearing capacity: Granular anchor piles improve the soil's capacity to bear heavy loads.

- Settlement prevention: These piles help prevent settlement issues, ensuring the stability of structures.

- Versatility: Granular anchor piles are versatile and can be tailored to suit various soil types and project specifications.

- Cost-effectiveness: Compared to other ground improvement methods, granular anchor piles provide a cost-effective solution.

II. RESEARCH SIGNIFICANCE

Most research on granular anchor piles focuses on their performance under different load conditions and the changes in displacement relative to pullout loads. The current study aims to assess the impact of the percentage of pile length failure and anchor length failure on the overall failure of granular anchor piles (GAP). Additionally, the study examines how variations in soil properties influence the percentage of failure length in both the pile and anchor of GAP.

This research work will provide –

- Geotechnical Innovation: The study presents a new approach to soil stabilization using granular anchor piles. This innovative technique could provide an effective alternative to address the challenges posed by black cotton soil, contributing to advancements in geotechnical engineering practices.

- Problem-Specific Solution: Black cotton soil is recognized for its expansive and problematic nature, creating substantial challenges in construction projects. The research focuses on the issues associated with this soil type, offering a customized solution that improves the stability and performance of foundations in such environments.

- Improved Structural Performance: The successful use of granular anchor piles can greatly enhance the load-bearing capacity and settlement behavior of structures built on black cotton soil. This improvement in structural performance is vital for ensuring the safety and longevity of infrastructure.

- Cost-Effective Stabilization: If proven effective, granular anchor piles could provide a cost-efficient alternative to traditional methods for stabilizing black cotton soil. This approach could help reduce construction costs and make projects more economically viable, especially in areas where black cotton soil is prevalent.

- Risk Mitigation in Construction: Black cotton soil presents risks like settlement, heave, and differential movement, which can negatively impact structures. The research seeks to address these issues, enhancing the resilience and stability of foundations in regions where black cotton soil is common.

- Transferability to Other Soil Types: The insights from this study could extend beyond black cotton soil, as the principles and findings may be applicable to other soil types encountering similar geotechnical challenges, thus broadening the potential impact of the research.

III. METHODOLOGY & MATERIALS

A. Materials

The soil properties used in the experimental studies were sourced from [14], with the following characteristics: a maximum dry unit weight of 19.2 kN/m³, cohesion (c) of 54 kPa, angle of shearing resistance (?) of 25°, undrained shear strength (c?) of 69 kPa, dry density of 16.1 kN/m³, deformation modulus of 9.87 MPa, and specific gravity of 3.61. The soil consists of no gravel, 63% sand, and 37% fines. The consistency limits include a plastic limit of 14%, liquid limit of 31%, shrinkage limit of 12%, and a plasticity index of 17%. Based on [3] Part-4 (1985) and [14], the soil is classified as clayey sand with low compressibility (SC-CL).

B. Granular material properties

The granular material used as the filling element had a particle size of 6 mm. The properties of the granular material, as outlined in Table 1, were sourced from [reference needed].

Table 1

Granular material properties

Material properties Values

Specific gravity 2.65

Angle of shearing resistance 42

Dry unit weight 16.72KN/m3

IV. METHODOLOGY

The ultimate pullout capacity (Qult) of a granular anchor pile (GAP) is primarily influenced by the physical parameters of the pile and the surrounding soil.

In this study, the ultimate pullout capacity of GAP is analyzed analytically using various formulations provided by [10,9] and [2] for calculating the Qult of anchors in clayey soils. The total ultimate pullout capacity (Qult) of the granular anchor pile is considered as the sum of the Qult of the pile and the Qult of the anchor.The ultimate pullout capacity of an anchor embedded in clays is calculated using the following formulas:

Pullout capacity of pile is calculated using: QuPile = p d L a cu Where: A = surface area of pile(m2), H = depth of embedment (m), C = cohesion(kPa), c= unit weight (KN/m2), Ø= angle of shearing resistance, cu = undrained shear strength of soil(kPa)

The undrained shear strength of the soil is influenced by shear strength parameters such as cohesion (c) and the angle of shearing resistance (?), and they are directly proportional to one another. As the value of cohesion (c) increases, the undrained shear strength (c?) of the soil also increases, and conversely, a decrease in cohesion leads to a reduction in the undrained shear strength. The interplay between these parameters plays a significant role in determining the soil's resistance to shear under undrained conditions. From Table 3, it can be observed that as the undrained shear strength of the soil and the L/d ratio of the granular anchor pile (GAP) increase, the pullout capacity of the GAP also increases. Figure 1 illustrates the comparison between the experimental values of from [14] and the calculated values. The plot demonstrates that the pullout capacity calculated using EQ-3 closely matches the experimental values provided by [14]. Therefore, EQ-3 is adopted for further analysis.

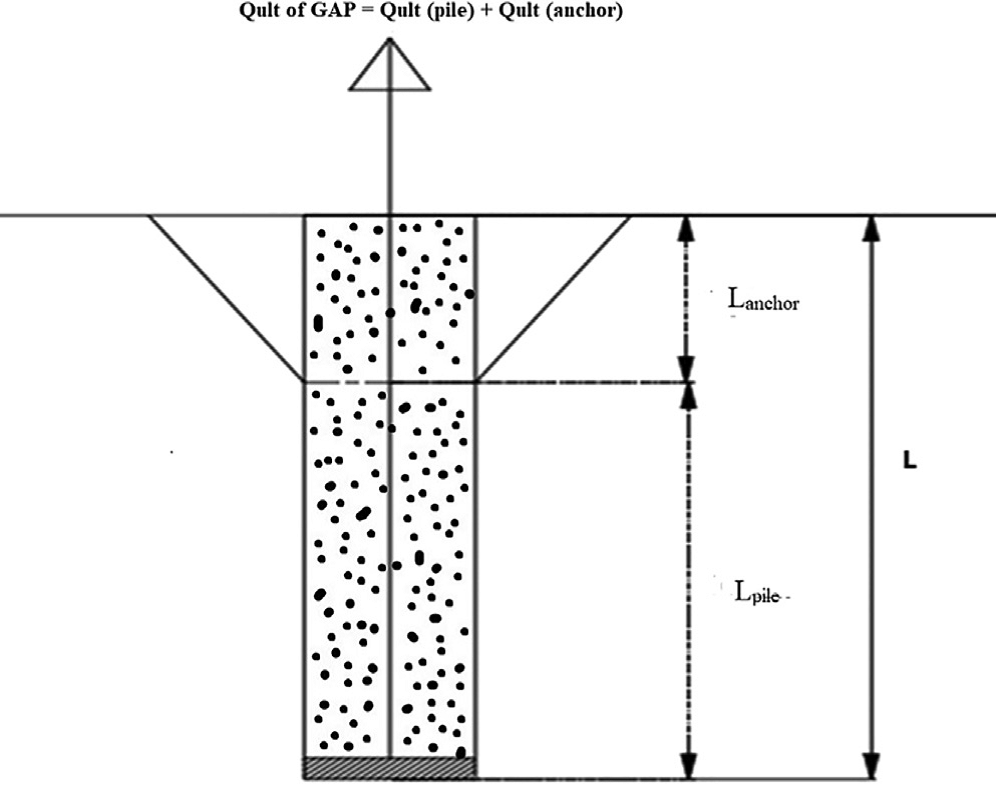

The present study aims to evaluate the contribution of the percentage of pile length failure and anchor length failure to the overall failure of the granular anchor pile (GAP). To determine the percentage length at which the granular pile and the anchor begin to fail due to the pullout force acting on the GAP, the following procedure has been adopted:

- The total length of the granular anchor pile, denoted as "L," is divided into two segments: "Lpile" and "Lanchor." Here, Lpile represents the percentage length of the pile that fails, while Lanchor corresponds to the percentage length of the anchor that fails in the granular anchor pile (GAP).

- The ultimate pullout capacity of the granular anchor pile (GAP) is calculated using different length combinations. Here:

- Lanchor= anchor failure length

- Lpile = pile failure length

- L= total length of the granular anchor pile

Using Fig. 2, the various length combinations adopted for the calculation of pullout load are:

L1 = 90% * Lpile + 10% * Lanchor

L2 = 80% * Lpile + 20% * Lanchor

L3 = 70% * Lpile + 30% * Lanchor

Table 2

Different formulae for Pullout Capacity of anchor

Author Formula

Anchor Meyerhof(1968) Qu ¼ AðCNcu þ cHN0 quÞ (A) Where Ncu = (N0 qu _ 1) * cot Ø

Anchor Meyerhof (1973) Qu ¼ AðcH þ CFC Þ (B) Where Fc = 1.2 * (H/h)

Anchor B.M. DAS(1978) Qu ¼ D2(cu N0 cr + c L) (C) where N0cr = 7.56 + 1.44 (L/D)

L4 = 60% * Lpile + 40% * Lanchor

L5 = 50% * Lpile + 50% * Lanchor

L6 = 40% * Lpile + 60% * Lanchor

L7 = 35% * Lpile + 65% * Lanchor

L7 = 30% * Lpile + 70% * Lanchor

L8 = 20% * Lpile + 80% * Lanchor

L10 = 10% * Lpile + 90% * Lanchor

Fig. 2. Representation of failure length of pile and anchor in GAP.

- The length combination of GAP is chosen when, calculated values are approximately equal to experimental values.

- The process is repeated for different test designations of the granular anchor pile (GAP) by considering varying L/d ratios and soil properties. This allows for a comprehensive analysis of how changes in these factors influence the pullout capacity and failure characteristics of GAP under different conditions.

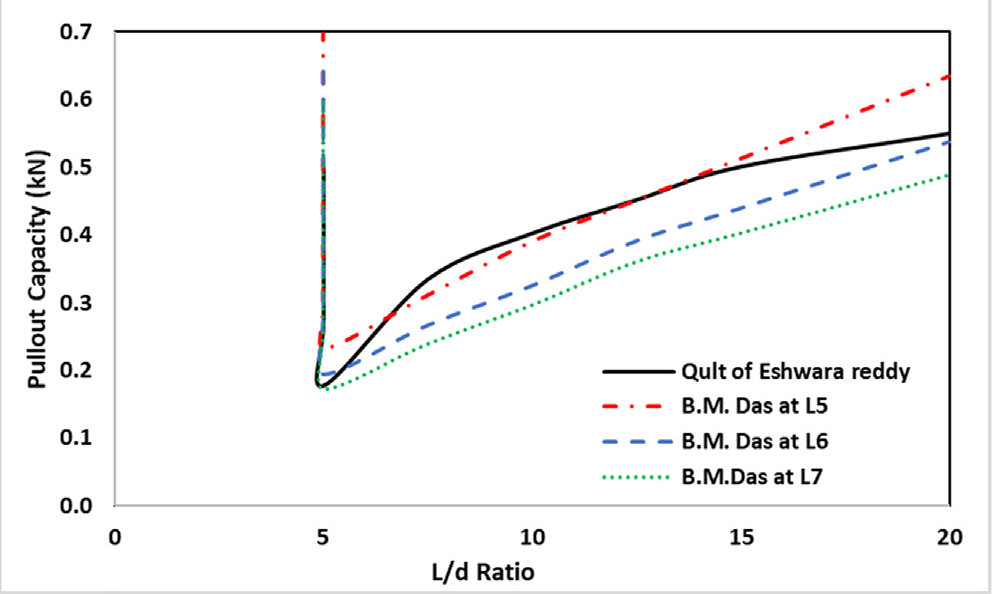

- It can be observed that as the percentage failure lengths change, the calculated values using EQ-3 vary in comparison to the experimental values. The specific length combinations at which the calculated values match the experimental values are analyzed, and it is found that **L5**, **L6**, and **L7** provide the best length combinations compared to the other combinations. These combinations offer the most accurate predictions of pullout capacity, making them optimal for further analysis.

Table 5 presents a comparison between the calculated values and the experimental values from [14]. The study reveals that at the length combinations **L5**, **L6**, and **L7**, the calculated values closely match the experimental values, indicating that these combinations provide accurate predictions of the pullout capacity.

Comparison of experimental values i.e., Qult of [14] values with the calculated values using EQ-3 are shown in Fig. 3. Change in ultimate pullout capacity w. r. t. L/d ratio of the GAP is shown.

Fig. 3. Pullout capacity of the GAP in cases- L5, L6, L7.

Fig. 3. Pullout capacity of the GAP in cases- L5, L6, L7.

From Table 4, it is observed that among the different length combinations (i.e., L5 ,L6, L7), L5 provides the most accurate values with the least percentage variation. Therefore, L5(i.e., L5 = 50% * Lpile + 50% * Lanchor**) best represents the contribution of the percentage length failure of both the pile and the anchor in the granular anchor pile (GAP), making it the optimal combination for analyzing pullout capacity.

Conclusion

To determine the ultimate pullout capacity of an anchor in a granular anchor pile, the formulation provided in [2] (EQ-3) yields more precise results compared to other methods. According to the study, the experimental and analytical values for the ultimate pullout capacity of the granular anchor pile are nearly identical for the length combinations L5, L6, and L7 of the GAP. i.e. (L5 = 50% * L pile + 50% * L anchor, L6 = 40%* L pile + 60%* L anchor, L7 = 35%* L pile + 65%* L anchor). The pullout capacity of the granular anchor pile (GAP) is determined when the anchor fails at 50%–65% of its length and the pile fails at 35%–50% of its length, which aligns with the experimental data. The study also observes that the pullout capacity of the GAP increases as the undrained shear strength of the surrounding soil and the length of the GAP embedment both increase.

References

[1] A.P. Ambily, S.R. Gandhi, Behavior of stone columns based on experimental and FEM analysis, J. Geotech. Geoenviron. Eng. 133 (4) (2007) 405–415. [2] B.M. Das, A procedure for estimation of ultimate uplift capacity of foundations in clay, Soils Found. 20 (1) (1980) 77–82. [3] IS 2720 Part 4 (1985). Methods of test for soils: Grain size analysis. [4] B.M. Krishna, V.G.P. Reddy, M. Shafee, T. Tadepalli, Condition assessment of RC beams using artificial neural networks, in: Structures, Elsevier, 2020, pp. 1–12. [5] B.M. Krishna, T.P. Tezeswi, P.R. Kumar, K. Gopikrishna, M.V.N. Sivakumar, M. Shashi, QR code as speckle pattern for reinforced concrete beams using digital image correlation, Struct. Monit. Maintenance 6 (1) (2019) 67. [6] B.M. Krishna, V.G.P. Reddy, T. Tadepalli, P.R. Kumar, Y. Lahir, Numerical and experimental study on flexural behavior of reinforced concrete beams: digital image correlation approach, Comput. Concr. 24 (6) (2019) 561–570. [7] M.R. Madhav, A.M. Krishna, Liquefaction mitigation of sand deposits by granular piles-an overview, in: Geotechnical Engineering for Disaster Mitigation and Rehabilitation, 2008, pp. 66 79. [8] R.S. Merifield, A.V. Lyamin, S.W. Sloan, H.S. Yu, Three-dimensional lower bound solutions for stability of plate anchors in clay, J. Geotech. Geoenviron. Eng. 129 (3) (2003) 243–253. [9] G.G. Meyerhof, Uplift resistance of inclined anchors and piles, Proc. 8th ICSMFE 2 (1973) 167–172. [10] G.G. Meyerhof, J.I. Adams, The ultimate uplift capacity of foundations, Can. Geotech. J. 5 (4) (1968) 225–244. [11] V. Noolu, B.M. Krishna, Y. Paluri, S. Mogili, Performance evaluation of recycled granular material as sustainable sub-base material, Mater. Today:. Proc.(2020). [12] A.S.S. Raghuram, B.R. Phanikumar, A.S. Rao, November). Load carrying capacity of expansive clay beds reinforced with geogrid-encased granular pile-anchors, in: International Congress and Exhibition‘‘ Sustainable Civil Infrastructures: Innovative Infrastructure Geotechnology”, Springer, Cham, 2018, pp. 35–44. [13] A.S.S. Raghuram, A.S. Rao, K. Purnanandam, Pullout behavior of geogridencased granular pile anchor embedded in expansive clays, Proceedings of Indian Geotechnical Conference, 2016. [14] O.E. Reddy, M.R. Madhav, E.S. Reddy, Ultimate pullout capacity of the granular pile anchors by laboratory model tests, Indian J. Geosynth. Ground Improvement 4 (1) (2015) 25–33. [15] S. Saran, G. Ranjan, A.S. Nene, Soil anchors and constitutive laws, J. Geotech. Eng. 112 (12) (1986) 1084–1100. [16] J.T. Shahu, Non-uniform granular pile–mat foundations: analysis and model tests, Geotech. Geol. Eng. 24 (4) (2006) 1065–1087. [17] A.S. Vesic, Breakout resistance of objects embedded in ocean bottom, J. Soil Mech. Found. Div. 97 (9) (1971) 1183–1205.

Copyright

Copyright © 2024 Ashutosh Kumar Singh, Dr. Ashish Gupta. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET65237

Publish Date : 2024-11-13

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online