Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Rice Grains Detection, Classification, and Quality Prediction Using Deep Learning

Authors: Ramya Asalatha Busi, Vaka Prasanna, Somala Sai Lakshmi Bhavana, Tallaparthi Yaswanth Kishore, Vanke Santhi, Yarram Venkata Sainath

DOI Link: https://doi.org/10.22214/ijraset.2024.59321

Certificate: View Certificate

Abstract

Rice, as the most consumed food worldwide, faces a continual demand, necessitating rigorous quality inspection for both local consumption and international trade. Manual quality assessment methods are fraught with issues such as time consumption, high costs, and error susceptibility. This research paper introduces an innovative solution employing Deep Convolutional Neural Networks (CNNs) to automate rice grain detection, classification, and quality prediction from scanned images. The methodology integrates comprehensive image pre-processing and quality assessment techniques, encompassing image acquisition, pre-processing, CNN architecture construction, model training, and evaluation. Notably, it includes noise removal and segmentation to optimize input images. The grain samples undergo image processing using MATLAB, where an algorithm is applied to analyze their features. Classification is then performed based on the color, shape, and size characteristics of the grains. Various image features are extracted such as centroids, mean intensity, chalkiness, and perimeter further aid in quality assessment. Performance evaluation of the trained model is conducted through confusion matrix analysis and computation of classification metrics like accuracy, specificity, sensitivity, precision, recall, and F1-score. This methodology offers a robust framework for automated rice grain classification and quality prediction, thereby significantly enhancing efficiency and reliability in the global rice industry.

Introduction

I. INTRODUCTION

Food serves as an essential requirement for sustaining life, without which survival is impossible. Thus, the daily consumption of high-quality food is imperative for human well-being. Despite India's status as a leading global producer of rice through agriculture, access to good quality food remains a challenge for many. Ensuring the quality of food is crucial for adequate nourishment, and the contemporary market demands untainted food grains free from adulteration. Food grains frequently harbor impurities like stones, damaged seeds, and broken granules, which diminish their composition and quality, impacting both nutrition and safety. However, detecting these inferior-quality grains in the market proves challenging. Traditional quality assessment methods, reliant on human visual inspection, are prone to inaccuracies. Hence, there is a pressing need for innovative technologies that can streamline the process of rice grain classification and quality prediction, enhancing efficiency and reliability across the rice industry value chain to ensure consumers receive safe and nutritious food.

Addressing these challenges, this research paper presents a novel approach that harnesses the power of Deep Convolutional Neural Networks (CNNs) to automate the detection, classification, and quality prediction of rice grains from scanned images. Through the application of advanced machine learning techniques, this approach seeks to transform the assessment of rice quality, providing a scalable and economical solution applicable throughout the rice production, distribution, and trading processes. By combining thorough image pre-processing with advanced quality assessment techniques, this method aims to enhance the accuracy, precision, and dependability of rice grain classification, effectively mitigating the shortcomings linked with manual inspection approaches.

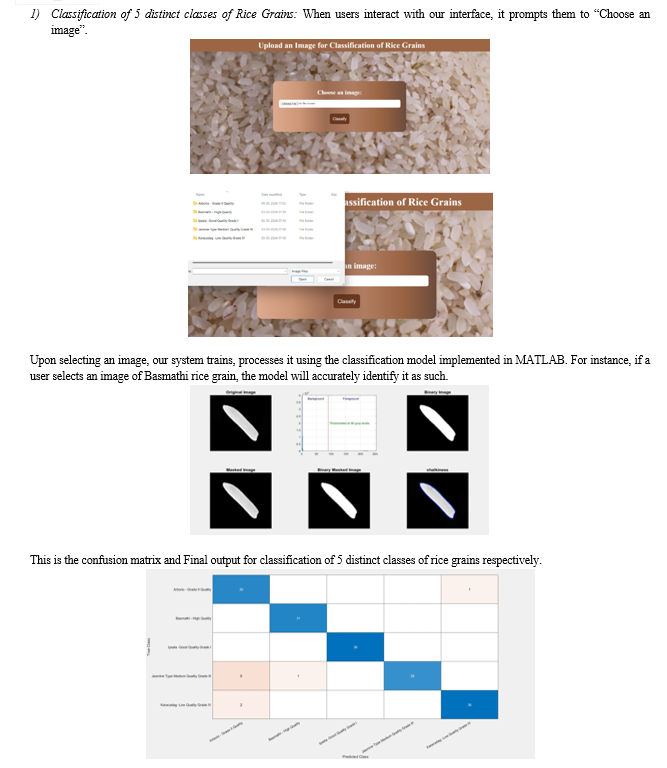

Our Rice Grain Quality Evaluation project is committed to advancing agricultural practices and ensuring the highest quality of rice production, providing numerous benefits to farmers and stakeholders. By enabling precise assessment of rice grain quality, our project facilitates early issue detection and minimizes crop losses. We meticulously implemented a systematic approach to classify five specific rice grain varieties commonly grown in Turkey: Arborio, Basmati, Ipsala, Jasmine, and Karacadag.

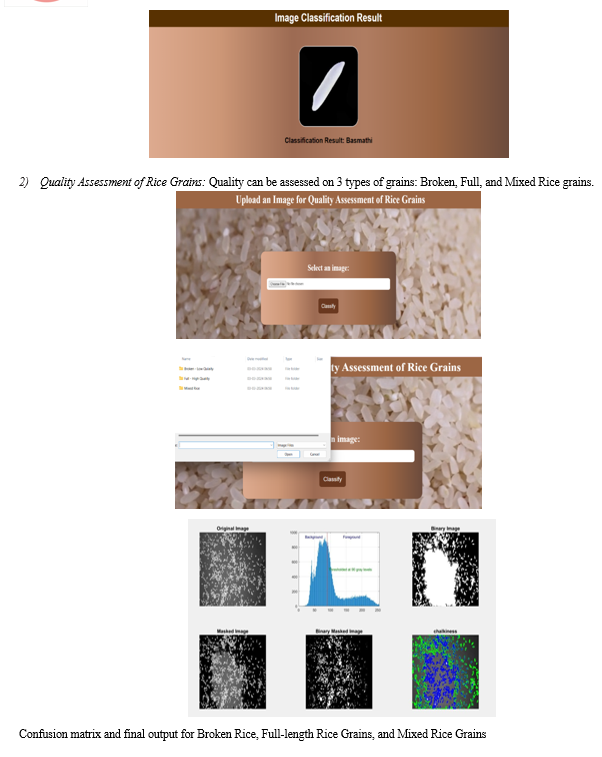

Furthermore, we focus on evaluating rice grain quality based on chalkiness, optimizing the assessment process for increased efficiency and accuracy while reducing reliance on labor-intensive methods. Leveraging convolutional neural networks, we developed a robust model capable of accurately assessing rice grain quality and addressing three distinct types of issues: Broken - Low Quality, Full - High Quality, and Mixed Rice. Our initiative also serves as an educational platform, fostering awareness and knowledge among students and agricultural experts, thus promoting sustainable advancements in rice production methodologies.

The project prioritizes a thorough image pre-processing pipeline, integrating noise removal and segmentation for optimal image analysis. A tailored CNN architecture enables precise classification of rice grain features, capturing subtle quality differences. Incorporating various image features like centroids and chalkiness enhances analysis depth. Extensive performance evaluation, including accuracy, specificity, sensitivity, precision, recall, and F1 score metrics, validates the methodology's efficacy. Rigorous analysis against ground truth data confirms the reliability of the automated system, promising efficiency and reliability enhancements in the global rice industry. This research advances automated quality control systems, boosting productivity, sustainability, and competitiveness in the rice supply chain.

II. LITERATURE REVIEW

As the food industry expands rapidly, the demand for precise methods to assess the quality of food grains at an early stage intensifies. Extensive research has been ongoing for a considerable period to develop effective measures for this purpose.

Qing Yao[1] presented an automated system employing machine vision for assessing rice appearance quality, addressing the inefficiencies and inconsistencies of manual inspection methods. The system integrates contacting angle analysis to segregate rice grains, an enhanced multi-threshold approach utilizing maximum entropy for chalkiness inspection, and the minimum enclosing rectangle method for evaluating rice shape. Evaluation across 21 rice varieties showcased the system's objectivity and efficiency in assessing rice quality.

Yong Wu and Yi Pan[2] have introduced an innovative method for measuring cereal grain size using digital image processing techniques. Their approach involves acquiring grain images via scanning, followed by meticulous preprocessing steps like image enhancement and morphological reconstruction. Subsequently, 2D Otsu segmentation accurately isolates individual grains from the background. Through comprehensive image analysis, parameters such as grain number, area, size, roundness, and size distribution are quantified, revealing each grain's intrinsic characteristics. Experimental results highlight the method's precision and efficiency, establishing it as a leading solution in grain size measurement.

Authors Megha R. Siddagangappa and A. H. Kulkarni[3] introduce an automated system to address the limitations of manual visual inspection in determining grain type and quality. Their approach utilizes a Probabilistic Neural Network for accurate and objective assessment. By employing color and geometrical features for classification, the system grades samples based on kernel size and impurity presence. With just six features - a mean of RGB colors and three geometrical attributes - the system achieves remarkable classification accuracy. Results demonstrate a 98% success rate in type identification and 90% and 92% success rates in quality analysis and grading of rice, respectively.

Authors Rubi Kambo and Amit Yerpude[6] propose a novel approach for basmati rice variety classification using principal component analysis (PCA). The paper emphasizes the importance of rice grain features in variety selection and introduces the PCA-based method as a solution. Experimental results confirm the effectiveness of the proposed methodology across diverse basmati rice samples.

Ahmad Fadzli Nizam Abdul Rahman and Siti Fairuz Abdullah[7] introduce an improved rice detection system for grading quality in the Malaysian agricultural industry.

The paper focuses on differentiating and classifying head and broken rice grains using image processing techniques, particularly the Moore-Neighbor Tracing method. The experimental analysis demonstrates high accuracy, reaching up to 95.83% in identifying rice quantity.

III. METHODOLOGIES

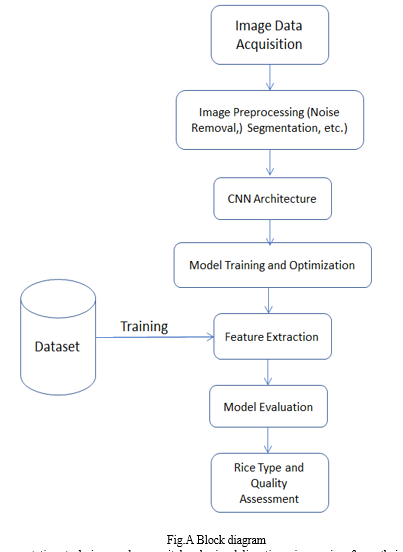

A. Implementation Of Block Diagram

- Step 1- Image Data acquisition: Collect images of rice grains from the dataset comprising 5 distinct classes. Organize these images into directories for efficient retrieval. High-quality and diverse image data are essential for effectively training a robust classification model.

2. Step 2- Image Pre-Processing & Segmentation:

a. Image Pre-Processing: Prepare images for analysis by applying various preprocessing steps. This includes reducing noise, enhancing contrast, and resizing to standardize image characteristics, ensuring consistent and high-quality input for subsequent analysis. Improving image quality and extracting pertinent features are essential steps for enhancing their utility in classification tasks.

- Noise Cancellation: Initially, noise cancellation techniques are applied to the rice grain images to remove any unwanted artifacts or disturbances, ensuring clean and clear images for further analysis.

b. Segmentation: Segmentation techniques play a vital role in delineating rice grains from their surroundings and any accompanying objects. This process is essential for precise classification, enabling the differentiation of individual rice grains for subsequent analysis.

- Masking: After obtaining binary images, specific regions of interest within the rice grain images are isolated using masking techniques. Masks are applied to highlight and extract individual rice grains or areas affected by defects, ensuring that only relevant information is retained for further analysis.

- Binary Masking: The masked images are further processed to create binary masked images, where the isolated regions of interest are represented in binary format. This step facilitates the extraction of key features and attributes from the rice grain images while filtering out unnecessary background noise or irrelevant details.

- Chalkiness Analysis: In conclusion, dedicated image processing algorithms assess chalkiness in rice grain images by analyzing intensity or color distribution within specific grain regions. This analysis offers crucial insights into chalkiness levels and their influence on grain quality.

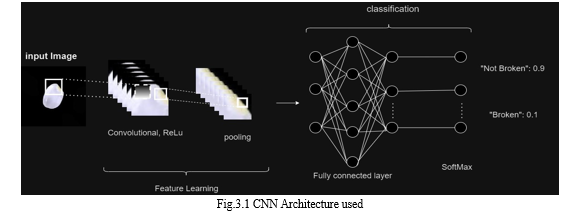

3. Step 3- CNN Architecture: We customize a CNN architecture for rice grain quality assessment, specifying layers and activation functions. The CNN learns to discern distinctive features that differentiate various types of rice grains through training with the provided dataset.

a. Input Layer: Receives rice grain images (128x128 pixels).

b. Convolutional Layer: Applies 16 filters (3x3 size) to produce 16 feature maps.

c. ReLU Layer: Applies ReLU activation function, setting negative values to zero.

d. Pooling Layer: Performs max pooling (2x2 window, stride 2), reducing feature map size to 64x64.

e. Fully Connected Layer: Flattens feature maps and passes through 256 neurons.

f. Output Layer (Softmax): Converts output scores to probabilities for 3 quality attribute classes.

4. Step 4- Model Training and Optimization: Divide the dataset into training, validation, and testing sets. Train the CNN model using backpropagation and gradient descent to optimize performance.

5. Step 5- Dataset, Training, Feature Extraction: Load and preprocess the dataset. Extract essential features like texture and color attributes from images. Extracted features, such as centroids and mean intensity, are utilized for both model evaluation and quality assessment, including metrics like confusion matrix and chalkiness analysis.

6. Step 6- Model Evaluation: Post-training, the CNN model's performance is assessed using an independent dataset. Metrics like confusion matrix, specificity, sensitivity, precision, recall, and F1-score are calculated to gauge the model's accuracy and efficacy in categorizing rice grains into distinct types.

7. Step 7- Rice Type and Quality Assessment: Utilize the trained CNN model for rice grain image classification and quality attribute evaluation. Quality assessment involves analyzing diverse rice grain attributes such as perimeter, chalkiness (indicative of rice quality), and histogram traits. These attributes provide insights into rice grain visual appearance and texture, influencing classification and overall quality evaluation, visualizations, including original images and histograms, aid in comprehending the classification process.

B. Rice Grains Classification

We gathered a dataset of 75,000 rice grain images from Kaggle, with each variety: Arborio, Basmati, Ipsala, Jasmine, and Karacadag-represented. To ensure fairness, we divided the dataset into training (52,500 images), validation (11,250 images), and testing (11,250 images) sets, allocating an equal portion for each rice type.

V. APPLICATIONS

- Agricultural Industry: Streamlines rice production by automating grain classification and quality assessment, optimizing resources, and improving yield.

- Food Processing: Facilitates efficient sorting and grading of rice grains in food processing facilities, ensuring consistent product quality.

- Research: Supports scientific endeavors in rice genetics, breeding, and crop enhancement by delivering precise classification data for analysis.

- Quality Control: Enables real-time monitoring and quality assurance in rice milling plants, maintaining adherence to industry standards.

- Market Analysis: Provides valuable market insights and consumer behavior trends derived from rice grain classifications, aiding strategic decision-making.

- Mobile Applications: Integration into mobile apps empowers farmers with on-the-go rice grain classification, empowering informed decision-making and enhancing productivity.

VI. ADVANTAGES

- Robustness: CNN models are robust to variations in rice grain appearance, including color, shape, and texture.

- Automation: Automates the classification process, reducing the need for manual intervention and labor-intensive tasks.

- Accuracy: Achieves high accuracy in classifying rice grains into different types and assessing their quality.

- Efficiency: Provides a fast and efficient method for processing large volumes of rice grain images.

- Adaptability: This can be adapted to handle diverse datasets and accommodate different rice grain varieties.

- Scalability: Scales well to handle increasing data volumes and can be deployed in various agricultural settings.

VII. LIMITATIONS

- Image quality significantly impacts classification accuracy. Poor resolution, lighting variations, or occlusions can result in inaccurate results.

- Limited generalization of the CNN model may occur if the training dataset lacks diversity in rice grain types, varieties, and quality attributes.

- Training Deep CNN models demands substantial computational resources, challenging real-time deployment or use on resource-constrained devices.

- Difficulty in capturing unique rice grain characteristics not well represented in the training data may lead to oversight or misinterpretation.

- Real-world deployment faces challenges such as changes in lighting, environmental factors, and physical restrictions, requiring further investigation and improvement for reliable operation.

VIII. FUTURE WORK

Moving forward, the proposed classification system can be enhanced through several avenues. Firstly, integrating more diverse and extensive datasets could bolster the model's ability to generalize and classify a broader range of rice grain varieties. Additionally, delving into advanced deep learning architectures or employing transfer learning techniques may further enhance classification accuracy. Integration with real-time image acquisition systems and deployment on edge devices could facilitate on-the-fly classification in agricultural settings, improving operational efficiency. Furthermore, exploring additional image features and optimization strategies could contribute to more comprehensive and efficient classification pipelines. Overall, ongoing research and development efforts hold promise for enhancing the system's utility and effectiveness in real-world applications, as evidenced by increased accuracy and effectiveness across various performance evaluation parameters, including measurements like centroid length and width of the grains.

IX. ACKNOWLEDGMENTS

- We appreciate everyone who contributed to developing and deploying this rice grain classification system using a Deep Convolutional Neural Network (CNN).

- We appreciate the researchers and developers whose work in computer vision, deep learning, and agricultural technology laid the foundation for rice grain detection and classification, guiding and inspiring our efforts.

- Special thanks go to the individuals and teams involved in data collection, annotation, and curation. Their meticulous efforts in preparing high-quality datasets were essential for training and evaluating the CNN models used in this project.

- We also extend our appreciation to the open-source community for providing access to libraries, frameworks, and tools that facilitated the implementation and deployment of the classification system. Their collaborative shared knowledge has been an invaluable resource.

- We are grateful for the teamwork, guidance, and collaboration that have enriched our project journey. We are thankful to Mrs. Ramya Asalatha Busi, our mentor, for their indispensable guidance, inspiration, and assistance from start to end of the project. Their knowledge base and perception have proved to be supreme in defining the path and the results of our work.

Conclusion

The research paper showcases an effective approach for classifying various types of rice grains using a Deep Convolutional Neural Network (CNN). Through rigorous image preprocessing, model training, and evaluation, this project demonstrates robustness in accurately categorizing rice grains. By leveraging advanced techniques such as noise removal, segmentation, and feature extraction, the model achieves commendable performance in discerning subtle differences among rice grain types. The evaluation metrics, including specificity, sensitivity, precision, recall, and F1 score, validate the model\'s efficacy in classification tasks. Overall, this solution provides a reliable framework for automating rice grain classification processes, contributing to enhanced efficiency and accuracy in the agricultural sector and the global rice industry.

References

[1] Qing Yao, Jianhua Chen, Zexin Guan, Chengxiao Sun, Zhiwei Zhu “Inspection of rice appearance quality using machine vision”, Global Congress on Intelligent Systems, 978-0-7695-3571-5/09, IEEE 2009. [2] Yong Wu and Yi Pan “Cereal Grain Size Measurement based on Image Processing Technology”, International Conference on Intelligent Control and Information Processing, August 13-15, 2010 - Dalian, China. [3] Megha R. Siddagangappa, A. H. Kulkarni “Classification and Quality Analysis of Food Grains,” IOSR Journal of Computer Engineering (IOSR-JCE), Aug. 2014. [4] Jaspreet Kaur, Vijay Kumar Banga “Image Processing in Quality Assessment of Pulses,” IJCEM International Journal of Computational Engineering & Management, Vol. 17 Issue 2, March 2014. [5] R.Kiruthika, S.Muruganand, Azha Periasamy “Matching of different rice Grains using digital image Processing”, International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering, Vol. 2, Issue 7, July 2013. [6] Rubi Kambo, Amit Yerpude “Classification of Basmati Rice Grain Variety using Image Processing and Principal Component Analysis,” VOL.11 number 2 May 2014. [7] Muhamad Marzuki Piramli, Ahmad Fadzli Nizam Abdul Rahman, Siti Fairuz Abdullah\"Rice Grain Grading Classification Based On Perimeter Using Moore-Neighbor Tracing Method,\" vol: 8 July 2016. [8] B. Mahale and S. Korde, \"Rice quality analysis using image processing techniques,\" International Conference for Convergence for Technology-2014, Pune, India, 2014, pp. 1-5, doi: 10.1109/I2CT.2014.7092300. [9] I. Aulia, D. R. Wijaya and W. Hidayat, \"Rice Quality Detection Using Gradient Tree Boosting Based On Electronic Nose Dataset,\" 2021 International Conference on Artificial Intelligence and Mechatronics Systems (AIMS), Bandung, Indonesia, 2021, pp. 1-5, doi: 10.1109/AIMS52415.2021.9466073. [10] T. G. Devi, P. Neelamegam and S. Sudha, \"Machine vision based quality analysis of rice grains,\" 2017 IEEE International Conference on Power, Control, Signals and Instrumentation Engineering (ICPCSI), Chennai, India, 2017, pp. 1052-1055, doi: 10.1109/ICPCSI.2017.8391871. [11] L. A. I. Pabamalie, H. L. Premaratne, “A Grain Quality Classification System”, IEEE 2010. [12] S. Borah, M. Bhuyan and H. Saikia, “ANN-based Color Detection in Tea Fermentation” [13] G. E. Hinton, S. Osindero, and Y. W. Teh, ‘‘A fast learning algorithm for deep belief nets,’’ Neural Comput., vol. 18, no. 7, pp. 1527–1554, Jul. 2014. [14] K. Simonyan and A. Zisserman, ‘‘Very deep convolutional networks for large-scale image recognition,’’ in Proc. Comput. Vis. Pattern Recognit., Sep. 2014, pp. 1409–1556. [15] C. Szegedy, A. Toshev, and D. Erhan, ‘‘Deep neural networks for object detection,’’ Adv. Neural Inf. Process. Syst., vol. 26, no. 3, pp. 2553–2561, May 2013. [16] W. Ding and G. Taylor, ‘‘Automatic moth detection from trap images for pest management,’’ Comput. Electron. Agricult., vol. 123, pp. 17–28, Apr. 2016.

Copyright

Copyright © 2024 Ramya Asalatha Busi, Vaka Prasanna, Somala Sai Lakshmi Bhavana, Tallaparthi Yaswanth Kishore, Vanke Santhi, Yarram Venkata Sainath. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET59321

Publish Date : 2024-03-22

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online