Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Risk Assessments in Water Treatment Plant in Maharashtra

Authors: Miss. Priyanka Lad, Dr. A. K. Dwivedi

DOI Link: https://doi.org/10.22214/ijraset.2024.65731

Certificate: View Certificate

Abstract

This study provides a method for identifying water treating plants operational and engineering hazards. It is qualitative. Here, a modelling framework is applied with the objective of developing a systematic approach for organizing and improving our understanding of the hazards at the treatment plant operational level that affect the risk of infection from the pathogen Cryptosporidium parvum. The approach was successful in identifying many technical and operational hazards. The continued assurance of the needs of drinking water and its proper quality is vital for ensuring good living conditions. This concept can result in improved effectiveness through risk analysis of the technological process of providing drinking water in the case of water tanks, as well as the establishment of a strategy for handling risks and ongoing pursuit of it. Water treatment plants are vital community facilities, as many unknowns might arise and have an impact on systems over their lifetime. This type of water treatment plant must do a risk analysis of these events in order to have effective and proper administration during the operating time. A well-crafted risk management strategy, when followed throughout the objective lifetime, keeps costs down and aquatic qualitative indicators within the predetermined bounds.

Introduction

I. INTRODUCTION

Given their significant impact on public health, water supply systems have been determined to be the most critical. These systems are comprised of devices and infrastructure that can be sabotaged, and they are characterised by the presence of the primary components of each system: the untreated water sources, water purification facilities (including many reasons treatment methods), and the networks that distribute drinking water to shoppers. Some contaminants may seep into the water distribution system through storage tanks and pipes; seepage through distribution systems can occur during or after maintenance and renovation work; and when the pipe's pressure is extremely low or inadequate, this drastically raises the chance of backflow damage or leakage in the system. When the hydrant is used for free suppression or during water hammer, for example, or when the pipe pressure is temporarily reduced for repair, this can happen. (1)

The internal degradation of metallic pipes and plumbing fittings can also lead to greater levels of metallic substances in water. High dissolved oxygen, low pH, very high temperature, and high dissolved particle content all contribute to faster corrosion rates in water, albeit the precise mechanism differs from metal to metal. Physico-chemical degradation of the water quality and related health risks are caused by chemicals from external lining materials and pipe lining, which frequently enter the water system first. (2) The regulated management of risks and dangerous events in the production of drinking water depends on risk analysis techniques. Examples of problems with water distribution systems include leaks or water contamination, catchment pollution caused by chemicals or biology, and treatment process breakdowns. The field of risk analysis consists of three main parts: the first part discusses risk management. Assessing the possible harm or hazard's severity and amount in the medium that could expose the public to toxic substances and surroundings is the main focus. (3,4, 5)

Using information from the assessment, risk evaluation evaluates various policy options. Specific control features are chosen and put into action, along with rules to abide by and apply when necessary. Being able to communicate crucial information regarding the hazard is one of the process's most essential elements, or risk communication. (6) Planning the technical team's (managers and assessors) course of action, assessing the risk, and sharing information are all included. The input from users and stakeholders is also included. This study offers indications of the techniques and tools utilised in order to help people make knowledgeable decisions about the risks associated with a treatment and distribution process. (7, 8) Given that our evaluation models may be adjusted according to the particular demands of officials, lawmakers, and system operators, we firmly believe that our research will be valuable not only for water output, treatment, including consuming research additionally for them.

A. Water Treatment Plant

The identification and management of workplace hazards through an experienced risk assessment approach has a significant impact on occupational safety and health. The efficiency and earnings of an organisation can be affected by workplace events and work-related injuries caused by biological, chemical, or psychological hazards. (9, 10) A technique for identifying and classifying dangers according to their likelihood, frequency, and seriousness as well as assessing any negative results, such as possible damage or an illness, is called hazards identification Risk Examination, or HIRA. To enhance the industry's success, the work process in this field needs to take environmental health and safety into consideration. Risk assessments have been conducted using risk guidelines and standards. The industry has to recognise hazards and evaluate the associated risks in order to tolerate continuous levels. A WTP is a crucial piece of infrastructure for maintaining environmental and public health. They are essential to providing civilisation with access to clean, wholesome water since they are a source of water. Concerns regarding the surroundings / public health and safety will arise as this goes on. (11)

Because there are so many hazards at work, there are often times when accidents and illnesses occur. Since it usually results in fatalities in tiny regions, it is believed to be risky to operate in the water treatment business. Occupational safety and health is not a priority in this industry. Processing staff is nevertheless susceptible to sickness and even death from exposure to chemicals used as water purification materials, despite the fact that many decision-makers feel that the present state of danger is substantially lower. Water treatment companies use equipment and machinery that could cause worker injuries. Accidents can occur in dangerous workplaces or when workers utilize machinery and equipment irresponsibly. Chemical exposure, operational flaws, and labour tiredness are potential risks that frequently arise. To find potential occupational risks, the study employed the HIRA (Hazard Identification and Risk Assessment) method. It is anticipated that this process of identifying potential risks and hazards will help the organization manage and control workplace safety and reduce the likelihood of disasters. (12, 13)

B. Most Common Problem In Water Treatment Plant

1) Training

The majority of water treatment facilities are tiny components of larger operational systems, such a 16-stage facility receiving water from a reverse osmosis system. The process is extremely technological, and teams are sizable. Every member of the team must receive comprehensive, continuous training in managing the systems involved and the intricate details of their industry. (14) This may be avoided and staff members throughout your entire operation can thrive as knowledgeable, up-to-date industry experts with excellent, continuous training. Every team member at a water treatment facility should be familiar with the fundamentals of the relevant subject matter, regardless of their position or work role. Among them are

- Knowing the functions, limitations, and characteristics of each piece of water treatment equipment.

- Being knowledgeable about preventive maintenance techniques to reduce the likelihood of issues.

- Understanding what metrics to keep an eye on along with how to spot issues.

The most frequent issues with water treatment that staff members are probably to run into are:

- Scaling

- Membrane fouling

- Bacteria

- Mechanical failure

- Instrument failure

Expert staff members can help fill information gaps by offering on-the-job support. Because of this, there is a better chance that issues will be found and fixed before they worsen.

Instead of actively training staff, the majority of facilities rely on equipment vendors for their technical knowledge. Nonetheless, by offering the advanced, within the organisation expert instruction, staff members will be able to recognise:

2) Bacterial Control

Bacteria growth is most extensive under the following conditions:

- The being there of food for the bacteria

- high temperature

- A reduced flow rate

- The lack of antimicrobial treatment

The majority of microorganisms consume substances that contain organic carbon. For most water-born microorganisms, the optimal breeding temperature range is between 30° and 40° (86 and 105°F), as this is when growth happens most quickly.

Total Organic Carbon, also known as Total Oxidisable Carbon, is a measurement of the amount of dissolved organic components in the feed water (TOC).

When material is continually being added at a slow speed, microorganisms thrive and bacteria have time to proliferate.Because of the overwhelming momentum of water, this is minimised by increasing flow rates.Biocides are chemicals that destroy microorganisms.

The usage of oxidising chemicals as biocidal agents, like chlorine, was once a standard procedure. But nowadays, UV bacterial disinfectants are the most widely used bacterial control methods due to the adoption of more stringent environmental, chemical, or health and safety standards, like COSHH.

For membrane filtration, UV bacterial disinfection is preferable since certain microorganisms are resistant to ultraviolet light.

Reverse osmosis and nanofiltration membranes that filter water typically have very low oxidising agent tolerances.

Eliminating these oxidising substances from the feed-water upstream of the membrane unit is recommended practice. The process involves putting the feedwater through a water softener or bed of activated carbon.

Membrane fouling is caused by bacterial growth that occurs when these oxidising chemicals are not removed. This slows down the flow and exacerbates the problem over time.

3) Equipment Design Specification

There is a growth in industrial water treatment. In light of the increasing number of OEMs (Original Equipment Manufacturers) joining the market, many of whom lack experience, it's critical to comprehend the perfect design specification in order to avoid issues. The following elements must be included in designs:

- The Rates of Economical Water Flux

- Cross-flow Rates That Are Generally High

- Enough apparatus for sufficient observation

- Enough space for cleaning.

The quantity of permeate that moves through the cell membrane area in an exact quantity of time is known as water flux, and it is expressed as GFD, or gallons of permeate produced, per square foot of membrane per day.

4) Maintenance

Serious performance consequences may arise from inadequate maintenance of the water treatment plant. Severe system damage, higher expenses, and customer financial losses can all be caused by poor maintenance.

For water filtration systems, it is critical to maintain ongoing maintenance procedures because

- Maintaining a schedule for preventive care by replacing the pre-filtration cartridges and bags can assist extend the membranes' lifespan in the system.

- It lessens membrane fouling and scaling

- Because leaks are discovered and fixed more quickly, there is a savings in downtime for the units.

- By collecting thorough maintenance records, clients may anticipate modifications to flow, pressure, and pure water quality to permit the optimum outcomes.

- The unit maintains optimal performance over an extended period of time by staying in good condition.

C. Risk Managements Processes

The steps that are necessary to establish an appropriate risk management system for any project or structure are outlined in the PMI Practice Standard Project Risk Management.

- The development of defining the goals and parameters of the risk management procedure is known as plan risk management. In the process, historical data is examined to identify prior hazards and their data in comparable structures; standards and documents are examined to determine the parameters to be measured and the degree of acceptance; and the business's tolerance thresholds for risks are examined.

- The process of recognising risks, their sources, and the features that define them is known as risk identification. Risks are identified base on the structure's design, execution, and most importantly exploitation phase, as well as on the knowledge gathered from the use of similar structures.

- Qualitative analysis is the technique used to examine hazards. It uses a risk index to rank the risks based on chance and impact. The risk index is calculated by multiplying the likelihood of an event occurring by the estimated gain or loss from it. It is referred to that analysis and ways to mitigate are required by adopting the Pareto principle, which claims that 80% of effects may be determined by the first 20% of causes.

- The process of mathematically examining the combinations of the effects of the identified risks and additional sources of uncertainty is known as quantitative analysis.

- Prepare risk responses: Assign risk owners (those who bear responsibility for any risk) and provide solutions for decreasing, avoiding, or transferring noted risks and any potential consequences.

- Implement risk responses refers to the procedure that, in the event that a risk materialises, proceeds with the prearranged planned actions.

- Managing risks is the process that keeps track of the risks that have been discovered, keeps an eye on the responses to those risks that have been agreed upon, finds and analyses new risks, and determines whether the risk process is effective.

II. LITERATURE REVIEW

- G Covatariu, D Covatariu and A Filip, 2020 Ensuring adequate living conditions requires continuous assurance of the needs for drinking water and its optimal purity. This approach can result in a more efficient process through risk analysis of the technological process of providing drinking water in the case of water tanks, as well as the establishment of a risk management plan and ongoing pursuit of it. Water tanks are vital community facilities, and many unknowns might arise and have an impact on them over their lifetime. For this type of building, conducting a risk analysis of these events is essential to having an effective and proper facility management during the operating term. Developing a sound risk control strategy plus adhering to it throughout the goal's lifespan maintains the water's qualitative indicators within predetermined bounds & lowers expenses.

- Aidan A. Cronina, Anjal Prakash, Satya Priyac and Sue Coate, 2014. India's water resources are developing at a rapid pace, yet despite large financial increases, a sizable resource base (albeit one that is remarkably variable in both space and time), and an abundance of land, there are still persistent management challenges. Professionals dealing with water resources have difficulties because of India's growing population and rising demand, which makes it harder for the country to achieve its water goals. In order to present viewpoints for the future, a thorough analysis of the water industry was conducted. The tensions and forces within the industry were analysed through a comprehensive analysis of the secondary literature and five regional meetings with important players. The community, market, water programs, the State, and civil society all had a part in giving the people access to and control over water, among other things. These included adjustments to the ease of use and accessibility of water. At the national and regional levels, recommendations are made and contrasted with those of two other noteworthy sector assessments. Regarding the emphasis on the major activities that have been suggested, there is a general agreement that these three major assessments have produced. These actions fall into the following categories: data and knowledge, policy and institutions, capacity and disaster management, drinking water and sanitation for health, and water resources.

- Jayne Lois San Juan, Carlo James Caligan, et.al, 2020 The author's research indicates that there is a growing need for energy and a risk of global warming; developments in the production of bioenergy are becoming crucial to addressing these problems. Biorefineries have proven successful in transforming biomass into energy and other useful goods. They also provide the added advantage of cleaning wastewater that is utilised as a growing medium. Relationships between sewage sludge and microalgae that may increase its energy and biomass yields are made possible by recent innovations. In order to help stakeholders design an integrated system that consists of wastewater treatment systems, an algal-based bioenergy park, and a sludge-based bioenergy park, this study suggests a multi-objective optimisation model. The framework would help determine which processes to use in treating sludge and waste water while minimising cost and carbon dioxide emissions. According to the model's baseline run, the three plants were used to treat both sludge and water to get the best result. Water disposal is given priority when the model is run without storage, however storage can contribute to increased energy production. Sensitivity analysis of demand and storage costs was done. The findings indicate that while raising demand can assist in lowering anticipated costs by using process capacities and storing more, declining demand is directly correlated with overall costs. Storage expenses immediately follow the change and do not significantly affect overall costs. (15)

- Kirsten S. Almberg, Mary E. Turyk, 2017 Negative reproductive consequences have been linked to consuming water contaminated with naturally occurring arsenic in locations where high levels of arsenic are present. The consequences of lower doses of arsenic on reproduction are less well understood. This study looked at the relationships in Ohio between small for gestational age (SGA), term low birth weight (term LBW), very low birth weight (VLBW), preterm birth (PTB), and very preterm birth (VPTB) and low-level arsenic in drinking water. Using data from the Safe Drinking Water Information System, the mean annual arsenic concentration in drinking water for each Ohio county from 2006 to 2008 was used to define exposure. 428,804 births in Ohio during the same time period had their birth outcomes determined from their birth certificate records. The association between each birth outcome and arsenic was evaluated independently using multivariable generalised estimating equation logistic regression models. Sensitivity studies were conducted to investigate the effects that the use of prenatal care and private wells play in these relationships. The consequences of foetal arsenic exposure on reproduction may not be mitigated by current regulatory regulations. (16)

- U. Praveen Goud, G.Hari Krishna, P.Jeevan, V.Babulal, 2018 Modifications to treatment procedures, the need to take advantage of technological advancements, the desire to enhance operating performance, or attempts to mitigate the impact of rising construction costs are the main causes of design changes in water treatment facilities. They've all had an impact on the current generation of water treatment plants. The facility's numerous features and apparatuses, such as the surface-wash system, under-drains, valves, sludge removal units, additional plant construction, settling and mixing basins, surface-wash system, new filter media, surface-wash system, and ongoing plans and studies. Three phases make up the wastewater treatment plant's overall design: i) Primary treatment, which includes sedimentation, grit removal, and screening ii) A bioreactor is used for secondary treatment; iii) Nitrogen removal, adsorption, and pH control are used for tertiary treatment. The following wastewater parameters are assumed or experimentally determined for plant design. Furthermore, there are daily fluctuations in both the overall flow rate and the concentrations, in addition to seasonal variations. For instance, the flow rate and BOD value are higher in the morning. In a similar vein, when the rainy season, surface runoff increases the amount of solid substances like silt. (17)

- WiemGuissouma, Othman Hakami, Abdul Jabbar Al-Rajab, Jamila Tarhouni, 2017 Consumer dental cavities are known to decrease when fluoride is added to drinking water, but excessive fluoride intake might cause skeletal and dental fluorosis. The fluoridated tap water from 100 water consumption locations in Tunisia was thoroughly surveyed and reported in this study. There was a range of 0 to 2.4 mg L-1 of fluoride in tap water. Using a four-step process that included hazard identification, toxicity reference values selection (TRVs), daily exposure assessment, and risk characterisation, the risk of fluoride exposure was evaluated based on the age of consumers. Based on the WHO-recommended fluoride concentrations in drinking water, our findings show that nearly 75% of Tunisians are at risk for dental decay, 25% may be at risk for dental fluorosis, and 20% may be at risk for skeletal fluorosis. Further research is recommended to establish the risk of fluoride exposure in other drinking water sources, such as bottled water. (18)

IV. RESULTS AND DISCUSSION

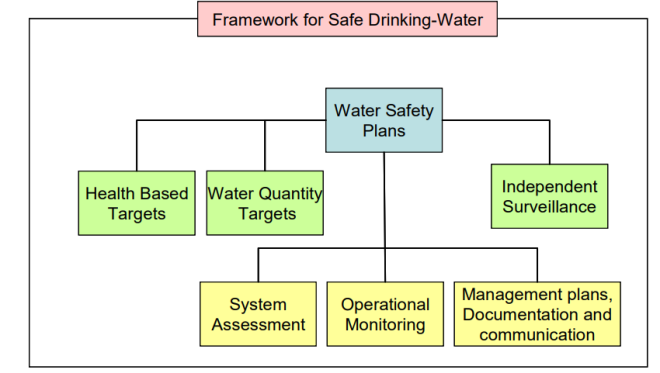

A General Framework for Integrated Risk Management in WSPs Developed by TECHNEAU Application at various levels of sophistication and for both operational and strategic goals is the goal of the TECHNEAU Generic Framework for Integrated Risk Management in WSPs. The framework's goals are as follows: (1) strengthening integrated risk management in water safety plans; (2) defending the public's health, society, and private functions; (3) shielding water utilities from dangers and improving their ability to provide users with acceptable amounts and quality of drinking water; (4) promoting rational decision-making; and (5) providing transparency. (6) To enable an iterative process of continual updating in response to new information and changes in the preconditions; (7) To raise the public's, decision-makers', and utility employees' awareness and knowledge of risk issues; (8) To make it easier for everyone to communicate. (19, 20) Thus, the framework seeks to enhance and give structure to integrated risk management in Water Safety Plans, including both water quality and quantity. Because water quantity is now given less attention in WSP, it is advised that the framework's description be slightly changed to more explicitly address water quantity problems (see Figure).

Suggested modification of the description of the WSP framework for more explicit considerations of water quantity aspects (19)

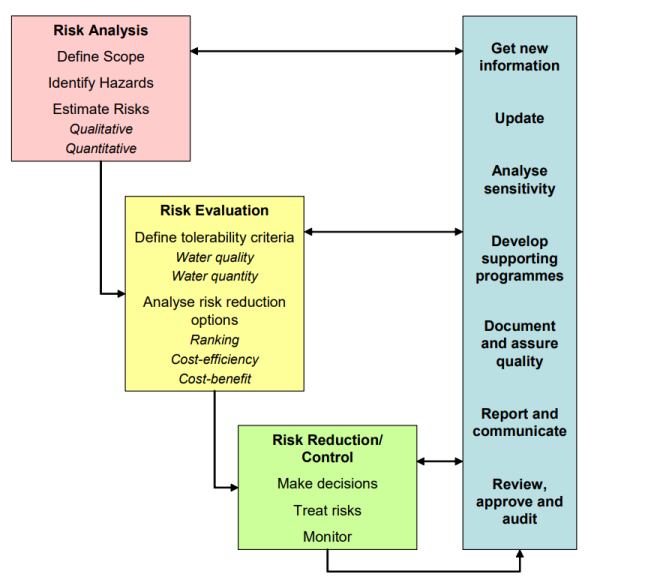

Risk management must make the following possible in order to achieve the goals: conformity with WSP Use in both operational and strategic contexts, with varying degrees of complexity, for surface and groundwater sources; (20) The extent of the risk management process should be precisely defined; utilising appropriate techniques to identify risks associated with water quantity and quality, such as those pertaining to microbiological, chemical, radiological, technical, operational, and administrative risks; employing pertinent techniques, such as fault tree analysis or structural diagrams, to organise and integrate source water systems, treatment systems, distribution systems, and plumbing network systems into a single integrated risk assessment model; applying appropriate techniques to risk assessment, both qualitative and quantitative; the application of pertinent techniques for risk assessment and uncertainty assessment; In order to prioritise risk reduction activities based on cost-benefit and/or cost-efficiency considerations, all hazards should be stated as much as feasible in monetary terms; the basis for risk evaluation being the applicable, established risk tolerance criteria; openness; the application of pertinent techniques for determining and evaluating the impact of risk reduction alternatives' performance; verification of outcomes, such as audit and review approval processes; the application of appropriate techniques to communicate risks to all parties involved. (21) According to WSP and the overall risk management approach, the proposed framework is fully compliant. Figure displays the major elements of the proposed framework. For the framework, the water corporation is the main target user. (22, 23) Every phase of the risk management process might not be able to be completed by every water firm, though. Tolerability standards for health risks, for instance, are usually outside the purview of water providers. In the source water system, the water company might also not be able to put risk-reduction measures in place. So, it is crucial to stress that all parties involved in the framework must communicate with one another. (24) According to WSP and the overall risk management approach, the proposed framework is fully compliant. The main components of the suggested framework are shown in the figure. The water corporation is the primary target user of the framework. (25, 26) However, not all water companies will be able to finish every step of the risk management process. For example, water providers typically have little control on tolerability requirements for health risks. The water company may also not be able to implement risk-reduction strategies in the source water system. (27) Thus, it is imperative to emphasise that communication is a necessary between all parties participating in the framework. A strong risk management strategy must consider the objectives and viewpoints of various stakeholders in order to create suitable tolerance standards and implement suitable and workable risk reduction techniques. (28)

Main components of TECHNEAU Generic Framework for Integrated Risk Management in WSP

Conclusion

When creating Water Safety Plans, risk management should be supported and given structure by the general framework that is outlined here. It is intended for use at the operational and strategic levels in both basic and complicated surface water and groundwater systems. Applying a single strategy for risk identification, estimation, valuation, reduction, and control on several levels and in different types of systems is not practical; instead, one must use combinations of methodologies suitable for the specific conditions at hand. TECHNEAU\'s current efforts are therefore concentrated on offering a toolkit of approaches together with examples of how these techniques can be applied effectively. From the source to the tap, every component of the water production system must be considered for effective risk management of drinking water delivery systems. (29) The whole risk management process, as well as each step that must be completed to achieve effective risk management, are included in the framework. It is imperative to emphasise that effective risk management requires both an organisational framework and a clear understanding of the possible benefits of risk management. Risk must be understood to have both positive and negative aspects. This means that while certain activities may necessitate risk reduction measures, these measures can also be designed to increase consumer safety and efficiency in the production of water. Recognising the importance of involvement and communication with stakeholders impacted by risk management choices is also essential An structured approach to risk management offers transparency and a clear basis for communication with pertinent parties, including regulators and customers. (30) Using risk assessment techniques to assist in decision-making is one of TECHNEAU\'s objectives. The right strategies should be used for the decisions at hand. The life cycle phase of a water company\'s development (e.g., design or operation) is one of several factors that will impact the selection of risk analysis techniques. type of water company Parts of the system that deal with the source, treatment, or distribution strategic or operational decisions in addition to stakeholder values. A comprehensive set of risk analysis techniques that satisfy the needs of many stakeholders ought to be furnished by a \"TECHNEAU catalogue\" of such approaches. (31) The catalogue should be able to adjust its approaches to such criteria. Practical applications and assessments are required for the framework\'s development as well as to gain experience with various risk analysis methods. Therefore, TECHNEAU now conducts a number of case studies using a variety of tool applications, ranging from the basic (RVA) to the more sophisticated. The framework\'s further development will include economic risk assessment as a crucial component for risk management that is both economical and efficient. (32)

References

[1] Aidan A. Cronina, Anjal Prakash, Satya Priyac and Sue Coate, “Water in India: situation and prospects”, Water Policy 16, 425–441, 2014. [2] A. N. Burile, Dr. P. B. Nagarnaik, “Performance Evaluation Of A Water Treatment Plant (Case Study)”, 2010 [3] A.K. Keshar, “Water Resources Scenario of India: Emerging Challenges and Management Options”, Indian Institute of Technology, 2007 [4] Andreas Wibowo, Sherif Mohamed, “Risk criticality and allocation in privatised water supply projects in Indonesia”, International Journal of Project Management, Vol. 28, Pp. 504–513, 2010 [5] Almat Kabyl, Ming Yanga, Rouzbeh Abbassi, Shihan Li, “A risk-based approach to produced water management in offshore oil and gas operations”, Process Safety and Environmental Protection 139, Pp. 341–361, 2020 [6] Anurag Bhambhani, Jan Peter van der Hoek, Zoran Kapelan, “Life cycle sustainability assessment framework for water sector resource recovery solutions: Strengths and weaknesses”, Resources, Conservation & Recycling, vol. 180 2022 [7] Asoka Jayaratne, “Application of a risk management system to improve drinking water safety”, Journal of Water and Health, 2008 [8] Charles R. Q\'Melia, “Coagulation And Sedimentation In Lakes, Reservoirs And Water Treatment Plants”, Wat. Sci. T.ch. Vol. 37, No.2, pp. 129-135, 1998. [9] C. Jagals and P. Jagals, “Application of HACCP principles as a management tool for monitoring and controlling microbiological hazards in water treatment facilities”, Water Science and Technology, Vol 50 No 1 pp 69–76, 2004 [10] Edoardo Bertone, Xuguang Ren, Oz Sahin, “Optimising water treatment operations with prediction modelling and smart technologies”, 2017 [11] Fajrul Falakh, OnnySetiani, “Hazard Identification and Risk Assessment in Water Treatment Plant considering Environmental Health and Safety Practice”, E3S Web of Conferences, 31, 2018. [12] G Covatariu, D CovatariuAnd A Filip, “Planning Risk Management In Case Of A Drinkable Water Tank Facility Operation”, Materials Science And Engineering, Vol. 789, 2020 [13] Guangji Hu, Anber Rana, Haroon R. Mian, Sana Saleem, Madjid Mohseni, Saad Jasim, Kasun Hewage, Rehan Sadiq, “Human health risk-based life cycle assessment of drinking water treatment for heavy metal(loids) removal”, Journal of Cleaner Production, vol. 267, 2020 [14] I.N. Ottenheijm, A. Fischer and J.F. Colton, “Modelling The Performance Of Water Treatment Plants Using Artificial Neural Networks – A Literature Review”. [15] Jayne Lois San Juan, Carlo James Caligan, et.al, “Multi-Objective Optimization of an Integrated Algal and Sludge-Based Bioenergy Park and Wastewater Treatment System”, Sustainability 2020, 12, 2020 [16] Kirsten S. Almberg, Mary E. Turyk, “Arsenic In Drinking Water And Adverse Birth Outcomes In Ohio”, Environmental Research, Vol. 157, Pp. 52-59, 2017 [17] U. Praveen Goud, G.Hari Krishna, P.Jeevan, V.Babulal, “Design And Analysis Of Water Treatment Plant”, International Journal For Technological Research In Engineering, Volume 5, Issue 8, April-2018 [18] Wiem Guissouma, Othman Hakami, Abdul Jabbar Al-Rajab, Jamila Tarhouni, “Risk Assessment of Fluoride Exposure In Drinking Water Of Tunisi”, Chemosphere, 2017. [19] H.-J. Ma lzer, N. Staben, A. Hein and W. Merkel, “Identification, assessment, and control of hazards in water supply: experiences from Water Safety Plan implementations in Germany”, Water Science & Technology, 2010 [20] Kandianawati, Mukhamad Najib and Setiadi Djohar, “Managing Operational Risks in Water Supply Sector”, Journal Manajemen Teknology, Vol. 18, No. 3, pp. 156-171, 2019 [21] Lars Rosén, Andreas Lindhe, Per Hokstad, Snorre Sklet, Jon Røstum, Thomas J. R. Pettersson, “Generic Framework for Integrated Risk Management in Water Safety Plans”, In proceedings of the 6th Nordic Drinking Water Conference, Pp. 9-11 , 2008. [22] Malay Chaudhuri And Richard S. Engelbrecht, “Removal Of Viruses From Water By Chemical Coagulation And Flocculation”. [23] Mojtaba Pourakbar, Mohammad Mosaferi, Saeed Lak, “Assessment of water supply system and water quality of Lighvan village using water safety plan”, Environmental Health Engineering and Management Journal, Vol. 2(4), PP. 187–192, 2015 [24] Nataša Ravbar, Janez Mulec, Cyril Mayaud, Matej Blatnik, Blaž Kogovšek, Metka Petri?, “A comprehensive early warning system for karst water sources contamination risk, case study of the Unica springs, SW Slovenia”, Science of the Total Environment, vol. 885, 2023 [25] N. Abdullah, N. Yusof, W.J. Laua, J. Jaafar, A.F. Ismail, “Recent trends of heavy metal removal from water/wastewater by membrane technologies”, Journal of Industrial and Engineering Chemistry, Journal of Industrial and Engineering Chemistry, vol. 76, Pp. 17–38, 2019 [26] Rachel Baum, Urooj Amjad, Jeanne Luh, Jamie Bartram, “An examination of the potential added value of water safety plans to the United States national drinking water legislation”, International Journal of Hygiene and Environmental Health, vol. 218, Pp. 677–685, 2015. [27] Shuokr Qarani Aziz, Jwan Sabah Mustafa, “Step-By-Step Design And Calculations For Water Treatment Plant Units”, Advances In Environmental Biology 13(8): 1-16, 2019 [28] Sudipa Choudhury & Apu Kumar Saha, “Prediction of Operation Efficiency of Water Treatment Plant with the Help of Multi-criteria Decision-making”, Water Conserv Sci Eng, 2017 [29] Tao Lin, Shilin Yu, Wei Chen, “Occurrence, removal and risk assessment of pharmaceutical and personal care products (PPCPs) in an advanced drinking water treatment plant (ADWTP) around Taihu Lake in China”, Chemosphere, Vol. 152, 2016 [30] Thomas Kistemann, Friederike Dangendorf, Martin Exner, “A Geographical Information System (GIS) as a tool for microbial risk assessment in catchment areas of drinking water reservoirs”, Int. J. Hyg. Environ. Health, vol. 203, Pp. 225-233, 2001 [31] Wisam Thamer Al-Mayah, “Chemical and microbial health risk assessment of drinking water treatment plants in Kut City, Iraq”, Materials Today: Proceedings, vol. 42, Pp. 3062–3067, 2021 [32] Xuelin Wang, Zhongyun Chen, Yonglei Wang, Wenjun Sun, “A review on degradation of perfluorinated compounds based on ultraviolet advanced oxidation”, Environmental Pollution, 291, 2021

Copyright

Copyright © 2024 Miss. Priyanka Lad, Dr. A. K. Dwivedi. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET65731

Publish Date : 2024-12-03

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online