Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

A Survey on Role of Artificial Intelligence and Internet of Things in Sericulture

Authors: Sonal P. S. , Siddanth D Bohra, Malini M Patil

DOI Link: https://doi.org/10.22214/ijraset.2024.64378

Certificate: View Certificate

Abstract

This paper takes a deep dive into the captivating world of sericulture and the unique varieties of silk that have graced humanity throughout history. The work carried out in the paper provides an insight of exploring the different types of silk, including Muga Silk, Tussar Silk, Mulberry Silk and Eri Silk. Each of these silk has its own distinct qualities, weaving a rich tapestry of textures, colors and cultural significance that has enthralled people for generations. As the technological advancements have provided the interdisciplinary approach of understanding the role of artificial intelligence, machine learning and deep learning approaches in the area of sericulture, wide verities of techniques, methods and analysis are available in the literature. The paper aims at presenting an exhaustive literature survey on using AI based methods, applications in sericulture. In essence, this paper showcases the beautiful synergy of tradition and technology in sericulture.

Introduction

I. INTRODUCTION

Artificial Intelligence (AI) and Machine Learning (ML) are fields of computer science that mimic human intellect and behavior. AI provides broad range of techniques that enable machines to stimulate human-like cognitive functions. In ML, algorithms are trained on large datasets, learning patterns and making predictions or decisions based on that data Silk is often used as the supreme textile due to its natural attributes, including exceptional moisture absorption, lightweight nature, shiny appearance, and remarkable elasticity. It was invented in the 4th millennium BC of Yangshao culture in China and was the sole producer of silk until a millennium later when the Silk Road was constructed joining the east and the west and was introduced to the world and became high in demand.

The silk industry is a global sector of economy involved in production of silk by harvesting cocoons produced by the silkworms. The silk produced are lustrous and highly durable. It represents blend of tradition coupled with modern technologies to produce high quality silks. The silk garments are largely worn in major parts of India and China as part of their tradition and culture.

Sericulture has undergone a significant transformation due to the advancement of AI and ML Technologies. These innovations have helped define Silk production with a whole new perspective. AI and ML algorithms are increasingly being used in sericulture practices to predict ideal environment for the growth of silk worm required for silkworm rearing and to automate the farming. High quality silk is being produced through computer inspection powered by AI. ML algorithms learn from the data set of the quality of the silk and enhance it further to give it better texture and sustainability. AI driven analytics optimize the supply chain, predicting demand, optimizing inventory and streamlining logistics. They maintain the integrity of the silk ensuring optimal silk production.

As we venture further into the paper, we encounter the fascinating fusion of tradition and technology in sericulture. We uncover how AI and ML technologies have stepped in to tackle age-old challenges in the silk industry. These advanced tools provide a helping hand in accurately counting silkworm eggs and detecting diseases with precision, giving Seri culturists invaluable insights into their silkworm populations. AI and ML also play a essential role in streamlining the silk production process. They automate various aspects of silkworm rearing, creating the perfect environment for their growth and administering medication when needed. This not only reduces the need for labor but also minimizes the potential for human errors. The introduction of IoT and image processing adds another layer of innovation by enabling real-time monitoring of environmental conditions, ensuring optimal silk quality and quantity. Finally, we explore how AI's analytical prowess extends to the market; helping Seri culturists align their production with consumer preferences. This ensures that the right amount of silk is produced, preventing waste and maximizing profits.

II. TYPES OF SILKS

Silk is a fabric revered for its luxurious texture and timeless elegance which has captivated the world with its shimmering beauty for millennia. Distinct varieties of silk have emerged, each possessing its own unique characteristics, production processes, and historical significance. There are four kinds of exquisite silks: Muga Silk, Tussar Silk, Mulberry Silk, and Eri Silk. Originating from various regions and cultivated through diverse methods, these silks offer a rich tapestry of textures, colors, and qualities that have elevated them to esteemed status within the textile industry. The detailed pictorial representation of all types of silks is depicted in Fig. 1 and also briefly explained as follows.

- Muga Silk: Muga Silk is majorly cultivated in the idyllic village of Sualkuchi situated in Assam in the north bank of the Brahmaputra at a distance of 30 km west of Guwahati city. It is the only place of world where very precious golden colored luxurious yarn considered as “the queen of fiber” is abundantly grown because the fertile ecological conditions and availability of host plants well suits the growth of muga silk worm. The qualities of muga silk yarn are truly remarkable. It possesses a natural golden hue with a lustrous texture that gleams in the light. This shimmering effect arises from the triangular prism-like cross-sectional structure of the silk weave, which refracts incoming light at various angles, producing an array of colors. Its ability to absorb moisture makes it comfortable to wear in warm weather. This organically produced silk stands as one of the strongest natural fibers [9].

|

Muga Silk Cocoon |

Muga Silk Yarn |

|

Eri Silk Cocoon |

Eri Silk Yarn |

|

Mulberry Silk Cocoon |

Mulberry Silk Yarn |

|

Tussar Silk Cocoon |

Tussar Silk Yarn |

Fig. 1 Types of Silks

- Tussar Silk: Tussar silk is cultivated in various parts of India, including states like Jharkhand, Chhattisgarh, Bihar, and West Bengal. The silkworms responsible for the production of Tussar silk are found both in the wild and under semi-domesticated conditions.Tussar silkworms feed on a variety of trees and plants found in their natural habitat. Their diet includes leaves from trees such as Arjun, Sal, and Saja. Tussar silk has a textured feel that sets it apart from other silks. It has a slightly coarse texture due to the irregularities in the fiber. It comes in a range of natural shades, from pale gold to deep honey brown. Since Tussar silk is often obtained from wild silkworms and forest resources, it's considered more sustainable and environmentally friendly. Cost of Tussar Silk Yarn can range from around Rs. 2,000 to Rs. 4,000 per kilogram, depending on the specific variety and quality [10].

- Mulberry Silk: Mulberry silk is a luxurious and highly prized type of silk produced by the silkworm species Bombyx Mori. The silkworm feeds solely on the leaves of the mulberry plant. The larvae feed on mulberry leaves, and when they have consumed a sufficient amount of food, during the pupa stage, they spin a delicate cocoon around themselves. It contains two main proteins namely sericin and Fibroin acts as the inner core and gives the fiber mechanical strength, while sericin is the outer glue-like coating. Each silk fiber contains two fibroin filaments coated with sericin. Mulberry silk is incredibly soft and smooth to the touch, making it comfortable to wear against the skin and suitable for various applications. It has a natural sheen and a beautiful, reflective quality that gives it an elegant and luxurious appearance. It is strong and durable, maintaining its integrity over time with proper care. This longevity makes it a valuable material for clothing and accessories. The proteins found in mulberry silk are less likely to trigger allergic reactions, making it a great option for those with sensitive skin or allergies. It has excellent temperature-regulating properties [11].

- Eri Silk:Eri silk is produced by the caterpillar of the Samiaricini moth, which is native to India and some parts of Southeast Asia. It's also known as "Endi" or "Errandi" silk. Eri silk is unique in that it is produced without harming the pupa. Hence, it is called as “Ahimsa Silk”. It is multivoltine silk spun from open ended cocoons. The silkworm is fed on castor leaves. The process of obtaining Eri silk is more humane (ahimsa silk) compared to other types of silk where the pupa is killed in the process. The popularity of eri silk in the textile world was limited due to the discontinuous filaments, reeling problems and lack of favorable environmental condition for rearing eri silk worms. However, the production of eri silk in India showed a sharp increase from 127 million tons during first plan period (1951-56) to 11,500 million tons during 2018-19 contributing 20% of total silk production in the country. Eri silk is a staple fiber and it has good fineness, density, cross-sectional shape and surface properties. It is darker and heavier than other silks. It feels like cotton, has luster like other silks, bulkiness and warmth like wool and is the softest among all other silks [12].

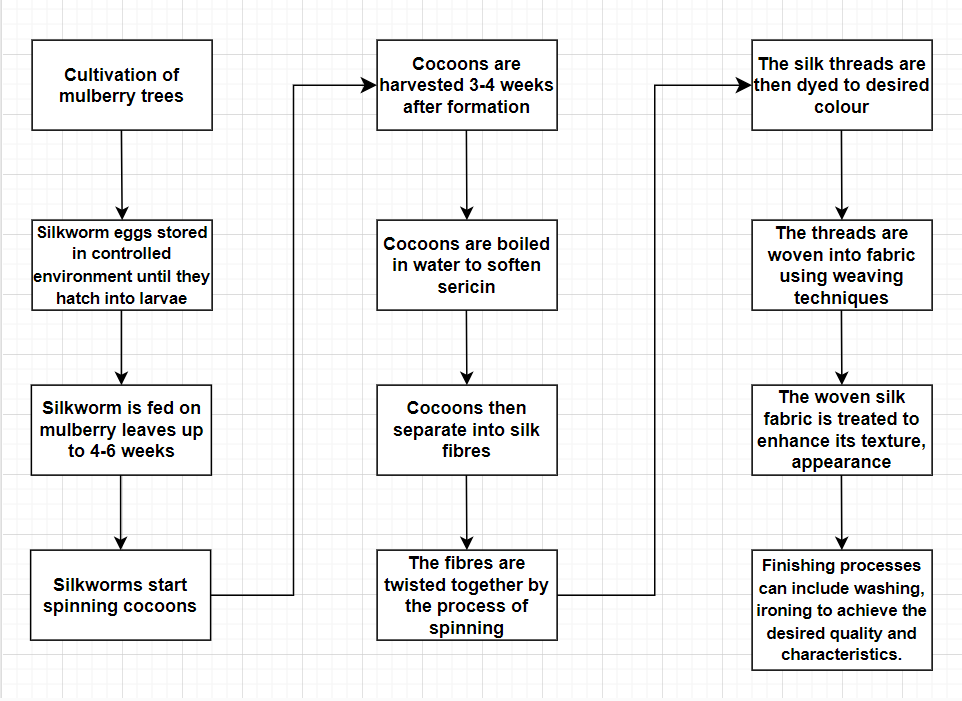

III. HOW SILK IS PRODUCED

The process of silk production involves several steps from raising silkworms to harvesting and processing of silk fibers. The mulberry tree is cultivated for the silkworms to grow. The silk worms’ eggs are stored in controlled environment until they hatch into larvae. Then the silkworm is fed on the mulberry leaves up to 6 weeks. The silkworms then start spinning cocoons around themselves. They release silk threads from special glands located in their heads. The fully formed cocoons are carefully harvested 3-4 weeks after their formation. To soften the sericin, a natural gum-like substance that holds the silk threads together and protects them, the cocoons are boiled in water. This process also helps in killing the pupae inside. Cocoons then separate into silk fibers. The silk fibers are then twisted together through a process known as spinning. This process produces the silk thread that can be woven into fabric. The silk threads are then dyed to get desired color. After dyeing, the threads are woven into fabric using traditional weaving techniques or modern machinery. Then finishing process includes washing, ironing to achieve desired quality and characteristics.

Fig. 2 Production of Mulberry Silk

IV. Role OF AI and IOT IN SERICULTURE

The integration of cutting-edge technology, particularly AI and the IoT, holds immense promise in revolutionizing the sericulture industry. These innovative approaches are poised to usher in a new era of safe and efficient silkworm farming while addressing long-standing challenges. One of the key challenges in sericulture has been the accurate counting, identification, and categorization of healthy and unhealthy silkworm eggs [2]. Traditional biological methods have proven ineffective in overcoming these hurdles. However, with the advent of advanced sericulture techniques, including digital machine learning, deep learning methodologies, and image processing, these challenges can be addressed successfully. These technological advancements can greatly improve counting accuracy and disease detection, providing Seri culturists with invaluable insights into their silkworm populations.

The cultivation of healthy silkworms can now reliably be ensured through the integration of advanced technologies which includes the utilization of computer-based methodologies such as Artificial Neural Networks (ANN), the IoT, AI strategies, and Image Processing Algorithms [1]. These innovations can extend to a comprehensive system for disease detection and protection, incorporating automated medicine administration. This automated approach will not only minimize the need for additional labor but also eliminates the potential for human errors.

- IoT and Image Processing for Enhanced Disease Detection and Environmental Control: A prototype sericulture unit can be developed using IoT and image processing methods. This innovative prototype shall offer various advantages, including remote monitoring and automated adjustment of environmental conditions within the system in real time. The image processing component will play a pivotal role in categorizing silkworms as healthy or diseased by detecting changes in color and texture [6]. This process involves creating a binary mask to isolate the silkworm, applying color thresholding to the silkworm's histogram, and classifying them into three groups: healthy, Flacherie-infected, and Pebrine-infected. Notifications will be sent to Seri culturists, alerting them to the presence of diseased worms and specifying the type of disease using senescence analysis. In the future, this method will be further improved to process actual silkworm photos captured by a digital camera. When a silkworm is detected, a robotic arm will immediately separate it from the others. The image processing system will identify the developmental stages of the silkworm and relay this information to the IoT for precise temperature control [3].

- Revolutionizing Sericulture with IoT and Automated Health Monitoring: An IoT-based system can be designed for remote monitoring of critical parameters, including humidity, temperature, and the presence of potentially hazardous gases within the controlled environment. By harnessing the data collected, it is possible to automate the regulation of the climatic conditions within this enclosed space. Meanwhile, a camera can be employed to continuously capture images of the silkworms at predefined intervals. These images shall serve as a means to assess the health status of the worms, identifying any signs of illness. In the event of sickness detection, an automated pump can be triggered to dispense the necessary medication. Consequently, this approach will not only reduce the physical labor required for silk production but also enhance both yield and silk quality. This transformative technology will surely equip farmers to overcome their challenges effectively, enabling them to uphold the standards and quantities of their silkworms, thereby contributing to the growth and sustainability of the sericulture industry.[4]

- Proactive Disease Management for Muga Silk Industry: One of the major constraints in the muga silk industry is the occurrence of diseases due to fluctuations in weather factors, such as temperature and humidity. A mobile-based forewarning application for early warning systems on flacherie disease infestation can be developed to mitigate crop loss. The system can work by generating land use/land cover maps and analyzing meteorological factors over a period of ten years for selected muga farms. An average of each factor can be considered in the 15 days leading up to brushing and harvest, in a sequence of 15, 10, and 5 days. It can be observed that a correlation can exist between land surface temperature (LST) and the occurrence of flacherie disease [7]. Therefore, it can be reported that a rise in temperature and humidity beyond a threshold limit shall increase flacherie infestation in the rearing field. Such a mobile-based early warning system can provide invaluable assistance to Seri culturists by enabling them to proactively manage and protect their muga silk crops from the detrimental effects of flacherie disease, ultimately enhancing their yields and overall success in the industry.

- AI Innovations in Silk Industry- GAN-Negative, S-GAN, and Predictive Insights: The application of Generating Adversarial Networks-Negative samples (GAN-Negative) can be envisioned in the realm of AI. It can utilize images of yellow fly or uzi fly-infested cocoons, Petrinized tussar silkworms, flossy or dead cocoons to produce and generate what is undesired. This capability shall contribute to enhancing the controllability of generations. Furthermore, in the context of Sequence Generating Adversarial Networks (S-GAN), this technology can play a pivotal role in natural sequence farming. It shall have the potential to provide guidance for optimizing farm allocation to enhance fertility recovery. The intelligence embedded in S-GAN shall prove to be an added advantage in planning tussar silkworm rearing, allowing for crop-wise management on different sections of plantations within a field. Additionally, this technology shall find application in the generation of product descriptions. It can take input images of host plant leaves, cocoons, seeds, and analyze their characteristics like color and shape to create detailed product descriptions. Furthermore, in the domain of predictions, based on news reports concerning silk imports and exports, AI shall be capable of forecasting the demand and supply of silk in the years to come, using summarized reports for these predictions [8].

- AI-Powered Genetic Analysis- Enhancing Silkworm Breeding for Quality and Productivity: Through genetic analysis and machine learning algorithms, AI can assist in identifying specific genes associated with desirable traits in silkworms, such as silk quality, cocoon size, and disease resistance. This information is crucial for targeted breeding programs. AI can predict the outcomes of different breeding combinations, helping Seri culturists select parent pairs to produce offspring with the desired characteristics. This accelerates the development of superior silkworm strains, leading to better silk quality and overall productivity.

- Revolutionizing Sericulture with Advanced Computer Vision: Accurate Silkworm Egg Categorization and Counting: The categorization and counting of silkworm eggs using image analysis shall be increasingly significant in the sericulture industry. Modern computer vision techniques, encompassing image processing, machine learning, and deep learning, can emerge as invaluable tools for achieving accurate and efficient results in this domain. Image processing techniques can be employed to enhance the quality of the images, removing noise, adjusting contrast, and highlighting the silkworm eggs within the images. ML algorithms can be trained to recognize and classify silkworm eggs, differentiating them from other objects or background noise. Deep learning methods, especially Convolution Neural Networks (CNNs), have demonstrated remarkable capabilities in this context by automatically learning intricate patterns and features from the images, further improving the accuracy of egg detection and categorization [5].These advanced techniques offer a multitude of benefits for sericulture practices. They facilitate precise egg counting, a critical aspect in sericulture, ensuring optimal resource allocation and production planning. Furthermore, they enable the categorization of eggs into various classes based on their health or other characteristics, such as the presence of disease, which is vital for effective pest and disease management in silkworm rearing. As a result, the integration of contemporary computer vision techniques has the potential to revolutionize sericulture by enhancing productivity and ensuring the health and quality of silkworm eggs, ultimately contributing to the success of the silk production industry.

- A Multi-Sensor System for Silkworm Cocoon Gender Classification via Image Processing: During the silkworm farming life cycle, a common issue is represented by the gender classification of the cocoons. Improper cocoon separation negatively affects quantity and quality of the yield resulting in negativity in productivity. To tackle this issue, a multi sensor system for silkworm cocoons gender classification and separation is used. Utilizing a load sensor and a digital camera, the system acquires weight and digital images from individual silkworm cocoons [13].

- Non-destructive testing of silkworm cocoons based on image processing technology: The major studied in this dissertation is the non-destructive testing method of silkworm cocoon's quality, based on the digital image processing and photo electricity technology. Through the images collection and the data analysis, procession and calculation of the tested silkworm cocoons with the non-destructive testing technology, internet applications automatically reckon all items of the classification indexes [14].

- Identification and classification of silks using infrared spectroscopy: Identification and screening method based on the infrared spectra of native silk feedstock and cocoons. Allows to group silks into distinct hierarchies and a classification that agrees well with current phylogenetic data and taxonomies [15]

- AI in Market Trends and Demand Forecasting: AI can play a vital role in analyzing market trends and demand forecasting. AI can analyze marketing patterns, consumer preferences, and historical sales data to forecast demand for different types of silk products. By understanding market dynamics, Seri culturists can adjust their production plans to align with consumer demand. This prevents overproduction or underproduction, enabling efficient resource allocation and better profit margins.

The integration of AI and IoT technologies in sericulture represents a transformative leap forward for the silk industry. These innovations address long-standing challenges in silkworm farming and provide efficient solutions to address them. By harnessing the power of AI, Seri culturists can not only optimize their production processes but also contribute to the growth and sustainability of the sericulture industry as a whole.

Conclusion

The survey was done to understand how modern technologies like AI and ML can be used in silk production to optimize silk farming, enhancing its features, reduce cost and maximize production. An IoT-based system can be designed to monitor humidity, temperature within the controlled environment. The quality of the silk can be controlled using AI systems and using ML algorithms to learn and predict ideal growing conditions for silkworm and automation of silkworm farming. Research advancement has offered new varieties in silk using various techniques. It is safe to assume that AI, ML can secure the growth and competitiveness in silk industry. It’s a story of how the silk industry continues to thrive while staying deeply rooted in its cultural and economic significance, thanks to the embrace of modern advancements.

References

[1] M Younus Wani, NA Ganie, KA Dar, MF Baqual, and MR Mir. \"Artificial intelligence: Glimmer of Hope for Reviving the Sericulture Industry in Jammu and Kashmir,\" The Pharma Innovation Journal, 2022,11(12S), pp. 198-202. [2] H.V. Pavitra, C.G. Raghavendra. \"An Overview on Detection, Counting and Categorization of Silkworm Eggs Using Image Analysis Approach,\" Global Transitions Proceedings, Volume 3, Issue 1, 2022, pp. 285-288. [3] Deepthi HS, Sastry AS. \"Image Processing-Based Smart Sericulture System Using IoT,\"International Journal of Advances in Agricultural Science and Technology, 2021, 8(9) pp. 23-31. [4] Shilpa Saikia and MonimalaSaikia (2023). Smart Sericulture and IoT: A Review. Biological Forum – An International Journal, 15(1) pp. 545-549. [5] Pradeepto Pal, Devendra Singh, Rajesh Singh, Anita Gehlot, VaseemAkram Shaik. \"Role of Artificial Intelligence, Machine Learning, Deep Learning for Sericulture: A Technological Perspective,\" 2023 International Conference on Artificial Intelligence and Smart Communication (AISC), pp. 352-356. [6] Manjunath Bhaskar, BaddulaLakshith Reddy. \"Smart Sericulture System using Image Processing,\" International Journal of Engineering Research & Technology (IJERT), Volume 11, Issue 01 (January 2022) Pages: 143-147. [7] Jonali Goswami, D K Gogoi, Nasreen Rasid, Bijoy Krishna Handique, Gangavarapu Subrahmanyam, Priyankush P Bora, Ranjit Das, P. L. N. Raju. \"Development of a Muga Disease Early Warning System – A Mobile-Based Service for Seri Farmers.\" Current Science, Volume 121, Issue 10, November 2021, pp. 1328-1334. [8] Hasansab A Nadaf, Vishaka GV, Chandrashekharaiah M, Rathore MS, Srinivas C. \"Scope and Potential Applications of Artificial Intelligence in Tropical Tasar Silkworm (Antheraeamylitta D.) Seed Production,\" Journal of Entomology and Zoology Studies, 2021, Vol. 9, Issue 1, pp. 899-903 [9] A. Tikader, Kunjupillai Vijayan, Saratchandra Beera. \"Muga Silkworm, Antheraeaassamensis (Lepidoptera: Saturniidae) - An Overview of Distribution, Biology, and Breeding,\" European Journal of Entomology, April 2013, Volume 110, Issue 2, pp. 293-300. [10] R. Manohar Reddy, M.K. Sinha, B.C. Prasad. \"Indian Tropical Tasar Silkworm, Antheraeamylitta Drury (Lepidoptera: Saturniidae) - Breeding Perspective for Silk Yield and Quality.\" Journal of Applied Sciences, 2010, Volume 10, Issue 17, pp. 1902-1909. [11] GetmetMelesse, Desalegn Atalie, AyanoKoyrita. \"Structural and Thermal Properties of Ethiopian Eri and Mulberry Silk Fibres,\" Advances in Materials Science and Engineering, October 2020, pp. 1-8. [12] Meenakshi Tamta, Surabhi Mahajan. \"The Novel Silk Fiber: Eri,\" International Journal of Home Science, 2021, Volume 7, Issue 1, pp. 101-104. [13] N. Joseph Raj, M. Sundaram, V. G. V. Mahesh, Z. S. Zhuang, and A. Simeone, \"A Multi-Sensor System for Silkworm Cocoon Gender Classification via Image Processing and Support Vector Machine,\" Sensors, vol. 19, no. 12: 2656,2019. [14] Yong, Gan. “Research on Non-destructive Test of Cocoon Quality,” (2004). [15] M. Boulet-Audet, F. Vollrath, and C. Holland, \"Identification and classification of silks using infrared spectroscopy,\" Journal of Experimental Biology, vol. 218, 2015. Published by The Company of Biologists Ltd.

Copyright

Copyright © 2024 Sonal P. S. , Siddanth D Bohra, Malini M Patil. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64378

Publish Date : 2024-09-28

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online