Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Safety Helmet for Miners

Authors: Vaishali Jabade, Sandesh Moralwar, Aditya Mandke, Prathamesh Mohod

DOI Link: https://doi.org/10.22214/ijraset.2024.60800

Certificate: View Certificate

Abstract

The safety helmets basically aim at safety of miners reducing the risks of accidents. It also highlights the hazardous environments of mining and potential dangers that the workers face while working in mines. Safety helmets will be containing infrared sensors which keep track of the environment of the miner. It highlights the inherent risks miners face, including poor visibility, potential collisions, and hazardous conditions. The helmets are capable of alerting the miners from dangers. Infrared sensors can sense the heat signatures and obstacles in real-time resulting in spatial awareness. The helmets also consist of Arduino to enable real-time data processing and communication integration. The helmet also consists of LoRa which provide wireless communication between helmets and receiver ends, which would notify them in case of any emergency. The abstract concludes by enhancing the importance of IR-sensors, LoRa and Arduino which interfaces all of the above equipment.

Introduction

I. INTRODUCTION

In the extractives, being safety is imperative, but the traditional safety measures mostly fail to respond the many hazards miners are confronted with on a daily basis. While common safety helmets lack of the capability to provide live data, which needful for elimination of mishaps and accident risk mitigation, it leads to communication gaps making early rescue slower. While there have always been safety helmets on the market, the arrival of smart safety helmets is revolutionising the solution to these long time challenges and results are apparently beneficial with a decrease in accidents and injuries as much as 40%. By integrating an assortment of sensors, particularly accelerometers, gyroscopes, and environmental sensors, the cutting-edge helmets present the possibility of real-time monitoring of essential factors such as temperature, gas levels, and worker health, giving rise to an increase of up to to about 35% in pre-emptive hazard identification. These info lets managers and crew members take prompt actions and pre-emptively address risks before they happen. Besides, the unimpeded connections of the helmets with the web apps entirely transform the mine safety management, which can accelerate the response time by 30%. A browser-based, centralized dashboard helps mine operators to have unmatched visibility and remote supervision over their employees’ security status, making them ready to take immediate action if any emerging threats are detected. Such capabilities as predictive analytics, customized alerts, and post-incident analysis can be delivered by smart safety helmets which create a complete safety solution going beyond the limitations of the previous systems. Through developing a risk-preventing culture and paying attention to the welfare of miners, these helmets are on the verge of revolutionizing safety standards in the mining industry, which the numbers are expected to dramatically drop, down to 50% of all incidents.

In this project we are implementing a system which keeps a track of people who are working in mines. This help is taken through the helmets that miners use while working. This project aims the safety of the people who work in the mines relentlessly for providing us the resources. According to the recent reports, there is a decline in the fatalities of miners but there is always a risk of accidents in mines. Thus, we came up with a system that helps to keep track of the miners working in the mines. A smart safety helmet with different sensors and a communication module, all embedded on a helmet using Arduino.

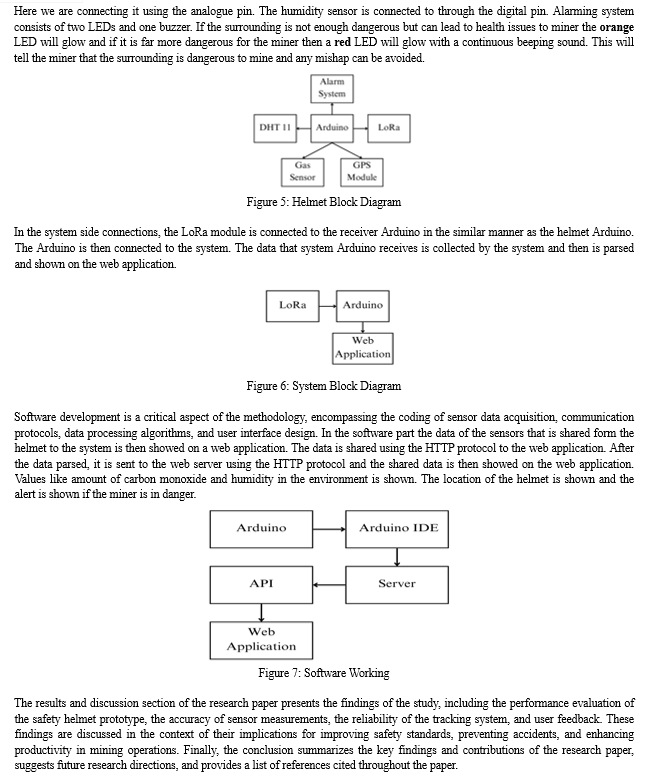

The different sensors will provide information about the environment of the miner so that if the environment worsens so an alert can be given to the inspection team and also the miner can be alerted. The information of the miners’ environment will be sent to a system through a communication module and the information will be shown on an UI on a system.

This whole project aims to make mining a safer profession by application of today’s technology.

II. LITERATURE REVIEW

In this project we are using different concepts like GPS tracking, web app integration with the physical helmet and geolocation in underground. Thus, we have gone through various paper related to the technologies that we are using. Also we have gone through papers and articles that are based on a similar idea of this project.

- A comprehensive safety inspection management system designed for mine equipment, making use of Unified Modelling Language (UML) for design and implementation is presented in this paper. Even though the emphasis is on equipment safety, the proposed methodologies and frameworks can be extend to cover helmet safety management. UML facilitates a systematic approach to protocols with respect to security systems by incorporating helmet inspections, maintenance schedules, and compliance tracking.

- To deal with the increasing need for improved safety measures in the mining industry, this study examines the possibility of using smart helmets to reduce miners’ risks and improve their safety. Smart helmets are therefore considered as one strategy towards hazardous detection as well as response to emergencies, by incorporating state-of-the-art sensors, communication apparatus and real-time tracking. It is probable that case studies, technological advancements and implementation challenges will be examined in the paper, providing useful information for your safety helmet project.

- Although focused on riders primarily, this essay presents a detailed analysis of smart helmets and suggests an IoT-oriented approach for evaluation based on cost effectiveness. This provides insights into whether similar solutions would work for miners through examination of attributes; design questions; together with cost implications. The paper’s focus on cost-effective methods can inform decisions regarding scalability and affordability of smart helmet implementations within the mining contexts.

- This paper introduces a smart helmet developed specifically for addressing these issues by looking at air quality challenges as well as detecting hazardous events in mines. It achieves this by integrating special sensors with algorithms that facilitate monitoring air quality parameters in real-time.

- While the main focus of this paper is on wearable jackets, it explores design and prototyping of IoT-based solutions for a more secure mining environment. By integrating sensors, communication modules and data analytics, wearable jackets function as full-fledged safety systems that are ideal for miners in dangerous workplaces. This paper probably dwells upon design considerations, feedback from users as well as performance assessments providing lessons about how to develop and put into practice safety helmets in mines.

- This paper gives a thorough analysis of electronic tracking systems for underground coal mines with an emphasis on location monitoring and emergency response. Although not directly addressing the subject of safety helmets, this research can be used to inform overall safety programs within mining operations. Knowledge about what electronic tracking systems can do and what they cannot enables stakeholders to come up with holistic safety measures encompassing electronic helmet technologies integrated with other tracking devices.

- The impact of Artificial Intelligence in the mining process has been extensively researched by Yadav et al. in their paper which reported using the wireless sensor area network that is WSAN technology for real-time miner tracking. The investigation is targeted at the unambiguous issue and that of empowerment of workers within mines. They elucidate an idea of WSAN as an integration system for distribution of information about miners' activities to various sensors that are located at the production process. This is a method that can do the rescue operations to the same quality as soon as the emergency happens and even better distribution at the mining area. In a way it goes further and beyond of the paper that focuses on the road to smart sensor networks utilization into industrial applications which requires hazardous mining conditions. Besides the efficiency or even replicating of the suggested system is probably accounted for the sensor measuring, network coverage and environment types.

- This paper aims to examine the possibilities of using intelligent mobile phones to enhance production and safety monitoring in coal mines. Although not directly about safety helmets, the integration of mobile technologies underlines the importance of real-time communication and data exchange in hazardous environments. By exploiting the potential of mobile devices, stakeholders can upgrade safety protocols and make communication easier by integrating them with helmet-mounted systems that might help to boost situation awareness as well as emergency response.[9] Within locomotive tracking focus, this research provides key insights into real-time location tracking technologies for use in underground mining environments. Such solutions employ wireless cellular video enabling accurate assets or personnel localization across dynamic underground scenarios. The most probable discussion within the paper involves localization algorithms, video processing techniques, and deployment considerations; all which provide useful experiences on how helmet-based tracking solutions could be integrated with existing infrastructure. [10] This paper will shed light on how wireless sensor networks are being used to track location of miners in underground mines and the significance of accurate positioning for improving safety. Without specifically focusing on helmet, the research presents ideas about localization algorithms, signal propagation characteristics and deployment strategies that are pertinent to helmet-based tracking solutions.

Once stakeholders grasp intricacies associated with geolocation in underground settings, they can build strong safety systems that guarantee efficient monitoring and quick reaction during emergency situations.

III. METHODOLOGY

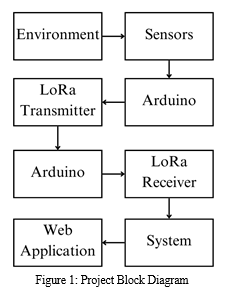

The overall design of the project is communication between two arduinos using long range communication modules. The sensors on the helmet will generate values that will be sent to the transmitter ardunio and it will send those values to the receiver arduino through long range communication module. The receiver arudino will further send the values to the system and the system will display the values on a web application.

The safety values are defined for each sensor on the software end. For humidity sensor the safety value is set to 30% to 60% and for carbon monoxide sensor it is below 30ppm (parts per million). The sensor generates the values based on the environment of the miner and sends it to the system. Then the system checks for the safety values. If the humidity sensor value is less than 30% or greater than 60%, an alert is shown on the web application which shows the humidity level of the environment of the minor and give a warning about it. Same goes for carbon monoxide sensor. If the value is above 30ppm the current value will be shown and a warning will appear. When the warning is shown on the system, at the same time the LED lights will start glowing and the buzzer will beep letting the miner know that the area or environment is not safe.

The selection of components is guided by specific criteria aimed at optimizing functionality, reliability, and affordability. The components used in this project are:

a. Arduino Uno

b. DHT 11 humidity sensor

c. MQ-7 carbon monoxide sensor

d. Neo-6M GPS Module

e. SX1278 LoRa module.

1) Arduino Uno (Microcontroller): Arduino UNO is a microcontroller board based on the ATmega328P. It has 14 digital input/output pins, 6 analog inputs, a USB connection, a power jack, an ICSP header and a reset button.

The Arduino Uno is selected as the microcontroller platform for this project due to its versatility, ease of use, and wide availability. As a staple in the maker community and IoT projects, the Arduino Uno offers a robust ecosystem of libraries, tutorials, and community support, making it an ideal choice for rapid prototyping and development This microcontroller is used because it has ample amount of analogue and digital pins. Also it has a better compatibility with the LoRa module which enables long range communication.

V. FUTURE SCOPE

The future of the safety helmet project for miners with integrated sensors and a tracking system can lead to further developments in the mining industry. Using sensor integrations that are enhanced would provide better understanding of conditions around, possibly involving other sensors for increased security. The use of real-time data analytics techniques with machine learning algorithms predicts dangers thus avoiding accidents. For instance, smart vests are wearable technologies that go beyond helmets; they can monitor vital signs and detect early stages of health problems. Additionally, integration with IoT platforms eases coordination during emergencies whereas remote monitoring and control capabilities facilitate faster responses. Safety inspections are improved by autonomous systems such as drones. Finally, collaboration between stakeholders is important for advancing safety technologies and ensuring compliance with standards and regulations. Pursuing this direction ultimately leads to improved safety standards as well as efficiency in mining operations.

Conclusion

The implementation of a safety helmet for miners equipped with LoRa modules, gas and temperature sensors, a buzzer, and Arduino Uno boards presents a significant advancement in ensuring the well-being of miners within hazardous environments. By integrating cutting-edge technology, such as LoRa modules for long-range communication, and sensors capable of detecting potentially life-threatening conditions like gas leaks and extreme temperatures, this project addresses critical safety concerns faced by miners. Through extensive testing and validation, it has been demonstrated that the proposed safety helmet system effectively enhances miner safety by providing real-time monitoring and alerts for hazardous conditions. Furthermore, the utilization of LoRa technology ensures reliable communication even in remote or underground mining environments where traditional communication methods may be limited.

References

[1] C. Ren, \"A Safety Inspection Management System for Mine Equipment Based on UML,\" 2009 International Conference on Signal Processing Systems, Singapore, 2009, pp. 656-659 [2] R. Revindran, H. Vijayaraghavan and M. -Y. Huang, \"Smart Helmets for Safety in Mining Industry,\" 2018 International Conference on Advances in Computing, Communications and Informatics (ICACCI), Bangalore, India, 2018, pp. 217-221 [3] D. N., A. P. and R. E.R., \"Analysis of Smart helmets and Designing an IoT based smart helmet: A cost effective solution for Riders,\" 2019 1st International Conference on Innovations in Information and Communication Technology (ICIICT), Chennai, India, 2019, pp. 1-4 [4] C. J. Behr, A. Kumar and G. P. Hancke, \"A smart helmet for air quality and hazardous event detection for the mining industry,\" 2016 IEEE International Conference on Industrial Technology (ICIT), Taipei, Taiwan, 2016, pp. 2026-2031 [5] G. E. M. Abro, S. A. Shaikh, S. Soomro, G. Abid, K. Kumar and F. Ahmed, \"Prototyping IOT Based Smart Wearable Jacket Design for Securing the Life of Coal Miners,\" 2018 International Conference on Computing, Electronics & Communications Engineering (iCCECE), Southend, UK, 2018, pp. 134-137 [6] C. Sunderman and J. Waynert, \"An overview of underground coal miner electronic tracking system technologies,\" 2012 IEEE Industry Applications Society Annual Meeting, Las Vegas, NV, USA, 2012, pp. 1-5 [7] D. K. Yadav, P. Mishra and S. K. Das, \"Study of real-time miner tracking using wireless sensor area network,\" 2015 International Conference on Microwave, Optical and Communication Engineering (ICMOCE), Bhubaneswar, India, 2015, pp. 330-333 [8] Q. -x. Ma, \"Use Intelligent Mobile Phones in Coal Mine Production and Safety Monitor,\" 2009 International Conference on Multimedia Information Networking and Security, Wuhan, China, 2009, pp. 667-669 [9] Y. Guofang, K. Liqiang and Z. Yujie, \"Research on real-time location-tracking of underground mine locomotive based on wireless mobile video,\" 2011 International Conference on Mechatronic Science, Electric Engineering and Computer (MEC), Jilin, China, 2011, pp. 625-627 [10] M. Ndoh and G. Y. Delisle, \"Geolocation in underground mines using wireless sensor networks,\" 2005 IEEE Antennas and Propagation Society International Symposium, Washington, DC, USA, 2005, pp. 229-232 vol. 3B

Copyright

Copyright © 2024 Vaishali Jabade, Sandesh Moralwar, Aditya Mandke, Prathamesh Mohod. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET60800

Publish Date : 2024-04-22

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online