Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Seed Testing to Improve Cultivation Using Android Application

Authors: Kommineni Chaitanya, Mr. B H Dasaradha Ram

DOI Link: https://doi.org/10.22214/ijraset.2023.54978

Certificate: View Certificate

Abstract

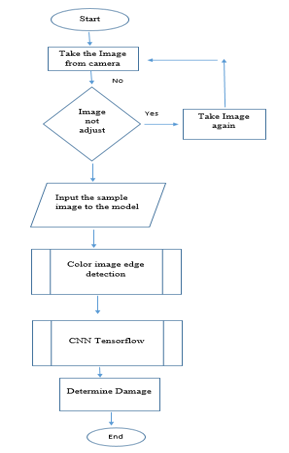

Corn is one of the most important agricultural products produced in India. Customers can get it in a variety of provinces and cities. Before just being distributed to consumers, corn kernels must undergo quality assurance. Most farmers in the nation use manual human inspection as the only method of classifying and evaluating maize kernels, and these methods are inconsistent, leading to inconclusive results. When dealing with a lot of kernels that need to be certified, this is more common. Through the use of a neural network method of inspection, this study proposes to reduce the inconsistencies. Because the physical characteristics of damaged maize kernels may be used to detect the damage, the neural network can rapidly determine the type of damage in a given sample. The following categories of damage, in addition to the healthy kernels, were examined in this study: drier damage, heat damage, OCOL (Other Color) Type A, and OCOL Type B. The neural network that will be employed is a convolutional neural network, which layers of processing on the images of the samples. In this research, colored image edge detection is also used.

Introduction

I. INTRODUCTION

According to Valiente-González et al. (2014), corn is one of the most significant cereals for use in human meals, animal feed, biofuels, and bio plastics. China, a major maize importer and consumer worldwide, needs a corn qualifying service to set the price of corn for various uses. The criteria for qualifying corn are based on a variety of factors, including appearance, shape, color, flavor, moisture level, infections, and the presence of contaminants.[1] Today, there are methods used to determine the damage done by shelled corn kernels. There really is proof that most of these methods provide data that is only partially accurate. When taken as a total for each harvest, inaccurate data may cause subsequent issues that could harm the overall quality of shelled corn kernels. Additionally, the methods now in use are antiquated, which essentially means that modern, technology-dependent procedures can surpass them.

This study develops a technique for measuring the quality parameters of grain seeds for agricultural researchers in order to solve this issue and enhance the effectiveness of the quality and chosen food species. The system views rice, wheat, and sorghum as the study objectives, recognises and segments the case of static grain seed particles, and analyses and processes the particles of various types of statistical grain quality characteristics parameters.

The system, which is based on particle image recognition and feature extraction techniques, exhibits high speed, high precision, good reproducibility, and personnel selection. It has a wide range of potential applications in fields like crop production quality assessment and breeding agricultural researchers. For quick and precise evaluations, machine vision has been widely used in food inspection and agricultural qualification processes [11]. The ability to grade various items, particularly agricultural products, has been made possible by the combination of digital image processing and neural network algorithms [5]. Cracks, toxins, breakages, and other quality-related characteristics on maize kernels can all be found using image processing. Furthermore, the inefficiency of human examination in determining maize quality can be reduced using computer vision or image processing. A convolutional neural network outperforms classic neural network models like SVM and ANN in a related study titled "Convolutional Neural Network Based Automatic Corn Kernel Qualification" [1].

The major goal of the study is to use a convolutional neural network that incorporates image processing methods to quantify the damage of shelled maize kernels. The specific objectives of this study are to: a. develop a prototype that can evenly distribute shelled corn kernels on a tray and operate a camera to evaluate three different angles of the test data (corn kernels); b. implement a colored image edge detection algorithm designed to detect edges; c. use a convolutional neural network model to process data on the physical deformations of shelled corn kernels; and d. test and validate the convolutional neural network model on reliable data.

II. METHODOLOGY

Chao Ni, Dongyi Wang [1] show an automatic corn qualification machine embedded with deep CNN classifier is presented. From mechanical view gravity based design with dual expends the machine field of view compared to existing qualification machine, even though in theory some spatial information is still loses using only two 2D images to describe a 3D object. Three cameras may be able to solve the problem, but it needs more complicated mechanical and illumination design. From software angle a k-means clustering guided curvature method is proper and applied beforehand to solve the dual kernel touching problem. Touching problem is a critical problem in bio system area. Existing algorithms are mainly focused on touching kernels with complete shape for kernel counting. However, our algorithm targets to touching kernels which have not only complete shapes but also broken shapes. The idea of preliminary screening the touching case based on value can be improved in our fallowing work to further avoid the system error. This problem could be solved by training a new CNN model with more touching kernel data generated in practice. Our curvature approach, however, is limited to two dual touching scenarios.

According to Maxime Oquab and Leon Bottou, Ivan Laptev and Josef Sivic [2] Building on the performance improvement seen on ILSVRC-2012, we have demonstrated how a straightforward transfer learning method produces cutting-edge outcomes on difficult benchmark datasets that are significantly smaller in size. We have also shown the high potential of the mid-level features taken from CNNs that have been trained on ImageNet. The best published results on the Pascal VOC 2012 classification and action identification tasks are already achieved using only 12% of the ImageNet corpus, despite the setup's performance improving when the source task data is increased. Our research contributes to the growing body of research showing that convolutional neural networks can be used to learn complex mid-level picture features that are applicable to a range of visual recognition applications. Our method's source code is accessible.

The words of Plamen Daskalov, Eleonora Kirilova, Violeta Mancheva and Tsvetelina Georgieva [4] comparing obtained results for color image analysis it has been found that in terms of the minimum total average error for all varieties best results given the Support Vector Machine classifier using features derived through the scalar feature ranking method. It is resulting in the range of 0.9-12.2% according to the side of image capturing and variety. In regard to spectra data technique where the coefficients of linear parametric models of discrete type Auto Regression were analyzed, and identification criterion is based on the limit values of ALV between class healthy and class infected seeds, so the maximum distance between the two classes -? A for the 10th order of AR- model is used to determine the limit value. It can be concluded that combining AR model and SVM classifier, and using all ten coefficients of AR models gives a higher recognition rate for all varieties. Regardless of the improved SCM classifiers, accuracy of classification using spectral data for some varieties is still not satisfactory.

Wei Yang, Ce Yang , Ziyuan Hao , Chuanqi Xie , And Minzan Li says[5] Since the creation of convolution neural networks, academics have become interested in the high performance of algorithms. The development of smart agriculture also requires the accurate detection of crop diseases, but the conventional recognition model, which is steady and based on artificially created features, has lesser accuracy. This study employs deep convolutional networks, hyperspectral image pre-processing, and sample extraction to develop five different cold damage recognition models for maize seedlings based on these issues. Throughout the entire process, various network structures are created in accordance with various input data, and the segmentation result is obtained. A convolution neural network (CNN) is applied to the corn cold damage detection model in the case of a small sample of cold-damaged corn seedlings, and the CNN model's structure is developed. The impact of the CNN's weight distribution properties, activation function, and various initialization techniques is examined.

III. CREATING CONVOLUTIONAL NEURAL NETWORK

The Convolutional Neural Network (CNN) will be used for the detection of the damages by the subjecting the datasets or samples through different layers within the cnn. The concept for this neural network is to refer to previous erroneous results to further improve and arrive at an acceptable range of conclusive data. Also the more the training dataset the system has and the more pre-processing can be done, the better the performance of the network will have. The neural network will be created through Intel’s Tensor flow. This neural network model can be produce results with outstanding accuracy. The convolutions that occur within the neural network model allow more dataset training which expends the it covers for each pixel within image. Since the concept of neural network is based from how human brains work, it can be theoretically cover the same considerations when dealing with corn qualification with lesser variable that can contribute to error. Using the convolutional neural network model, the test accuracy for grading or qualifying core kernels can reach up to 90%. This also uses several dataset training phases to remove and further reduce the post-processing inaccuracy as well as consider the images captured by a single camera that should be removed before feeding the dataset onto the convolutional neural network.

Prior to processing it with the convolutional neural network, the input image will be shrunk. There is no relationship with regard to spatial data between an images from one side of a kernel to another while taking pictures on different sides of a corn kernel concurrently. The main idea behind neural networks is that they make reference to previous mistakes and correct themselves accordingly to produce decisive data that is either true or acceptable. According to agricultural specialists from the NFA, this is because the conclusions generated from each image are distinct from one another if the geographical data varies from that of the comparable image by a specific amount.

The filters on the convolutional layers will be moved incrementally from pixel to pixel horizontally and then vertically over the entire image. Convolution eventually comes to an end when each pixel in the feature has its matching value (weight). Conv2d layers are 3x3 in size. The initial convolution will then be normalized to exclude any negative values. As a method of normalization, ReLU will be applied. The process then moves on to pooling layers, where the data is shrunk to create a smaller image with the same features and values. The pooling's image size is 2x2. The same layers will be applied again in a second batch. Afterwards to arrive at a much smaller and more filtered set of data.

Conclusion

Here we given different corn seed damages like Blue eye mold damage cob root damage, germ damage, heat damage, drier damage. We trained the model using batches to manage the memory efficiently because there are more data. The online program uses the train and test split, tensorlfow will give the good accuracy based on the performance of the model. Here we are concluding like corn damage or not detection using CNN and tensorlfow with pre trained model accurately. We got accuracy of 96% in this proposed model.

References

[1] C. Ni, D. Wang, M. Holmes, R. Vinson, and Y. Tao, “Convolution Neural Network Based Automatic Corn Kernel Qualification”, 2018 ASABE Annual International Meeting, Detroit, Michigan, 2018. [2] M. Oquab, L. Bottou, I. Laptev, and J. Sivic, “Learning and Transferring Mid-Level Image Representations using Convolutional Neural Networks”, Computer Vision and Pattern Recognition 2014, Colombus, Ohio, 2014. [3] R. Gerpacio, J. Labios, R. Labios, and E. Diangkinay, “Maize in the Philippines: Production Systems, Constraints, and Research Priorities”, CIMMYT, Mexico, 2004. [4] Plamen Daskalov, Eleonora Kirilova, Violeta Mancheva and Tsvetelina Georgieva, “Comparative Study on the Application of Visible and Near Infrared Hyperspectral Imaging for Fusarium Disease Assessment of Corn Seeds Vol. 17, No. 13, pp. 235-240, Iowa, 2001. [5] Wei Yang, Ce Yang , Ziyuan Hao , Chuanqi Xie , And Minzan Li says, “Diagnosis of Plant Cold Damage Based on Hyperspectral Imaging and Convolutional Neural Network Vol. 3, No.1, pp. 1194-1201, Gujarat, India, 2015. [6] N. Youssef, A. Bouzid, and N. Ellouze, “Color Image Edge Detection Method Based on Multiscale Product using Gaussian Function”, ATSIP 2016 - 2nd International Conference on Advanced Technologies for Signal and Image Processing pp.228-2232, Monastir, Tunisia, 2016. [7] S. Zagoruyko, and N. Komodakis, “Learning to Compare Image Patches via Convolutional Neural Networks”, Computer Vision and Pattern Recognition 2015, Boston, Massachusetts, 2015. [8] United States Department of Agriculture, “Visual Reference Images”, Washington, D.C., 2016 [9] Z. Xiaoli, “Edge Detection Algorithm Based on Multiscale Product with Gaussian Function”, in Procedia Engineering Vol. 15, pp. 2650-2654, 2011. [10] P. Dolata, M. Mrzyglod, and J. Reiner, “Double-stream Convolutional Neural Networks for Machine Vision Inspection of Natural Products”, in Applied Artificial Intelligence Vol. 31, pp. 643-659, 2017. [11] K. Kiratiratanapruk, and W. Sinthupinyo, “Color and texture for corn seed classification by machine vision”, 2011 International Symposium on Intelligent Signal Processing and Communications Systems (ISPACS), pp. 1-5, Chiang Mai, 2011. [12] S. Aygün and E. Güne?, \"Computer vision techniques for automatic determination of yield effective bad condition storage effects on various agricultural seed types,\" 2016 Fifth International Conference on AgroGeoinformatics (Agro-Geoinformatics), pp. 1-6., Tianjin, 2016. [13] M. J. Macawile, V. V. Quinones, A. Ballado Jr., J. Dela Cruz, and M. V. Caya “White Blood Cell Classification and Counting Using Convolutional Neural Network”, 2018 3rd International Conference on Control and Robotics Engineering, pp. 259-263 Manila, Philippines 2018. [14] D. A. Padilla, G. V. Magwili, A. L. Morohom, C. M. Co, J. C. Gano, and J. M. Tuazon “Portable Yellow Spot Disease Identifier on Sugarcane Leaf via Image Processing Using Support Vector Machine”, 2019 5th International Conference on Control, Automation and Robotics, pp 901- 905, Manila, Philippines, 2019. [15] J.C. Dela Cruz and R. C. Ucat “Postharvest Grading Classification of Cavendish Banana Using Deep Learning and Tensorflow”, 2019 International Symposium [16] V. K. Chaithanya Manam, V. Mahendran, and C. Siva Ram Murthy. \" Performance Modeling of DTN Routing with Heterogeneous and Selfish Nodes.\" Wireless Networks, vol. 20, no. 1, pp. 25-40, January 2014. [17] V. K. Chaithanya Manam, Gaurav Gurav, and C. Siva Ram Murthy.\" Performance Modeling of Message-Driven Based Energy-Efficient Routing in Delay-Tolerant Networks with Individual Node Selfishness.\" In COMSNETS’13: Proceedings of the 5th International Conference on Communication Systems and Networks, pp. 1-6, January 2013. [18] V. K. Chaithanya Manam, V. Mahendran, and C. Siva Ram Murthy. \"Message-Driven Based Energy-Efficient Routing in Heterogeneous Delay-Tolerant Networks.\" In MSWiM HP- MOSys’12: Proceedings of ACM MSWIM Workshop on High-Performance Mobile Opportunistic Systems, pp. 39-46, October 2012. [19] V. K. Chaithanya Manam, V. Mahendran, and C. Siva Ram Murthy. \"Performance Modeling of Routing in Delay-Tolerant Networks with Node Heterogeneity\" In COMSNETS’12: Proceedings of the 4th International Conference on Communication Systems and Networks, pp. 1-10, January 2012. [20] V. K. Chaithanya Manam, Dwarakanath Jampani, Mariam Zaim, Meng-Han Wu, and Alexander J. Quinn. \"TaskMate: A Mechanism to Improve the Quality of Instructions in Crowdsourcing.\" In Companion Proceedings of The 2019 World Wide Web Conference (WWW \'19). Association for Computing Machinery, New York, NY, USA, pp. 1121–1130, May 2019. [21] V. K. Chaithanya Manam, and A. Quinn. \" WingIt: Efficient Refinement of Unclear Task Instructions.\" In HCOMP\'18: Proceedings of the 6th AAAI Conference on Human Computation and Crowdsourcing, pp.108-116, June 2018. [22] S. Nyamathulla , Dr. P. Ratnababu , Dr. G. Shobana , Dr. Y. Rokesh Kumar4 , K.B.V. Rama Narasimham A Fast, Dynamic method to identify attributes sets using Corelation-Guided Cluster analysis and Genetic algorithm Techniques” in Design Engineering ISSN: 0011-9342 | Year 2021 Issue: 7 | Pages: 5497-5510. [23] Mrs.Shobana gorintla ,2 Mr.B.Anil Kumar ,3Mrs.B.Sai Chanadana ,4 Dr.N.Raghavendra Sai,5 Dr.G.Sai Chaitanya Kumar “Deep-Learning-Based Intelligent PotholeEye+ Detection Pavement Distress Detection System” in Proceedings of the International Conference on Applied Artificial Intelligence and Computing (ICAAIC 2022) IEEE Xplore Part Number: CFP22BC3-ART; ISBN: 978-1-6654-9710-7 [24] G. Shobana, Dr Bhanu Prakash Battula” A Novel Imbalance Learning with Fusion Sampling using Diversified Distribution” in International Journal Of Research In Electronics And Computer Engineering -IJRECE VOL. 6 ISSUE 3 ( JULY - SEPTEMBER 2018) ISSN: 2393- 9028 (PRINT) | ISSN: 2348-2281 (ONLINE). [25] G. Shobana, Dr Bhanu Prakash Battula “ A comparitive study of skewed data sources using fusion sampling Diversified Distributon” International Journal of Research in Advent Technology, Special Issue, March 2019 E-ISSN: 2321- 9637

Copyright

Copyright © 2023 Kommineni Chaitanya, Mr. B H Dasaradha Ram. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET54978

Publish Date : 2023-07-24

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online