Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Waste Plastic Induced in Self Compacting Concrete to Avoid Plastic Pollution

Authors: M. Manikandan, Dr. V. Ramasamy, S. Selvakmar

DOI Link: https://doi.org/10.22214/ijraset.2023.56010

Certificate: View Certificate

Abstract

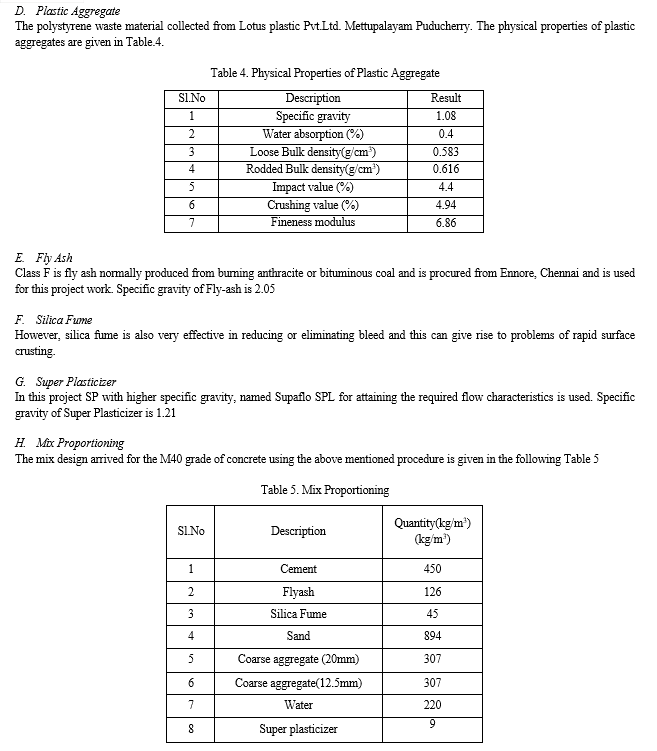

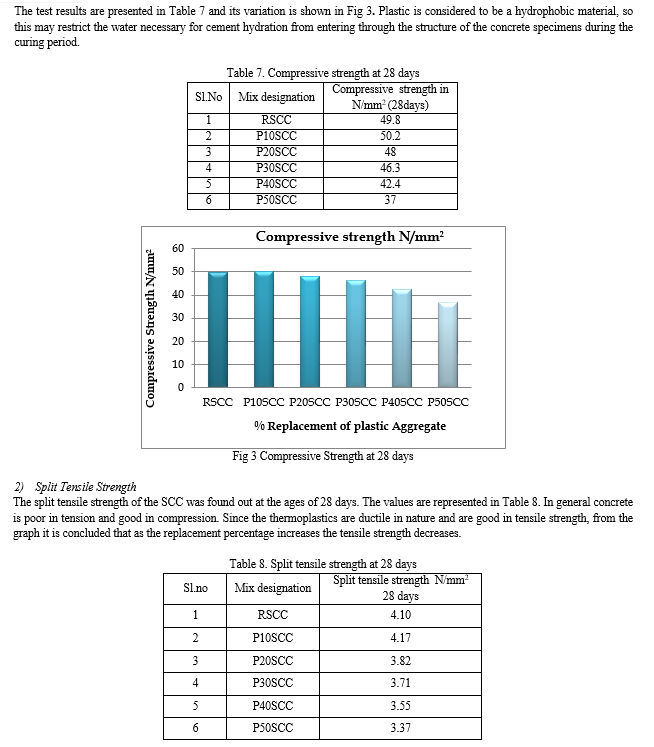

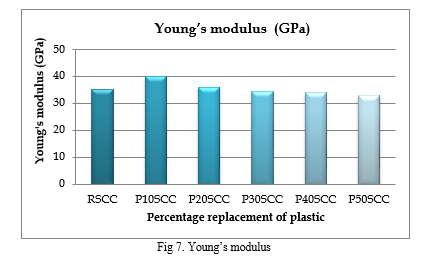

In this present study the plastic aggregate obtained from E-waste is used as a partial replacement of coarse aggregate in self-compacting concrete. An experimental investigation on the fresh, hardened characteristics of concrete using M40 grade of Self compacting concrete are carried out by casting standard concrete with various volume fractions of plastic aggregate such as 0%, 10%, 20%, 30%, 40%, 50% to determine optimal dosage. The fresh properties of SCC reveal that the workability of concrete are improved by using plastic aggregate. Strength properties such as compressive strength shows that up to 30% substitution of coarse aggregate there is no major change in compressive strength as compared to normal concrete. Beyond that there is drop in compressive strength for 50% replacement of coarse aggregate by plastic aggregate. Split tensile strength, Flexural strength and Young modulus of concrete increases for 10% plastic aggregate. Beyond that strength decreases upto 50% replacement. Impact strength decreases for all replacement levels.

Introduction

I. INTRODUCTION

SCC contains powder material as constituent in addition to the traditional concrete materials. Therefore, in general, the density of SCC seems to be higher than the density of normal concrete. Use of lightweight aggregates in the production of concrete can decrease the self-weight of structures. This can result in reduced members’ sections and, therefore, it will save on overall construction costs. Lightweight aggregates are generally classified either as natural or artificial. Polystyrene plastic aggregate are a type of artificial ultra-lightweight non-absorbent aggregate. It is obtained from the Polystyrene type of plastic waste. Mostly polystyrene type plastics are used for making electronic goods. Also plastic is composed of several toxic chemicals, and therefore plastic pollutes soil, air and water. Since plastic is a non-biodegradable material, land-filling using plastic would mean preserving the harmful material forever. The hazards that plastics pose are numerous. They may block the drainage system of a city.

II. LITERATURE REVIEW

In the majority of the studies, a lower slump value of fresh concrete due to the incorporation of several types of plastic aggregates than that of the conventional concrete mix was observed and an increasing addition of plastic aggregate further lowers the slump value .The reasons for the lower slump value of the concrete mix containing plastic aggregate are the sharp edges and angular particle size of plastic aggregate. In a few studies, an increase in the slump value due to the incorporation of plastic aggregate is also reported .The increase of the slump of concrete mixes due to the incorporation of plastic aggregates is due to the presence of more free water in the mixes containing plastic than in the concrete mix containing natural aggregate since, unlike natural aggregate, plastic aggregates cannot absorb water during mixing.

Albano et al reported that concrete with 10% of recycled PET exhibits a compressive strength that meets the standard strength values for concrete with moderate strength .The reduction in compressive strength was more pronounced in concrete containing larger flaky PET aggregate than smaller one. Saikia and de Brito observed similar trends in compressive strength for concrete containing fine and coarse flaky PET aggregate, which was mainly due to the loss of workability of the concrete mix due to the shape of the PET aggregate, especially for larger particles. Batayneh et al. also observed a reduction in the compressive strength of concrete due to the addition of plastic waste as a partial substitution of fine aggregate . For 20% replacement compressive strength shows a sharp reduction up to 72% of the original strength. Ismail and Al-Hashmi reported that the compressive strength of concrete prepared by replacing 10%, 15% and 20% of fine natural aggregate by PET aggregate are higher than the minimum compressive strength required for structural concrete, which is 17.24 MPa, even though the values are lower than the compressive strength of concrete containing only natural aggregate. Albano et al. the decrease in splitting tensile strength was due to the increased porosity of concrete caused by the incorporation of PET aggregate as well as the increase in w/c ratio . Kan and Demirbog?a also reported that the splitting tensile strength of concrete containing heat-treated expanded polystyrene (MEPS) aggregate decreases with its increasing content in concrete, due to the generation of more porosity because of the incorporation of MEPS . Batayneh et al. reported that the decreasing trend of splitting tensile strength was not as prominent as that for compressive strength. Ismail and Al-Hashmi their results showed that the flexural strength of plastic waste concrete mixes at each curing age was prone to decrease with the increase of the plastic waste ratio in these mixes. Saikia and de Brito also found lower flexural strength values for concrete containing PET aggregate than for concrete containing natural aggregate only Hannawi et al. reported that the elastic nature and the non-brittle characteristics under loading of the plastic aggregate might have an effect on the observed flexural strength. Marzouk et al. reported that the modulus of elasticity values (as determined by the ultrasonic method) decreased as PET quantity increased. Compared with the modulus of elasticity of reference mortar (27.94 MPa), a 50% reduction was observed for the mortar prepared by replacing 50% of fine natural aggregate by PET aggregate. The reduction in modulus of elasticity was due both to the reduction of mortars bulk densities and to the presence of plastic aggregates, which decreased the velocity of wave by disturbing the ultrasonic wave propagation.

Conclusion

1) Reduction in the compressive strength was between 15%and 33% for concrete containing 20–50% plastic waste. 2) The reduction in Split tensile strength of about 17.8% at 50% plastic aggregate when compared to reference concrete. 3) The reduction of Flexural strength about 19.9% at 50% replacement of plastic aggregate when compared to reference concrete. 4) Impact strength of concrete tends to decrease at all replacement of coarse aggregate by plastic aggregate .The decrease of about 66 % at 50% replacement when compared to reference concrete. 5) For 10% replacement the elastic modulus is higher than reference concrete. The reduction of about 7% at 50% replacement of plastic aggregate when compared to reference concrete.

References

[1] Albano C, Camacho N, Hernandez M, Matheus A, Gutierrez A(2009),Influence of content and particle size of pet waste bottles on concrete behaviour at different w/c ratios, Waste Management(Oxford) ;29:2707–16. [2] Akcaozoglu S, Atis CD, Akcaozoglu K(2010).An investigation on the use of shredded pet waste bottles as aggregate in lightweight concrete, Waste Management;32:285–90. [3] Brahim Safi , Mohammed Saidi , Djamila Aboutaleb , Madani Maallem (2013).The use of plastic waste as fine aggregate in the self-compacting mortars: Effect on physical and mechanical properties Construction and Building Materials, 436–442. [4] Choi YW, Moon DJ, Kim YJ, Lachemi M (2009). Characteristics of mortar and concrete containing fine aggregate manufactured from recycled waste polyethylene terephthalate bottles”. Construction Building Materials; 23:2829–35. [5] Choi YW, Moon DJ, Chung JS, Cho SK (2005). Effects of pet waste bottles aggregate on the properties of concrete. Cement Concrete Research; 35:776–81. [6] Fraj AB, Kismi M, Mounanga P(2010).Valorization of coarse rigid polyurethane foam waste in lightweight aggregate concrete, Construction Building Materials;24:1069–77. [7] Frigione M (2010). Recycling of PET bottles as fine aggregate in concrete, Waste Management; 30:1101–6. [8] Hannawi K, Kamali-Bernard S, Prince W (2010). Physical and mechanical properties of mortars containing PET and PC waste aggregates, Waste Management; 30: 2312–20. [9] Ismail ZZ, Al-Hashmi EA(2008).Use of plastic waste in concrete mixture as aggregate replacement, Waste Management ;28:2041–2047. [10] Kan A, Demirbog?a R (2009). A novel material for lightweight concrete production, Cement Concrete Composite; 31:489–95. [11] Kou SC, LeeG, Poon CS, Lai WL (2009). Properties of lightweight aggregate concrete prepared with PVC granules derived from scraped PVC pipes, Waste Management ;29:621–8. [12] Marzouk OY, Dheilly RM, Queneudec M (2007). Valorisation of post-consumer plastic waste in cementitious concrete composites, Waste Management; 27:310–8. [13] Nan Su, Kung-Chung Hsu, His-Wen Chai (2001). A simple mix design method for self-compacting concrete, Cement and Concrete Research, Taiwan, pp. 1799-1807. [14] Nanthagopalan Prakash and Manu Santhanam (2010).A simple and systematic mixture design procedure for self-compacting concrete”, 6thInternational RILEM Symposium, Vol. II, 55. [15] Recycling of plastics, Dr. Sue Jackson and Dr. Tamás Bertényi(2006).Department of Engineering, University of Cambridge. [16] Saikia N, de Brito J(2012). Mechanical properties and abrasion behaviour of concrete containing shredded pet waste bottle aggregate as a partial substitution of natural aggregate. Cement Concrete Composite. [17] Siddique R, Khatib J, Kaur I(2008).Use of recycled plastic in concrete: a review. Waste Management; 28:1835–52. [18] Vengadesh Marshall Raman, R. Aswini.\"Studies on Self Compacting Fuel Dispenser Hose Pipe Rubber in Concrete\", Volume 4, Issue XII, International Journal for Research in Applied Science and Engineering Technology (IJRASET) Page No: , ISSN : 2321-9653,www.ijraset.com [19] J.Vengadesh Marshall Raman, M. Sriram .\"Experimental Investigation on Fully Replacement of Steel Slag as Course Aggregate in M30 Grade Concrete\", Volume 5, Issue II, International Journal for Research in Applied Science and Engineering Technology (IJRASET) Page No: , ISSN : 2321-9653, www.ijraset.com [20] J Vengadesh Marshall Raman and R Kirubakaran,” Durability Properties on Fuel Dispenser Hose Pipe Rubber as a Coarse Aggregate in Self Compacting Concrete” Vol. 2, No. 2, April 2017 , International Journal of civil engineering and construction structures (IJCECS),ISSN:2455-7714, www.trpubonline.com [21] J.Vengadesh Marshall Raman, V.Murali Krishnan \"Partial Replacement of Cement with GGBS in Self Compacting Concrete for Sustainable Construction\", SSRG International Journal of Civil Engineering(SSRG-IJCE),V4(3),24-28March2017.ISSN:2348–8352. www.internationaljournalssrg.org/IJCE/index.html. Published by: Seventh Sense Research Group [22] Vengadesh Marshall Raman, J & Ramasamy, V 2021, ‘Augmentation of dissimilar Technique for Enhancing the Concrete properties with Recycled Coarse Aggregate and Manufactured Sand’, Journal of Material Research and Technology, vol.14, pp.1180-1190. [23] Kandasamy S, Gowthaman M , Gowdhamramkarthik P, Vengadesh Marshall Raman J, Magenthiran B,2022, “Strength and durability performance of concrete cast using permeable formwork liner’, Journal of Building Pathology and Rehabilitation (2022) 7:89, [24] J.Vengadesh Marshall Raman, R. Aswini.\"Studies on Self Compacting Fuel Dispenser Hose Pipe Rubber in Concrete\", Volume 4, Issue XII, International Journal for Research in Applied Science and Engineering Technology (IJRASET) Page No: , ISSN : 2321-9653, [25] J.Vengadesh Marshall Raman, M. Sriram .\"Experimental Investigation on Fully Replacement of Steel Slag as Course Aggregate in M30 Grade Concrete\", Volume 5, Issue II, International Journal for Research in Applied Science and Engineering Technology (IJRASET) [26] J. Vengadesh Marshall Raman, R. Senthil Raj.\"Mechanical Studies of Self Compacting Concrete Using Plastic Aggregate\", Volume 5, Issue II, International Journal for Research in Applied Science and Engineering Technology (IJRASET) Page No: , ISSN : 2321-9653,www.ijraset.com [27] J. Vengadesh Marshall Raman, R. Kirubakaran.\"Experimental Investigation of Partial Replacement of Sand by Laterite Soil in Concrete\", Volume 5, Issue II, International Journal for Research in Applied Science and Engineering Technology (IJRASET) . [28] J.Vengadesh Marshall Raman, M. Sriram.\"Study on Replacement Level of Concrete Waste as Fine Aggregate in Concrete\", Volume 5, Issue II, International Journal for Research in Applied Science and Engineering Technology (IJRASET) Page No: , ISSN : 2321-9653. [29] J.Vengadesh Marshall Raman , K.Jaiganesan , \"Durability Study on Replacement Level of Concrete Waste as Fine Aggregate in Concrete\" Vol. 2 - Issue 2 ( January - February 2017), International Journal of Research in Engineering Technologys (IJRET). [30] J.Vengadesh Marshall Raman , K.Jaiganesan , \"Non-Destructive Test and Durability Studies of Self Compacting Concrete Using Plastic Aggregate\" Vol. 2 - Issue 2 ( January - February 2017), International Journal of Research in Engineering Technologys (IJRET. [31] J.Vengadesh Marshall Raman and K Ajeeth Kumar , “Studies on Partially Replacement of Municipal Solid Waste Ash as Cement in Concrete” Vol. 2, No. 2, April 2017, International Journal of civil engineering and construction structures (IJCECS), ISSN: 2455-7714, [32] J Vengadesh Marshall Raman and R Kirubakaran,” Durability Properties on Fuel Dispenser Hose Pipe Rubber as a Coarse Aggregate in Self Compacting Concrete” Vol. 2, No. 2, April 2017 , International Journal of civil engineering and construction structures (IJCECS),ISSN:2455-7714, [33] J Vengadesh Marshall Raman and S Kirubakaran, “ Study on Partial Replacement of Fine Aggregate by Crushed Waste Bottles in Concrete” Vol. 2, No. 2, April 2017, , International Journal of civil engineering and construction structures (IJCECS),ISSN 2455-7714, [34] J.Vengadesh Marshall Raman, V.Murali Krishnan \"Partial Replacement of Cement with GGBS in Self Compacting Concrete for Sustainable Construction\", SSRG International Journal of Civil Engineering (SSRG-IJCE),V4(3),24-28March2017.ISSN:2348–8352. www.internationaljournalssrg.org/IJCE/index.html. Published by: Seventh Sense Research Group [35] J Vengadesh Marshall Raman and K Chellaperumal,” Study on Mechanical Properties of Glass Fiber Reinforced Concrete” Vol. 2, No. 2, April 2017, International Journal of civil engineering and construction structures (IJCECS),ISSN:2455-7714, www.trpubonline.com [36] J. Venkatesh Marshall Raman “Planning and Design of Seismic Resistant Structure using Base Isolation Technique” Vol. 6, Issue 02, 2018, IJSRD - International Journal for Scientific Research & Development, ISSN (online): 2321-0613, www.ijsrd.com. [37] J.Vengadesh Marshall Raman and N.Vijay “Experimental Study On Glass Fiber Reinforced Concrete Using Metakaolin As Mineral Admixtures” Volume 10, Issue 5, May-2019 ,IJSER - International Journal of Scientific & Engineering Research, ISSN 2229-5518 , [38] J.Vengadesh Marshall Raman and P.Soundarya “An Experimental Study On Rapid Hardening Cement Concrete Paver Blocks By Using Corundum As A Mineral Admixture” Volume 16, Issue 3 Ser. I (May. - June. 2019),IOSR- Journal of Mechanical and Civil Engineering (IOSR-JMCE) e-ISSN: 2278-1684,p-ISSN: 2320-334X, , PP 01-09 [39] J.Vengadesh Marshall Raman and P.Soundarya “Planning, Designing and Estimation of High Ceiling Residential Building(G+1)” Vol. 9,Issue 5 (Series -V) May 2019, pp 60-75 ,Journal of Engineering Research and Application w.ijera.com ISSN : 2248-9622 Vol. 9,Issue 5 (Series -V) May 2019, pp 60-75 [40] J.Vengadesh Marshall Raman, V.Gnanadevi and V.Anitha “Experimental Investigation on Quarry Dust and Recycled Aggregates in Concrete”, International Journal of Civil Engineering and Applications. ISSN 2249-426X Volume 9, Number 1 (2019), pp. 1-9 © Research India [41] J.Vengadesh Marshall Raman, R.Rajesh and P.Sabari Velswaran “Study on Strength of High Performance Concrete by Partial Replacement of Fine Aggregate by Copper Slag” International Journal of Applied Engineering Research ISSN 0973-4562 Volume 14, Number 11 (2019) pp. 2795-2798 © Research India Publications. [42] J. Vengadesh Marshall Raman “Sustainable Technological Solutions for Faster And Cost Effective Construction Of Mass Housing (A Case Study Of Rapid - Monolithic - Disaster Proof Technology) “Journal of Civil Engineering and Technology (JCIET) Volume 06, Issue 01, January - December 2019, pp. 01-16. [43] Vengadesh Marshall Raman, J & Ramasamy, V 2020, ‘various treatment techniques involved to enhance the recycled the recycled coarse aggregate in concrete: A review’, Material Today Proceedings, vol.45, no.7, pp.6356-6363, ISSN: 2214-7853, Impact Factor -1.46. (Elsevier) https://doi.org/10.1016/j.matpr.2020.10.935 [44] IS 456 (2000) Plain and Reinforced concrete, BIS, New Delhi. [45] IS 2386 (1963) Methods of test for Aggregate for concrete, BIS, New Delhi [46] IS 12269 (2013), 53 Grade Ordinary Portland cement Specification, BIS, New Delhi. [47] IS 10262 (2009) Concrete mix proportioning, BIS, New Delhi. [48] IS 516 (1959) Method of tests for strength of concrete, BIS, New Delhi.

Copyright

Copyright © 2023 M. Manikandan, Dr. V. Ramasamy, S. Selvakmar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET56010

Publish Date : 2023-10-04

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online