Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Semi-Auto Cupcake Master: Boosting Baking Efficiency and Quality

Authors: Prof. Nishigandha Patel Gajanan Jadhav, Bhushan Sawant, Shohein Khanian, Abbas Kapadia

DOI Link: https://doi.org/10.22214/ijraset.2024.62533

Certificate: View Certificate

Abstract

This project introduces an innovative cupcake baking system that merges simple technology with traditional methods to streamline and enhance production. The system features precise conveyor control, automated baking, and intelligent monitoring, catering to both amateur and professional bakers. The project begins with an extensive analysis of current cupcake baking practices, identifying cost, efficiency, and usability challenges. The design phase integrates key components such as a programmable chain conveyor with heating coils, a batter dispensing mechanism, and a user-friendly monitoring and control interface. Custom-designed components were assembled during the fabrication process, using materials that meet safety and functionality standards. Micro-controllers ensure precise movement of cupcakes into and out of the baking station, achieving uniformly baked results. The batter dispensing mechanism is optimized for control and minimal waste, while safety features prevent overheating and over-dispensing, ensuring a secure baking environment. Performance evaluation through tests and trials showed significant improvements in cupcake uniformity, time efficiency, and user convenience compared to traditional methods. In conclusion, this project successfully demonstrates an advanced cupcake baking system that addresses key challenges in the baking process. By integrating technology, the system enhances cupcake quality and consistency, offering a cost-effective solution for bakers of all skill levels and paving the way for future advancements in baking technology.

Introduction

I. INTRODUCTION

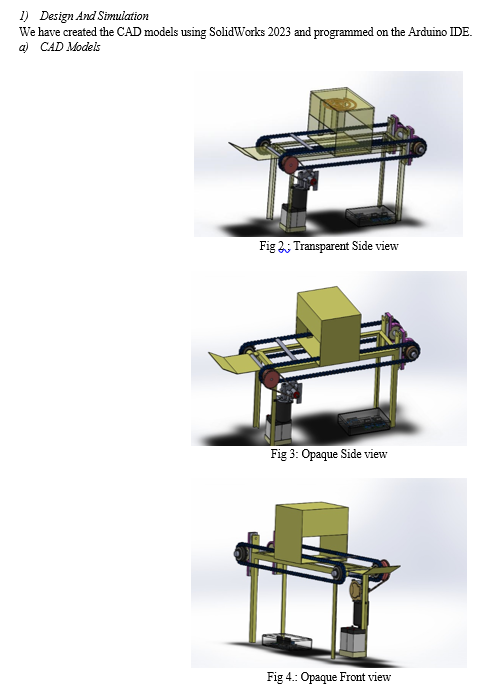

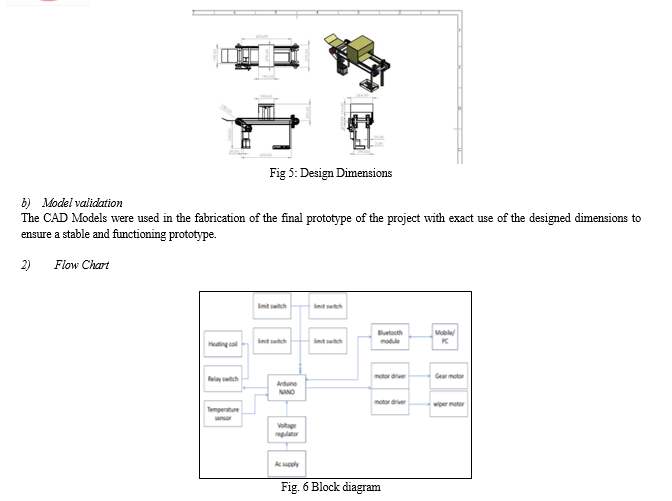

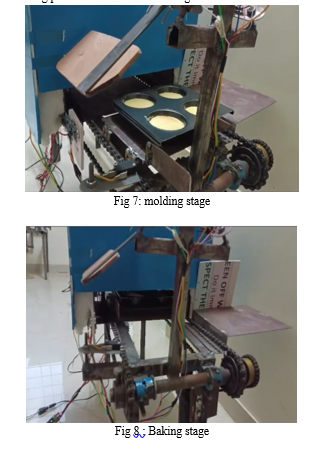

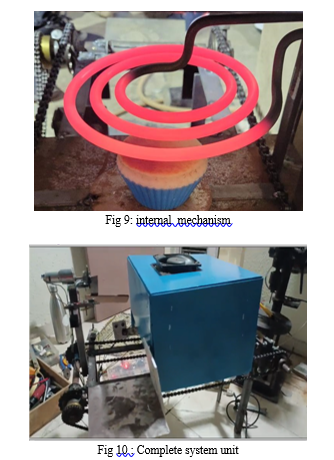

The bakery industry has long been characterized by following traditional methods and relying on old techniques passed down from generation to generation. However, the baking landscape has changed in recent years as technology has been integrated into traditional processes. This change opened the way to innovative solutions aimed at improving the efficiency, uniformity and quality of confectionery production. In this context, the focus of this research is the design and manufacture of an advanced cupcake baking system that uses technology to simplify and optimize the baking process. The system represents a fusion of simple technology and traditional baking methods and offers a usable solution for hobbyists as well as professional pastry chefs. The heating system is an MS frame where the heating coil is placed at the top in a box shaped frame through which the cupcakes get baked for 7 minutes and exit the box once baking is completed. The system utilizes a conveyor system to transport the cupcakes from initial position to the heating phase where a heating coil is placed for the baking process of the cupcake to begin, once the baking phase completes, the cupcakes are transported out of the heating phase and successfully dispensed onto a plate, ready for serving. We switch on the coil to start the preheating process which takes 10 min and then the cupcake batter is filled in a silicon mould and the mould is placed on a thin rectangular plate which is welded to the conveyor and the conveyor starts moving once the machine is switched on. The entire process runs with the help of an Arduino microcontroller responsible for the automatic movement and accurate delay provided where necessary to complete 1 cycle. Each cycle comprises of 3 cupcakes being baked simultaneously and once dispensed it returns to the initial position for the next batch cycle to begin. Along with the insulation done with ceramic fiber and asbestos rope, the baking of the 3 cupcakes after multiple test runs takes approx. 7 minutes as a result.

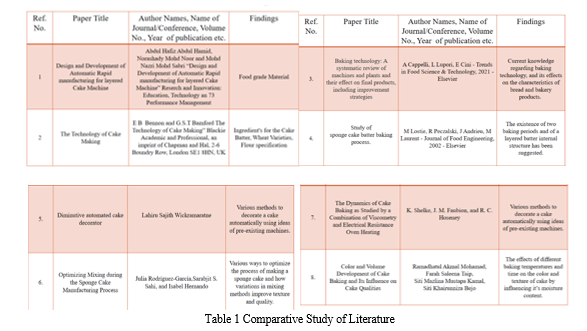

II. RELATED WORK

Ruslan et al,. [1] paper presents a plan and improvement of an independent cupcake machine and examines how an independent cupcake machine may well be created and unravel the issues. Yusuf Abdullahi Badamasi [2] presents a paper on the working principle of Arduino Uno and its software and hardware uses and applications along with the programming methods using the Arduino. Ureta et al,. [3] focused on research centered on considering the test impact of agent conditions on volume extension and the warm exchange elements amid the preparation of sponge cake and as a result the test and recreated temperature profiles that confirmed that the final locale to attain a correct degree of baking is the one near the crust around the axial axis.

Hamid et al,. [4] emphasized on an automatic sheet cake machine that had the full capacity to do all similar processes in one machine, capable of producing 288 sheets per machine per day. Abdullah et al,. [5] emphasizes a model to anticipate the nourishment from the microbes and keep up the temperature of the nourishment by utilizing the temperature sensor LM35 which is controlled with Arduino. Bassey et al,. [6] emphasized on the integration of mini-conveyor, detecting, checking, and remote organize innovation into one frame work makes it profoundly consistent and appropriate for checking generation line yield in fabricating businesses. The quick headway in remote innovation is making modern arrangements and applications for industry checking frameworks. Sahi et al,. [7] addresses the central structural control mechanisms available to the baker, as well as the choice of ingredients, formulations, equipment and processing methods that affect the quality of the final product. Ologunye et al,. [8] elaborated on his work on an electric oven that is designed to improve the efficiency and effectiveness of an existing oven by integrating a thermostat and key switch. K Shelke et al., [9] emphasized on the combination of oscillatory viscometry and electrical resistance heating techniques was applicable to the continuous observation of the cake baking system and could be used to follow the effects and roles of various ingredients on batter viscosity and cake quality during heating. Ramadhatul et al., [10] emphasized the effect and the relationship of different baking parameters to the cake qualities during baking process. The results show that the total colour difference, ΔE, and volume expansion rapidly changed due to the rise in temperature of cake and has a positive relationship with cakes' firmness and the moisture loss. The data also demonstrated that the browning and volume expansion were more significant to the baking temperature (P<0.001) than baking times. Hassan et al., [11] emphasized on a programming model that is found to be useful for small and medium enterprises to gauge their profits based on their labour, machine use and raw materials requirements and also that this study can be further extended with regard to the flavor varieties of the products such as chocolate, strawberry and vanilla and to other SME’s with their own unique constraints in accordance to their required goals peculiar to their trade.

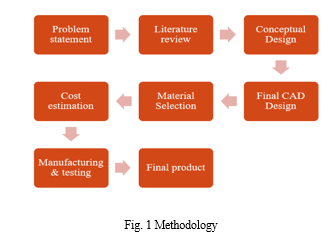

III. METHODOLOGY

A. Introduction

The experimental methodology section outlines the systematic approach employed in the present study to design and fabricate a cost-effective and smart small-scale cake baking machine. The objective is to address existing research gaps by developing an innovative solution that combines affordability, scalability, and advanced technological features.

B. Methodology Details

- Objective Definition: Clearly define the objectives of the evaluation, such as assessing baking uniformity, productivity gains, user-friendliness, and adaptability to market needs.

- Machine Setup: Set up the semi-automatic cake baking machine according to manufacturer specifications. Ensure proper installation of the heating coil, conveyor system, and dispensing plate.

- Baking Parameter Calibration: Calibrate the heating coil to achieve the desired temperature for cupcake baking.Conduct preliminary tests to determine the optimal baking time for cupcakes.

- Sample Preparation: Prepare consistent batches of cupcake batter for testing. Use standardized cupcake molds to maintain uniformity in size and shape.

- Experimental Design: Design a series of experiments to test the machine's performance. Vary parameters such as baking time, temperature, and batter quantity to assess their impact on cupcake quality.

- Baking Process Execution: Run multiple batches of cupcakes through the machine, utilizing the conveyor system to move molds into the heating chamber .Monitor the baking process, recording data on temperature, time, and any observed variations.

- Quality Testing: Conduct thorough quality testing on the baked cupcakes. Assess texture, taste, and visual appearance to ensure uniformity and adherence to quality standards.

- Productivity Assessment: Measure the time taken for each baking cycle., Evaluate the efficiency gains achieved through the use of the conveyor system in comparison to traditional methods.

- User Interface Evaluation: Assess the usability of the machine's interface.Gather feedback from operators regarding the intuitiveness of controls and ease of monitoring.

- Adaptability Testing: Test the machine's ability to handle different cupcake sizes and recipes. Explore variations in batter consistency and assess the machine's adaptability.

- Energy Consumption Measurement: Monitor and record the energy consumption during the baking process. Compare energy efficiency with industry standards and explore potential optimizations.

- Quality Control Sensor Validation: Validate the accuracy of quality control sensors, such as temperature sensors and batter consistency monitors. Ensure these sensors contribute to maintaining consistent product quality.

- User Feedback Collection: Collect feedback from operators and users regarding their overall satisfaction with the machine. Identify areas for improvement and potential future features.

- Data Analysis: Analyse the collected data to draw conclusions regarding the machine's performance in terms of baking uniformity, productivity, user-friendliness, and adaptability.

- Iterative Refinement: Based on the analysis, identify areas for improvement and refinement. Consider adjustments to the machine design, software, or operational procedures.

- Documentation and Reporting: Compile a comprehensive report detailing the methodology, experimental results, and conclusions. Provide recommendations for potential upgrades and future developments.

C. Closure

This chapter summarises the methodology and working process for operation of the semi-automatic cake baking machine. The next chapter briefs about the design and CAD model of the machine.

IV. TOOLS AND TECHNOLOGY USED

The proposed system uses the following tools and technology

- MS Frame

- Arduino Uno

- Conveyor Chain

- Motor

- Motor Driver

- Temperature sensor

- Ultrasonic sensor

- Relay

- Standard Heating Coil

- Limit Switch

- Pedestal Bearing

- Sprockets

- Free Wheel Bush

A semi-automatic cake baking machine offers a range of applications and uses in both small-scale and large-scale baking operations. Here are some of the key applications and benefits:

A. Applications

- Commercial Bakeries

a. Increased Production Efficiency: Semi-automatic machines streamline the baking process, allowing bakeries to produce a higher volume of cakes in less time compared to manual methods.

b. Consistency and Quality Control: These machines ensure consistent baking times and temperatures, leading to uniform quality and appearance of cakes.

2. Small and Medium Enterprises (SMEs)

a. Scalability: Small and medium-sized bakeries can use these machines to scale up production without a significant increase in labor costs.

b. Product Diversity: Semi-automatic machines can often handle different types of cakes, enabling SMEs to diversify their product offerings.

3. Catering Services

a. Customized Production: Caterers can use these machines to produce cakes tailored to specific events or customer preferences with consistent quality.

4. Home-Based Businesses

a Efficiency for Home Bakers: Individuals running home-based baking businesses can benefit from the improved efficiency and reduced manual effort offered by semi-automatic machines.

5. Institutional Use

a. Schools, Hospitals, and Canteens*: Institutions that need to produce cakes regularly in large quantities for students, patients, or staff can benefit from the reliable and consistent output of semi-automatic baking machines.

B. Uses

- Mixing and Baking Automation

a. Consistent Mixing: Automated mixers ensure that cake batter is mixed to the correct consistency every time.

b. Uniform Baking: Semi-automatic baking ovens provide precise temperature control, ensuring that cakes are baked evenly and thoroughly.

2. Labor Reduction

a. Reduced Manual Labor: These machines reduce the amount of manual labor required, freeing up staff to focus on other tasks such as decorating or packaging.

3. Time-Saving

a. Quicker Production Cycles: By automating repetitive tasks, these machines significantly reduce the time required to produce each batch of cakes.

4. Improved Hygiene

a. Hygienic Processing: Automated processes reduce the amount of direct human contact with the product, thereby maintaining higher hygiene standards.

5. Energy Efficiency

a. Optimized Energy Use: Modern semi-automatic machines are designed to be energy efficient, reducing overall operational costs.

6. Customization Options

a. Flexible Settings: Many semi-automatic machines come with programmable settings, allowing bakers to customize baking times, temperatures, and mixing speeds for different types of cakes.

C. Specific Features and Examples

- Automatic Ingredient Dispensing: Ensures precise measurement of ingredients, leading to consistent cake quality.

- Conveyor Belt Systems: Facilitates the continuous movement of cake molds through the baking process, improving production efficiency.

- Temperature and Humidity Control: Advanced controls maintain optimal baking conditions, ensuring perfect texture and moisture content in cakes.

- Multi-Function Capabilities: Some machines can handle multiple steps in the baking process, from mixing and baking to cooling and decorating.

V. RESULTS AND ANALYSIS

A. Results

- Baking Uniformity: The heating coil has proven effective in providing consistent and uniform heat distribution, resulting in evenly baked cupcakes. Quality testing indicates minimal variations in texture and taste among the cupcakes produced.

- Productivity: The conveyor system successfully moves two cupcake molds at a time, optimizing the baking process and enhancing overall productivity. The efficiency gains are notable, with a reduction in manual handling and a smoother workflow.

- Baking Time Accuracy: The 7 and a half minutes baking time using the heating coil has been found to be optimal for achieving the desired cupcake texture and taste. Extensive testing and adjustments have been made to ensure precise baking times.

- Dispensing Plate Transfer: The transition of cupcakes from the heating chamber to the dispensing plate occurs seamlessly, indicating the completion of the baking cycle. The automated transfer eliminates the risk of human error in the handling process.

- User-Friendly Interface: Initial user feedback suggests that the machine's interface is intuitive and user-friendly. Operators can easily monitor and control the baking process with minimal training.

B. Discussions

- Efficiency and Labor Reduction: The semi-automatic nature of the machine significantly reduces the need for manual labor in the baking process. This can lead to increased efficiency, lower labor costs, and a more consistent product.

- Quality Assurance: The incorporation of quality control sensors ensures that each cupcake meets the desired standards. This not only enhances customer satisfaction but also contributes to the reputation of the product in the market.

- Adaptability to Market Needs: The flexibility of the machine in handling different cupcake sizes and recipes positions it well to adapt to changing market demands. Regular market research and updates to the machine's capabilities will be crucial in staying competitive.

- Energy Consumption: Ongoing efforts to optimize energy consumption will contribute to sustainability and cost-effectiveness. Exploring alternative heating technologies and energy-efficient components can further enhance the machine's environmental footprint.

- User Satisfaction: Continued user feedback and satisfaction surveys are essential for identifying areas of improvement. This iterative process ensures that the machine remains aligned with user expectations and preferences.

- Market Positioning: With the baking industry evolving, strategic marketing and positioning of the machine in relation to competitors are critical. Highlighting its efficiency, quality, and adaptability will be key factors in establishing a strong market presence.

- Future Upgrades: Regular updates and potential future upgrades, such as incorporating smart technologies and automation enhancements, should be considered to keep the machine at the forefront of industry advancements.

Conclusion

A. Conclusion The automatic cake baking machine utilizing a heating coil and a conveyor system for baking cupcakes offers several advantages in terms of efficiency and consistency in the baking process. The incorporation of a heating coil along with a temperature sensor ensures precise temperature control, resulting in evenly baked cupcakes. The conveyor system, capable of handling four cupcake molds simultaneously, adds to the productivity of the machine. Variable baking times can be chosen depending on user’s choice, the cupcakes are transferred to the dispensing plate, indicating the completion of the baking cycle. This automation reduces the manual effort required for monitoring and transferring cupcakes, making the baking process more streamlined. The machine\'s automatic nature strikes a balance between automation and human involvement, allowing for control over the baking process while also benefiting from efficiency gains. B. Future Scope 1) Recipe Customization: Implement a user-friendly interface that allows for easy customization of cupcake recipes. This can cater to different flavors, sizes, and dietary preferences. 2) Energy Efficiency: Focus on optimizing energy consumption by exploring advanced heating technologies or incorporating energy-efficient components. 3) Expand Capacity: Consider designing a machine with the capability to handle a higher volume of cupcake molds simultaneously, increasing overall production capacity. 4) Safety Features: Prioritize the incorporation of safety features to ensure the well-being of operators and compliance with industry standards. 5) Environmental Considerations: Explore eco-friendly materials and technologies to make the machine more sustainable and environmentally friendly. 6) Industrialization: Can be used as a draft for a bigger mechanism that can be used to bake more cakes on a larger scale. 7) Incorporation with batter making machine: Can be incorporated into a batter making machine in order to make an entirely automated cake making process. 8) Utilize AI: Can be incorporated with AI programming to upgrade the entire process and also eliminate human intervention on any level to provide complete autonomy.

References

[1] Mondal, Arpita, and A. K. Datta. \"Bread baking–A review.\" Journal of food engineering 86.4 (2008): 465-474. [2] Figoni, P.I., 2010. How baking works: exploring the fundamentals of baking science. John Wiley & Sons. [3] Lostie, M., Peczalski, R., Andrieu, J. and Laurent, M., 2002. Study of sponge cake batter baking process. Part I: Experimental data. Journal of Food Engineering, 51(2), pp.131-137. [4] Abdul Hafiz Abdul Hamid, Norashady Mohd Noor and Mohd Nazri Mohd Sabri “Design and Development of Automatic Rapid manufacturing for layered Cake Machine” Reserch and Innovation: Education, Technology an 73 Performance Management . [5] Lahiru Sajith Wickramaratne., 2016. Diminutive automated cake decorator. [6] Julia Rodríguez-García, Sarabjit S. Sahi, and Isabel Hernando, 2014. Optimizing Mixing during the Sponge Cake Manufacturing Process [7] K. Shelke, J. M. Faubion, and R. C. Hoseney , 1990. The Dynamics of Cake Baking as Studied by a Combination of Viscometry and Electrical Resistance Oven Heating. [8] Ramadhatul Akmal Mohamad, Farah Saleena Taip, Siti Mazlina Mustapa Kamal, Siti Khairunniza Bejo, 2015. Color and Volume Development of Cake Baking and Its Influence on Cake Qualities. [9] Hassan, N., Pazil, A.H.M., Idris, N.S. and Razman, N.F., 2013. A goal programming model for bakery production. Advances in Environmental Biology, 7(1), pp.187-190. [10] Polichshuk, R., Khamzin, S., Mussin, K. and Ali, M.H., 2018, June. Development of an autonomous cupcake machine. In 2018 Joint 7th International Conference on Informatics, Electronics & Vision (ICIEV) and 2018 2nd International Conference on Imaging, Vision & Pattern Recognition (icIVPR) (pp. 399-404). IEEE. [11] Gunal, A.K., Williams, E.J. and Sadakane, S., 1996, November. Modeling of chain conveyors and their equipment interfaces. In Proceedings of the 28th conference on Winter simulation (pp. 1107-1114).

Copyright

Copyright © 2024 Prof. Nishigandha Patel Gajanan Jadhav, Bhushan Sawant, Shohein Khanian, Abbas Kapadia. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62533

Publish Date : 2024-05-23

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online