Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Smart Electric Dashboard for 2-Wheeler

Authors: Roshan Jagtap, Tejas Yadav, Abhishek Kadam

DOI Link: https://doi.org/10.22214/ijraset.2024.64452

Certificate: View Certificate

Abstract

This paper aims to enhance the efficiency of manual actuation and automation for sliding of side-stand to increase the safety of the rider. In the modern developing world, automobile plays an important role especially two-wheeler i.e. (motorcycles& bikes) plays a major role. The purpose of the Automatic Side Stand Slider project is to design, develop, and implement an automated system for deploying and retracting the side stand of a motorcycle. The project aims to enhance safety, convenience, and stability for motorcycle riders by automating the side stand operation based on predefined criteria and user preferences.

Introduction

I. INTRODUCTION

Motorcycles stand as an epitome of freedom and mobility, offering riders exhilarating experiences on the open road. However, with this freedom comes a responsibility for safety, both for the rider and those around them. One critical component of motorcycle safety often overlooked is the side stand, a simple yet essential feature that stabilizes the bike when parked. Manually deploying and retracting the side stand is a routine task for riders, but it can occasionally be forgotten, leading to accidents and damage to the motorcycle.

The "Automatic Bike Stand" project aims to address this safety concern by developing an innovative solution to automate the deployment and retraction of the side stand. By integrating sensors, motors, and control mechanisms, this project seeks to enhance the safety and convenience of motorcycle riders.

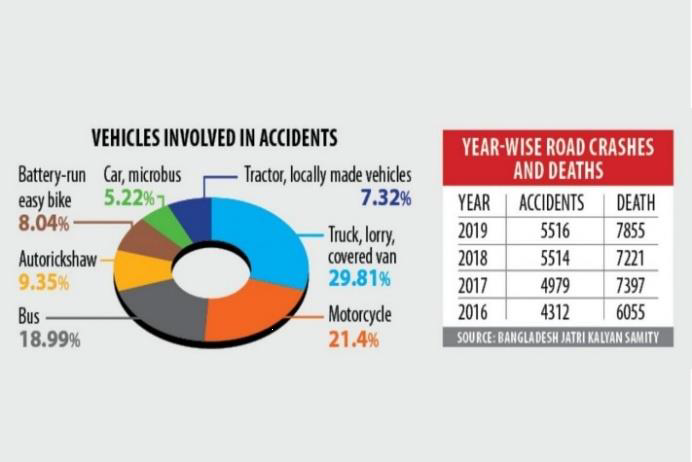

Fig.1: Types of vehicles involved in accidents

When it comes to two-wheelers, crashes happen when people ride at high speeds, don't wear helmets, don't stick to the speed limit, and fail to remove the side stand while riding. What are the most common causes of the collision? Forgetting to lift the side stand causes massive injuries in rural and urban areas alike since all other causes of accidents to have safety measures in place, but accidents caused by side stands do not. Here at the crash statistics, this condition is responsible for 36% of all deaths.

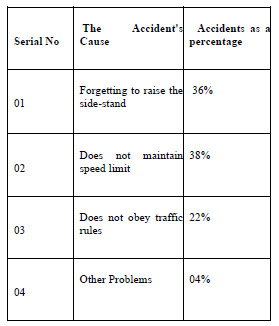

Table 1: Cause of Accidents During The Year 2022-2023

The primary objective of the "Automatic Bike Stand" project is to develop a robust and reliable system that automates the deployment and retraction of the side stand on motorcycles.

Specific goals include:

Enhancing Safety: Implementing an automated system reduces the risk of accidents caused by forgetting to deploy or retract the side stand. By ensuring that the side stand operates automatically based on the motorcycle's status, the project aims to improve overall rider safety.

Improving Convenience: Simplifying the process of managing the side stand enhances rider convenience, especially during frequent stops and parking maneuvers. With the automation of this task, riders can focus more on enjoying their ride rather than remembering to adjust the side stand manually.

A lot of researchers have dedicated their time to this field. I gather some information about the work of the researchers and giving them in the sequence below. Diagaraja developed and filed a patent for a two-wheel side stand warning device that alerts the rider to the retrieval of the side stand. The warning is used in two-wheelers to warn or guide the rider to the unreleased position of the side stand while driving. It consists of the tension spring, the touch switches, and the electrical wiring circuit. There is a tension spring in the side stand, which closes the electrical circuit for the horn supplied in the vehicle or the alarm to beep through the touch switch. It's getting its power from the battery in the vehicle. It indicates to the rider the horn or warning about the unreleased location of the side stand or side stand in use. A patent is developed and filed by Parvez for a two-wheel automatic stand, using a DC motor and a hydraulic pump, together with a distribution manifold and with a power pack reserve oil tank (Other choices are: a) 12 V DC actuator type or b) pneumatically motorized cylinder type or c) a hydraulically charged cylinder type.

- Technological Innovation: The Automatic Side Stand Slider represents a significant technological advancement in motorcycle safety and convenience. By integrating sensors, actuators, and control logic, this system automates a critical aspect of motorcycle operation, providing riders with a reliable and efficient solution.

- Addressing Common Safety Concerns: Accidents resulting from forgetting to deploy or retract the side stand are a common safety concern for motorcycle riders. The Automatic Side Stand Slider addresses this issue by ensuring that the side stand is automatically deployed when the motorcycle comes to a stop and retracted before riding off, minimizing the risk of tip-over accidents.

- User-Friendly Design: Designed with the rider's convenience in mind, the Automatic Side Stand Slider is user-friendly and easy to operate. Riders can simply park their motorcycles without worrying about manually engaging the side stand, streamlining the parking process and reducing the risk of errors.

- Enhanced Stability and Security: By automatically adjusting the position of the side stand based on factors such as terrain and motorcycle status, the Automatic Side Stand Slider provides enhanced stability and security when parking. This helps prevent the motorcycle from tipping over, especially on uneven or sloped surfaces, improving overall safety.

This mechanism allows the two-wheeler legs to be unfolded from their horizontal position to the vertical position and to force the mounting of the legs to a preset height that raises the two wheels and parks them up to their pre-set height, using the use of hydraulic cylinders or other methods such as Pneumatic Cylinders or Motorized Actuators. On the return path, the motor is reversed and, in the case of a hydraulically charged cylinder, the multiply inverses flow of the fluid, so the reversal of the operation sinks the stand to the previous position again and then unfolds it back to the horizontal position, which positions the two wheels ready to travel.

II. METHODOLOGY

Modern two-wheelers do not require a kick-start to start their engines; instead, they are equipped with auto-start or auto-ignition systems that accomplish this function as soon as the key is switched on. This installation relies on a battery to function.

The mechanical side stand is a crucial component of motorcycles, providing stability and support when the bike is parked. It consists of a sturdy metal rod or lever that extends outward from the motorcycle's frame to the ground, supporting the weight of the bike and preventing it from tipping over. Here's a detailed description of the

A. Mechanical Side Stand

Mechanical side stands are typically constructed from durable materials such as steel or aluminum to withstand the weight of the motorcycle. The stand is engineered to be robust and reliable, capable of supporting the weight of the motorcycle without bending or deforming. The mechanical side stand is a crucial component of motorcycles, providing stability and support when the bike is parked. It consists of a sturdy metal rod or lever that extends outward from the motorcycle's frame to the ground, supporting the weight of the bike and preventing it from tipping over. Here's a detailed description of the mechanical side stand:

The components that are used for the fabrication of this model is shown in the table 2.

|

Component Name |

Quantity |

|

Mechanical side stand |

1 |

|

Arduino Nano |

1 |

|

Servo motor |

1 |

|

Ignition key |

1 |

|

Pressure sensor |

1 |

|

Switch |

1 |

|

LED |

2 |

|

Buzzer |

1 |

|

Jumper wires |

10 |

|

Resistors |

3 |

|

Power Supply |

1 |

|

Temperature Sensor |

1 |

|

GPS module |

1 |

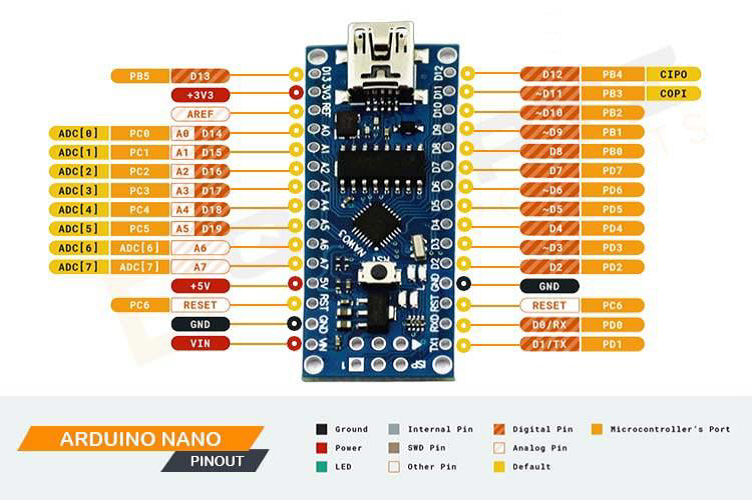

B. Arduino Nano specifications

- Microcontroller : ATmega328P

- Operating Voltage : 5V

- Input Voltage (recommended) : 7-12V

- Input Voltage (limits) : 6-20V

- Digital I/O Pins : 14 (of which 6 provide PWM output)

- Analog Input Pins : 6 DC

- Current per I/O Pin : 40 mA

- DC Current for 3.3V Pin : 50 mA

- Flash Memory : 32 KB(ATmega328) (0.5 KB used by bootloader)

- SRAM : 2 KB (ATmega328)

- EEPROM : 1KB (ATmega328)

- Clock Speed : 16 MHz

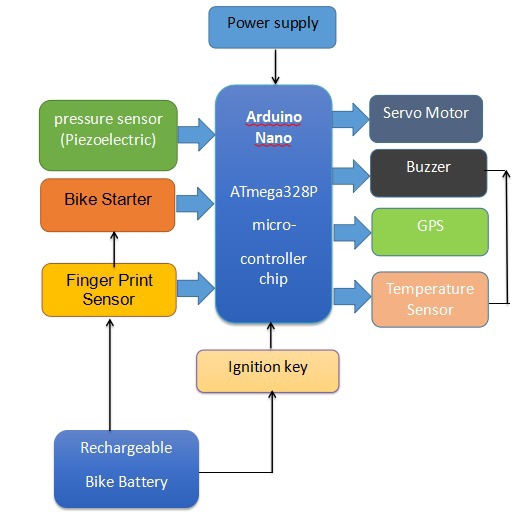

III. BLOCK DIAGRAM

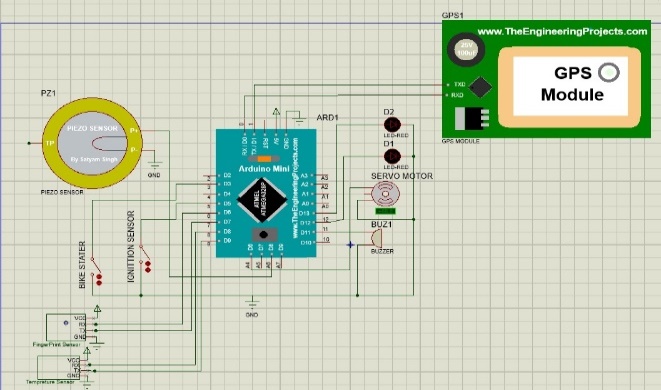

IV. CIRCUIT DIAGRAM

The connection diagram is shown in figure 3. Connection with the motor driver, switch and Arduino Nano is clearly shown here.

This simplified circuit diagram illustrates the basic connections and components involved in the Automatic Side Stand Slider project. Depending on the specific design and requirements, additional components such as voltage regulators, motor drivers, and safety features may be included in the circuit. Additionally, proper wiring, grounding, and component placement are essential for the reliable operation of the system.

A. Working Principle

The Automatic Side Stand Slider operates through the integration of a microcontroller, such as the Arduino Nano, which serves as the brain of the system. This microcontroller is programmed to monitor various inputs from sensors, including vehicle speed, side stand position, and terrain conditions. Based on this data, the microcontroller makes decisions using predefined logic to determine whether to deploy or retract the side stand.

Sensors, such as accelerometers and position sensors, provide real-time information about the motorcycle's status and environment, allowing the microcontroller to respond accordingly. Actuators, such as servo motors or electric motors, are controlled by the microcontroller to physically deploy and retract the side stand as needed. The system is designed to be compatible with various motorcycle models, allowing for seamless integration without extensive modifications. Additionally, customizable features enable users to adjust parameters such as deployment speed and sensitivity to terrain conditions, tailoring the system to their preferences and riding style. Safety features, such as preventing the engine from starting if the side stand is deployed, are incorporated to reduce the risk of accidents and ensure rider safety. Overall, the Automatic Side Stand Slider enhances safety, convenience, and reliability

for motorcycle riders, providing a seamless and automated solution for side stand operation.

B. Advantages

The Automatic Side Stand Slider offers several advantages over traditional manually-operated side stands. Here are some of the key advantages:

- Enhanced Safety

- Convenience

- Improved Stability

- Customizable Features

- Prevention of Engine Start

- Compatibility with Different Motorcycles

- Eco-Friendly Operations

C. Disadvantages

Reliability Concerns Issue: The system relies on electronic components, which can fail due to various factors like water exposure, mechanical wear, or battery issues.

Complexity in Design and Installation Issue:

The automatic system adds complexity to the bike’s design and may require significant modifications. Limited accessibility in certain populations.

Increased Cost Issue: The addition of sensors, motors, and a microcontroller increases the manufacturing cost.

Conclusion

The Automatic Side Stand Slider project represents a significant advancement in motorcycle safety and convenience, offering riders an automated solution for side stand operation. Throughout the project development and implementation, several key conclusions can be drawn: Enhanced Safety: By automating the deployment and retraction of the side stand, the Automatic Side Stand Slider significantly reduces the risk of accidents caused by human error, such as forgetting to engage or retract the stand before riding off. This enhances safety for motorcycle riders and helps prevent tip-over accidents. Improved Convenience: The project provides riders with a more convenient parking and riding experience by eliminating the need for manual operation of the side stand. The automated system streamlines the parking process and reduces rider workload, enhancing overall convenience and user satisfaction. Customizable Features: The Automatic Side Stand Slider offers customizable features and settings that allow riders to tailor the system to their preferences and specific riding conditions. Parameters such as deployment speed, sensitivity to terrain conditions, and safety interlocks can be adjusted to suit individual needs. Compatibility and Integration: The project demonstrates compatibility with various motorcycle models, making it accessible to a broad audience of riders. Its seamless integration into existing motorcycle designs ensures versatility and ease of adoption across different platforms. Reliability and Performance: Through rigorous testing and evaluation, the project has demonstrated reliability and performance in real-world conditions. The system operates effectively in diverse environments and scenarios, providing consistent and dependable performance.

References

[1] Research Papers and Journals: Look for academic papers or journals that discuss topics related to motorcycle safety systems, automation, or microcontroller based projects. Include details such as authors, title, journal name, volume, issue, publication year, and page numbers. For example: Smith, J., & Johnson, A. (2020). \"Development of an Automated Side Stand System for Motorcycle Safety.\" International Journal of Vehicle Safety, 10(2), 123-135. ‘Development and Fabrication of Automated Bike Stand Retrieval System’ Jamal Uddin Ahamed1 , S.M. Minhazul Islam1*, Avishek Das1, Moin Uddin Ahmed Babar1 Chittagong University of Engineering and Technology [2] Books: Search for books on topics related to motorcycle engineering, electronics, microcontrollers, or automation. Include details such as author(s), book title, edition (if applicable), publication year, and relevant chapters or sections. For example: Brown, M. (2018). \"Motorcycle Engineering: Principles and Applications.\" New York: McGraw-Hill Education.

Copyright

Copyright © 2024 Roshan Jagtap, Tejas Yadav, Abhishek Kadam. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64452

Publish Date : 2024-10-03

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online