Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Smart Fault Detector Robo to Detect Gas and Fire

Authors: Shivam S Ghode, Samiksha K. Gedam, Tejas S. Mahajan, Piyush R. Nikalje, Ankit M. Parate, Ameenkhan F. Pathan

DOI Link: https://doi.org/10.22214/ijraset.2024.61011

Certificate: View Certificate

Abstract

The Smart Fault Detector Robo revolutionizes safety protocols with its cutting-edge design, employing a synergy of state-of-the-art sensors, AI, and robotics. Its primary goal is the early identification of gas leaks and fire incidents across diverse settings. Utilizing advanced gas sensors, it can detect a broad spectrum of harmful gases, including methane and carbon monoxide, with remarkable precision. Powered by sophisticated AI algorithms, it swiftly analyzes data in real-time, distinguishing between normal fluctuations and potential hazards, ensuring unparalleled accuracy and reliability.

Introduction

I. INTRODUCTION

In an era marked by technological advancements and growing concerns over safety and security, the development of innovative solutions for early detection of gas leaks and fire incidents has become paramount. Among these solutions, the Smart Fault Detector Robo emerges as a promising system that integrates cutting-edge sensors, artificial intelligence, and robotics to proactively identify potential hazards in various environments. Designed to address the pressing need for swift and accurate detection of gas leaks and fire outbreaks, this advanced technology offers a proactive approach to ensuring safety and minimizing risks to individuals and assets.

The Smart Fault Detector Robo's ability to detect a wide range of harmful gases, such as methane, propane, and carbon monoxide, with high sensitivity and accuracy underscores its potential impact in mitigating potential hazards. Moreover, its sophisticated artificial intelligence algorithms enable real-time analysis of sensor data, distinguishing between normal environmental variations and hazardous situations. By leveraging these capabilities, the Smart Fault Detector Robo represents a groundbreaking solution for enhancing gas and fire safety in diverse settings. This research paper explores the technological principles, applications, and potential implications of this innovative system in ensuring a safer environment for all.

II. OBJECTIVE OF THE PROJECT

The primary aim of the Smart Fault Detector Robo project is to pioneer the development of an advanced robotic system that excels in the detection and swift response to gas leaks and fire incidents across a spectrum of environments. Central to this endeavor is the project's overarching goal of meeting the urgent demand for early identification of potential hazards, thereby furnishing a proactive mechanism to bolster safety protocols and avert catastrophic events.

One of the pivotal objectives of the project is to engineer a resilient gas detection system leveraging state-of-the-art sensors. These sensors are meticulously calibrated to discern the presence of hazardous gases such as methane, propane, and carbon monoxide with unparalleled sensitivity and precision. The ultimate aim here is to achieve a level of detection prowess that facilitates timely interventions, thus effectively curbing potential risks before they escalate.

Another critical facet of the project entails the development of a user-friendly interface tailored for seamless interaction with the Smart Fault Detector Robo. This interface serves as the conduit through which users can monitor the system's operations, promptly receive alerts regarding detected anomalies, and, if deemed necessary, instigate manual interventions. The interface design prioritizes accessibility and clarity, furnishing users with vital insights and data to inform their decision-making processes effectively.

In sum, the Smart Fault Detector Robo project endeavors to make significant strides in bolstering gas and fire safety measures. Through the meticulous pursuit of its objectives, the project seeks to usher in a new era characterized by proactive and intelligent solutions aimed at safeguarding lives and property across a diverse array of environments. By harnessing cutting-edge technology and fostering interdisciplinary collaboration, this initiative aspires to leave an indelible mark on the landscape of safety and security.

III. PROBLEM AND SOLUTION

In India, the threat of terror attacks and natural disasters like earthquakes poses significant challenges to public safety and disaster management.

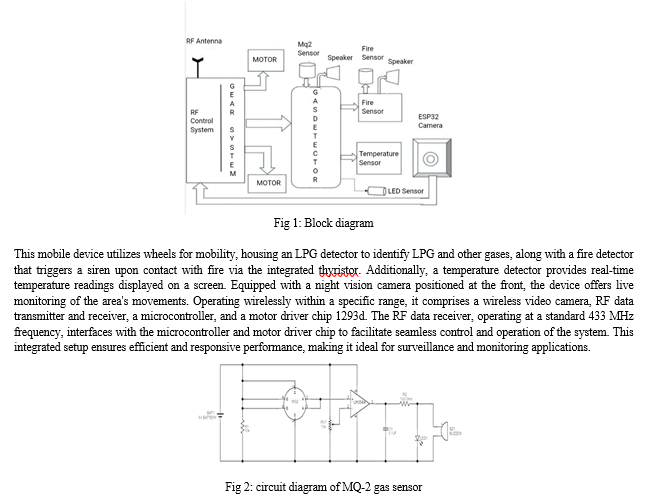

Introducing the Spy and Survivor Robo system offers a viable solution to mitigate these risks and enhance survival rates. This innovative device operates through a radio frequency system, providing controlled mobility within a specified range. Equipped with wheels, the robo can navigate diverse terrains, aiding in swift response and rescue efforts during crises.

Given the inadequacies in current disaster management practices, there is a pressing need to develop systems that minimize losses and maximize efficiency in handling such situations. Whether it's natural calamities such as earthquakes and tsunamis or technical disasters like building collapses and gas leaks, the Spy and Survivor Robo stands poised to revolutionize disaster response by optimizing both internal and external resources for effective management and mitigation of risks.

The MQ-2 gas sensor utilizes SnO2 as its gas sensitive material, which exhibits low electrical conductivity in clean air. However, when combustible gas is present in the surrounding air, the sensor's electrical conductivity rises in correlation with the concentration of the combustible gas. This change in electrical conductivity can be harnessed to generate an output signal through the implementation of a straightforward circuit.

Upon connecting the VCC and GND wires, the module's Power LED illuminates, indicating proper power supply. It is advisable to allow the power supply to preheat for a minimum of 2 minutes before usage to ensure optimal performance. While slight heating is expected due to the presence of a heating wire inside the sensor, excessive overheating should be considered abnormal. Under normal conditions, when there is no presence of gas or the gas concentration remains below the preset threshold, the digital interface D0 outputs a high level, and the voltage of the analog interface A0 hovers around 0V.

However, once the gas concentration surpasses the threshold, D0 switches to a low level, activating the digital indicator light. Additionally, the output voltage of the analog interface A0 escalates in tandem with the gas concentration, ranging from 0.1V to 0.3V for relatively non-polluted environments and up to 4V for higher gas concentrations. Adjusting the potentiometer clockwise widens the sensing range of gas concentration, albeit only affecting the sensitivity of the TTL output.

Moreover, the digital output D0 can directly drive a relay module to create a gas switch, or it can drive a positive buzzer module to form a gas alarm. Furthermore, connecting the analog output A0 to an AD module enables the retrieval of approximate values for ambient gas concentration through AD conversion.

2) Thermal Resistance

For semiconductor devices used across consumer and industrial electronics, the concept of thermal resistance offers a straightforward approach to selecting appropriate heat sinks. Heat transfer from the semiconductor die to ambient air is visualized as a sequence of resistances: from the die to the device case, from the case to the heat sink, and from the heat sink to the surrounding air.

The cumulative effect of these resistances yields the total thermal resistance from the die to the ambient air. Thermal resistance, akin to electrical resistance, quantifies the temperature increase per unit of power and is denoted in degrees Celsius per watt (°C/W). Once the device dissipation in watts is established, and the overall thermal resistance is determined, it becomes feasible to compute the temperature rise of the die relative to the ambient air. While the notion of thermal resistance for a semiconductor heat sink serves as a useful approximation, it overlooks factors such as non-uniform heat distribution across the device or heat sink.

Additionally, it assumes thermal equilibrium within the system and does not account for temporal changes in temperature. Moreover, it fails to acknowledge the non-linear relationship between radiation/convection and temperature rise. Nonetheless, manufacturers provide typical thermal resistance values for both heat sinks and semiconductor devices, streamlining the selection of commercially available heat sinks.

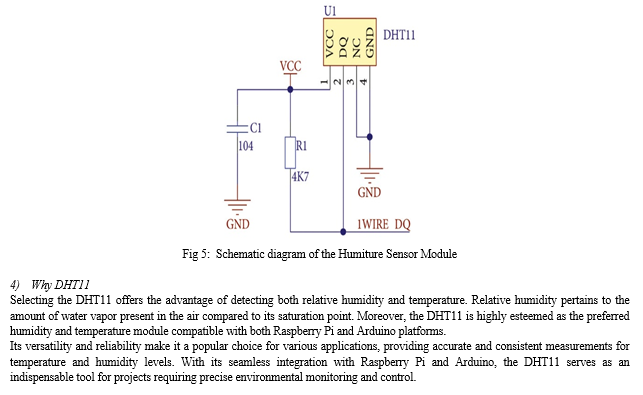

3) DHT11 Temperature sensor

The DHT11 digital temperature and humidity sensor stands as a versatile composite sensor offering calibrated digital outputs for temperature and humidity measurements. By employing dedicated digital modules and advanced temperature and humidity sensing technologies, this sensor guarantees high reliability and enduring stability.

Its design incorporates a resistive moisture sensing component along with an NTC temperature measurement device, seamlessly integrated with a high-performance 8-bit microcontroller. This combination ensures accurate and consistent readings of temperature and humidity. The sensor's architecture underscores its capability to deliver reliable data for a wide range of applications, making it a valuable tool in various industries.

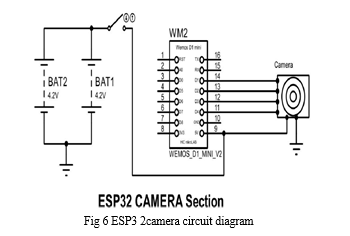

ESP32 represents a family of cost-effective, energy-efficient system on a chip microcontroller that come equipped with integrated Wi-Fi and dual-mode Bluetooth capabilities. These microcontrollers, available in various configurations, utilize either a Tensilica Xtensa LX6 microprocessor, offered in both dual-core and single-core variants, or an Xtensa LX7 dual-core microprocessor, alongside a single-core RISC-V microprocessor. In addition to their processing power, ESP32 devices feature built-in antenna switches, RF balun, power amplifier, low-noise receive amplifier, filters, and power-management modules. This comprehensive integration of components streamlines the development process and enhances the overall performance of devices built on the ESP32 platform. Whether used for IoT applications, wireless communication projects, or other embedded systems, the ESP32 series offers a versatile and capable solution that meets the demands of modern connectivity requirements. Its combination of affordability, efficiency, and robust features makes the ESP32 an attractive choice for developers seeking to integrate wireless connectivity into their designs while optimizing power consumption and overall system performance.

The ESP32 microcontroller finds extensive application across a wide array of commercial and industrial devices. Notable examples include Alibaba Group's IoT LED wristband, utilized during the group's 2017 annual gathering, where each wristband functioned as a "pixel", enabling synchronized LED light control for the creation of a dynamic and wireless screen. Ding Talk's M1 leverages the ESP32 for biometric attendance tracking, offering a reliable solution for workforce management.

Additionally, products like the LIFX Mini series of LED light bulbs provide remote controllability, while Pium serves as a home fragrance and aromatherapy device, enhancing indoor ambiance. Furthermore, the ESP32 powers Hard Kernel's Odroid Go handheld gaming device kit, catering to gaming enthusiasts with its portable design. In the industrial sector, TECHBASE's Moduino X series and NORVI IIOT Industrial Devices utilize ESP32-based computers for automation and monitoring tasks, featuring support for digital and analog inputs/outputs, relay outputs, and various networking interfaces. These devices exemplify the versatility and reliability of the ESP32 microcontroller in both commercial and industrial settings, demonstrating its effectiveness across diverse applications.

IV. ADVANTAGES

- Wireless gadget

- Construction is straightforward and uncomplicated

- Also effective in low light environments due to night-vision capability

- Versatile application across numerous scenarios is feasible

- Size is compact

V. DISADVANTAGES

- Batteries may deplete with excessive usage

- Human error is possible

- Utilizing batteries may contribute to an increased weight

VI. FUTURE SCOPE

- Use GPS in this device

- By making some changes it becomes water resistance

- A fire proof cover can be adding to this which provides protection from fire and high voltage

- We can add robotic arm for holding materials

- A Bakelite cover to be use for protection

Conclusion

In closing, the emergence of a smart fault detector robot engineered to detect both gas leaks and fires marks a significant stride towards bolstering the safety and security of individuals and their surroundings. This pioneering technology amalgamates cutting-edge sensors and artificial intelligence to swiftly pinpoint potential dangers, enabling timely intervention and risk mitigation efforts. Through its incorporation of real-time monitoring capabilities, the smart fault detector robot embodies a proactive approach to safety, diminishing the likelihood of catastrophic incidents and serving as a valuable asset for emergency responders. As society continues its embrace of technological advancements for the betterment of daily life, the advent of such intelligent and autonomous systems underscores their potential to foster a safer and more resilient environment for communities at large. This underscores the pivotal role that innovation plays in safeguarding lives and property, reinforcing the imperative of ongoing technological advancement in the realm of safety and security.

References

[1] S. D. Lawaniya, S. Kumar, Y. Yu, H. G. Rubahn, Y. K. Mishra and K. Awasthi, \"Functional nanomaterials in flexible gas sensors: Recent progress and future prospects vol. 29, no. 2, 2023. [2] Annelot Nijkoops,Manuela Ciocca , Soufiane Krik , Ali Douaki ,Arvind Gurusekaran Sahira Vasquez , Mattia Petrelli,Martina Aurora Costa Angeli , Luisa Petti , and Paolo Lugli Flexible and Printed Chemiresistive Ammonia Gas Sensors Based on Carbon Nanotube and Conjugated Polymers: A Comparison of Response and Recovery Performance IEEE VOL. 7, NO. 6, JUNE 2023 [3] A. Douaki et al., \"Carbon nanotube ammonia gas sensor: A comparative analysis between impedance spectroscopy and resistive measurements\", Proc. IEEE Sensors, pp. 1-4, 2021. [4] S. Popli, R. K. Jha, and S. Jain, “A comprehensive survey on Green ICT with 5G-NB-IoT: Towards sustainable planet,” Computer Networks, Vol. 199, 108433, November 2021. [5] M. Wilpshaar, G. D. Bruin, N. Versteijlen K. V. D. Valk, and J. Griffioen, “Comment on “Greenhouse gas emissions from marine decommissioned hydrocarbon wells: Leakage detection, monitoring and mitigation strategies” by Christoph Böttner, Matthias Haeckel, Mark Schmidt, Christian Berndt, Lisa Vielstädte, Jakob A. Kutsch, Jens Karstens & Tim Weiß,”International Journal of Greenhouse Gas Control, Vol. 110, 103395, pp. 1–11, September 2021. [6] K. Cen, et al., “Quantitative risk assessment of gas leakage and explosion accidents and its security measures in open kitchens,”Engineering Failure Analysis, Vol. 130, 105763, December 2021. [7] J. Yépez, and S.-B. Ko, “IoT Based Intelligent Residential Kitchen Fire Prevention System,” Journal of Electrical Engineering & Technology, 15, pp. 2823–2832, August 2020. [8] H. A. B. Salameh, M. F. Dhainat, and E. Benkhelifa, “An End-to-End Early Warning System Based on Wireless Sensor Network for Gas Leakage Detection in Industrial Facilities,” IEEE Systems Journal, pp. 1-9, August 2020. [9] W. Booneua, S. Chai-Arayalert, and N. Boonnam, “Automated Hydroponics Notification System Using IOT,” International Journal of Interactive Mobile Technologies, pp. 206–220, Vol. 16, No. 6, 2022. [10] J. D. Esquicha-Tejada, and J. C. C. Pineda, “Low-Cost and Energy-Efficient Alternatives for Home Automation using IoT,” International Journal of Interactive Mobile Technologies, pp. 153–168, Vol. 16, No. 5, 2022. [11] Z. Baharum, A. S. Sabudin, E. M. M. Yusof, and N. A. Ahmad, “Mobile-Based Application: The Designation of Energy Saving Smart Light System for Monitoring and Controlling,” International Journal of Interactive Mobile Technologies, pp. 90–103, Vol. 15, No. 18, 2021. [12] A. Gaur, A. Singh, A. Kumar, K. S. Kulkarni, S. Lala, K. Kapoor, V. Srivastava, A. Kumar, and S. C. Mukhopadhyay, “Fire Sensing Technologies: A Review,” IEEE Sensors Journal, pp. 3191–3202, Vol. 19, No. 9, 2019. [13] M. San, C. K. Win and K. Z. Mon, \"Design and Simulation of \'Fan Speed Control using Arduino UNO and LM35DZ\", International Journal of Engineering Research and Advanced Technology (TJERAT) (E-ISSN: 2454-6135), vol. 6, no. 6. June 2020. [14] Annelot Nijkoops, Manuela Ciocca, Soufiane Krik, Ali Douaki,Arvind Gurusekaran , Sahira Vasquez , Mattia Petrelli,Martina Aurora Costa Angeli , Luisa Petti , and Paolo Lugli Flexible and Printed Chemiresistive Ammonia Gas Sensors Based on Carbon Nanotube and Conjugated Polymers: A Comparison of Response and Recovery Performance IEEE VOL. 7, NO. 6, JUNE 2023 [15] K. Wang, and K. Psounis, \"Efficient scheduling and resource allocation in 802.11ax multi-user transmissions,\" Computer Communications, Vol. 152, pp. 171–186, February 2020. [16] A. Nag, A. I. Zia, X. Li, and S. C. Mukhopadhyay, “Novel Sensing Approach for LPG Leakage Detection—Part II: Effects of Particle Size, Composition, and Coating Layer Thickness,” IEEE Sensors Journal, Vol. 16, No. 4, pp. 1088–1094, February 2016.

Copyright

Copyright © 2024 Shivam S Ghode, Samiksha K. Gedam, Tejas S. Mahajan, Piyush R. Nikalje, Ankit M. Parate, Ameenkhan F. Pathan . This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET61011

Publish Date : 2024-04-25

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online