Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Smart Grass Cutter and Pesticide Sprayer Robot with Mobile Control

Authors: Atik Pathan, Chaitanya Autade, Dhirajkumar Bairy, Prof. Dhananjay Poul, Prof. Bhausaheb Shinde

DOI Link: https://doi.org/10.22214/ijraset.2024.64411

Certificate: View Certificate

Abstract

This paper presents a novel approach to agricultural automation through the development of a Smart Grass Cutter and Pesticide Sprayer Robot with Mobile Control. The robot combines the functions of grass cutting and pesticide spraying, making it a multi-functional robot for agricultural applications. The robot is powered by solar energy, reducing the need for fossil fuels and minimizing environmental pollution. The robot can be controlled remotely using a mobile device, allowing farmers to monitor and control the robot\'s activities from a distance. The paper discusses the design, development, and testing of the robot, as well as its benefits, including reduced labour costs, minimized environmental pollution, improved crop yields, and enhanced safety for farmers and agricultural workers.

Introduction

I. INTRODUCTION

The advent of automation in agriculture and landscaping has revolutionized traditional practices, offering innovative solutions to enhance efficiency and productivity. With the increasing demand for precision and reduced labor costs, the development of autonomous robotic systems has become essential. This research focuses on the design and implementation of a "Smart Grass Cutter and Pesticide Sprayer Robot with Mobile Control," which aims to automate the processes of grass cutting and pesticide application.

Current methods for lawn maintenance and pest control often rely on manual labor or conventional machinery, which can be time-consuming and labor-intensive. By integrating advanced technologies, such as the Raspberry Pico microcontroller and ESP32 for mobile communication, this project seeks to provide a more efficient alternative. The use of a motorized cutting mechanism paired with a programmable pesticide sprayer allows for targeted application, reducing waste and environmental impact.

This paper will explore the technical specifications, operational mechanisms, and user control interface of the robot. Through this project, we aim to demonstrate the potential of robotic automation in enhancing agricultural practices while providing insights for future advancements in this field.

II. LITRATURE REVIEW

The integration of robotics into agriculture has gained significant attention in recent years, driven by the need for efficiency, precision, and sustainability. Numerous studies have explored various robotic systems designed for tasks such as planting, harvesting, and pest management. For instance, a study by Zhang et al. (2019) examined the application of autonomous drones for pesticide spraying, highlighting their ability to cover large areas efficiently while minimizing chemical use. This emphasizes the trend towards automated solutions that not only save time but also enhance environmental sustainability.

Another important area of research involves the development of robotic lawn mowers. According to a study by Anderson and Thompson (2020), these systems utilize advanced navigation algorithms and sensor technologies to operate independently. While these robots excel in grass cutting, they often lack integrated pest management capabilities. This gap presents an opportunity for innovation, combining grass cutting and pesticide spraying into a single autonomous unit, as proposed in this project.

In terms of component selection, the Raspberry Pico microcontroller has gained popularity due to its versatility and low power consumption. Research by Patel et al. (2021) highlights its effectiveness in controlling various actuators and sensors in robotic applications. Similarly, the ESP32 microcontroller, known for its robust Wi-Fi and Bluetooth capabilities, has been widely adopted for mobile control in IoT applications. This technology can facilitate real-time communication between the robot and mobile devices, as noted in a study by Li and Wang (2022).

Moreover, motor drivers like the L298 have been extensively used in robotics to control DC motors. As detailed by Kumar and Singh (2020), the L298’s ability to drive multiple motors makes it ideal for applications requiring precise movement control, such as in robotic lawn care.

Overall, the existing literature demonstrates a growing trend toward the use of robotics in agriculture and landscaping, with various technologies already proving their worth. However, there remains a need for systems that combine multiple functionalities—specifically, grass cutting and pesticide spraying. This project aims to address that gap, contributing to the ongoing discourse on automation in agricultural practices.

III. METHODOLOGY

A. Components Used

1) Raspberry Pi Pico

The Raspberry Pico is a compact microcontroller board developed by the Raspberry Pi Foundation, designed to provide an affordable and versatile platform for a wide range of electronic projects. Unlike traditional Raspberry Pi models that run a full operating system, the Pico operates using the RP2040 chip, which features a dual-core ARM Cortex-M0+ processor. This allows for efficient processing of tasks while consuming minimal power, making it particularly suitable for battery-operated devices and robotics.

Fig. Raspberry Pico

One of the key features of the Raspberry Pico is its extensive GPIO (General Purpose Input/output) capabilities. With 26 multifunctional pins, the Pico can interface with various sensors, motors, and other peripherals. This flexibility is crucial for projects like the Smart Grass Cutter and Pesticide Sprayer Robot, where multiple components need to be controlled and monitored simultaneously. Additionally, the board supports both digital and analog input/output, allowing for a wide range of applications from basic control tasks to more complex sensor interactions.

2) ESP32

The ESP32 is a highly versatile and powerful microcontroller that has become a popular choice for IoT (Internet of Things) applications and robotics projects. Developed by Espressif Systems, the ESP32 integrates a dual-core processor, Wi-Fi, and Bluetooth capabilities into a single chip, making it an excellent option for projects requiring wireless communication and data processing. One of the standout features of the ESP32 is its dual-core architecture, which allows it to handle multiple tasks simultaneously. This is particularly useful in applications like the Smart Grass Cutter and Pesticide Sprayer Robot, where real-time processing of sensor data and control of motors must occur concurrently. The chip supports a variety of protocols, including TCP/IP, which facilitates seamless communication with mobile devices and other networked systems.

Fig. ESP 32

Programming the ESP32 is accessible, with support for languages such as C/C++ and MicroPython. A variety of development environments, including the Arduino IDE and PlatformIO, enable users to quickly get started with coding. This ease of use fosters rapid prototyping, which is essential in a research context where testing and iteration are crucial.

3) L298N Motor Driver

The L298N motor driver is a widely used integrated circuit (IC) that enables the control of DC motors and stepper motors in various robotics and automation applications. This dual H-bridge driver is capable of controlling the speed and direction of motors, making it an essential component for projects that require precise motor management, such as the Smart Grass Cutter and Pesticide Sprayer Robot. One of the key advantages of the L298N is its ability to drive two DC motors independently or one stepper motor. The H-bridge configuration allows for the reversal of motor polarity, which is necessary for changing the direction of rotation. By applying different signals to the control inputs, users can easily manage the movement of the motors, enabling the robot to navigate its environment effectively.

Fig. L298N Motor Driver

Another notable feature of the L298N is its built-in thermal shutdown and overload protection. These safety mechanisms help prevent damage to the IC and connected motors under extreme conditions, such as overheating or excessive current draw. This reliability is crucial in robotic applications where consistent performance is essential. The control of the L298N is straightforward, requiring only a few logic inputs to manage motor speed and direction. By utilizing Pulse Width Modulation (PWM) signals on the enable pins, users can adjust the speed of the motors smoothly. This capability is especially important in applications where precise control over movement is necessary.

4) TT Gear Motor

The TT gear motor is a compact and widely used motor option in various robotics and automation applications. Characterized by its simple design and affordability, the TT gear motor combines a DC motor with a gear reduction system, allowing for enhanced torque and reduced speed. This combination makes it particularly suitable for projects requiring precise movement and control, such as the Smart Grass Cutter and Pesticide Sprayer Robot. One of the main advantages of the TT gear motor is its ability to provide high torque output, which is essential for driving wheels or cutting mechanisms in robotic systems. The gear reduction system effectively increases the motor's torque while simultaneously decreasing its speed. This is beneficial in applications where quick acceleration is less critical than maintaining a steady force, such as navigating uneven terrain or cutting through grass. The TT gear motor typically operates at a low voltage, commonly ranging from 3V to 6V, making it compatible with various battery types. Its compact size allows for easy integration into small robotic platforms, ensuring that it does not add significant bulk or weight to the design. This is particularly advantageous when space is limited, as in the case of a mobile robot.

Fig. TT Gear Motor

5) Mini Motor Pump

A motor pump is a mechanical device that combines a motor and a pump to move fluids, making it an essential component in various applications, including agriculture, irrigation, and industrial processes. In the context of a Smart Grass Cutter and Pesticide Sprayer Robot, the motor pump plays a crucial role in delivering pesticides or fertilizers precisely where they are needed. The motor typically powers the pump, allowing it to draw fluid from a reservoir and propel it through a nozzle or spray system. This setup enables efficient liquid transfer, which is vital for tasks such as spraying pesticides over large areas of land.

Fig. Mini Motor Pump

The choice of motor pump is important, as it must be capable of generating sufficient pressure to ensure even and effective distribution of the liquid. Motor pumps come in various types, including centrifugal pumps and positive displacement pumps. Centrifugal pumps use rotational energy to move fluids, making them suitable for applications requiring high flow rates but lower pressure. On the other hand, positive displacement pumps are designed to move a fixed volume of fluid with each cycle, providing higher pressure and better control, which is often preferred for precise spraying applications.

6) HC-05 Bluetooth Module

The HC-05 Bluetooth module is a popular and versatile component widely used in robotics and IoT projects due to its ability to facilitate wireless communication between devices. Operating in Bluetooth Classic mode, the HC-05 allows seamless pairing with smart phones, tablets, and computers, making it user-friendly and easy to integrate with microcontrollers like the Raspberry Pico or Arduino. With a communication range of up to 10 meters, it provides the flexibility needed for remote control applications, such as in the Smart Grass Cutter and Pesticide Sprayer Robot. The module supports both Master and Slave modes, enabling it to initiate connections or respond to connection requests, depending on project requirements. Additionally, its low power consumption makes it suitable for battery-operated systems, enhancing operational efficiency.

Fig. HC05 Bluetooth Module

In the context of the robotic project, the HC-05 module is crucial for enabling mobile control, allowing users to send commands to manage the robot’s functions and receive real-time feedback. Overall, the HC-05 is an essential tool for creating automated systems that require reliable and efficient wireless communication.

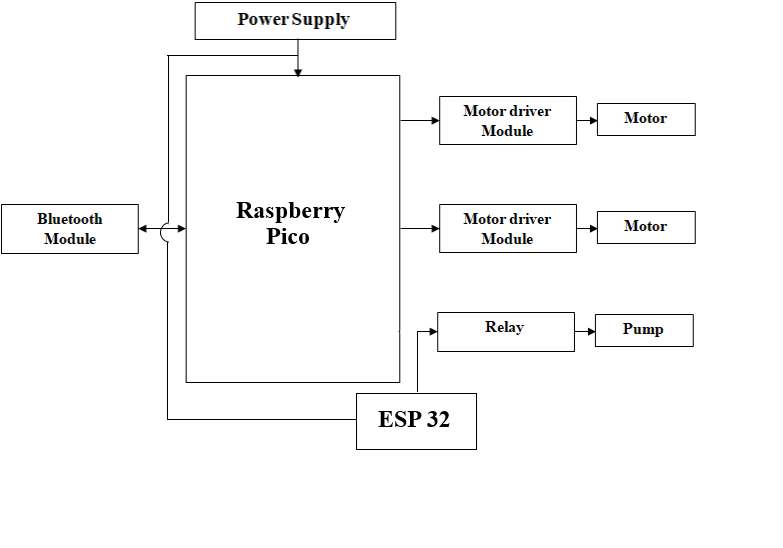

IV. Block Diagram

In the Smart Grass Cutter and Pesticide Sprayer Robot, the power supply is essential for energizing the Raspberry Pico and the ESP32 module, which serve as the system's core components. The Raspberry Pico plays a pivotal role by managing the motor direction and speed through Bluetooth communication. It sends commands to the motor driver, which adjusts the power supplied to the DC motors, allowing the robot to move forward, backward, or turn as needed. Simultaneously, the ESP32 module is tasked with controlling the pesticide spraying mechanism via a motor pump. This coordination allows the robot to operate autonomously while ensuring that pesticides are applied accurately and efficiently. By integrating these components, the system enhances both the functionality and usability of robotic applications in agricultural and landscaping tasks, offering a streamlined solution for effective lawn care and pest management.

Fig. block diagram

Conclusion

In conclusion, the Smart Grass Cutter and Pesticide Sprayer Robot represent a significant advancement in agricultural automation, combining innovative technologies to enhance efficiency and precision in lawn care and pest management. By integrating a Raspberry Pico microcontroller, motor drivers, gear motors, a motor pump, and a Bluetooth communication module, the system achieves seamless operation and remote control capabilities. The careful selection of components ensures robust performance, allowing the robot to navigate various terrains while effectively applying pesticides. This project not only showcases the potential of robotics in improving agricultural practices but also emphasizes the importance of sustainable solutions in resource management. As automation continues to evolve, such systems pave the way for smarter, more efficient approaches to farming and landscaping, ultimately contributing to improved productivity and environmental sustainability.

References

[1] “Agricultural robots for field operations: Concepts and components” Avital Bechar, Clement Vigneault Institute of Agricultural Engineering, Agricultural Research Organization, The Volcani Center, Bet- Dagan, Israel. [2] “AGRICULTURAL ROBOT” Kavita Zole1, SanghasevakGedam2, Aditya Dawale3, Kiran Nikose4, Jayant Hande Research Student, Dept. of ETC, PriyadarshiniJL College of Engineering Nagpur, Maharashtra, India [3] “HRI usability evaluation of interaction modes for a teleoperated agricultural robotic sprayer” GeorgeAdamidis, Christos Katsanos, Yisrael Parmet, Georgios Christou, Michalis Xeons, Thanasis Hadzilacos, Yael Edan. [4] “Development of Smart Pesticide Spraying Robot” by Pvr Chaitanya, Dileep Kotte, A. Srinath, K. B. Kalyan [5] “Application of systematic methods in the electromechanical design of an agricultural mobile robot” Rubens Andre Tabile, Eduardo Paciencia Godoy, Giovana Tripoloni Tangerino, Arthur José Vieira Porto, Ricardo Yassushi. Inamasu, Rafael Vieirade Sousa [6] “Solar powered automatic grass cutter and pesticide spreading robot” by Argade Pratik Pralhad, Bhosale Swapnil Bhagwan, Khadke Sagar Subhash,Phadtare Nikhil Vijay , Prof.Kale R.U5;B.E ,Dept. of E&tc Engineering, S.B. patil college,Indapur ,Maharashtra, India [7] “Smart Pesticide Spraying Robot” Yash Dnyaneshwar Jiwtode1, Neema Amish Ukani2, Sandeep Sonaskar3, Saurabh S. Chakole4 [8] Amrita Sneha. A, Abirami. E, Ankita. A, Mrs. R. Praveena, Mrs. R. Srimeena, 2015 IEEE International Conference on Technological Innovations in ICT for Agriculture and Rural Development, “Agricultural Robot for Automatic Ploughing and Seeding” (TIAR 2015). [9] Pvr Chaitanya, Dileep Kotte, A. Srinath, K. B. Kalyan, “Development of a Smart Pesticide Spraying Robot,” Volume 8, Issue 5, January 2020, ISSN: 2277-3878, International Journal of Recent Technology and Engineering (IJRTE). [10] Peng Jian-sheng, “Intelligent Robot System for Spraying Pesticides”, The Open Electrical & Electronic Engineering Journal, 2014, 8, 435-444. [11] Ege Ozgul, Ugur Celik, “Design and implementation of Semi-Autonomous Anti-Pesticide Spraying and Insect Repellent Mobile Robot for Agricultural Applications”, 2018 5th International Conference on Electrical and Electronics Engineering.

Copyright

Copyright © 2024 Atik Pathan, Chaitanya Autade, Dhirajkumar Bairy, Prof. Dhananjay Poul, Prof. Bhausaheb Shinde. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64411

Publish Date : 2024-09-30

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online