Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Smart Pesticides Spraying Robot

Authors: Shivani Aher, Rahul Aade, Rahul Bibave, Prof. Dr. Dipesh. B. Pardeshi

DOI Link: https://doi.org/10.22214/ijraset.2024.64152

Certificate: View Certificate

Abstract

The reason of this project is to make a intelligent pesticide robot that will spray pesticides to increase agricultural sustainability and efficiency. To precisely target and administer pesticides only where necessary, the robot blends cutting-edge innovations counting computer vision, machine learning, and robotics, limiting chemical use and environmental impact. With its sensors and cameras, the robot can distinguish between diseased and healthy plants. It modifies spraying patterns and amounts based on real-time data analysis, resulting in optimal coverage and waste reduction. This breakthrough has the potential to benefit farmers in several ways, including increased crop health, lower labor costs, a decrease in skin infections due to the negative effects of pesticides, which raise the risk of heart attacks, injuries to the face and eyes, and the promotion of environmentally friendly agricultural methods.

Introduction

I. INTRODUCTION

An important role that agriculture plays in the Indian financial system. For the countryside population, farming serves as their primary source of income. Every farmer applies insecticides including growers of organic food. Insecticides come from both natural and manmade sources. are employed by all farmers. The advantage is that organic farmers are better at using pesticides from the elements. However, natural and synthetic pesticides have different phases of poisoning. These days, heavy chemicals play a major role in solutions. A herbicide is a chemical used to eradicate, prevent, and control pests. However, when farmers Spray pests is a very hazardous technique for them, therefore they want to be as safe as possible and cautious, such as wearing masks, gloves, appropriate clothing, etc. Our goal is to increase the yield of the crop and avoid risks to humans from toxic pesticides. There is additional time and labor involved in this method. Using the traditional spraying method makes it difficult to apply the insecticide evenly and properly throughout the tree. The tank of the hand-operated sprayer weight 15–17 kg. Farmers spend hours carrying this. It could result in spinal problems, bodily aches, or shoulder ailments. Extended exposure to pesticides can cause memory loss, stress, mood swings, and difficulty focusing. With the help of the farmer, tractor-operated sprayers can be difficult to adjust because of current cropping practices, available subject size, and wet season region conditions. must go over those nuisance requirements to improve adaptability. We present a four-wheeled pesticide sprayer that can be remotely operated to apply pesticides and insecticides to crops more quickly and with less effort, we introduce a remotely operated four-wheeled pesticide sprayer.

II. LITERATURE REVIEW

Pesticide Spraying and Leaf Disease Diagnosis with an Agricultural Robot (AGROBOT). In addition to identifying the defected leaf and its area and applying pesticides, it will moreover detect leaf diseases and determine which pest is best for that particular plant [1]. The identification of faulty plants is the primary issue facing the agricultural industry. These will make it simple to identify the defective plants. For that reason, an cleverly sensor-based environment checking is being created [2]. This project will enable us to use an IOT to screen the climate, temperature, and all other climatic conditions because weather monitoring is not always practicable in low-population areas, mostly in farmland, etc. gadgets [3]. The engineering solution is an autonomous pesticide-spraying robot that eliminates all health risks by precisely spraying very deadly chemicals on defective plants, sparing the farmer from having to deal with dangerous chemicals in a small area [4]. Intelligent control is applied in a pesticide spraying simulation system that is created utilizing an embedded system. software, applying pesticides to the crops is the primary goal of this project. This innovation was made particularly for remote arrange terminals that interface to the upper gadget through a particular NC arrange [5]. A bionic electric spraying rod is developed that can do two tasks. Firstly, it can spray water throughout the farm while also, Since it has a snake-like structure, it will easily spread the pesticides over the entire farm when the time comes [6]. The driver module may control the snake bot, which has a bone arm and muscles constructed of several sets of thin wires. It can spray pesticides by using a snake arm that is attached to a spray nozzle. These days, farmers play a vital role in helping societies in various regions meet their basic necessities by toiling diligently in agricultural fields and cultivating crops. Pesticide consumption is higher in India, where it is 70%, than it is globally, which is just 44% [7].

This study's primary objective was to make and construct computer program and equipment for an brilliantly sprayer that can control the nozzles' variable-rate splash yields according to the density of the canopy being sprayed and the availability of a target in view. To an extent, this has been achieved. Nevertheless, there is still some inefficiency connected to the operation of this sprayer, a topic for future research [8].

III. PROPOSED METHOD

Applying fertilizer and pesticides are labor-intensive task. Farmers still view pesticide spraying as a dangerous procedure even though it is now mandated. The goal of this project is to create an agricultural robot vehicle that follows farmer directions to navigate between crops using an Android application.

This robot is more temperate since its parts are less expensive. The agriculturist can utilize any Android smartphone with this software to move the robot around the field. Farmers can operate pesticide sprinkling equipment via an IoT application. In agricultural applications, this low-cost robotic vehicle would match labor demand while improving efficiency and safety. Our System consists of 3 components are as follows:-

A. Input Component

In addition to providing power to the entire circuit, the input unit serves as a storage device, keeping the liquid pesticide.

???????B. Processing for Spray and Control

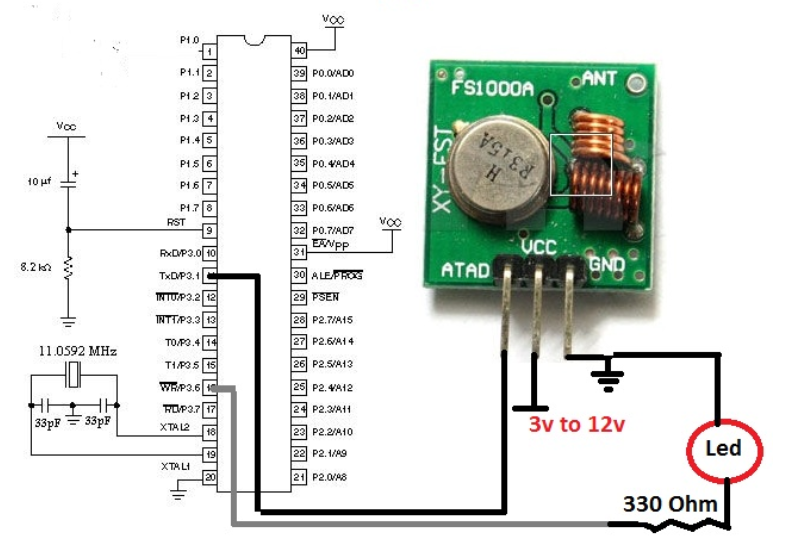

The RF Transreceiver Controller, sometimes referred to as the Robot's Heart, is the primary part of the circuit. The Arduino board is linked to a driver circuit, which controls the robot's movement. Liquid pesticide is also transferred from the storage tank to the sprayer head using a pesticide pump.

???????C. Unit of output

The direction control unit, which is part of the output unit, is used to control the directions with wireless technology. The spraying device will carry out our instructions and spray the

nutrients for the plants.

The components of this system are the driver module, prototype, power supply, and RF transceiver. DC gear motor, battery, RF controller, and vehicle module. The primary element of the Motor driver (L298N), is also referred to as the "heart" of the entire system framework. Pesticides are sprayed with a sprayer; sprayers are frequently utilized for the projection of water, pesticides, weed eaters, etc. In this instance, L298N

module is put to use. This 16-pin integrated circuit driver motor is utilized to propel the robot on precise guidelines by our directives.

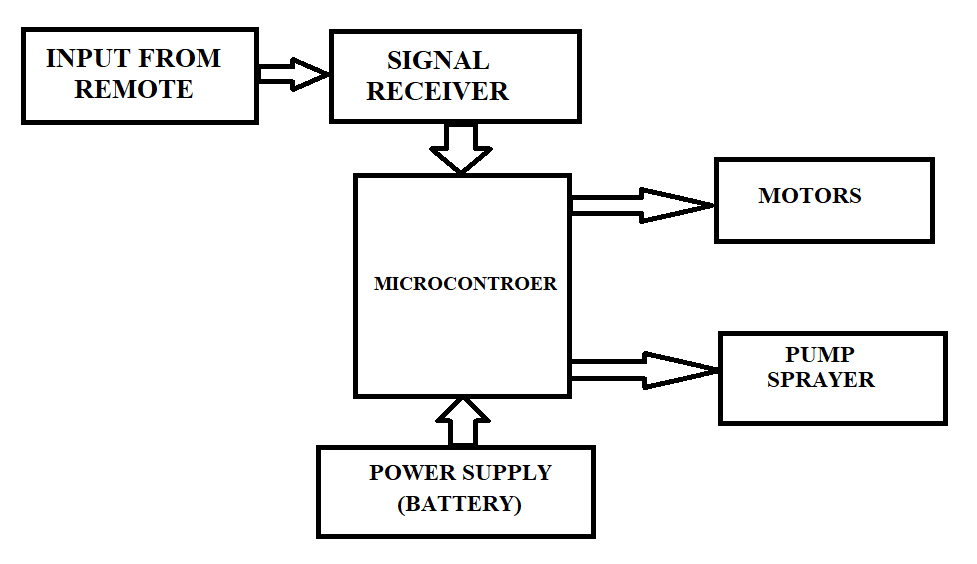

Block Diagram

Fig 1: Block Diagram

A. Energy Source

The 12-volt, 1.3 Ah battery power source will supply power to the input circuit, which will only demand as much as necessary.

B. Controller Wireless

A 2.4 GHz PS2 Dual Shock radio frequency controller is used to control the activities, and it will transmit the commands to the receiver that are interfaced with the controller.

C. Spraying Arm

This multi-nozzle spraying arm is attached to the bot and is used to spray insecticides all over the farm.

D. Microcontroller

The microcontroller, which is fastened to the bot's prototype, regulates the robot's movement.

1) Hardware Requirements

- Microcontroller board

- RF controller for the vehicle's design

- DC motor

- Battery

- Spraying motor

- Switch

- RO tube

2) Software Prerequisites

- Microcontroller Board

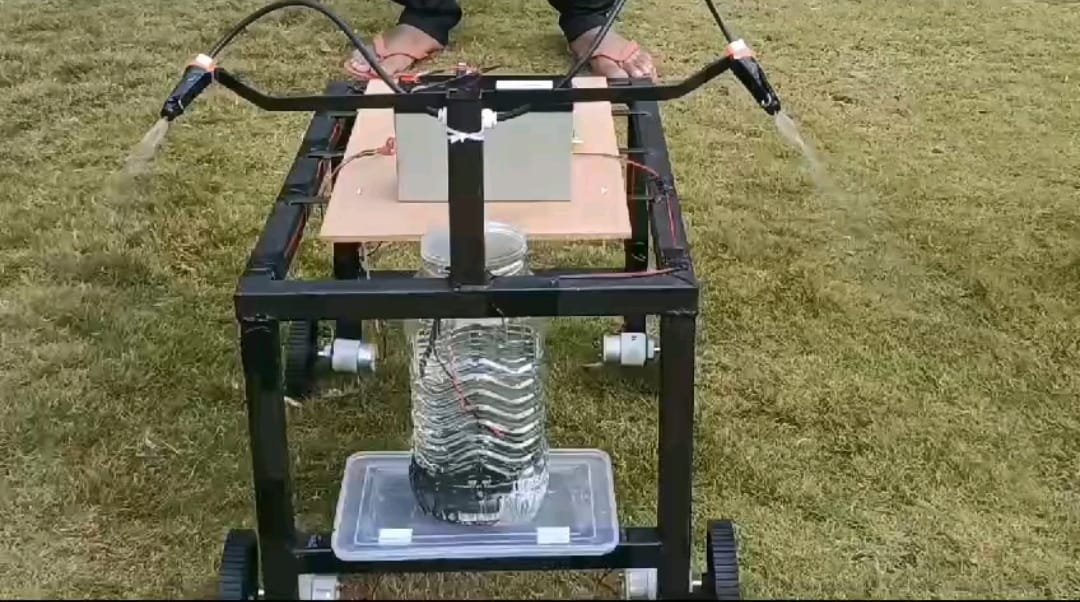

IV. CONSTRUCTION AND WORKING PRINCIPLE

The D.C. gear motor and battery are mounted on a frame that is part of the pesticide spraying machine's structure. The pesticide spraying apparatus is depicted in Fig. The entire machine is supported by the base. The robot's mobility is

managed by commands sent wirelessly from a secure distance to the Arduino through a radio frequency controller. All that's left is the pesticide storage device and the spraying mechanism, which consists of an arm on which a multipoint spray rod is positioned to spray the pesticides using a DC motor.

The spout cap may be pivoted and balanced, giving us control over how finely the bug spray is splashed. A submersible engine pump is utilized within the robot. This shows that one parcel of the pump is kept up exterior and is utilized to embed the pipe. The supply is a 12-volt DC supply that’s connected to the battery.

All of the mechanism is battery-operated the whole image of our robot is equipped with every single part. The robotic sprayer may be moved from its starting location to its destination with the help of this entire setup. This would facilitate your comprehension of the operation and mechanics.

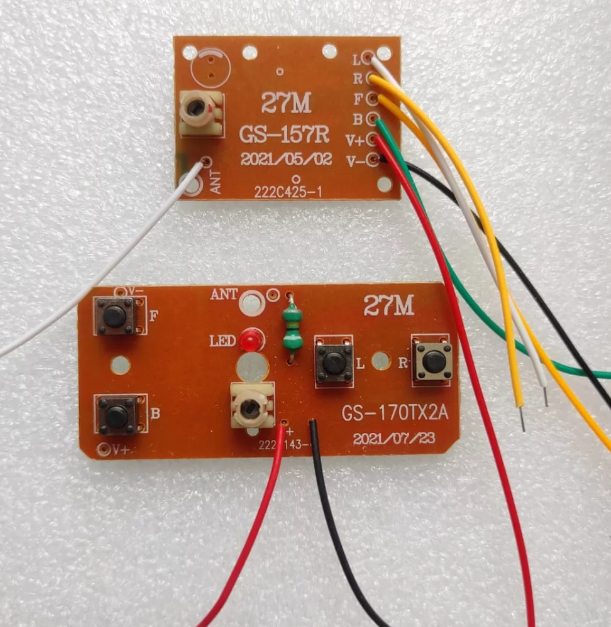

Fig 2: RF Transmitter and Receiver

Fig 3: Microcontroller with RF Transreceiver

Fig 4: Snap Shot of Vehicle

V. RESULTS AND DISCUSSION

The outcomes suggest that the intelligent robot for applying pesticides is a viable option for contemporary farming methods. The application of pesticides with extreme precision reduces environmental effects while simultaneously improving pest control performance. With worries over pesticide residues in food and the implications of abuse on the environment growing, this accuracy is especially crucial.

For farmers, the increased covering efficiency and less pesticide use result in substantial cost savings. These savings stem from lower chemical expenses as well as possible gains in crop output from improved insect control.

Furthermore, less chemical runoff into nearby ecosystems due to decreased pesticide application promotes sustainability. For the robot to be used in real applications, its autonomy and navigational skills are essential. The intelligent robot that applies pesticides has great promise for transforming agricultural pest control. The project's performance indicates that this technology could become a mainstay in contemporary farming techniques, supporting more efficient and sustainable agriculture, with more improvements in scalability and refinement.

Using a robot to spray pesticides with intelligence has shown to be a breakthrough in agricultural technology. The findings demonstrate how it can improve pest management's sustainability, accuracy, and efficiency. The robot distinguishes itself as an important instrument for contemporary farming methods by lowering the need for pesticides, enhancing crop health, and generating financial gains. These fruitful results open the door to increased innovation and wider precision agricultural usage.

A. Advantages

- They can operate with narrower tolerances, minimizing direct interaction between pesticides and human health while increasing output.

- The machines work faster and with fewer errors, and they can reliably identify higher-quality commodities.

- Robots allow farmers to use up to 30% less pesticide.

- There may be jobs available for those who design and maintain robots.

B. Applications

- Employed in farms and fields.

- Used by hardware-related businesses and industries.

- It is relevant to gardening.

- Maintain parks and public areas.

- Spray paint is also utilized in the automotive industry.

- Offers stability in agriculture.

Conclusion

By focusing on the precise areas that require treatment and minimizing the total amount of pesticides used, intelligent pesticide-spraying robots improve precision in agriculture. This accuracy reduces environmental impact while facilitating more efficient pest management. These robots assist in lessening the amount of chemicals present in the environment by only using pesticides when required. By safeguarding beneficial insects, lowering soil and water contamination, and fostering biodiversity, this technique aids in sustainable farming. Smart spraying robots may have a high initial cost, but over time, they can result in significant cost savings. Cost efficiency is increased when there is less of a need for pesticides, less labor is spent, and crop losses are reduced as a result of better pest management. The need for physical labor is reduced when pesticides are applied automatically, which can be especially helpful in areas with manpower scarcity or high labor expenses. By directing human resources toward other important responsibilities, farmers can increase total farm output. By lowering their exposure to dangerous chemicals, the employment of robots for pesticide spraying enhances the health and safety conditions for agricultural workers. This has a big impact on encouraging safer work conditions. Smart spraying robots frequently have sensors and data-gathering tools installed. Farmers may make better judgments and enhance their farming techniques by using this data to examine insect patterns, crop health, and environmental conditions.

References

[1] \"Remote use of Pesticides in Agricultural Field,\" Shubhangi B. Londhe, K. Sujata, International Journal of Computer Applications (0975–8887), Volume. 167, Issue 3, June 2017. [2] \"Smart Farming System Implementation,\" IOT Applications, International Social, Internet of Things in Mobile, Analytics, and Cloud Conference(I-SMAC2017) K. Lokesh Krishna, K. Anuradha. [3] Kazi Agricultural Robot Vehicle based Pesticide Sprayer, Khalid Abdul Karim, Mankari Hemant Tanaji, Bodhgire Yogesh Uttamrao, Md. Momin, MD. Arbi, and MD. Husain, IJSRD - International Journal of Scientific Research and Development, Vol. 6, 03 March 2018,R.K.Gupta. [4] \"Agricultural robotic vehicle based pesticide sprayer,\" 2015 IEEE International Conference on Technological Innovations in Information And Communication Technology for Agriculture and Rural Development, Aishwarya B. V., Archana G. and C. Umayal (TIAR 2015). [5] “Research and evaluation of robotic spraying machines\" Journal of Agricultural Engineering, vol. 56, Issue 3, page 123.135-145, 2019, A. Sharma, R. K. Gupta, and N. S. Rathore. [6] In the 2020 issue of the International Journal of Agricultural and Biological Engineering, P. Zhang, J. Wei, and M. Wang write, \"Smart Agriculture: Application of UAV and AI in Pesticide Spraying,\" pp. 56–63 [7] K. E. Goldsborough, Technologies and Applications for Precision Agriculture: Enhancing Crop Management, Springer, 2018. [8] Precision Agriculture and Food Production, R. Gebbers and V. I. Adamchuk, Springer, 2010. [9] J. Doe, \"Pesticide Spraying Drones: Advances in Agricultural Robots,\" AgriTech Tomorrow, March 2021. Accessible on the Internet: AgriTech Future [10] Farmers Weekly, \"Smart Farming: The Future of Agriculture,\" June 2021. Farmers Weekly is accessible online. [11] The paper \"Application of robot offline programming in thermal spraying original research article\" was published in Surface Coatings Technology in 2012. It was written by S. H. Deng, Z. Cai, D. D. Fang, H. Liao, and G. Mont Avon. [12] N. Dai, \"Development and Usage of Agricultural Robot,\" Agricultural Research, vol. 31, no. 2, 2009, pp. 241-243 [13] X. Zhao, \"Intelligent robots\' primary use in agriculture automation,\" Chinese Agricultural Science Bulletin, vol. 26, no. 10, 2010, pp. 360–364. [14] Gao, Gao, Zhou, and Niu, A., \"A fuzzy neural network-based intelligent variable spraying decision-making system for greenhouse mobile robot,\" Intelligent Computing for Sustainable Energy and Environment, vol. 355, pp. 257-265, 2013 [15] Editor: Prof. C.S. Aryan; Jundare Manisha A, Jundare Pallavi T, Jundare Pragati V; International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering, Volume 5, Issue 3, 2016, \"Plant Disease Detection and Image Processing.\" 8. \"Image Segmentation Implementation Using Raspberry PI,\" Trends and Science International Conference on Energy Engineering, 2016, V.R.S. Mani, T.V. Sathya Sankari. 9. [16] \"Robotics for Agriculture, Unmanned Robotic Service Units for Agricultural Tasks,\" A.A.C. Fernando and C. Ricardo, LEEE Industrial Electronics Magazine, pp. 48–58, Sep 2013. 10. [17] \"The Electrical Technology Text Book in S.I. Units, Volume II, AC & DC machines, Technical Publications for S.Chand,\" by B.L. Theraja and A.K. Theraja. 11. [18] \"Implementation of RGB and Gray Scale Images in Plant Leaves Disease Detection-Comparative Research,\" K. Padmavathi and K. Thangadurai, Indian J. in Sci. and Tech., vol. 9, pp. 1-6, Feb. 2016. [19] Prof. S. S. Mungona and Navin V. Dumare, \"Identification of Cotton Leaf Diseases Using Raspberry PI,\" International Journal on Recent and Technology Trends in Computing and Communication, Volume 5, Issue 5, 2017. 4. \"A Special Method for the Detection of Grape Leaf Diseases,\" [20] Prathamesh K. Kharde and Hemangi H. Kulkarni, International Journal of Scientific Research, Volume 2, Issue 4, 2016. Journal of Engineering and Technology, Volume 8, No 5, 2016, [21] Jayaprakash Sethupathy, Veni S. \"Open CV Based Disease Detection of Mango Leaves.\" 6. \"Detection and Grading of Plant Disease Using Image Processing,\" Basavaraj Tigadi and Bhavana Sharma, International Journal of Engineering Science and Computing, Volume 6, Issue 6, 2016. [22] \"Plant Leaf Disease Detection and Classification Using Image Processing Techniques,\" Prakash M. Manikar, Shreekant Ghorpade, and Mayur Adawadkar, International Engineering Journal, Volume 2, Issue 4, 2015. \"Plant Monitoring Using Image Processing, Raspberry PI, and IOT,\" [23] Prof. Bhavana Patil, Mr. Hemant Panchal, Mr. SHUBHAM Yadav, Mr. Arvind Singh, and Mr. Dinesh Patil, Journal of Engineering and Technology, Volume 4, Issue 10, 2017.

Copyright

Copyright © 2024 Shivani Aher, Rahul Aade, Rahul Bibave, Prof. Dr. Dipesh. B. Pardeshi. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64152

Publish Date : 2024-09-03

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online