Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Enhancement of Soil Properties through Stabilization with Xanthan Gum and Polypropylene Fiber

Authors: Er. Rohit Kumar, Er. Vinod Kumar Sonthwal

DOI Link: https://doi.org/10.22214/ijraset.2025.66235

Certificate: View Certificate

Abstract

This paper consists of experimental investigation on soil with use of Xanthan gum and polypropylene fibre to analyze its geotechnical behavior. The soil used for the experiments was sourced locally, ensuring its relevance to real-world applications. The proportions of XG and PF were varied at two levels, 1% and 1.5%, to examine their influence on soil properties. XG and PF were procured from readily available local markets, emphasizing these materials\' cost-effectiveness and practical applicability for ground improvement. Experiments were further carried out to evaluate the compaction and strength properties of the soil, including Standard Proctor Tests (SPT), California Bearing Ratio (CBR) tests, and Unconfined Compressive Strength (UCS) tests. All the tests were performed strictly according to the procedures outlined in the Indian Standard codes, ensuring accuracy and reliability in the experimental results. Results suggested that combined use of Xanthan gum and polypropylene fibre have significant effects on improving soil strength, stiffness, and compaction behavior, making them a promising solution for ground improvement applications.

Introduction

I. INTRODUCTION

The increasing global population and limited land availability have led to more land reclamation, often resulting in construction on unstable soils like loose sands, soft clays, and organic materials. These soils pose significant challenges, making soil stabilization a critical concern for modern engineers, particularly in urban areas with poor soil conditions. Unstable soils can lead to foundation failures, excessive settlement, and slope instability, highlighting the need for ground improvement. Various methods, including physical techniques (compaction, vibration, drainage), chemical stabilization (lime, cement), and polymer-based stabilization (e.g., Xanthan gum), are used to enhance soil properties such as strength and drainage. These methods are also vital in waste disposal and landfill sites to prevent contamination and ensure stability. Past studies by researchers like Hoek and Brown (1980), Bromhead (1992), and Terzaghi et al. (1996) emphasize the importance of proper soil treatment to prevent structural failures such as tunnel collapses and landslides.

A. Soil Stabilization Using Biopolymers

Most soil stabilization research has focused on mechanical methods and reinforcement materials, with less emphasis on biological approaches [1-4]. Recently, biopolymers—natural polymers produced friendly materials, first used in soil stabilization in 1946, offer a sustainable alternative for ground improvement.

List of Biopolymers with their Applications

|

Sr. No. |

Name of Biopolymer |

Source |

Effect |

Application |

|

1 |

Beta-1, 3/1, 6 Glucan |

This biopolymer is sourced from yeast, fungi, cellulose, cereals, and certain bacteria. |

When dissolved in water, it forms a gelatinous solution. |

It is widely used in the medical field and is also being explored for its potential in soil stabilization within civil engineering. |

|

2 |

Xanthan Gum |

A polysaccharide biopolymer produced through the fermentation of glucose and sucrose |

It acts as an effective thickener, emulsifier, and stabilizer, preventing the separation of ingredients. |

Xanthan gum is commonly used in the food, oil, and cosmetics industries. |

|

3 |

Alginate, Also referred to as sodium alginate |

this biopolymer is extracted from brown seaweed and is composed of mannuronic acid and guluronic acid in linear, unbranched chains |

Its key properties include film formation, ionic crosslinking, and gelling capabilities. |

Alginate is used in various applications, including waterproof fabrics, pharmaceuticals, and dye printing. |

|

4 |

Carboxymethyl Cellulose (CMC): |

This biopolymer is produced through the alkali-catalyzed reaction of cellulose with chloroacetic acid. |

It serves as a thickening agent, viscosity modifier, and emulsion stabilizer |

from medical fields to food science and culinary uses |

|

.5 |

Guar Gum |

Derived from guar beans, this water-soluble, non-ionic polysaccharide exhibits thickening and stabilizing properties |

.:. India leads global production, accounting for 80% of the world's supply. Guar gum is stable in solutions with a pH between 5 and 7 |

it is extensively used in the food industry as a thickener and a binding agent in pharmaceuticals and other industries. |

|

6 |

Chitosan |

Extracted from the chitin shells of shrimp and other crustaceans |

this biopolymer is biocompatible, biodegradable, and non-toxic |

Its applications include use in the medical field, biotechnology, agriculture, and more |

|

7 |

Buta-glucan |

derived from renewable sources, with the added benefit of being biodegradable. Unlike conventional stabilizers such as cement and lime, it has a significantly lower carbon footprint |

Its ability to form cross-linking networks strengthens the soil's resistance to deformation by increasing cohesion with soil particles. Furthermore, its hydrophilic nature enables it to retain water, especially in drought-prone, arid regions. |

Beta-glucan offers several advantages as an eco-friendly material used to improve soil. Its binding properties also help reduce soil erosion, improving slope stability. Unlike synthetic biopolymers, beta-glucan naturally degrades over time, minimizing its environmental impact.

|

Table 1: List of Biopolymers with their Applications

Although several authors studied the soil behaviour using individual and bi combination of biopolymer but very few works have been seen on soil behaviour with the combined use of XG and PF. Hence this work consists of investigating the effect of XG and PF mixed with Soil.

II. EXPERIMENTATION AND METHODOLOGY USED-

Experiments were conducted to investigate the combined impact of Xanthan Gum (XG) and Polypropylene fiber (PF) mixed with soil.

Fig 1. (a)Xathan Gum Powder, (b) Molecular Structure of Xanthan Gum (Suresh K et al.2022)

Fig. 2 Polypropylene fiber

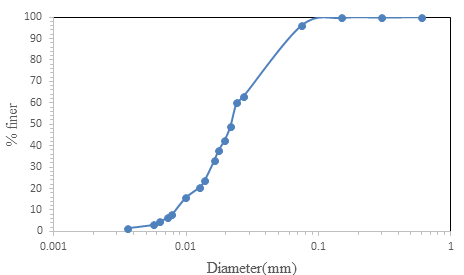

The soil used in this study was alluvial. The first vegetation was removed to obtain the soil. After this, the soil was dug out, and a sample of soil was obtained from a depth of 1.5 m to avoid the roots of the plants. The particle size distribution of the soil was evaluated as per IS: 2720 (part 4). The grain size distribution curve is shown in Fig.1. The Atterberg limits, i.e., liquid limit and plastic limit of soil, were estimated as per IS: 2720 (part 5) and found to be 35% and 21%, respectively. As per IS: 1498, the soil was classified as CL, i.e., clay with low plasticity.

Fig. 3 Grain size distribution of soil used in this study

Four series of tests were conducted to evaluate the combined effect of XG and PF on the compaction and strength behavior of the soil. The details of the test series are presented in Table 2. To evaluate the compaction behavior of mixed standard proctor tests, the strength behavior of soil was assessed, and California bearing ratio test (CBR) and unconfined compressive strength (UCS) tests were conducted. Xanthan Gum content (XGC) and Polypropylene fiber content (PFC) are varied in this study. Series 1 was performed on soil alone. Series 2 was performed on the soil mixed with XG, and series three was performed on the soil mixed with PF. XGC in series 2 varied by 1% and 1.5%, while PF in series 4 varied by 1% and 1.5%. Series 4 was performed on the soil mixed with XG and PF. To evaluate the combined impact of the PFC was considered 1.5%, and XG varied to 1% and 1.5%.

Table 2 Details of the test series

|

Series No. |

Details of mix |

Variable |

|

1 |

Soil alone |

- |

|

2 |

Soil+XG |

XGC= 1%, 1.5% |

|

3 |

Soil+PF |

PFC= 1%, 1.5% |

|

4 |

Soil+ XG +PF |

XGC= 1%, 1.5% & PFC = 1.5% |

A. Sample Preparation

To prepare the soil sample alone, the first oven-dried sample was taken. After this, the soil was pulverized to break the lumps of the soil. Then, the desired amount of water was added per the compaction, CBR, and UCS test requirements. Dry soil was used to prepare the soil sample mix with Xanthan Gum, and the desired XGC was taken. XGC is defined as per equation 1, as shown below [5-7]. Xanthan gum and soil were first mixed in dry conditions after this desired amount of water was added per the test requirement.

XGC=Weight of Xanthum Gum weight of soil+weight of Xanthum GumX100 ---- (1)

Similarly, it was mixed with PF to prepare the soil sample and dry soil, and PF was taken as required. PFC is defined according to equation 2.

PFC=Weight of PFweight of soil+weight of PF --- (2)

In the same way, to prepare a mix of soil, PF, and XG, all the ingredients were first taken in dry condition. After this, all these materials were mixed in dry condition. After this desired amount of water was added, the content of the admixture can be defined as follows in equation 3.

Content of admxiture= weight of admixture (XG or PF)weight of admxiture+weight of soil ...... (3)

Further Light compaction tests, CBR test and Unconfined Compressive test have been performed on the prepared samples.

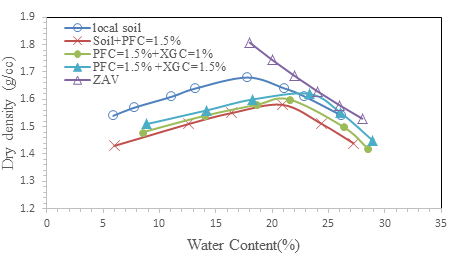

III. RESULT AND DISCUSSION

Standard Proctor Tests (SPTs) were conducted on soil samples with varying amounts of Xanthan Gum (XG) and Polypropylene Fiber (PF) to evaluate compaction behavior [8-10]. The results showed that adding PF alone decreased the maximum dry density (MDD) and increased the optimum moisture content (OMC). Specifically, with 1.5% PF, the MDD was 1.58 g/cc, and the OMC rose to 20.9%. Introducing 1% XG improved the MDD to 1.6 g/cc and further raised the OMC to 23%, while increasing XG content to 1.5% resulted in an MDD of 1.62 g/cc and an OMC of 24.5%. The compaction curve for the mixture shifted closer to the Zero Air Void (ZAV) line, indicating reduced air voids and higher moisture retention due to XG’s water-absorbing properties and PF’s moisture retention [11,12]. Compared to untreated soil, the modified soil became more sensitive to water content variations, affecting overall compaction characteristics.

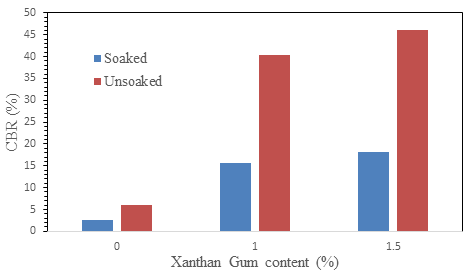

The California Bearing Ratio (CBR) tests revealed that combining XG and PF significantly improved soil strength, with a sevenfold increase in soaked CBR and sixfold in unsoaked conditions compared to untreated soil. This combined effect was attributed to the cementitious and reinforcing actions of both additives.

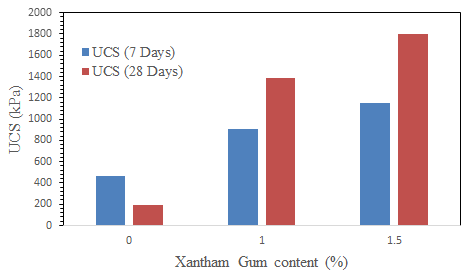

In Unconfined Compressive Strength (UCS) tests, increasing XG content and curing time both enhanced the soil’s strength. After 7 days, the UCS reached 907 kPa with 1% XG, and 1155 kPa with 1.5% XG. After 28 days of curing, the UCS improved to 1389 kPa and 1802 kPa, respectively. This demonstrates that both XG concentration and curing duration significantly enhance the soil’s strength, with XG forming a gel-like structure that improves particle adhesion. The combination of XG and PF thus offers a promising solution for soil stabilization, enhancing strength and stability, especially with longer curing periods.

Fig. 4 Compaction curve of soil mixed with XG and PF.

Fig. 5 CBR of soil mixed with different content of XG and PF (PFC=1.5%)

Fig. 6 UCS of soil mixed with different Content of XG and PF (PFC=1.5%)

Conclusion

This study investigated the effects of Xanthan Gum (XG) and Polypropylene fiber (PF) on soil geotechnical behavior. The proportions of XG and PF were varied at two levels, 1% and 1.5%, to examine their influence on soil properties. The results and subsequent analysis revealed several key insights regarding soil behavior when treated with XG and PF. The major conclusions drawn from these findings are summarized and explained below: 1) Combined Impact of XG and PF on Compaction Behavior: The combined use of XG and PF significantly influences the soil\'s compaction characteristics. Due to their synergistic interaction, the soil mix\'s OMC increases further. XG\'s gel-like behavior and PF\'s water absorption capacity collectively modify the moisture requirements for compaction. 2) Combined Impact on Strength Performance: The inclusion of both XG and PF leads to substantial improvements in the soil\'s strength properties, as observed in the CBR and UCS tests. The combined effect of XG and PF outperforms their contributions. While XG provides enhanced bonding and cohesion, PF adds tensile reinforcement, making the soil mix more robust and deformation-resistant. This synergistic behavior highlights the potential of using XG and PF together for efficient soil stabilization

References

[1] Firoozi, A.A., Guney Olgun, C., Firoozi, A.A. and Baghini, M.S., 2017. Fundamentals of soil stabilization. International Journal of Geo-Engineering, 8, pp.1-16. [2] Hejazi, S.M., Sheikhzadeh, M., Abtahi, S.M. and Zadhoush, A., 2012. A simple review of soil reinforcement by using natural and synthetic fibers. Construction and building materials, 30, pp.100-116. [3] Elias, V., Christopher, B.R., Berg, R.R. and Berg, R.R., 2001. Mechanically stabilized earth walls and reinforced soil slopes: design and construction guidelines (updated version) (No. FHWA-NHI-00-043). United States. Federal Highway Administration. [4] Gray, D.H. and Sotir, R.B., 1996. Biotechnical and soil bioengineering slope stabilization: a practical guide for erosion control. John Wiley & Sons. [5] Chang, I., Im, J., Prasidhi, A.K. and Cho, G.C., 2015. Effects of Xanthan gum biopolymer on soil strengthening. Construction and Building Materials, 74, pp.65-72. [6] Dehghan, H., Tabarsa, A., Latifi, N. and Bagheri, Y., 2019. Use of xanthan and guar gums in soil strengthening. Clean Technologies and Environmental Policy, 21, pp.155-165. [7] Mendonça, A., Morais, P.V., Pires, A.C., Chung, A.P. and Oliveira, P.V., 2020. A review on the importance of microbial biopolymers such as xanthan gum to improve soil properties. Applied Sciences, 11(1), p.170. [8] Mohamed, A.M.O., O’Kelly, B.C. and Soltani, A., 2024. Strength and Compressibility of Xanthan Gum-Treated Soils. In Sustainability in Ground Improvement: The Case of Xanthan Gum Biopolymer (pp. 163-198). Cham: Springer Nature Switzerland. [9] Hamza, M., Nie, Z., Aziz, M., Ijaz, N., Ameer, M.F. and Ijaz, Z., 2023. Geotechnical properties of problematic expansive subgrade stabilized with xanthan gum biopolymer. Road Materials and Pavement Design, 24(7), pp.1869-1883. [10] Kwon, Y.M., Moon, J.H., Cho, G.C., Kim, Y.U. and Chang, I., 2023. Xanthan gum biopolymer-based soil treatment as a construction material to mitigate internal erosion of earthen embankment: A field-scale. Construction and Building Materials, 389, p.131716. [11] Sorze, A., Valentini, F., Dorigato, A. and Pegoretti, A., 2023. Development of a xanthan gum based superabsorbent and water retaining composites for agricultural and forestry applications. Molecules, 28(4), p.1952. [12] Yang, H., Zhang, F., Chen, Y., Xie, Y., Wang, R., He, Y. and Song, P., 2024. Xanthan gum/ZrMOF biodegradable gel fertilizer: Sustainable water retention and crop growth. International Journal of Biological Macromolecules, p.138969. [13] Hoek, E. and Brown, E.T., 1980. Empirical strength criterion for rock masses. Journal of the geotechnical engineering division, 106(9), pp.1013-1035. [14] Bromhead, E., 1992. The stability of slopes. CRC Press. [15] Terzaghi, K., Peck, R.B. and Mesri, G., 1996. Soil mechanics in engineering practice. John wiley & sons. [16] Terzaghi, A., 1996. Soil management for improvement of soil physical characteristics related to erosion in Uruguay. Wageningen University and Research.

Copyright

Copyright © 2025 Er. Rohit Kumar, Er. Vinod Kumar Sonthwal. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET66235

Publish Date : 2025-01-02

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online