Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Solar Panel Cleaning Robot

Authors: Gargi Sandey, Arya Doshi, Harsh Hulenwar, Prof. Sunil Tayade

DOI Link: https://doi.org/10.22214/ijraset.2024.65325

Certificate: View Certificate

Abstract

Solar panel efficiency is often reduced by dust and debris accumulation, making regular cleaning essential but challenging. This research presents an automated solar panel cleaning robot controlled via Wi-Fi using a NodeMCU microcontroller. Equipped with DC motors for movement and sweeping, and a water pump system, the robot ensures thorough cleaning. Testing showed a 15-20% increase in solar panel energy output post-cleaning. The system demonstrated reliable operation and responsive remote control via a web interface. This solution is suitable for various applications, including residential rooftops, commercial solar farms, and remote off-grid systems, enhancing solar maintenance efficiency, and reducing costs.

Introduction

I. INTRODUCTION

Solar energy has emerged as one of the most promising renewable energy sources in the quest for sustainable and environmentally friendly power generation. Solar panels, which convert sunlight into electricity, are pivotal to harnessing this energy. However, their efficiency can be significantly reduced by the accumulation of dust, dirt, bird droppings, and other pollutants on their surfaces. This issue is particularly pronounced in arid and semi-arid regions with high dust levels or areas experiencing frequent adverse weather conditions such as heavy rainfall or storms, which often leave residues. Maintaining the cleanliness of solar panels is, therefore, crucial to ensuring their optimal performance and longevity, as even a thin layer of dust can reduce energy output by up to 25%.

Manual cleaning of solar panels, while effective, presents several challenges, including labor-intensive efforts, high water consumption, and the risk to personnel working on elevated installations or in large solar farms. In addition to safety concerns, manual methods can be time-consuming and impractical, particularly for remote locations or extensive solar farms that span hundreds of acres. Furthermore, the frequent use of cleaning agents can have an environmental impact, making it imperative to explore sustainable and automated alternatives to manual cleaning. To address these limitations, automated solar panel cleaning systems have gained traction in recent years. Such systems not only reduce the dependency on manual labor but also offer consistent and efficient cleaning without interrupting power generation. This research focuses on the development of a solar panel cleaning robot controlled via Wi-Fi using a NodeMCU microcontroller. The proposed robot is equipped with multiple DC motors for precise movement and cleaning actions, as well as a water pump system to facilitate thorough washing of solar panels. The integration of a Wi-Fi-based control system enables remote operation, making it convenient for users to control and monitor the cleaning process from a distance. The robot's design incorporates features to optimize resource consumption, such as reducing the use of water and energy while maintaining high cleaning efficiency. Its modular design allows for scalability and customization, making it suitable for a wide range of applications, from residential rooftops to large commercial solar farms. By automating the cleaning process, the robot ensures that the panels remain free of dirt and debris, significantly enhancing energy output and system reliability.

The proposed work explores the architecture, components, and operation of the solar panel cleaning robot and highlights its potential advantages over traditional cleaning methods. Furthermore, the design ensures cost-effectiveness, safety, and environmental sustainability, making it an ideal solution for maintaining solar panel efficiency. By addressing a critical challenge faced by solar energy systems, this project contributes to the broader goal of enhancing renewable energy technology and supporting the global transition toward clean energy. Ultimately, the proposed solution promotes the longevity and reliability of solar panel installations, encouraging their adoption across various sectors, including residential, commercial, and industrial applications. This innovation aligns with global efforts to combat climate change and achieve energy security by leveraging renewable energy sources.

II. LITERATURE SUREVY

Solar panels are an essential component of renewable energy systems, providing clean and sustainable energy. However, their efficiency was significantly impacted by dust and dirt accumulation on the surface. Sambhaji S. Shankar et al. introduced a solar panel cleaning system, focusing on the effects of dust accumulation and the performance of solar PV panels. The study found that dust accumulation could reduce the power output of solar panels by up to 50%.

An automated cleaning system using a sensor and sliding brushes was proposed to improve the efficiency of solar power generation [1] Author S. Santosh Kumar proposed a solar panel cleaning robot that periodically cleaned the PV panel autonomously. The robot used air blowing and water spraying to clean the panel surface [2]. Author Abdulaziz Alshalian described the design and development of a solar panel cleaning system. The main objective was to clean the solar panels using an automated system to enhance their efficiency. The system included a robotic platform, cleaning mechanism, and control system [3]. A comprehensive review of the literature on robotic solar panel cleaning was also conducted, highlighting the importance of cleaning solar panels to maintain efficiency and the various types of cleaning robots available. Sani et al. discussed the importance of cleaning solar panels to maintain efficiency and the various types of cleaning robots available, including autonomous, semi-autonomous, and manual robots [4]. The authors also highlighted the challenges and future research directions in the field of robotic solar panel cleaning.

The authors presented an improved design method for solar panel cleaning robots to solve issues like charging problems, wind overturning, and transportation difficulties. They described the design ideas and structural principles of different schemes, including the use of big data and artificial intelligence. The authors established a 3D model of the cleaning robot and analyzed the role of advanced technologies in the development of intelligent cleaning robots for solar panels [5]. The paper by Halbhavi, Kulkarni presented a microcontroller-based automatic cleaning system for solar panels. It addressed efficiency loss caused by dust accumulation and proposed an automated cleaning mechanism utilizing a microcontroller for precise control. The system reduced manual intervention, improved energy output, and ensured reliable, cost-effective solar panel maintenance. The authors proposed improved design methods for solar panel cleaning robots to solve issues like charging problems, wind overturning, and transportation difficulties. These designs aimed to enhance cleaning efficiency, reduce labor intensity, and better meet the requirements of photovoltaic power stations [7]. The authors designed the system to remove dust from photovoltaic modules to improve power generation efficiency. The cleaning mechanism consisted of a sensor and sliding brushes controlled by the microcontroller [8].

Solar panel cleaning robots leverage ultrasonic sensors, gear motors, and rotary brushes to enhance cleaning efficiency and ensure mobility on varied terrains, reducing risks in manual maintenance. These systems operate autonomously, integrating microcontrollers for precise control in challenging environments [9]. The reviewed system for solar panel cleaning uses an Arduino-controlled portable robotic device designed for efficient dirt removal, enhancing photovoltaic efficiency. It features a dual-motor symmetrical design for stability, automated panel boundary detection using infrared sensors, and supports adaptability to varying panel sizes [10].

Solar panel cleaning robots are an essential component of solar power generation systems, as they improve the efficiency of the panels by removing dust and dirt. The literature review highlighted the various design and implementation approaches used in these robots, as well as their performance and effectiveness in improving the power output of solar panels.

III. METHODOLOGY

The design and implementation of the solar panel cleaning robot involved several critical stages, each employing specific technical components and methodologies. The primary control unit utilized for this project was the NodeMCU microcontroller, based on the ESP8266/ESP32 platform, chosen for its robust Wi-Fi capabilities and ease of integration with various hardware components. The NodeMCU facilitated remote control and monitoring via a web-based interface, allowing users to issue commands for movement, sweeping, and water spraying. The software was developed using the Arduino IDE, leveraging libraries such as `ESP8266WiFi` and `ESP8266WebServer` to manage network connectivity and HTTP server functionalities.

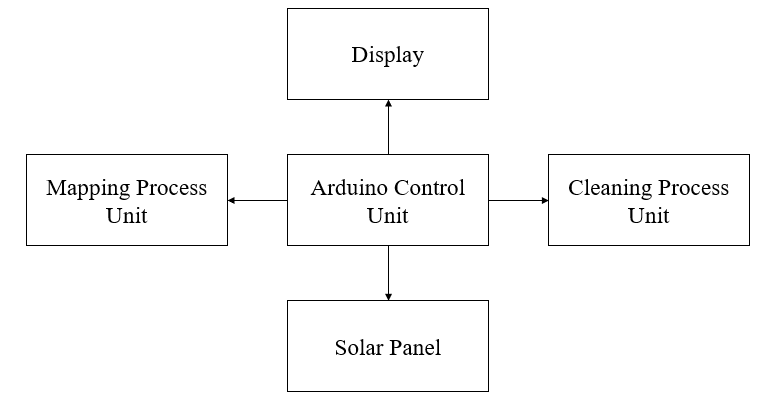

Fig.2.Block Diagram

The block diagram represents the functional structure of a solar panel cleaning robot system. At its core is the Arduino Control Unit, which manages all operations, receiving inputs from the Mapping Process Unit that uses sensors (like LIDAR or ultrasonic) to map the solar panel layout and guide navigation. The Cleaning Process Unit executes the cleaning actions, such as brushing and spraying water, as directed by the Arduino. A Display provides real-time feedback on system status, cleaning progress, and errors, ensuring user monitoring and control. Together, these units ensure efficient cleaning of the Solar Panel, maximizing energy output.

Algorithm:

1. Initialize the NodeMCU with the following pins:

- MA1, MA2, MB1, MB2 for motor control

- RL1, RL2, RIN for roller control

2. Connect to the Wi-Fi network using the SSID "OnePlus" and password "aryadoshi10"

3. Start the web server on port 80

4. Set all the motor and roller pins to LOW (stop state)

5. Wait for a client connection

6. When a client connects:

- Read the HTTP request from the client

- Trim the request string

- Perform actions based on the request:

- If request is "GET /B HTTP/1.1":

- Set MA1 and MA2 to LOW and HIGH respectively

- Set MB1 and MB2 to LOW and HIGH respectively

- Print "Back" and wait for 5 seconds

- Set all motor pins to LOW (stop state)

- If request is "GET /F HTTP/1.1":

- Set MA2 and MB1 to LOW

- Set MA1 and MB2 to HIGH

- Print "Front" and wait for 5 seconds

- Set all motor pins to LOW (stop state)

- If request is "GET /L HTTP/1.1":

- Set MA1 to HIGH, MA2 to LOW

- Set MB1 and MB2 to LOW

- Print "Left" and wait for 1 second

- Set all motor pins to LOW (stop state)

- If request is "GET /R HTTP/1.1":

- Set MB1 to HIGH, MB2 to LOW

- Set MA1 and MA2 to LOW

- Print "Right" and wait for 0.9 seconds

- Set all motor pins to LOW (stop state)

- If request is "GET /S HTTP/1.1":

- Set all motor pins to LOW (stop state)

- Set RL1 and RL2 to LOW

- Print "Stop" and wait for 1 second

- If request is "GET /RO HTTP/1.1":

- Set RL1 to HIGH, RL2 to LOW

- Set RIN to HIGH

- Print "ROLLER STARTED"

- If request is "GET /RF HTTP/1.1":

- Set RL1, RL2, and RIN to LOW

- Print "ROLLER STOPPED"

7. Repeat step 6 for the next client connection

The mechanical design incorporated a chassis constructed from lightweight yet durable materials, supporting four wheels driven by two DC motors for navigation. The motors were controlled through an L298N motor driver module, which provided the necessary current and voltage regulation for precise movement control. An additional DC motor was employed to operate the sweeper mechanism, designed to effectively remove dust and debris from the solar panel surface. The water pump system, comprising a small DC water pump and an appropriately sized water tank, was integrated to deliver a targeted water spray, enhancing the cleaning process. A MOSFET was used to control the pump, managed via a GPIO pin on the NodeMCU.

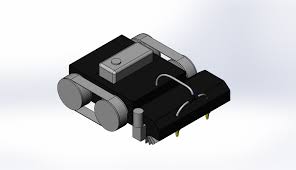

Fig.3. CAD model of Solar panel cleaning robot

System integration involved extensive testing and calibration to ensure seamless operation of all components. The motor control algorithms were fine-tuned to provide accurate directional movement, incorporating feedback mechanisms to maintain stability and responsiveness. The web interface was designed to be intuitive, offering control buttons for forward, backward, left, and right movements, as well as for activating the sweeper and water pump. Performance evaluation was conducted under various environmental conditions to assess the robot’s cleaning efficiency and operational reliability. Data collected from these tests informed iterative improvements, optimizing both the hardware and software aspects of the robot to ensure robust and effective solar panel maintenance.

IV. RESULTS AND DISCUSSIONS

The performance of the solar panel cleaning robot was evaluated through a series of controlled tests, focusing on cleaning effectiveness, operational stability, and remote-control responsiveness. The results demonstrated a significant improvement in solar panel efficiency post-cleaning, with an average increase of 15-20% in energy output. The sweeper mechanism, driven by a dedicated DC motor, effectively removed dust and debris, while the water pump system provided an adequate water spray to wash away finer particles. These outcomes highlight the robot's capability to maintain optimal solar panel performance, ensuring maximum energy production.

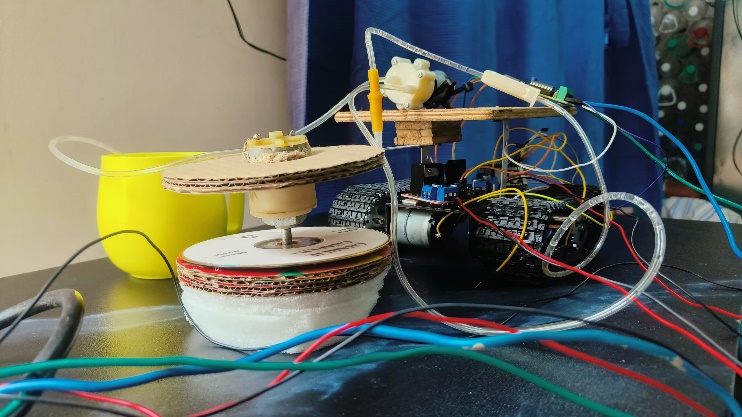

Fig.4 (A)

Fig.4 (B) Working Prototype of Solar Pannel cleaning robot

The solar panel cleaning robot in the above figures shows a compact and efficient device designed for automated maintenance of solar panels. It is equipped with a motorized chassis that allows precise movement in all directions—forward, backward, left, and right ensuring complete coverage of the panel surface. The robot features a spray system mounted on the front axis, which dispenses water as needed for cleaning, controlled through a programmable interface. The rotating front axis enables continuous and uniform cleaning across the panel's surface by distributing water evenly and scrubbing effectively. This design ensures thorough cleaning while minimizing manual intervention, enhancing solar panel efficiency and reliability.

Operational stability was another key area of assessment the solar robot . The robot navigated various panel surfaces, including flat and slightly inclined setups, without any stability issues. The L2930N motor driver module, coupled with the NodeMCU microcontroller, ensured precise control of the DC motors, resulting in smooth and accurate movements. The chassis design, which balanced weight distribution and provided sufficient traction, contributed to the robot's reliable operation. Over extended periods, the robot maintained consistent performance, demonstrating the robustness of the mechanical and electronic components used in its construction.

Remote control responsiveness was validated through extensive user testing. The NodeMCU's integrated Wi-Fi module enabled efficient remote operation via a web-based interface. Commands for movement and the activation of the sweeper and water pump were executed with minimal latency, ensuring real-time control. Users found the interface intuitive and reliable under various network conditions. While the overall performance was satisfactory, some areas for improvement were identified, such as optimizing water consumption and enhancing the sweeper mechanism to handle more stubborn contaminants. Future enhancements could include automated scheduling, solar-powered recharging, and integration of IoT technologies for real-time performance monitoring. These improvements would further solidify the robot's practicality and effectiveness in both residential and commercial solar installations.

V. APPLICATIONS

A. Residential Solar Installations

Homeowners with rooftop solar panels can utilize the robot to maintain their solar systems, ensuring optimal performance without the inconvenience and safety risks associated with manual cleaning. Regular cleaning can significantly improve energy output, making solar investments more efficient and cost-effective.

B. Commercial and Industrial Solar Farms

Large-scale solar farms can deploy multiple cleaning robots to maintain extensive arrays of solar panels. Automated cleaning reduces the need for labor-intensive maintenance and ensures that the panels consistently operate at peak efficiency. This is particularly beneficial for utility companies and large-scale solar power producers who need to maximize energy production and minimize operational costs.

C. Remote and Off-Grid Solar Systems

In remote locations where access for manual cleaning is impractical or costly, the robot provides a reliable solution. This is crucial for off-grid solar systems used in remote homes, telecommunications equipment, and other critical infrastructure where consistent power generation is essential.

D. Agricultural Solar Installations

Solar panels used in agricultural settings, such as those powering irrigation systems or greenhouses, can benefit from the robot. Dust and debris are common in agricultural environments, and regular cleaning helps maintain the efficiency and reliability of solar-powered systems essential for modern farming operations.

E. Solar-Powered Street Lights and Traffic Signals

Ensuring that solar panels on street lights and traffic signals remain clean can enhance their reliability and performance, especially in urban areas with high levels of dust and pollution. This helps municipalities maintain public safety and reduce energy costs through efficient solar-powered lighting systems. By integrating this cleaning robot into various applications, solar panel installations can achieve higher efficiency, reduced maintenance costs, and prolonged operational life, contributing to the broader adoption and effectiveness of solar energy solutions.

Conclusion

The development and implementation of a solar panel cleaning robot, controlled via Wi-Fi using a NodeMCU microcontroller, represent a significant advancement in the maintenance and efficiency optimization of solar energy systems. This project successfully demonstrated the feasibility of automating the cleaning process, thereby addressing the challenges associated with manual maintenance, such as labor intensity, safety risks, and inconsistent cleaning schedules. The robot\'s design, incorporating multiple DC motors for movement and sweeping, and a water pump system for effective cleaning, has proven to be both effective and reliable. Through extensive testing, the robot showed a marked improvement in solar panel efficiency, with a notable increase in energy output post-cleaning. The stable operation across various surfaces and responsive remote control via a web-based interface further validated the robustness and practicality of the design. These results highlight the potential for widespread application, from residential rooftops to large commercial solar farms, and even remote off-grid installations. The ability to maintain solar panel cleanliness autonomously ensures sustained performance and maximizes the return on investment for solar energy systems. Looking ahead, there are opportunities to enhance the robot’s capabilities, such as optimizing water usage, improving the sweeper mechanism for tougher contaminants, and incorporating features like automated scheduling and solar-powered recharging. Additionally, integrating IoT technologies for real-time monitoring and performance analytics could further elevate the robot\'s functionality and efficiency. Overall, this project contributes significantly to the renewable energy sector by providing a practical, scalable, and efficient solution for maintaining solar panel performance, thereby supporting the global shift towards sustainable energy sources.

References

[1] Sambhaji S. Shankar , Mayur B. Bande , Swapnil A. Gore , Prof. Manmohan O. Sharma , Prof. A.V.Harkut, “International Journal of Research in Advent Technology, Special Issue, Convergence”, Bangalore, India, 2019. [2] S. Santosh Kumar, S. Shankar and K. Murthy, \"Solar Powered PV Panel Cleaning Robot,\" 2020 International Conference on Recent Trends on Electronics, Information, Communication & Technology (RTEICT), Bangalore, India, 2020. [3] N. H. B. M. Hashim, M. N. Mohammed, R. A. Selvarajan, S. Al-Zubaidi, and S. J. Mohammed, \"Designing and Manufacturing a Robot for Dry-Cleaning PV Solar Panels,\" in 2023 IEEE International Conference on Automatic Control and Intelligent Systems (I2CACIS), 2023, [4] Sadiku Aminu Sani, Amina Ibrahim, Aminu Ya’u, Abubakar Sani Muhammad, Muhammad Ahmad Baballe, “Global Journal of Research in Engineering & Computer Sciences”, July 2023. [5] Yan, S.Z., Jian, Y. & Xu, L.J. “The 20th International Conference on Electronic Business, Hong Kong SAR”, China, December 5-8, 2020. [6] S. B. Halbhavi, S. G. Kulkarni, and Dr. D. B. Kulkarni, \"Design and Implementation of Microcontroller Based Automatic Dust Cleaning System for Solar Panel,\" International Journal of Latest Trends in Engineering and Technology (IJLTET), vol. 5, no. 4, July 2015. [7] Jothi Venkatesh K, SankaraNarayanan S, Arjun P, and Kannan K, \" A Solar Panel Cleaning Robot Design and Application,\" in International Journal of Emerging Trends in Engineering and Management Sciences (IJETMS), vol. 7, no. 2, March-April 2023. [8] Sagar Patil, Pratik Jadhav, Akshay Jadhav, Saurabh Jadhav, and Prof. Sachin Patil, \" Robotic Device for Cleaning Photovoltaic Arrays,\" in International Journal of Innovative Research in Electrical, Electronics, Instrumentation and Control Engineering (IJIREEICE), vol. 5, no. 4, April 2017. [9] Ronnaronglit, Nawat, and Noppadol Maneerat. \"A cleaning robot for solar panels.\" In 2019 5th International Conference on Engineering, Applied Sciences and Technology (ICEAST), pp. 1-4. IEEE, 2019. [10] Jaradat, Mohammad A., Mohammad Tauseef, Yousuf Altaf, Roba Saab, Hussam Adel, Nadeem Yousuf, and Yousef H. Zurigat. \"A fully portable robot system for cleaning solar panels.\" In 2015 10th International Symposium on Mechatronics and its Applications (ISMA), pp. 1-6. IEEE, 2015.

Copyright

Copyright © 2024 Gargi Sandey, Arya Doshi, Harsh Hulenwar, Prof. Sunil Tayade. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET65325

Publish Date : 2024-11-16

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online