Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Design and Analysis of a Solar-Powered Water Heating System

Authors: Neelam Sharma, Bhushan Akhare, Dr. K. K. Gupta

DOI Link: https://doi.org/10.22214/ijraset.2024.65299

Certificate: View Certificate

Abstract

Water heaters consume a large amount of electricity for heating water. Traditional heaters require heating coils to heat up water using a minimum of 2000 Watts for the process. Well, when we use solar energy for water heating it requires around 30 to 50 Watts of power thus saving more a lot of energy. We here developed a more efficient solar water heater to heat up water at a faster rate using efficient coiling along with heat trapping and reflecting mirrors. The water heater can more efficiently heat up water at a faster pace than traditional solar water heaters. The system makes use of steel pipes coiled together for passing water through them. The pipes are heated by solar rays directly falling on them. We additionally use an aluminium plate behind the pipes to absorb the rays passing through in between pipes. Over this we use 2 additional reflective sheets to gather and reflect additional solar rays over the pipes. This system heats up the pipes thus heating up the water passing.

Introduction

I. INTRODUCTION

The world relies heavily on fossil fuels for most of its energy demands, and this has caused a lot of harm to the Earth. The increase of green-house gas levels in the atmosphere is largely due to the combustion of fossil fuels as a source of energy. This has caused global warming which has led to climate change, floods, forest fires, rising sea levels and the melting of glaciers. These are just some consequences of the over-reliance on fossil fuels for our energy demands. Solar energy provides an alternative and environmentally friendly energy source to the fossil fuels used for our energy needs. Over the last few decades, solar energy systems have gained more recognition because they can provide energy at a low long-term cost and minimal environmental damage. Researchers have developed several techniques for harnessing solar energy, these techniques include applications for space heating, water heating, electricity generation and many others.

Solar energy is generated by the fusion reaction of hydrogen atoms in the sun. This fusion reaction results in the release of high-energy particles called gamma rays. Gamma rays are transmitted as electromagnetic radiation to the Earth, which is at about 150 million kilometers from the sun.

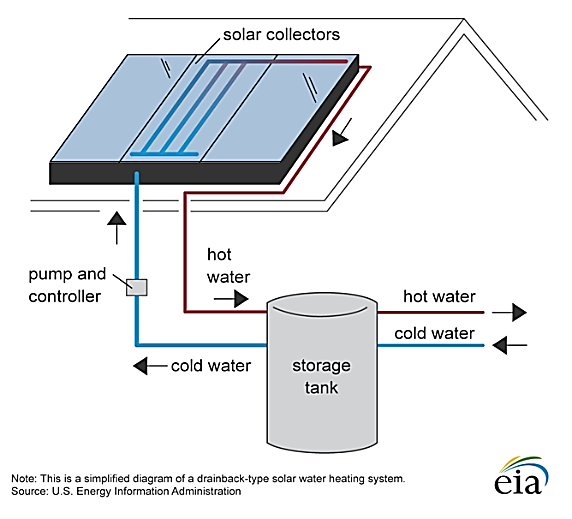

Electromagnetic radiation comes in three forms: infrared rays, visible light, and ultraviolet rays. Solar energy reaching the Earth’s surface can be harnessed directly by using photovoltaics (solar cells) and solar concentrators. Photovoltaics are used for electricity generation, while solar concentrators are used as a source of thermal energy. The utilization of solar energy collectors (concentrators) to transform radiation into heat energy is the basis of the solar water heating technology. A simple solar water heater consists of a collector, a tank, and the flow channel through which the working fluid is transported.

Greatest amount of solar energy is available in two broad bands [1] encircling the earth between 15? and 35? latitude north and south. The next best position is the equatorial belt between 15?N and 15?S latitude [2]. Most of the developing countries, being situated in [3] these regions, are in a favourable position in respect of solar energy. Bangladesh is situated between 20.34? and 26.38? latitude [4] north and as such has a good solar energy potential. Average daily solar irradiation [5] at flat sur-face is around 4.0 to 6.5 kWh/m2 in Bangladesh (Figure 1).

Solar water heaters are used all over the world [6,7] specifically in sunny countries where sun-shine is abundant. The hot water is used for household purpose and in restaurants, hospitals, dormitories, etc. for cleaning dishes and other works. These heaters are also used for preheating water for industrial purpose. In Bangladesh, solar water heaters are getting popular slowly. There are a few companies who are selling these heaters. Most of the water heaters are of Chinese origin and some are of Indian origin. Unlike Nepal, water heaters are not that popular as gas heaters are cheaper in our country. As the water heaters are installed for 13 months on OAB building so data of 1 year (12 months) have been collected and analysed. However, the data collected in the wintertime contains some useful information.

Figure 1: simplified diagram of drain back type solar water heating system

A. Aim and Objectives

The aim of this project is to design and construct a portable solar water heater. The objectives are:

- To design a portable solar water heater.

- To construct the portable solar water heater.

- To carry out the performance evaluation of the constructed solar water heater.

- To obtain a baseline cost of a locally built solar water heater.

B. Uses

- The solar water heater geyser is installed and utilized for domestic usages such as apartments, houses, flats, and Bungalows and for commercial usages such as hospitals, hostel, restaurants, hotels, and hospitals.

- The solar water heater geyser is installed and utilized for industrial usage too such as Process Industries and Preheating boiler feed water.

- Hot water for bathing, washing garments, and utensils, etc. is used in the domestic field. However, the criteria may differ according to the season of the year and the family number.

Solar water heating systems is designed to satisfy the above requirements in commercial & industrial sectors, where large quantities of water are needed at reasonably high temperatures. the system can be either a modular or a high-capacity single tank system based on the delivery pattern of hot water.

II. LITERATURE REVIEW

In the recent past years tremendous work has been done on solar powered water heating systems. It can be noted that some of the research work added a lot of contribution to this subject and acted as a strong reference for the adopted methodology and concluding results. Summary of relevant works is brought out here.

Records show the solar water heater (SWH) was first invented in the Roman empire around 200 B.C.E (Gong & Sumathy, 2016). The Romans had a simple system, they used the solar heating concept to heat their public baths to enable a reduction in using coal and the labour required. These systems were not self-sufficient, but every innovative idea starts somewhere, and the solar water heating concept began here. After the Roman empire collapsed, humans forgot the concept of using the sun to heat water for over a millennium. It was in the late 18th century (1767) that a Swiss natural scientist, De Saussure, re-introduced the concept of using solar energy for water heating (Gong & Sumathy, 2016). He built an insulated box with two glass panes covering the surface, the bottom of the box was painted black to increase solar radiation absorption. This is the prototype for all solar water heaters. De Saussure found that whenever the insulated box was exposed to solar radiation, the insides reached temperatures greater than water’s boiling point. He had shown the green-house effect for the first time by doing this (Perlin, 2008). De Saussure hoped researchers would find his innovative device useful, but it took over a century for this to happen.

In 1891, Clarence Kemp, an American manufacturer, patented the world’s first commercial SWH called Climax (Gong & Sumathy, 2016). It was a simple system in which he put the black coated metal tank in an insulated box which had comparable designs to that of De Saussure’s.

This metal tank served as both the solar energy collector and storage. The major issue with Kemp’s invention was that the water was stored and heated in the same tank. Hence, when exposed at night and in poor weather, the water sometimes cooled down to an undesired temperature. William J. Bailey solved this drawback in 1909 by developing a system which had the collector and the tank separate from each other. The solar collector he built comprised fluid tubes connected to a black-coated metallic plate in a box with a transparent surface. The storage tank for the system was placed above the collector. It was the first system in history that transported the working fluid using the thermosyphon principle. This principle made it possible for water to circulate without the use of a mechanical pump. William Bailey’s company was called the Day and Night SWH Company, emphasizing the advantage his solar water heating system had over that of Clarence Kemp’s. By the 1920s, the discovery of natural gas and oil in southern California led to the emergence of gas water heaters. This crippled the solar water heating industry. Reductions in electricity cost and the copper scarcity during the second world war replaced whatever was left of the solar industry.

In the 1970s, about half a century later, the SWH got global attention again, revitalized by the OPEC embargo which caused a major oil crisis and a hike in oil prices. Ever since, the solar water heating industry has expanded all over the world. Growing concerns about the planet’s increasing carbon emissions, global warming and climate change have flared up interest in the solar water heating industry. As of 2018, the SWH market was valued at over a billion dollars, the yearly installation is expected to surpass three million units by 2025 (Gupta, 2019).

III. METHODOLOGY

Fabrication is an important industry that involves cutting, manipulating and assembling materials to produce desired structures. And while different fabrication companies use different techniques, most rely on three basic processes: cutting, bending and assembling.

A. Cutting

The first process of fabrication is cutting. During this process, the metal fabrication company cuts one or more pieces of raw metal for use in the creation of a new metal structure or product. Whether it’s steel, aluminium, iron or any other common type of metal, though, cutting metal requires special tools. Some metal fabrication companies use torches to cut metal, whereas others numerical control (CNC) machines involving lasers or water jets. When finished, the company will have clean, appropriate-sized sheets or sections of metal with which to work.

B. Bending

After cutting raw metal, metal fabrication companies must bend it. Again, there are different ways to bend metal after cutting it. Some metal fabrication companies hammer the metal sheets or sections into the desired shape. Hammering can be done by hand, or it can be done using a machine (power hammering). Recently, though, many metal fabrication companies have begun using press brakes to bend their metal. This heavy industrial machine automatically presses metal sheets and sections into a specific shape when engaged. It essentially clamps the metal between a punch die, forcing the metal into the desired shape.

C. Assembling

The third and final process of metal fabrication is assembling. As the name suggests, this process involves assembling the metal sheet or sections into the desired finished product. Assembling is typically performed via welding, though other steps may be included in the process as well. In addition to welding, for example, metal fabrication companies may crimp seams, apply screws or other fasteners, and apply glue. After assembling the metal, the company will finalize the product before shipping and selling it to its customers.

Metal fabrication is a driving force behind the country’s ever-growing manufacturing sector. Although there are countless machines and techniques used by metal fabrication companies, must rely on a three-step process that consists of cutting, bending and assembling. These three processes allow metal fabrication companies to transform raw metal materials into new products.

IV. SYSTEM DESIGN

A. Design Consideration.

Several structural design considerations should be considered for economical and efficient manufacturing. Many of these apply to other joining methods, and all apply to both subassemblies and the complete structure.

- The device should be suitable for local manufacturing capabilities.

- The attachment should employ low-cost materials and manufacturing methods.

- It should be accessible and affordable by low-income groups, and should fulfill their basic need for mechanical power

- It should be simple to manufacture, operate, maintain and repair.

- It should be as multi-purpose as possible, providing power for various agricultural implements and for small machines used in rural industry.

- It should employ locally available materials and skills. Standard steel pieces such as steel plates, iron rods, angle iron, and flat stock that are locally available should be used. Standard tools used in machine shops such as hacksaw, files, punches, taps & dies; medium duty welder; drill press; small lathe and milling machine should be adequate to fabricate the parts needed for the dual-purpose bicycle.

- It should make use of standard parts wherever possible

- The device should adapt easily No permanent structural modification should be made

- Excessive weight should be avoided, as durability is a prime consideration.

Ergonomics considerations in design

• Ergonomics is defined as the study of the man - machine - working environment relationship

Areas covered under ergonomics -

• Communication between man (user) and machine

• Working environment

• Human anatomy and posture while using the machine

• Energy expenditure in hand and foot operations

Aesthetic considerations in design

• Appearance is an outward expression of the quality of the product and is the first communication of product with the user.

• Aesthetics is defined as the set of principles of appreciation of beauty. It deals with the appearance of the product.

Aspects of aesthetic design-

Form(shape), Symmetry and shape, Continuity, Variety, Proportion, Noise, Contrast, Impression and purpose, Style.

Material and surface finish, Tolerance

B. Manufacturing Considerations In Design

- Minimum total number of parts in a product

- Minimum variety of parts

- Use standard parts.

- Design parts to be multifunctional.

- Design parts for multiple use.

- Select least costly material.

- Design parts for ease of manufacture.

- Shape the parts for minimizing the operations.

C. Standardization

- It is the process of establishing the set of norms to which a specified set of characteristics of a component or a product should conform

- Example: Standardizing the shaft consists of specifying the set of shaft diameters and material

1) Objectives of standardization

- To make the interchangeability of the components possible

- To make the mass production of components easier

2) Objectives of the project

- To cater to the issue of competition in the mechanical industry the need for automation is assessed by all the industry.

- To identify the key policy avenues considered to be appropriate to meet the challenge of sustainable manufacturing and packaging industry for the future.

- To provide alternatives for industries aiming toward reducing human effort and improvement in material handling systems by implementing automation.

- Sustainable and practical automation solutions for the future industrial environment.

3) Objective Of Work

- To study ergonomics and problems of project.

- Different projects analysis and it's type and it's major uses.

- To achieve comfort and easy response concepts that satisfying most of the needs and which gives more suitable and also economical.

- To evaluate the CAD model in real environment.

D. System Cad Drawing And Components Selection

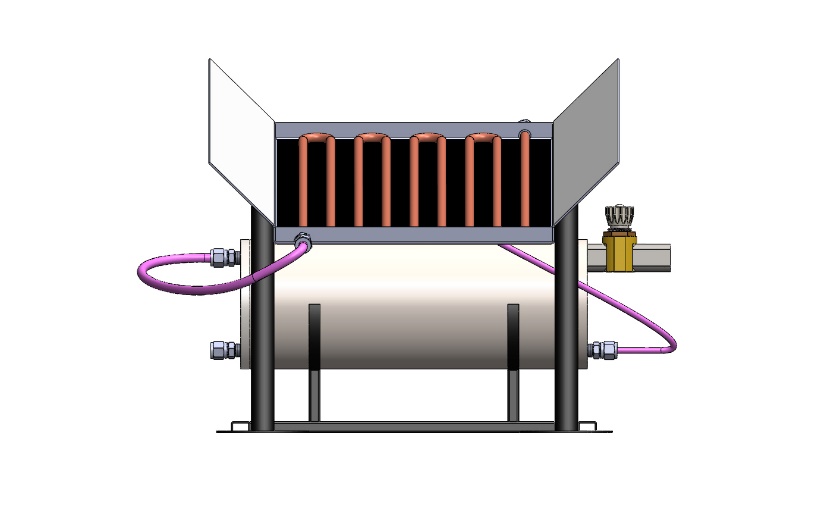

Figure 2 Front view of assembly

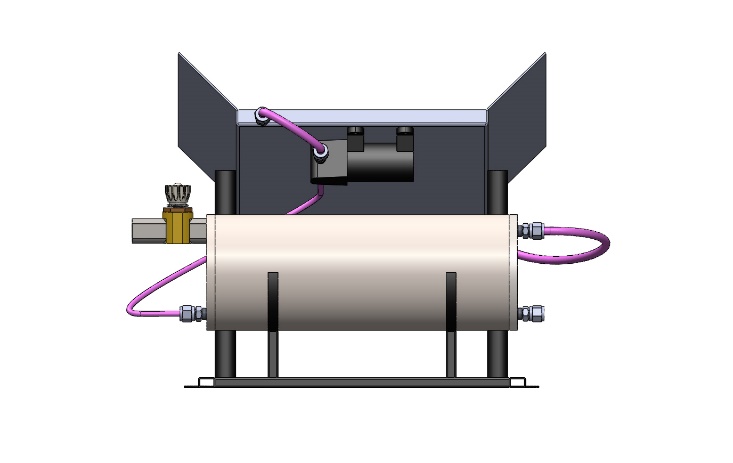

Figure 3 back view of assembly

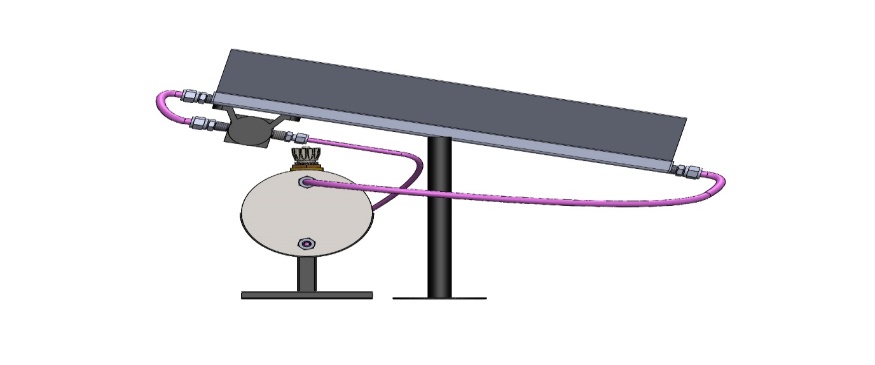

Figure 4 Side view of assembly

???

E. Components

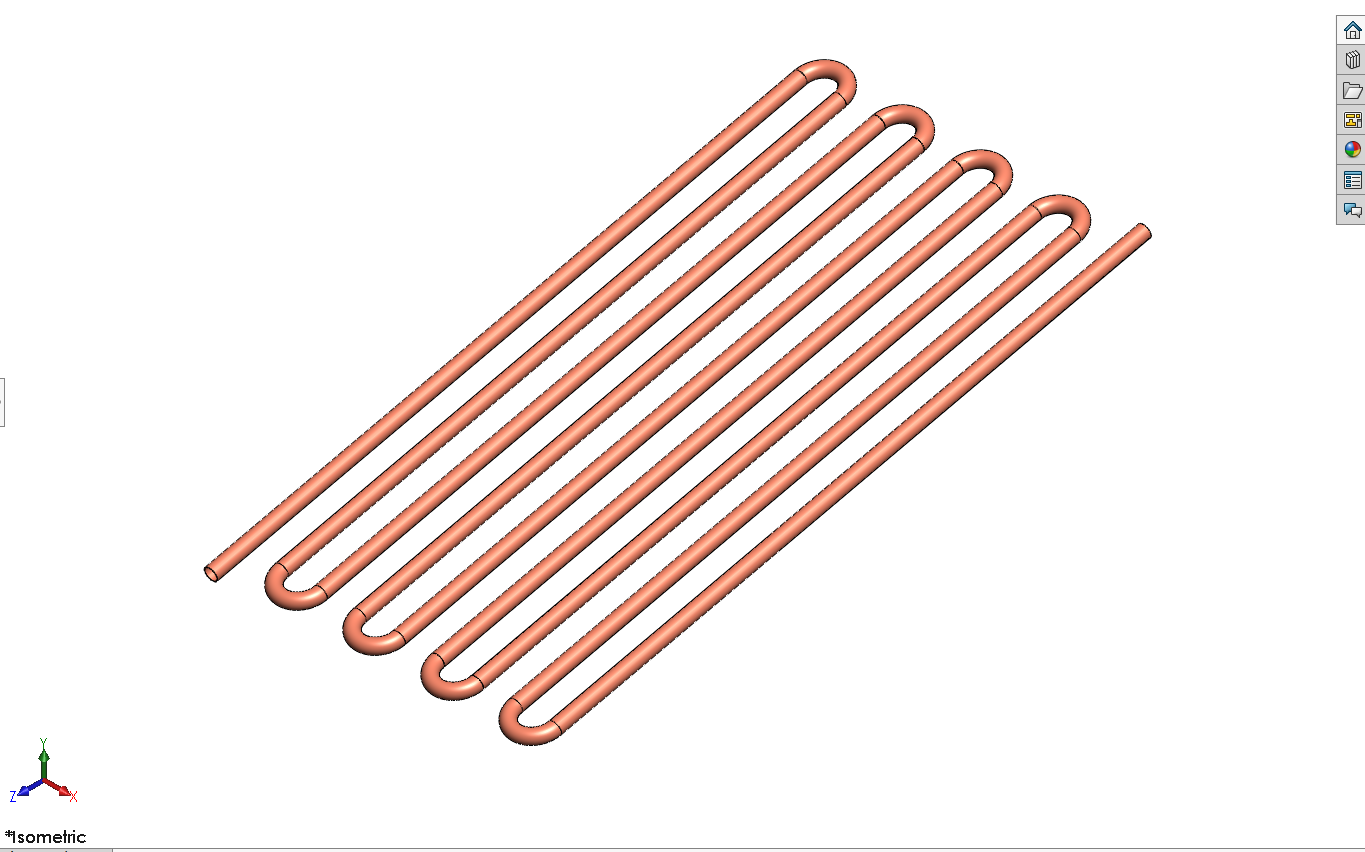

1) Copper Pipes

Figure 5 coiled copper pipes

Material – Copper

Diameter – 10mm

Copper is easy to work and has excellent thermal conductivity, corrosion resistance and durability. It is available in two basic types of tube—plumbing tube and air conditioning/refrigeration (ACR) tube, and in both drawn (hard) and annealed (soft) tempers.

Copper pipes is used to circulate the water through the pipes. So, that the copper pipes increase the temperature of the water.

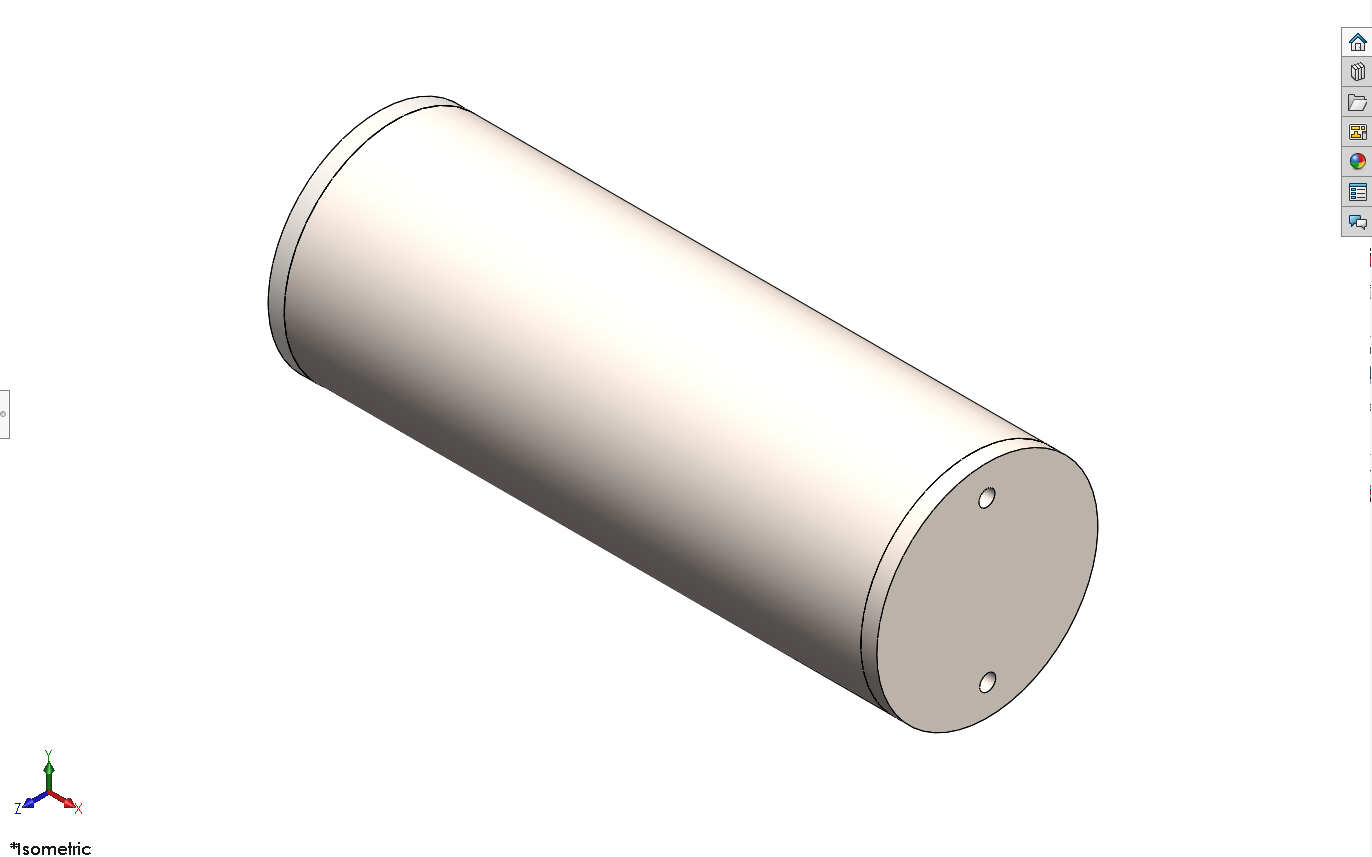

2) Water Tank

Figure 6 water tank design

Material – MS

Internal Diameter – 213mm

Outer Diameter – 219mm

Height – 562mm

Cap ends – 10mm width

It is used to store the water from the Solar water heater.

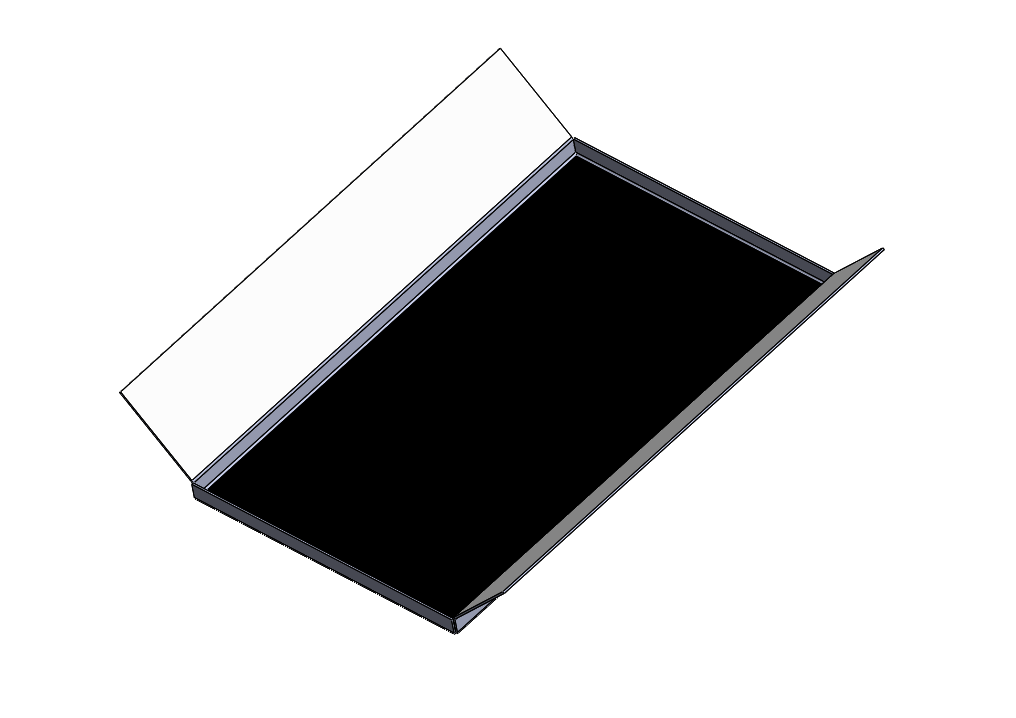

3) Base Frame/ Plate

Figure 7 Base frame design

Material – Aluminium

Thickness – 1.5mm

It has low density, is non-toxic, has a high thermal conductivity, has excellent corrosion resistance, and can be easily cast, machined, and formed. It is also non-magnetic and non-sparking. It is the second most malleable metal and the sixth most ductile.

As we know that Aluminium is a lightweight material and very good in conduction of heat. So, here we used Aluminium material for base plate it conducts heat from sunlight to copper pipe as it directly contacts with copper pipes.

We send for laser cutting and then after bending to achieve the plate.

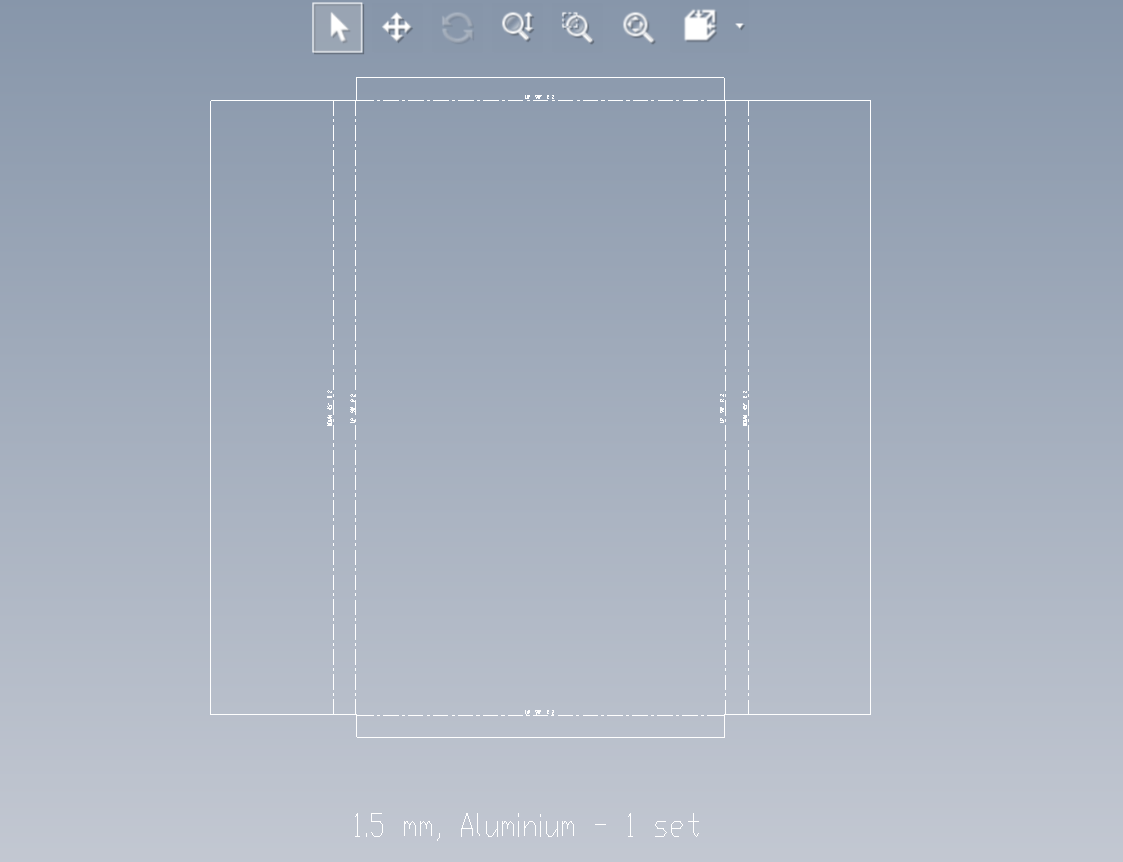

Figure 8 Base frame dimensional view

4) PU Connectors

Figure 9 PU connectors

A pneumatic coupling is used to connect compressed air tools to a compressed air line. A pneumatic coupler allows a tool to be easily connected or disconnected to a hose or pipe while it is under pressure. The system consists of two parts: the quick coupling (the female part) and the plug-in or nipple (the male part).

5) PU Pipes

Figure 10 PU pipes

Dimension – 8 & 12 OD

A pneumatic hose and tube distribute compressed air to components within a system, such as valves and actuators. Industrial plants and manufacturing facilities rely on pneumatic equipment.

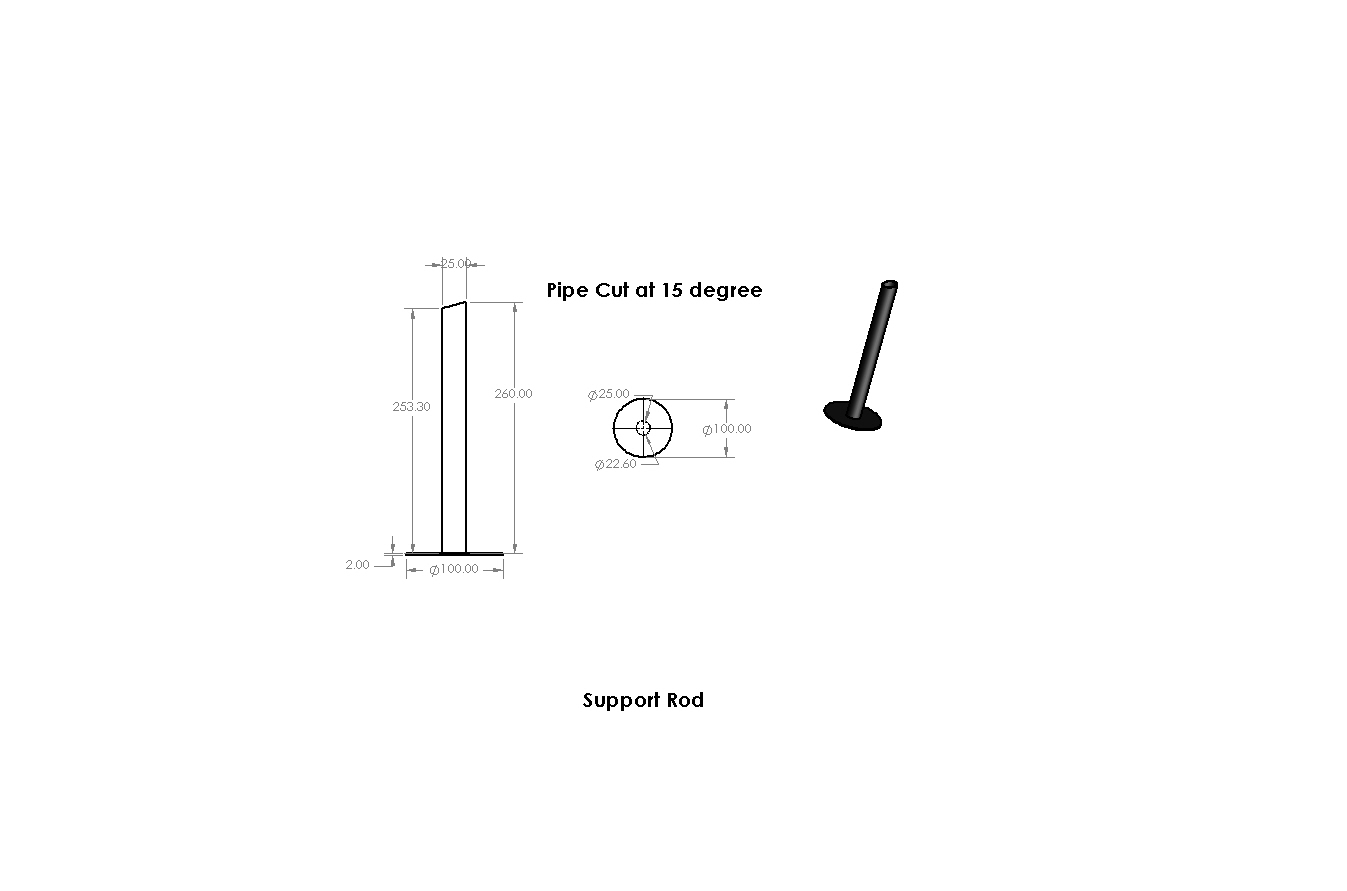

6) Base Stand

Material – Mild Steel (MS)

It is used to give support to the Solar plate.

pipe support or pipe hanger is a designed element that transfer the load from a pipe to the supporting structures.

Load includes the weight of the pipe , the content that the pipe carries, all the pipe fittings attached to pipe, and the pipe covering such as insulation. The four main functions of a pipe support are to anchor, guide, absorb shock and support a specified load. Pipe supports used in high or low temperature applications may contain insulation materials. The overall design configuration of a pipe support assembly is dependent on the loading and operating conditions.

Figure 11 base stand design

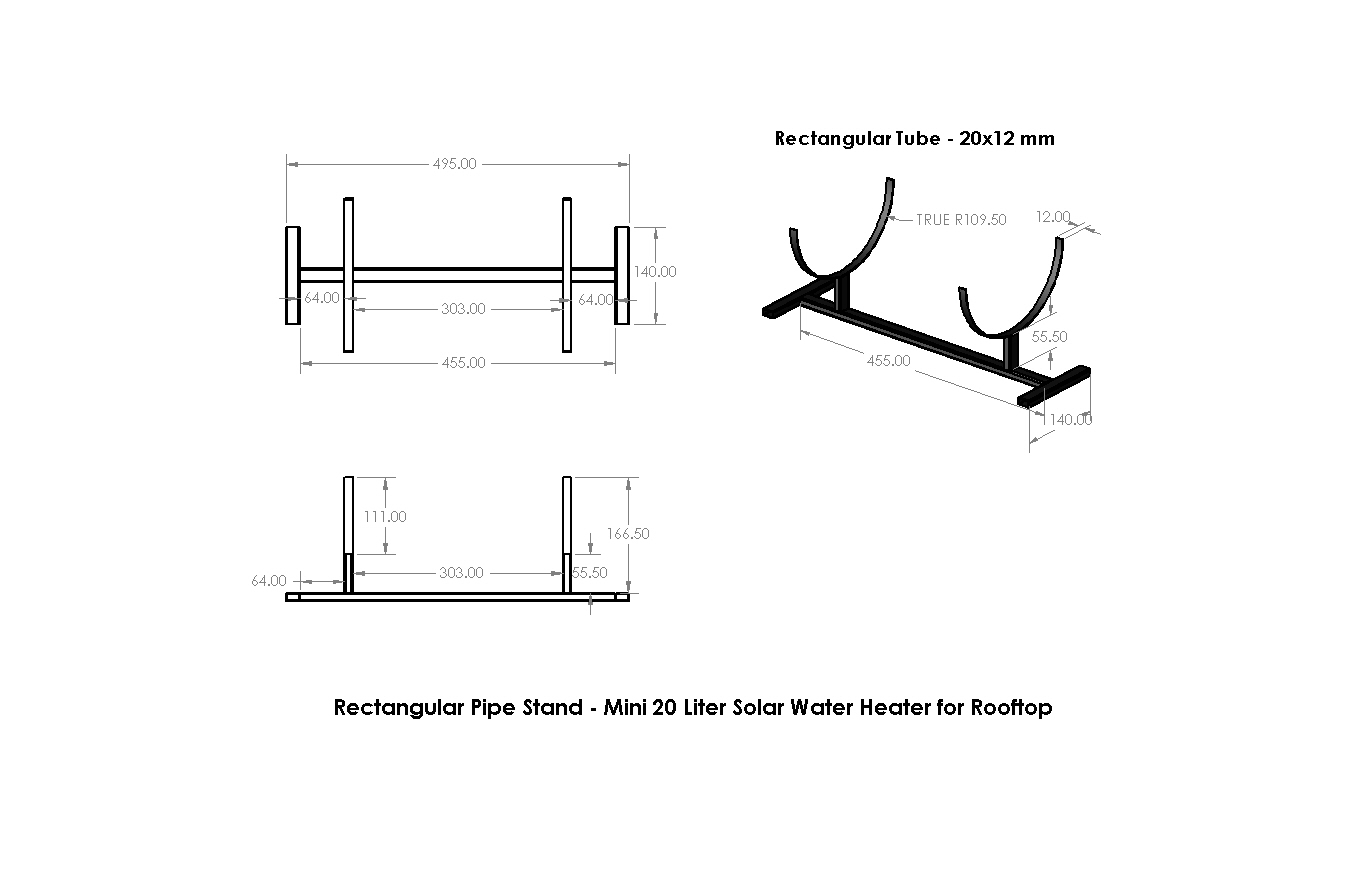

7) Support Frame

A frame is often a structural system that supports other components of a physical construction and/or steel frame that limits the construction's extent.

Material – MS

Dimension – 20x12 mm rectangular tube used

Figure 12 Support frame dimensional view

8) LPM Water Pump

Figure 13 LPM water pump

This is 550 Diaphragm Pump 12V Water Pump for Water Spray Fish Tank Reflux Pump. DC 12V 3.5L/Min Micro 550 Diaphragm Water Pump Watering Spray Aquarium Return Pump For Home Garden.

The configuration of the bath is according to the saving configuration: 12V2A power supply, bus connector, 4m 7 x 10 silicone tube, a 550 water pump, as for the shower nozzle, you can find a plastic bag, a good quality plastic bag or big cola bottle, The water intake and the amount of water can be equivalent.

Features:

- Watering configuration: much the same, additional sprinklers and timers are required

- 12V DC reflux diaphragm pump 550, the price is the price of a pump, without other accessories

- Voltage: 12V, current: at least 2A, measured 1A is not able to bring

- Suction: 3 meters or so, preferably 2 meters (no problem if the vertical height is 1.5 meters).

- Head: 4-5 meters (head is not shot)

- Highest temperature resistance 55

- Connect the mouth: the same as the outer diameter of the inlet and outlet, about 8.5mm, then connect the inner diameter of 7mm silicone tube tightly

9) Insulation Foam

It is used to provide insulation to aluminium sheet so that minimum energy loss in reflection of sun light to copper pipes, also it is used to provide insulation to water tank so that minimum energy loss will be there.

Figure 14 Insulation foam

10) Switch

Figure 15 Electrical switch

In electrical engineering, a switch is an electrical component that can disconnect or connect the conducting path in an electrical circuit, interrupting the electric current or diverting it from one conductor to another.

11) Connectors

Regular 220 V connectors are used to connect pump to electricity to flow of hot and cold waters in between tank and collectors.

V. ASSEMBLY AND WORKING

Copper pipes are bend using bending machine and aluminum sheet taken and screwed with reflectors. The tank is connected with one end of copper coiled pipes whereas other end is connected with water pump which will take input of cold water from water source along with this one motor is attached behind aluminum sheet to circulate water from copper pipes, the whole system is assembled with two iron frames. The system makes use of copper pipes coiled together for passing water through them. The pipes are heated by solar rays directly falling on them. We additionally use a metal plate behind the pipes with a black paint to absorb the rays passing through in between pipes. Over this we use 2 additional reflective sheets to gather and reflect additional solar rays over the pipes. This system heats up the pipes thus heating up the water passing.

We now have a water tank for water storage. The system makes use of a 3.5 LPM Pump motor to pump water through the pipes. It is a low power motor which needs external power supply of up to 28 Watts. The motor drives water from the pipes through the heating pipes and right back into the tank thus heating the water continuously.

The water in the tank can then be used through a third outlet for usage.

Figure 16 Final experimental setup of Solar water heater

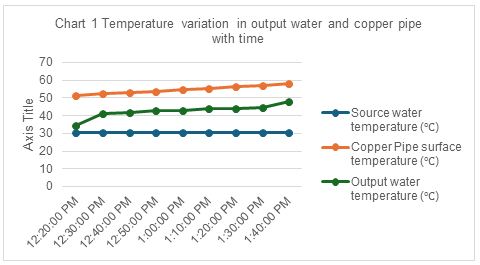

A. Test Results

We have taken one thermometer and conducted 9 temperature measurement tests in 10 mins intervals and found below temperature readings.

|

Time |

Source water temperature (?) |

Copper Pipe surface temperature (?) |

Output water temperature (?) |

|

12:20:00 PM |

30.7 |

51.5 |

34.2 |

|

12:30:00 PM |

30.7 |

52.3 |

41.3 |

|

12:40:00 PM |

30.7 |

53.2 |

42 |

|

12:50:00 PM |

30.7 |

53.3 |

43 |

|

1:00:00 PM |

30.7 |

54.7 |

43.1 |

|

1:10:00 PM |

30.7 |

55 |

43.8 |

|

1:20:00 PM |

30.7 |

56.2 |

44.2 |

|

1:30:00 PM |

30.7 |

57 |

44.7 |

|

1:40:00 PM |

30.7 |

57.8 |

48 |

Table 1 Test results of temperature variation with time in output water from solar heater

Thus, we can see that as time passes, temperature of output water also getting increased because repetition of hot water via tank to copper pipes.

B. Calculation

The water heater electrical energy consumption is given by below formula

E(kWh-Heater) = P(W) x Hr / 1000

- For 1500 watts immersion rod if it heat water from 30.70 degree to 48 degree in 10 mins

Than 10 mins=10/60 hr

E(kWh-Heater) = 1500 x 10/ (60 x 1000)

= 0.25 Kwh

- For proposed solar water heater

It is taking 80 mins to heat water from 30.70 degree to 48 degree

Than 80 mins=80/60 hr

Water pump pressure 0.48MPa=480000 Pa

Volume rate= 3.5L/min=3.5 /(1000x60) m³/s

P= 480000 Pa x 3.5/(1000x60) m³/s= 28 watts

E(kWh-Heater) = 28 x 80/ (60 x 1000)

= 0.037 kWH

Energy saving =0.25-0.037=0.213 kWH

Energy saving in %=0.213×100 /0.25

= 85.20% saving

VI. RESULTS

Successfully we have achieved the results for Solar Water Heater by the help of copper coiled pipes , aluminium sheet and reflectors and 3.5 LPM pump.

if we use this solar water heater instead conventional immersion rod than we can save upto 85% electrical energy.

A. Advantages

- Once we invest in a solar hot water heater, we'll start to get that money back in the form of free energy.

- Reduced Carbon Footprint.

- High Efficiency.

- They Take up Less Space than Traditional Solar Panels.

- They're Cheaper than conventional heaters and Solar PV Panels.

Conclusion

As a closure to this project, Solar Water Heater is one of the most beneficial methods for heating shower water. And this is a great opportunity for villagers to reconsider their way of living and to adapt to this new technology that will save them great deal of money that can be used in other important things.

References

[1] Solar water heating: comprehensive review, critical analysis and case study, https://www.sciencedirect.com/science/article/pii/S2666202723002185#bib0040 [2] Bazza, T. (2019). 35% of Moroccan Electricity Came from Renewable Sources in 2018. [online] Morocco World News. Available at: https://www.moroccoworldnews.com/2019/01/262953/moroccoelectricity-renewable-sources/ [Accessed 7 Apr. 2019]. [3] Contributor, P. (2019). Difference between SWOT, PEST, STEEP and STEEPLE Analysis. [online] PESTLE Analysis. Available at: https://pestleanalysis.com/difference-swot-pest-steep-steepleanalysis/ [Accessed 22 Apr. 2019]. [4] Shodhganga.inflibnet.ac.in. (2019). INTRODUCTION TO SOLAR WATER HEATERS. [online] Available at: http://shodhganga.inflibnet.ac.in/bitstream/10603/195744/9/09_chapter%201.pdf [Accessed 10 Mar. 2019]. [5] Energy.gov. (2019). Solar Water Heaters. [online] Available at: https://www.energy.gov/energysaver/water-heating/solar-water-heaters [Accessed 11 Feb. 2019]. [6] Green riverside. (n.d.). Solar Water Heating. [online] Available at: https://www.energydepot.com/RPUres/library/Swaterheater.asp [Accessed 11 Feb. 2019]. [7] Gujarat, A. (n.d.). Solar Collector - Solar Flat Plate Collector Manufacturer from Ahmedabad. [online] https://www.dimanoverseas.net/solar-collector.html#solar-flat-plate-collector. Available at: https://www.dimanoverseas.net/solar-collector.html [Accessed 12 Feb. 2019]. [8] Solarbayer.com. (2019). Vacuum tube solar collectors CPC NERO. [online] Available at: https://www.solarbayer.com/Vacuum-tube-collector-CPC.html [Accessed 12 Feb. 2019]. [9] Dabiri, S. (2018). Diagram of a parabolic trough collector. [online] Research Gate. Available at: https://www.researchgate.net/figure/Diagram-of-a-parabolic-trough-collector_fig4_318360867 [Accessed 12 Feb. 2019]. [10] Walker, A. (2016). Solar Water Heating | WBDG - Whole Building Design Guide. [online] Wbdg.org. Available at: https://www.wbdg.org/resources/solar-water-heating [Accessed 3 Mar. 2019]. [11] Giz-energy.ma. (2017). Renewable energy and energy efficiency in Morocco. [online] Available at: http://giz-energy.ma/wp-content/uploads/sites/128/2016/11/170519_PAREMA_Brochure_- Anglais_Sans-Reperes-1.compressed.pdf [Accessed 10 Mar. 2019]. [12] Invest.gov.ma. (n.d.). Invest in Morocco - Solar Energy. [online] Available at: http://www.invest.gov.ma/?Id=24&lang=en&RefCat=2&Ref=145 [Accessed 13 Mar. 2019].

Copyright

Copyright © 2024 Neelam Sharma, Bhushan Akhare, Dr. K. K. Gupta. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET65299

Publish Date : 2024-11-16

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online