Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Speed Control of Induction Motor using Fuzzy Logic

Authors: Sony Verma, Anil Kumar, A. K. Gupta

DOI Link: https://doi.org/10.22214/ijraset.2024.58052

Certificate: View Certificate

Abstract

In this paper, speed control of induction motor using fuzzy logic controller is proposed. Speed control of induction motor takes place by, Direct torque control(DTC) method i.e. by directly controlling torque. Here we have used Voltage/Frequency speed control method of induction motor. The fuzzy logic controller (FLC) solves the problem of non linearity’s and parameter variation of induction motor. Unlike the conventional standard controllers, the proposed controller has much less computationally demanding. Direct torque control scheme of induction motor is firstly used. Then, the specified rule and their membership functions of proposed fuzzy logic system will be represented. The performance of a controller is evaluated under various operating conditions. A simplified FLC with relatively fewer rules will be implemented for perfect speed control.

Introduction

I. INTRODUCTION

The most commonly used electric motors in industry are induction motors. In recent years the control of induction motor drives has received widespread research interests .It has been most widely used motor in industries due to their verity of modes of operation. The motors are more useful for industries because of their property i.e. low sensibility to disturbance and maintenance free operation. It has good self- starting capability, simple, rugged structure, low cost and reliability etc. It has grabbed the attention , due to their varied mode of operation both under steady state and dynamic states. Nowadays, in industries 85% of motors used are of Induction machines.

Induction motor has so many advantageous properties though there are some disadvantages too. Like, is not true constant speed motor and slip varies. But as it is more useful in industries, we have to find some solutions to overcome these disadvantages of induction motor. We have a solution for this , as speed controller .Speed controller take necessary action to provide accurate speed control. Speed controller not only control speed but also control various parameters of induction motor as torque, flux, voltage, stator current etc. Out of the so many methods of speed control of an induction machine, the closed loop constant Voltage/frequency speed control method is most popular method used for controlling speed. In this method, the Voltage/frequency ratio is kept constant which, maintains the magnetizing flux constant that eliminates harmonics in the system. Maximum torque is constant in this method.

Direct Torque Control is the method that controls IGBT inverter and motor as a complete system. An ordinary PWM drive simulates power network by adjusting motors static operation point and flux vector drive more or less emulates DC drive. In DTC both inverter and motor are controlled together. All parts that create delay have been removed. The core of the system is the Direct Torque Comparator and Flux Comparator block with the optimal switching logic. The accurate adaptive motor model is also a very essential part of the DTC. Motor model e currents and intermediate circuit dc voltage. Also different models can be used Torque and flux references are compared with the actual values and control signals are produced by using a two-level hysteresis control method.

The controller used are conventional Proportional integral (PI) controller and fuzzy logic controller and their comparison is done. For controlling speed here scalar control method is employed, where magnitude of the stator voltage and frequency is changed proportionately. For this Voltage/Frequency control, a reference speed is chosen and controller is designed as such, it can provide that desired (reference) speed in case of frequent load changes. The major merit of Fuzzy controller over PI controller is use of linguistic variable and user defined rule base that makes it possible to incorporate human intelligence in the controller.

Fuzzy logic based controller also has the capability to control both linear and nonlinear system. Inputs given to the fuzzy logic based controller are speed error (e) and change in speed error (Δe), and output is the change of control (ω), which is the frequency correction. So the inputs error and change in error are processed according to the rule base, which is user defined and output correction is provided to the inverter.

The membership functions and the rules are defined in fuzzy inference system (FIS) editor window. Based on rules, control surface is also generated. The system or model for speed controlling of induction drive is simulated Fuzzy controller and results are analyzed , Fuzzy controller is found to perform better than the conventional controllers.

II. SYSTEM BLOCK DIAGRAM

A. Block Diagram Description

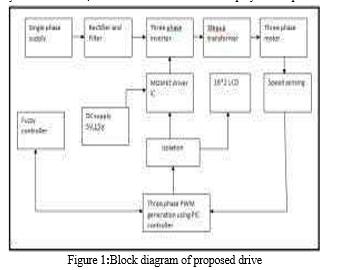

The system block diagram is shown in Figure 1. It consists of Hall Effect speed sensor to sense motor speed in rpm, a microcontroller for controlling systems activities, a LCD for local real-time display of the speed of motor.

The design of various hardware components to implement the three phase induction motor control drive using PIC 16f877 a microcontroller is explained as follows. It includes inverter design, gate drive circuit, isolation and microcontroller for the proposed work. Fig.1 show the block diagram of the proposed drive, which consists of various blocks which are as follows

- Microcontroller

- Isolator

- MOSFET drive

- Rectifier

- Voltage source inverter

- Speed sensing

- Step up transformer

- Fuzzy implementation

For the operation of the inverter, variable frequencies are generated by the microcontroller and applied to voltage source inverter through gate drive circuit. The frequency for operation is read by microcontroller and displays it. The gate drive circuit consists of opto-isolator to provide isolation for microcontroller . The other gate drive circuitry, which is work on low voltage from the high power circuit side. The basic three phase voltage source inverter consists of six power MOSFETs with built in anti parallel diodes. The IRFP–460 N- CHANNEL MOSFET is semiconductor device which works as a switch. It operates at highest possible turn-ON and turn- OFF speeds, extremely high dv/dt capability and maintaining the most accurate operation of the inverter.

AC voltage from the power grid is rectified using the power bridge and capacitor is used as a filter, the output of filter gives pure DC to the three phase inverter as DC source. Depending upon the frequency generated by microcontroller, the power supplied to the motor is varied. Hall effect sensor used to measure the speed of motor using external interrupt and in build timer feature of a PIC microcontroller this measured speed send to matlab through UART feature of microcontroller also 16*2 LCD is interfaced to show actual speed of motor which is sensed by hall effect sensor.

III. HARDWARE SETUP

Hardware consist of :

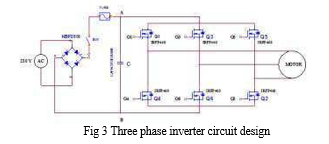

- Three Phase Inverter Design

The inverse diode associated with the device is sufficient to operate the circuit at higher frequencies. MOSFET technology promises to use much simpler and efficient drive circuits with significant cost benefits compared to bipolar devices; hence MOSFET is selected in this design application. High voltage capacitor is connected across the rectifier out to provide low impedance path for high frequency current at switching of power devices. If input is of single phase then 230 V 50Hz, AC voltage is fed to the bridge rectifier and the output DC voltage is taken from the point A and B, as shown in fig 2. The DC filter capacitor bank of value 1000 ?F / 450 V is used for the filtering action. If the input supply VD exceeds above the + VD (max) then the fuse will damage and circuit will act as open circuit, which protect the circuit components from high voltage. The positive terminal of the DC voltage is applied at the Drain terminals of MOSFET Q1, Q3 and Q5 and the negative terminal is connected to source terminals of MOSFET Q2, Q4 and Q6. Output, from the gate drive circuit is connected to the Gate terminals of the MOSFET. Only three MOSFETs remain on at any instant time. The conduction sequence of MOSFET is 612, 123, 234, 345, 456, 561, and 612. This gating sequence is generated so that MOSFETs of the same branch cannot be conduct at the same time. There must be some short time delay between turn off MOSFET and turn on MOSFET. This time delay must be greater than or equal to turn-off time of MOSFET (20 nS). Each phase to

phase contain 120°phase shift.

2. MOSFET drive design

The opto-coupler is an electrical component that is used to isolate high power circuitry to digital or control devices by optical means. It is a combination of light emitting diode (LED) and a silicon phototransistor. The input signal is applied to an LED and the output is taken from the phototransistor. An opto-coupler connects input and output sides with a beam of light modulated by input current.

3. Gate Drive using IC- IRS 2110:

The gate to source voltage needed for desired operation of the MOSFETs is on at 12V–15V level. Also, the high side MOSFETs in the hex-bridge do not have the source connected to ground, so the actual voltage needed to drive the gate depends on the varying voltage at the source. To protect the control hardware from the high-power hex-inverter dielectric isolation is desired. A single chip, the IRS2110, was found to have the desired functionality. It served to implement gate drives, including the circuitry that takes into account the voltage biasing of the high side MOSFETs.

4. PIC16F877A

PIC16F877A is a 8 bit microcontroller with 8K * 14 words flash Program memory and 368 * 8 of RAM and 256 * 8 of EEPROM and many other extra peripherals. Such as it contains only 35 instructions, It has 3 timers and Watchdog timer (WDT), 5 ports are available, 8 channel 10 bit ADC, In build UART module, total 13 interrupt available and power consumption is very low less than 20MA at 5V and 4MHz.

5. Hall effect Speed sensor

When a current-carrying conductor is placed into a magnetic field, a voltage will be generated perpendicular to both the current and the field. This principle is known as the Hall Effect. The sensor is used here as a feedback to controller which gives correct speed sensing and removes errors in speed controlling to achieve exact speed within minimum settling time. The hall effect circuit includes CMOS of class A, hall circuit, and a linear amplifier. The problem related to low voltage level analog signals are reduced by using hall circuit and amplifier on a single chip.

6. Three phase induction motor specification

The motor specification as : 15 W, 415V, 14A, 4 pole 1440 rpm

IV. FUZZY LOGIC CONTROLLER DESIGN FOR SPEED CONTROL OF IM

fuzzy logic controller has a set of rule which is fixed , they are selected by trial and error method. Number of rules in FLC depend upon inputs which are provided to a controller. The controller convert applied input value to a fix value or we can call it as a crisp value, then this crisp values are applied to set of rules which are previously stored in controller.

Here, for this speed control of induction motor, controller used has given two input and one output. Speed error and change in speed error as input variable and frequency of input to motor as output variable to a FLC. Here, Mamdani fuzzy inference system is selected for speed control of IM. Triangular membership function is used for both input and output variables. By this membership functions, input and output are selected rules are applied to have accurate speed control.

Following five fuzzy rule sets are used : NL (Negative Large), NS (Negative Small), ZE(Zero), PS (Positive Small) and PL (Positive Large). Hence, there are total 25 rules defined for this system.

VI. RESULT

Fuzzy controllers are very efficient for speed controlling of three phase ac induction motor. They provide precise controlling action within their limits. Fuzzy controlling is another mean for this application. It’s advantage is that it provides minimum settling time as compared to other methods. The designing of Fuzzy Controller is particularly rule based which simplifies the implementation. It is found that speed controlling with fuzzy controllers is better than any other controlling methods.

VII. ACKNOWLEDGEMENT

We take this opportunity to thank all the individuals for their guidance, help and timely support which made us to carry out the project work in stipulated time. We also thank all teaching and non-teaching staff members for their patience and special consideration for the completion of our work. Lastly, we offer our regard for all those, in particular our parents who supported us in every aspect during this project work

Conclusion

In this project, fuzzy logic approach is used , where we define variables in subjective way. Thus we can avoid numerical complicacy involved in higher order systems. Fuzzy logic provides a certain level of artificial intelligence to the controllers since they try to imitate the human thought process. This reduces settling time, gives more accurate speed control of three phase induction motor. Fuzzy logic construction based on non linear system theory they perform best with linear as well as nonlinear systems. Fuzzy logic speed control is beneficial over other conventional methods.

References

[1] Gilberto C. D. Sousa, Bimal K. Bose and John G. Cleland, “Fuzzy Logic Based On- Line Efficiency Optimization Control of an Indirect Vector- Controlled Induction Motor Drive” IEEE transaction on industrial electronics, vol 4, no 2, april 1995. [2] G. El-Saady, A.M. Sharaf, A. Makky, M.K. Sherriny, and G. Mohamed, “A High Performance Induction Motor System Using Fuzzy Logic Controller,” IEEE Trans. 078031772-6/94, pp. 1058-1061,1994. [3] R.Ouiguini, K. Djeffal, A.Oussedik and R. Megartsi, “Speed Control of an Induction Motor using the Fuzzy logic approach.”, ISIE?97 - Guimariies, Portugal, IEEE Catalog Number: 97TH8280, vol.3, pg. 1168 – 1172 [4] J. Martínez García, J.A. Domínguez, “Comparison between Fuzzy logic and PI controls in a Speed scalar control of an induction machine,” CIRCE – ge3 – Departamento deIngeniería Eléctrica C.P.S., Universidad de Zaragoza, Conf. Paper [5] ” Perfect Speed Tracking of Direct Torque Controlled-Induction Motor Drive Using Fuzzy Logic” by T. S. Radwan\', SMIEEE Riyadh College of Technology, Riyadh, Saudi Arabia e-mail: tsradwangieee.org [6] “Direct Flux and Torque Control of Three Phase Induction Motor Drive Using PI and Fuzzy Logic Controllers for Speed Regulator and Low Torque Ripple”by Tejavathu Ramesh, Anup Kumar Panda ,Member, IEEE [7] “Simulation and comparative study analysis of speed control of induction motor using fuzzy logic, PI, PID contoller” by teena patil and P.P.Mahajan in IJIEEE journal in aug 2016. [8] “Fuzzy logic control of induction motor drive for performance improvement” by madhusmita nayak and smrutidhara singh, dept of electrical engg, National institute of technology , Rourkela.

Copyright

Copyright © 2024 Sony Verma, Anil Kumar, A. K. Gupta. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET58052

Publish Date : 2024-01-15

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online