Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Strength Optimization of Fibre Reinforced Concrete by Using Waste Plastic Bottles

Authors: Aishwarya Deshbhratar, Arjuman Sheikh, Mohammad Loot Ansari, Prof. Syed Sohailuddin

DOI Link: https://doi.org/10.22214/ijraset.2024.59910

Certificate: View Certificate

Abstract

This research investigates the potential for optimizing the strength of fibre-reinforced concrete by incorporating waste plastic bottles as a sustainable additive. The study aims to explore the feasibility of utilizing waste materials to enhance the mechanical properties of concrete while promoting environmental sustainability through recycling efforts. Various proportions of waste plastic bottles are incorporated into the concrete mix, and the resulting mechanical properties, such as compressive strength, flexural strength, and impact resistance, are evaluated through rigorous testing procedures. The findings of this study contribute to advancing sustainable construction practices by providing insights into the effectiveness of waste plastic bottles as a reinforcing agent in concrete. Additionally, the research highlights the importance of recycling initiatives in the construction industry and underscores the potential for utilizing waste materials to improve concrete performance while reducing environmental impact.

Introduction

I. INTRODUCTION

A. General

Concrete is undoubtedly the most widely used man-made construction material globally, with its production experiencing a significant surge in recent years. In 2006 alone, approximately 7 billion cubic meters of concrete were produced, with Asia-Pacific countries contributing to 65% of this production. However, this growth in concrete production comes at a cost to the environment, as it requires the extraction of around 4 billion tonnes of raw materials, including aggregates like crushed rock and sand, as well as cement (Meshram A. et. al, 2023). The global production of Portland cement, the most common form of cement, has been steadily increasing, leading to the release of large quantities of CO2 gas into the atmosphere. It has been estimated that the cement production industry alone emits around 1.6 billion tonnes of CO2 gas annually, a figure that is expected to rise in the future. Given the present concerns over environmental issues, there is an urgent need to reduce cement production to curb CO2 emissions.

B. Overview

Another pressing environmental issue is the disposal of plastic waste, which poses a significant challenge worldwide. Plastics, being long-chain synthetic polymers, take an extensive amount of time to degrade under natural environmental conditions. The accumulation of waste plastics in landfills is becoming increasingly problematic due to dwindling landfill space. However, in recent years, there has been a growing interest in finding sustainable solutions to the environmental problems associated with plastics, including their disposal. Studies have focused on repurposing waste plastic in the production of various construction materials, offering a potential solution to reduce the amount of plastic waste.

In line with the broader trend towards sustainable and environmentally friendly practices in the construction industry, there has been increasing interest in utilizing waste materials in concrete production. Fiber Reinforced Concrete (FRC) has emerged as a promising solution for improving the mechanical properties of concrete, offering higher tensile strength, toughness, and durability compared to traditional concrete. While fibers such as steel, glass, and synthetic fibers are commonly used in FRC to enhance its performance, the high cost and environmental impact associated with these fibers have led researchers to explore alternative reinforcements.

Waste plastic bottles, abundant in urban environments and challenging to dispose of, have shown potential as a sustainable and cost-effective reinforcement in concrete. Typically made from polyethylene terephthalate (PET) or high-density polyethylene (HDPE), waste plastic bottles are durable and resistant to chemical degradation, making them attractive materials for enhancing the mechanical properties of concrete. Several studies have investigated the use of waste plastic bottles as a partial replacement for coarse aggregate or as fiber reinforcement in concrete, with promising results.

The incorporation of waste plastic bottles in concrete offers several benefits, including reducing the amount of plastic waste that ends up in landfills or oceans, providing a sustainable alternative to traditional reinforcement materials, and potentially improving the mechanical properties of concrete. However, despite these potential benefits, the use of waste plastic bottles in concrete is still in the early stages of research and development. There is a need for further investigation to optimize the strength and durability of concrete containing waste plastic bottles as reinforcement.

C. Proposed Approach

This study aims to contribute to this body of knowledge by exploring the effects of incorporating waste plastic bottles on the mechanical properties of concrete, specifically focusing on strength optimization. By studying the strength optimization of fiber-reinforced concrete using waste plastic bottles, this research seeks to provide insights into the viability of using waste plastic bottles as a sustainable reinforcement material in concrete construction. The findings of this study could have significant implications for the construction industry, offering a sustainable solution for improving the performance of concrete structures while reducing environmental impact.

The utilization of waste plastic bottles as reinforcement in concrete presents a promising avenue for enhancing the sustainability and performance of concrete structures. By repurposing waste materials and reducing reliance on traditional reinforcement materials, this innovative approach aligns with the goals of sustainable development and environmental conservation. Through rigorous experimentation and analysis, this study aims to advance knowledge and industry adoption of waste plastic bottles as a sustainable reinforcement material in concrete construction, ultimately contributing to a more sustainable built environment.

II. LITERATURE REVIEW

Altamashuddinkhan Nadimalla et. al [2022], “The study investigates the feasibility of utilizing Polyethylene Terephthalate (PET) bottle waste as a fine aggregate in concrete and presents several key findings. It notes that the slump value of concrete mixes is influenced by the shape and texture of PET bottle aggregates, with angular and sharp edges reducing the slump value and smooth-surfaced aggregates increasing it. Compressive strength is found to improve with up to a 10% substitution of fine aggregate with PET bottle waste but diminishes with higher replacements. Similarly, split tensile and flexural strengths exhibit improvement with up to 10% addition of PET bottle aggregate but decline with higher replacements. Additionally, the elastic modulus of concrete mixtures decreases with the incorporation of PET bottle aggregates due to their lower elastic modulus. Overall, the findings suggest that a certain percentage of PET bottle waste can be effectively used as a substitute for fine aggregate in concrete, offering potential benefits for sustainability and environmental conservation.”

Donald Kwabena Dadzie et. al [2020], “The consider explores the utilize of squander plastic bottles in building houses to assist with the lodging deficiency in creating nations.

By analyzing conceivable taken a toll investment funds, natural benefits, toughness, and special openings, the inquire about demonstrates that including plastic bottles to development ventures can radically reduce costs, make strides warm control, and bolster supportability. Through a blend of writing survey, case thinks about, and subjective investigation, the inquire about appears that buildings made with plastic bottle dividers give way better warm separator and vitality effectiveness whereas appearing solidness comparable to conventional materials. The revelations highlight the potential for creative development plans and request more inquire about to explore the possibility of squander plastic bottles as a economical arrangement for handling lodging challenges in creating countries.”

Divyani Harpal et. al [2019], “The think around examines the reasonability of tallying waste PET bottle strands in concrete to boost its quality, revealing essential disclosures. It reports that the development of PET strands has extended the compressive quality of the concrete, with the preeminent favorable comes about seen at a 1% PET fiber mix, showing up transcendent quality compared to both normal and steel fiber concrete. Other than, the explore emphasizes the characteristic benefits of utilizing waste PET bottles in concrete, highlighting its capacity to address solid waste exchange concerns and reduce characteristic defilement. The compressive quality comes around progress invigorate the claim that plastic strands can update the assistant properties of concrete, promoting promising prospects for their utilization in improvement sharpens pointed at practicality and misuse reducing.”

Sawsan D. A. Shubbar et. al [2017], “The study explores the possibility of utilizing waste plastic bottles in concrete production to see its effects on compressive strength, density, and workability. By following a structured process that involves gathering, processing, and adding waste plastic to concrete mixtures, the investigation identifies an ideal percentage for replacing to maximize strength properties. The findings suggest that substituting 2% of sand with granulated plastic from discarded bottles results in the highest compressive resistance and split strength, along with a decrease in concrete density. Despite workability declining with higher plastic content, the concrete remains manageable. The study hints at the potential benefits of incorporating waste plastic bottles into concrete production as a means of recycling and reducing environmental harm while potentially improving certain concrete properties. However, additional research is necessary to determine the optimal plastic replacement rate for achieving optimal outcomes.”

Wasan Ismail Khalil et. al [2017], “The study investigates the feasibility of utilizing PET plastic waste aggregate in eco-friendly concrete and evaluates its impact on various mechanical and thermal properties. The research findings indicate that incorporating PET plastic waste aggregate into concrete mixtures results in reduced dry density and improved flexural energy absorption, making it suitable for dynamic loading conditions. Additionally, the inclusion of PET plastic waste contributes to lower thermal conductivity, suggesting its potential for thermal insulation applications in buildings. However, the study highlights a decrease in compressive strength with higher PET content and varying effects on impact resistance. Overall, the findings support the use of concrete with high PET content in structural insulated lightweight concrete members and concrete masonry units, offering a sustainable alternative to traditional materials. Further research is recommended to optimize the percentage of PET plastic waste aggregate for optimal performance in concrete applications.”

Mastan Vali N et. al [2017], “The research focuses on the impacts of including PET waste on unit weight,-compressive strength, flexural strength, and split tensile strength of the concrete. It has been found out that adopting PET waste greatly decreases the concrete's unit weight. The optimal replacement is recognized at a 10% substitution of fine-aggregate with PET bottle fibers. This leads to improved compressive and flexural strength. Nevertheless, there is a gradual fall in compressive strength after crossing the 10% replacement level, aligning with the trends observed in flexural and split tensile strengths. From an economic view, using PET waste seems advantageous compared to fine aggregate. The conclusion underscores that a 10% substitution of fine aggregate with PET bottle fibers achieves a fine balance between strength enhancement and weight reduction, unlocking the potential for more sustainable and cost-effective construction techniques.”

Rajat Saxenaa et. al [2016], “The think about digs into the plausibility of utilizing squander plastic in concrete generation and its suggestions for economical advancement. Through a cascade of tests, the ponder scrutinizes the impacts of including plastic squander on concrete's workability, quality properties, solidness, and maintainability. The comes about uncover that whereas the expansion of plastic squander diminishes concrete's workability, it doesn't altogether affect its quality or solidness. Concrete implanted with plastic squander illustrates comparable quality to reference concrete up to certain limits, making it pertinent for auxiliary applications. Besides, the strength properties of concrete with plastic squander stay associated to those of reference concrete, demonstrating its long-term convenience. The ponder complements the supportability perspective of utilizing plastic squander in concrete, because it can contribute to creating ecologically inviting concrete. By and large, the discoveries propose that joining plastic squander into concrete blends presents a twofold arrangement to squander management and fabric shortage within the development industry, adjusting with endeavors towards natural preservation.”

R. N. Nibudey et. al [2013], “The research delves into the potential of plastic fiber reinforcement concerning enhancing the properties of concrete, placing emphasis on compressive and split tensile strengths. The study discovers that the inclusion of plastic fibers within concrete boosts its strength features, with the ideal fiber content being around 1%. This particular content upgrades compressive strength by a staggering 4.30% and split tensile strength by a remarkable 11.21% when compared to the control concrete structure!!! Moreover, the incorporation of plastic fibers changes the flow properties and density of concrete, resulting in a somewhat lightweight composition, and switches the failure mode from brittle to ductile, showcasing improved toughness. Mathematical equations have been established to anticipate the strengths of plastic fiber reinforced concrete, indicating its potential as a promising reinforcement material for concrete, bringing about both environmental and structural advantages. Further exploration is suggested to fine-tune the fiber content for optimal performance in different concrete applications.”

Ankit Arora et. al [2013], “The ponder investigates the utilization e-waste and plastic bottle squander inside concrete generation, centering around their affect on compressive quality and taken a toll reserve funds. Employing a point by point technique including gathering, handling, and joining squander materials into concrete blends, the ponder assesses their fabric properties and evaluates their wellness for concrete generation. The discoveries uncover that the incorporation of pounded e-waste and plastic squander may progress compressive quality by 5% and cut concrete generation costs by 7% at the perfect squander rate. Furthermore, the prepared squander materials appear promising holding with cement, recommending their potential as economical development materials. The think about moreover emphasizes the cost-saving focal points of consolidating e-waste in tile generation, giving an choice to conventional vitrified tiles. In pith, the results propose that mixing e-waste and plastic bottle squander into concrete presents openings to upgrade mechanical properties and cost-effectiveness, in this manner advancing economical development hones. Assist thinks about are energized to examine ways to optimize pressing thickness and grow tile plans for improved advertise acknowledgment.”

Zainab Z. Ismail et. al [2008], “The study investigates the feasibility of using waste plastic as a partial replacement for sand in concrete mixtures and assesses its effects on various mechanical properties of concrete. Through a series of experiments, the study evaluates the compressive strength, flexural strength, density, and workability of concrete mixtures containing different percentages of waste plastic. The findings reveal that while the addition of waste plastic tends to decrease the compressive and flexural strengths of concrete, especially at higher ratios, the concrete mixtures maintain adequate workability for various applications. Additionally, both the fresh and dry densities of the concrete mixtures decrease with the incorporation of waste plastic. Despite these effects on mechanical properties, the study concludes that using waste plastic in concrete mixtures offers a promising solution to reduce material costs and address solid waste management issues, contributing to sustainable construction practices.”

III. METHODOLOGY

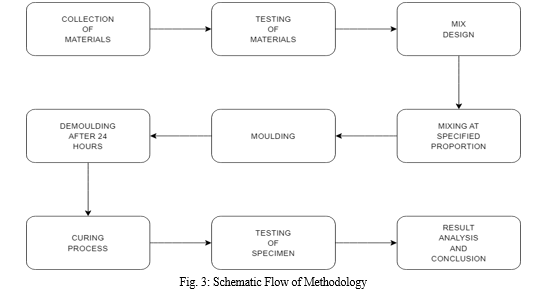

A. Schematic Flow of Methodology

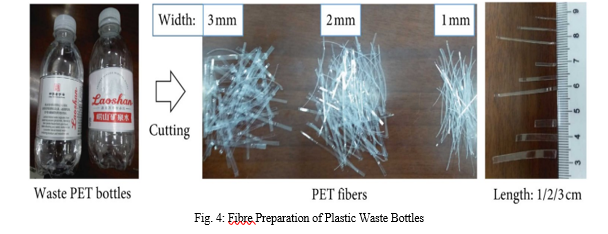

B. Fibre Preparation of Plastic Waste Bottles

Utilizing waste plastic drinking water bottles to create fibers for concrete reinforcement presents an innovative approach to recycling and sustainable construction practices. By cutting these bottles into three different sizes (1mm, 2mm, and 3mm), we can tailor the fibers' dimensions to optimize their reinforcement properties in concrete. Incorporating these fibers into concrete as a partial replacement for cement (15%, 20%, and 25%) offers the potential to enhance the concrete's mechanical properties while reducing the environmental impact of plastic waste.

The process involves cutting the bottles into the desired fiber sizes and thoroughly mixing them into the concrete mix before casting cubes for testing. The objective is to determine the compressive strength of the concrete specimens with varying fiber sizes and replacement percentages to identify the combination that yields the highest strength.

This approach not only addresses the pressing issue of plastic waste management but also offers a sustainable solution for enhancing concrete properties. The use of waste plastic bottles as a reinforcement material can potentially reduce the consumption of traditional construction materials, leading to cost savings and environmental benefits.

Additionally, this research can contribute valuable insights into the effectiveness of using waste plastic fibers in concrete, paving the way for further exploration and adoption of sustainable construction practices. Overall, this study has the potential to drive innovation in the construction industry by demonstrating the feasibility and benefits of incorporating waste plastic materials into concrete production.

In our project, Plastic Waste bottles is being used as a partial replacement for coarse aggregate in concrete mixes. This means that a portion of the fine aggregate in the concrete mix is being replaced with Waste Plastic Bottles. The percentage of replacement can vary depending on the desired properties of the concrete.

C. Mixing of Plastic Waste Bottles Cutting Piece

In our experiments, we are focusing on M25 grade concrete mixed with plastic waste bottles as an admixture. This research involves replacing a range of fine aggregate with plastic waste bottles, specifically 15%, 20% and 25%. The primary objective of this study is to assess how the inclusion of waste ceramic tiles affects the performance characteristics of the concrete. By using waste materials as substitutes for traditional components, we aim to explore sustainable practices in concrete production, reduce environmental impact, and promote recycling efforts. This research is crucial for advancing sustainable construction practices and addressing environmental challenges in the construction industry. Water-cement ratio 0.47 was used in this research.

D. Casting of Specimens

All the samples were casted alluding to the blend extents specified in table. For these blend extents, required amounts were weighed. Beneath this extend, casting of examples for diverse properties. Examples for Compressive Quality 150x150x150 mm measured 3d shape (12 3d shapes) examples were arranged for compressive quality and part ductile quality. The materials required were weighed agreeing to the blend extent. Cement, Ground Granulated Impact Heater Slag, fine totals and coarse totals were dry blended to begin with to have a uniform colour.

After that 50% of the total water required was included to the blend to have careful blending for 3-4 minutes. At that point 40% of the water was included with expansion to the blend. Remaining 10% of water was sprinkled on the above mix and it was altogether blended within the mixer. The oiled tests were at that point filled with the blend arranged and after that filled molds were put on the vibrating table for their appropriate blending. Instantly after casting 3d shapes, the examples were put into open discuss for curing for 24 hours.

E. Compressive Strength

Compressive strength is a fundamental mechanical property that measures a material's ability to withstand axial loads, such as those encountered in structural applications. When it comes to Normal Concrete and Partial Replacement of Fine aggregate with Fiber Reinforced Concrete, the compressive strength is a critical parameter that reflects the material's overall performance and durability. In the experimental procedure, specimens were demolded from their molds after 24 hours of casting. Subsequently, they were submerged in a curing tank for a predefined period to ensure proper hydration and strength development. Upon reaching the testing age, the specimens were removed from the tank and allowed to surface dry for 10-15 minutes to eliminate excess moisture.

Compression tests were conducted using a Compression Testing Machine (CTM) at a specified load rate of 5 kN/sec, as per the guidelines outlined in IS: 516-1959. The CTM used in the experiments had a capacity of 5000 kN, ensuring compatibility with the testing requirements. The failure load of the specimens was then determined, providing valuable data on the compressive strength of the Normal Concrete and Partial Replacement of Coarse Aggregate with Waste Ceramic Tiles. This meticulous testing procedure ensures that the compressive strength values obtained are reliable and reflective of the actual performance of Normal Concrete and Partial Replacement of Coarse Aggregate with Waste Ceramic Tiles. The results of these tests are crucial for evaluating the effectiveness of waste ceramic tiles as a sustainable alternative in concrete production and for informing future construction practices.

IV. RESULTS & DISCUSSIONS

TABLE 1

COMPRESSIVE STRENGTH OF NORMAL OPC CONCRETE (M25)

|

Compressive Strength of Normal OPC Concrete (M25) |

|||

|

Duration |

7th Day |

14th Day |

28th Day |

|

Cube 1 |

21.20 |

23.58 |

26.95 |

|

Cube 2 |

21.25 |

23.52 |

26.94 |

|

Cube 3 |

21.28 |

23.62 |

26.89 |

V. FUTURE SCOPE

Based on the findings of this study, there are several avenues for future research and development in the use of waste plastic bottles in concrete production. One key area for future exploration is to decrease the replacement percentage of PET with fine aggregate. By reducing the amount of PET used in the concrete mix, it may be possible to mitigate the decrease in compressive strength observed in this study while still benefiting from the sustainability aspects of using waste plastic materials.

Additionally, further research could focus on optimizing the mix design by experimenting with different combinations of PET sizes, shapes, and treatment methods. This could help enhance the bonding between the PET fibers and the concrete matrix, potentially improving the overall strength and durability of the concrete.

Another important aspect for future consideration is the long-term durability of concrete with PET fibers. Conducting durability tests, such as freeze-thaw resistance, chloride ion penetration, and carbonation resistance, could provide valuable insights into the performance of PET-reinforced concrete in real-world conditions.

Furthermore, exploring the use of other waste plastic materials, such as polypropylene or high-density polyethylene, as reinforcement in concrete could expand the scope of sustainable construction practices. These materials may offer different properties and advantages compared to PET, opening up new possibilities for improving the sustainability and performance of concrete structures.

Overall, the future scope of research in this field is vast and holds significant potential for advancing sustainable construction practices through the innovative use of waste plastic materials in concrete production.

Conclusion

In conclusion, the testing conducted on various materials, including cement, coarse aggregate, and fine aggregate, yielded important results. The cement met the required specifications for fineness, initial and final setting times, and consistency. Coarse aggregate demonstrated satisfactory specific gravity and water absorption levels, although the crushing test value and impact value were slightly higher than desirable. Similarly, the fine aggregate met the specific gravity and water absorption requirements, with acceptable moisture content. Moving on to the mix design, M25 grade concrete was chosen, adhering to the stipulations outlined by the Indian standard codebook. The mix design incorporated plastic waste bottles as an admixture, with replacement percentages of 15%, 20%, and 25%. The objective was to evaluate the performance of concrete with varying levels of waste ceramic tile inclusion, aiming to promote sustainable construction practices. The compression test results revealed that concrete with 15% PET replacement exhibited the highest compressive strength across all curing periods, surpassing even the normal OPC concrete. However, as the PET content increased to 20% and 25%, a slight decline in compressive strength was observed, particularly noticeable on the 28th day. These findings underscored the potential of PET as a supplementary material for enhancing concrete strength, highlighting the need for further optimization and research to determine the most effective PET percentage for specific applications. Overall, this study contributes to advancing sustainable construction practices and addressing environmental challenges in the construction industry by exploring the incorporation of waste materials into concrete production.

References

[1] Meshram, A. (2023). Optimizing and predicting compressive strength of one-part geopolymer concrete. International Journal for Research in Applied Science and Engineering Technology, 11(5), 7457–7472. https://doi.org/10.22214/ijraset.2023.53436 [2] Donald Kwabena Dadzie, A. K. Kaliluthin, D. Raj Kumar “Exploration of Waste Plastic Bottles Use in Construction” Civil Engineering Journal Vol. 6, No. 11, November, 2020 pp. 2262-2272 http://dx.doi.org/10.28991/cej-2020-03091616 [3] Rajat Saxenaa, Abhishek Jaina and Yash Agrawala Utilization of Waste Plastic in Concrete Towards Sustainable Development: A Review International Journal of Engineering Research and Application ISSN: 2248-9622, Vol. 6, Issue 12, (Part -4) December 2016, pp.88-100 [4] Zainab Z. Ismail, Enas A. AL-Hashmi, Use of waste plastic in concrete mixture as aggregate replacement, Waste Management, Volume 28, Issue 11, 2008, pp.2041-2047, ISSN 0956-053X, https://doi.org/10.1016/j.wasman.2007.08.023 [5] Arora, Ankita and Urmil Dave. “UTILIZATION OF E- WASTE AND PLASTIC BOTTLE WASTE IN CONCRETE.” International Journal of Students\' Research in Technology & Management 1 (2013): 398-406. [6] Sawsan D. A. Shubbar and Aqeel S. Al-Shadeedi “Utilization of Waste Plastic Bottles as Fine Aggregate in Concrete” Kufa Journal of Engineering Vol. 8, No. 2, June 2017, P.P. 132-146 Received 29 March 2016, accepted 20 December 2016 [7] Wasan Ismail Khalil, Khalaf Jumaa Khalaf “Eco-Friendly Concrete Containing Pet Plastic Waste Aggregate” Diyala Journal of Engineering Sciences ISSN 1999-8716 Printed in Iraq Vol. 10, No. 01, pp. 92-105, March 2017 [8] R. N. Nibudey, Dr. P. B. Nagarnaik, Dr. D. K. Parbat, Dr. A. M. Pande Strengths Prediction of Plastic Fiber Reinforced concrete (M30), International Journal of Engineering Research and Applications (IJERA) ISSN: 2248-9622 www.ijera.com Vol. 3, Issue 1, January -February 2013, pp.1818-1825 [9] Mastan Vali N, SS. ASADI PET Bottle Waste as A Supplement to Concrete Fine Aggregate, International Journal of Civil Engineering and Technology (IJCIET) Volume 8, Issue 1, January 2017, pp. 558–568, Article ID: IJCIET_08_01_063 [10] Altamashuddinkhan Nadimalla, Siti Aliyyah Binti Masjuki, Asmahani Binti Saad, Kamsiah Binti Mohd Ismail, Maisarah Bt Ali Polyethylene Terephthalate (PET) Bottles Waste as Fine Aggregate in Concrete International Journal of Innovative Technology and Exploring Engineering (IJITEE) ISSN: 2278-3075, Volume-8, Issue- 6S4, April 2019 [11] Divyani Harpal, Abhishek Kosare, Pravin Kumbhare, Vitthal Sonune, Anurag Vilaytkar, Rushikesh Dandge, Madhwi Hedau Waste Pet Bottle Fibre Used in Concrete for Increasing the Strength International Research Journal of Modernization in Engineering Technology and Science (Peer-Reviewed, Open Access, Fully Refereed International Journal) Volume:04/Issue:04/April-2022Impact Factor- 6.752 www.irjmets.com

Copyright

Copyright © 2024 Aishwarya Deshbhratar, Arjuman Sheikh, Mohammad Loot Ansari, Prof. Syed Sohailuddin. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET59910

Publish Date : 2024-04-06

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online