Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Analyzing Strength Parameters in Fiber-Reinforced Concrete: Compressive, Tensile & Flexural Strength Evaluation

Authors: Dr. A. Krishna Rao, B. Prasad, P. Sathwik, P. Rohith, K. Vinay Kumar

DOI Link: https://doi.org/10.22214/ijraset.2024.60465

Certificate: View Certificate

Abstract

The present day world is witnessing the construction of very challenging and difficult civil engineering structures. Quite often, concrete being the most important and widely used material is called upon to possess very high strength and sufficient workability properties. Researchers all over the world are attempting to develop high performance concretes by using fibers and other admixtures in concrete up to certain proportions. Concrete is a brittle material that has low tensile strength and low strain capacity. In fact, many deteriorations and failures in the concrete structures are due to the brittle nature of this material. These disadvantages may be avoided by adding short discontinuous fibers to plain concrete which has been a major motivation for many research works in recent years. Fibers are added into a brittle-matrix composite to help improve three major aspects, toughness, ductility and strength (tensile). Fibers tend to increase toughness of the composite material by bridging the cracks and provide energy absorption mechanism related to de-bonding and fiber pull-out. Concrete is the composition of aggregates, cement. Fiber reinforcement involves micro- reinforcement of fiber in concrete. Hence, finding out the optimum quantity of polypropylene fibers required to achieve the maximum compressive strength for M25 grade concrete is aim. From the exhaustive and extensive experimental work it was found that with increase in polypropylene fiber content in concrete there was a tremendous increase in compressive strength. Even at 1.5% polypropylene fiber content compressive strength of 24N/mm was observed against compressive strength 18N/mm² at 0%.

Introduction

I. INTRODUCTION

Even though plain cement concrete is the key constituent of the structures all over the world. these structures are prone to a lot of problems like cracking and plastic shrinkage So, in order to overcome these problems, supplement such as is being used so that the strengths a disturbed significantly. Concrete is world's most widely used construction material. Due to its low tensile strength and a low tensile strain limit it results in the development of micro cracks in it. So in order reduce this effects polypropylene fibers can be used. Excessively wide cracks can also result in leakage in structures such as dams, tanks, and pools. In many of the cases this cracking is so significant that it may lead to failure of the structure. The deterioration of such structures is of great concern since the repairing and rehabilitation of these structures are time consuming and costly. By adding polypropylene fibers into the concrete, the plastic shrinkage cracks of concrete at the early age is reduced and it can also reduce the surface bleeding and settlement of aggregate of fresh concrete, which can prevent the formation of sealing cracks and shrinkage. High early strength, low shrinkage, freeze the resistance, sulfate resistance, and corrosion resistance are the properties of fiber reinforced concrete. Fiber reinforced concrete is relatively new composite material in which fibers are introduced into matrices as micro reinforcement so as to improve the tensile cracking and other properties of concrete. Some types of fibers produce greater impact abrasion and shutter resistance and also reduce the bleeding in concrete.

II. EXPERIMENTAL WORK

A. Materials

The details of materials used in the present experimental investigation are as follows: fine aggregates, coarse aggregates, water, alkaline solutions such as sodium hydroxide and sodium silicate, glass fibers were used in experimental work. The experimental program consists of laboratory tests on polypropylene fiber reinforced concrete (PFRC) to characterise the properties such as flow ability in fresh state, early age plastic shrinkage and mechanical properties in hardened state.

For this purpose, concrete mixtures with PFRC mixes were casted. The PFRC mixes was for 12mm length of polypropylene fiber and the different volume fraction of fiber were 0%, 2%, 4%, 6%. The materials, mix design, casting, curing, test methods and procedures for workability of PFRC, and tests for selected mechanical properties of hardened concrete are described in detailed in the respective sections.

- Aggregates: Aggregates are the important constituents in concrete. They give strength to the concrete and reduce shrinkage. Aggregates occupy 70-80 percent of the volume of concrete; their impact on various characteristics and properties of concrete is undoubtedly considerable. Coarse and fine aggregates are in saturated surface dry condition.

- Cement: Cement is a binder, a substance used for construction that sets, hardens and adheres to other materials, binding them together. Chemical Composition of cement is Calcium Oxide (CaO), Silica, (SiO2), Alumina, (Al2O3), Iron, (FeO3), Gypsum (CaSo,.2H?0).In this study we used 53 grade of cement having specific gravity of 3.15. The physical properties are confirming to IS code of zone II IS: 383-1970.

- Polypropylene Fibers: Polypropylene fiber is polymeric unit made of propylene monomers with chemically inert nature and has high strength, temperature resistance, corrosion resistance, available at low price.It is a synthetic resin built up by the polymerization of propylene. One of the important family of polyolefin resins, polypropylene is molded into many plastic products in which toughness, flexibility, light weight, and heat resistance are required. These are gaining in significance due to the low price of the raw polymer material and their high alkaline resistance. It is manufactured in a continuous process by extrusion of a polyproplylene homopolymer resin

- Water: The Ph value of water should not be less than 6.It should be as per the codal provisions which is mentioned in the IS 3025.

B. Testing of Cement

Testing of cement can be brought under two categories: (a) Field testing (b) Laboratory testing.

- Field Testing

a. When the cement bag is opened, there should not be any visible lumps.

b. The color of the cement should normally be greenish grey and When the hand is inserted into the cement bag, it must give a cool feeling. There should not be any lump inside.

2. Laboratory Testing

It is incumbent on the part of the user to test the cement in the laboratory to confirm the requirements of the Indian standards with respect to it physical and chemical properties. The following tests are usually conducted in laboratory.

a. Fineness test

b. Standard consistency

c. Initial setting

d. Specific gravity

C. Mix Design

Concrete of M25 grade is as per IS 10262-2009. Code books of IS 383-1970, IS 456-2000 are recommended for mix of polypropylene fiber reinforced concrete.

In this investigation mix design procedure is adopted according to IS 10262-2000. The materials were tested prior to the casting and checked for conformity with relevant Indian standards. The quantities of various materials for the concrete mix are given.

A mix proportion of 1:1:2 with 0.45 as water cement ratio the get characteristic strength of M25 was used for this study.

Aggregates of 10mm size are used and fibers are taken with weight of cement i.e. 0%,2%,4%,6%.

D. Test Done on Fresh Concrete

As the mixing of mateials according to the proportions, the concrete obtained with or without. The was first tested to know its workability i.e. the flow of concrete which shows whether it can be used or not for placing. These factors suggest if the concrete can be accepted or should be rejected.

Two standard methods were used to study workability of concrete in terms of flow ability. The being standard slump test and compaction factor test. These tests were performed on the same batch of concrete for the purpose of homogeneity and the results obtained thus were compared and calibrated.

- Standard Slump Test

The slump test is the host well known and widely used test method to characterize the workability of fresh concrete. The inexpensive test, which measures consistency, is employed in laboratory or at site of work to determine rapidly whether a concrete batch should be accepted or rejected. It is not a suitable method for very wet or very dry concrete.

The apparatus for conducting the slump test essentially consists of a metallic mould inn the form of a frustum of a cone having the internal dimensions as under

a. Bottom diameter: 20cm

b. Top diameter: 10cm

c. Height: 30cm

E. Tests on Hardened Concrete

Some of the mechanical properties of concrete and PFRC are considered in this study. One of the purposes of testing hardened concrete is to confirm that the concrete used at site has developed the required strength. As the hardening of the concrete takes time, one will come to know, the actual strength of concrete for some time.

- Compression Test

Compressive strength is the capacity of a material or structure to withstand loads tending to reduce size. The compression test is carried out on specimens cubical or cylindrical in shape. The test is conducted at surface dry condition. This machine applies compressive stress on the cylinder due to downward movement of plates. The compressive strength of the concrete cube is given by:Compressive strength=load/area

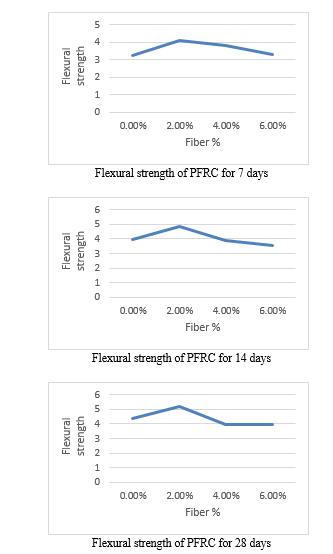

2. Flexural Strength Test

Flexural strength, also known as bending strength or modulus of rupture, is a mechanical property of materials that describes their ability to resist deformation under bending or flexural loads. It is a critical parameter in engineering and materials science, particularly in the design of structures and components that experience bending forces.formula is given by F=PL/bd^2

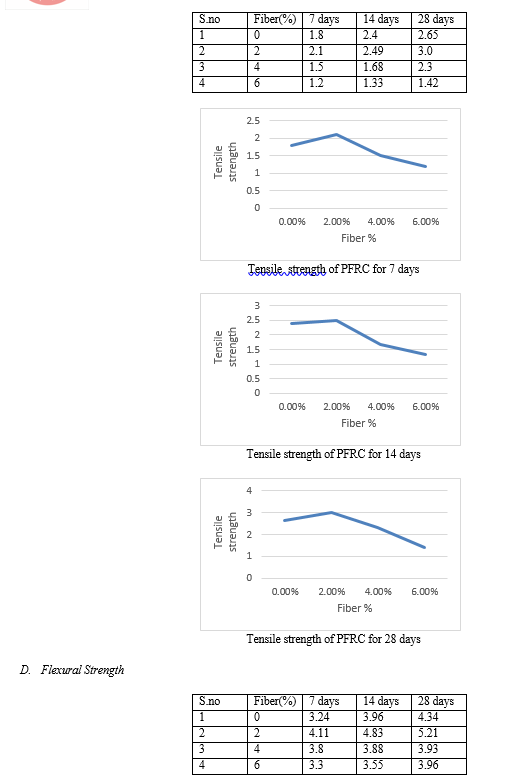

3. Tensile Strength Test

A tensile strength test, also known as a tensile test or tension test, is a fundamental mechanical test used to determine the strength and mechanical properties of materials under tension. The test is widely used in material science, engineering, manufacturing, and quality control to assess the performance of materials and to ensure they meet design specifications and standards. Formula is given by F=2f/πDL

III. RESULTS

The results of laboratory tests are presented and discussed. These include results of workability tests of fresh concrete using different test procedures, results of compression and tensile on hardened concrete at ages of 7, 14, 28 days respectively

A. Workability of fresh PFRC

For the workability of fresh concrete, the tests performed were slump cone test, compacting factor test and Vee -Bee consistometer test. Tests performed on concrete without polypropylene fibers and on PFRC is slump test and the results were compared.

The values of slump test, compaction factor test and Vee-Bee consistometer test are obtained within the permissible limits as mentioned in IS 1199-1959

|

s.no |

% of Fiber |

Height of slump |

|

1 |

0 |

75mm |

|

2 |

2 |

100mm |

|

3 |

4 |

112mm |

|

4 |

6 |

120mm |

B. Compressive Strength

In this step cubes of fly ah based with and without Polypropylene fibres are tested and the results are given in the following table.

Compressive strength = load/area

Load = average of loads applied on each specimen

|

S.no |

Fiber(%) |

7 days |

14 days |

28 days |

???????

???????

Conclusion

Based on the experimental investigations the following conclusions were drawn: 1) Workability of concrete decreases with increase in Polypropylene fiber volume fraction. This is due to the resistance of fibers for the free flow of concrete. 2) With comparison of Conventional (0% polypropylene) concrete: 3) Among different various percentages of polypropylene fibers, 2% Polypropylene fibers show optimum results to use with concrete. 4) The Compressive strength of concrete is increased by 18.85 % with 2% Polypropylene fibers. 5) The Tensile strength of concrete is increased by 16 % with 2% Polypropylene fibers 6) The flexural strength of concrete is increased by 24.5% with 2% Polypropylene fibers 7) There is significant change in the Tensile strength, Flexural strength with variation of Polypropylene fibers when compared to Conventional concrete.

References

[1] P.Pavithra, “M. P. Mechanical properties, pore size distribution, and pore solution of fly ash- belite cement mortars. Cement 3.and Concrete Research, 1999, 29(11),pp vol1 ” [2] KÖNIG G STARK. J KRUMBACH, FRIEDEMANN, K.; SEYFARTH, K. and HEINRICH, U. “Durability investigations of high performance concrete. In Proc of the 6 International Symposium on High 4. R.:Strength/High Performance Concrete. Leipzig. 2002,pp. 1107-1117” [3] URBAN, M. “Properties of hardened self-compacting concrete with fly ash. In Proc of 3 International Scientific Conference Quality and Reliability in Building Industry, Levoca, 2003 pp. 533-538.” [4] ANTIOHOS. S. MAGANARI, K. and TSIMAS “Evaluation of blends of high and low calcium fly ashes foruse as supplementary cementing materials. Cement andConcrete Composites, 2005, 27(3), pp. 349-356.” [5] Mr. Amol R.Rode, Ms. Swati R.Shewale “International journal of recreach in advent technology, Vol.2, No.8, August 2014, E-ISSN: 2321-9637” [6] Zitouni Mohamed, Belkacem Lamri, Kada Abdelhak, “Fire Resistance Performance of Glass Fiber Reinforced Concrete Columns,jan 2022” vol 2 [7] Ninghui Liang, Lianxi Ren, Shuo Tian, Ru Yan, “Study on the Fracture Toughness of Polypropylene–Basalt Fiber-Reinforced Concrete,Jun 2021” vol 1

Copyright

Copyright © 2024 Dr. A. Krishna Rao, B. Prasad, P. Sathwik, P. Rohith, K. Vinay Kumar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET60465

Publish Date : 2024-04-16

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online