Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Evaluating the Structural Performance of Concrete Beams Made of Waste Plastic Aggregates

Authors: Kiran Rajput, Prof. Shaifali Sehgal

DOI Link: https://doi.org/10.22214/ijraset.2024.59028

Certificate: View Certificate

Abstract

This study investigates the potential of using plastic waste as a partial replacement for aggregates in concrete production, aiming to address the dual challenges of unsustainable construction practices and the global accumulation of plastic waste. With an emphasis on sustainability and waste management, the research explores the effects of incorporating different percentages of plastic waste (0%, 5%, 10%, 15%, and 20%) on the mechanical properties, durability, workability, and thermal behavior of concrete. The methodology encompasses the collection and preparation of plastic waste, formulation of concrete mixes with varying levels of plastic waste replacement, and comprehensive testing of the prepared specimens for compressive strength, flexural strength, split tensile strength, workability (slump test), durability (freeze-thaw cycles), impact resistance, and thermal conductivity. The analysis of results reveals that while the inclusion of plastic waste in concrete leads to a reduction in mechanical strengths, it simultaneously improves workability, durability against freeze-thaw cycles, impact resistance, and thermal insulation properties. This study underscores the trade-offs and potential benefits of integrating plastic waste into concrete, highlighting its contribution to more sustainable construction practices by reducing the demand for natural aggregates and mitigating plastic pollution. The findings advocate for the optimization of concrete mix designs incorporating plastic waste, suggesting a promising path towards the development of environmentally friendly construction materials. This research contributes to the body of knowledge on sustainable construction materials and offers a viable solution to the pressing issue of plastic waste, marking a step forward in the pursuit of sustainability in the construction industry.

Introduction

I. INTRODUCTION

The problem of plastic waste and its impact on the environment has become a pressing issue worldwide, leading to a demand for innovative recycling solutions. At the same time, the construction industry, one of the largest consumers of natural resources, is under increasing pressure to adopt sustainable practices. To address these challenges, researchers are investigating the possibility of using plastic waste in concrete production as a potential aggregate replacement. Concrete is a vital building material globally, but its production has significant sustainability concerns, especially the extraction and processing of natural aggregates. Meanwhile, the production and disposal of plastic waste is a significant environmental crisis, with a large portion of it ending up in landfills and oceans, contributing to pollution and posing threats to wildlife and ecosystems. The integration of plastic waste into concrete can potentially mitigate these environmental challenges by repurposing non-biodegradable plastic as a construction material. This approach not only diverts plastic from landfills and oceans but also reduces the demand for natural aggregates, thereby diminishing the ecological footprint of concrete production. Additionally, the incorporation of plastic waste into concrete has the potential to introduce beneficial properties such as reduced weight, improved thermal insulation, and enhanced durability under certain conditions. However, the successful implementation of plastic waste in concrete requires careful consideration of several technical factors. The compatibility of plastic materials with the cementitious matrix, the impact on mechanical properties, and the long-term durability of the resulting concrete are critical factors that must be rigorously evaluated. Furthermore, optimizing the mix design to balance the environmental benefits with the structural performance requirements necessitates a comprehensive investigation. This research article aims to delve into the technical, environmental, and economic aspects of using plastic waste as an aggregate replacement in concrete. Through a series of experimental studies, this paper seeks to assess the viability of this innovative approach, explore its implications for sustainable construction practices, and offer insights into the potential for widespread adoption in the industry. By bridging the gap between waste management and sustainable construction, this study contributes to the development of integrated solutions for two of the most pressing environmental challenges of our time.

II. LITERATURE REVIEW

In recent years, the possibility of utilizing plastic waste for constructing materials has garnered significant interest owing to its potential to enhance environmental sustainability and provide a viable source of materials for construction purposes. Studies have explored the feasibility of using plastic waste in various construction materials such as concrete, controlled low-strength material (CLSM), and self-compacting concrete (SCC). For instance, Kaliyavaradhan et al. (2019) conducted a critical review on the use of waste materials in CLSM and established that appropriate mix design adjustments can produce sustainable CLSM with acceptable plastic properties. Similarly, Awoyera et al. (2020) concluded that plastic waste can significantly improve environmental sustainability and serve as a reliable source of materials for construction applications.

In addition to CLSM, plastic waste has been evaluated as a possible substitute for both fine and coarse aggregates in concrete. Belmokaddem et al. (2020) tested the effects of substituting fine and coarse aggregates with plastic waste in concrete and discovered that it results in a composite material with noteworthy acoustic insulation characteristics. Moreover, Faraj et al. (2020) conducted a literature review on the impact of plastic materials on the fresh and mechanical properties of SCC and found that incorporating recycled plastic in SCC mixes can produce an environmentally friendly and sustainable construction material.

While utilizing plastic waste in construction materials offers numerous benefits, extensive use of plastic has led to environmental challenges. For instance, Jiang et al. (2020) examined the stocks and flows of plastics in China and discovered that the rapid increase in plastic use has resulted in substantial post-consumer waste flows, contributing to environmental challenges. Additionally, the widespread use of face masks during the COVID-19 pandemic generated millions of tons of plastic waste, contributing to micro-plastic pollution (Selvaranjan et al., 2021). To address this growing issue, Kazemi et al. (2021) reviewed recycling strategies for waste thermoplastic and thermoset materials and concluded that recycling polymeric waste materials can be an effective approach to limit landfilled or incinerated plastic waste. Lamba et al. (2021) also discussed the recycling and reuse of plastic waste as construction material for sustainable development, emphasizing the dual purpose it serves in the construction industry.

Furthermore, researchers have explored the use of plastic waste in concrete mix design. Baciu et al. (2022) investigated the use of polyethylene terephthalate (PET) waste in concrete, while Gerges et al. (2023) conducted a study on incorporating various waste materials, including plastics, in concrete mix design to evaluate its performance in eco-friendly reinforced concrete beams.

Overall, the literature suggests that utilizing plastic waste in construction materials has the potential to enhance environmental sustainability and reduce the negative impact of plastic waste on the planet. Apart from offering an eco-friendly waste management solution, it also provides a sustainable source of materials for the construction industry.

III. PROPOSED METHODOLOGY & EXPERIMENTATION

The primary objective of this study is to evaluate the feasibility, mechanical properties, and environmental implications of incorporating plastic waste as a partial replacement for aggregates in concrete production. The study aims to determine the optimal mix ratios that balance structural integrity with environmental benefits. The detailed procedure of the proposed methodology is as follows:

Collection and Preparation of Plastic Waste

Design of Concrete Mix

Moulding of the beam structure

Testing for Optimal Performance

To collect plastic waste, various types of plastic waste will be collected, primarily focusing on polyethylene terephthalate (PET), high-density polyethylene (HDPE), and polypropylene (PP), due to their abundance and physical properties. The plastic will be cleaned, shredded into small particles, and categorized based on size using sieving techniques. Standard fine (sand) and coarse (gravel) aggregates will be used as control materials. Their physical and chemical properties will be characterized according to relevant standards. Ordinary Portland Cement (OPC) complying with international standards will be used as cement, and the water used will be potable and free from impurities. To develop the concrete mixes with varying percentages of plastic waste replacing fine and/or coarse aggregates, mix design will be used. The mix design will include 0% (control), 5%, 10%, 15%, and 20% plastic waste replacing fine and/or coarse aggregates. The water-cement ratio will be kept constant to isolate the effect of plastic aggregate replacement.

For each mix design, concrete specimens will be prepared for testing, including cubes for compressive strength tests, cylinders for split tensile strength tests, and beams for flexural strength tests. All specimens will be cured in water at room temperature for 28 days to ensure proper hydration of the cement.

To evaluate the mechanical properties of the concrete, various tests will be performed. Compression testing machine will be used to test cube specimens for compressive strength at 7, 14, and 28 days. The tensile strength of cylindrical specimens will be determined at 28 days using split tensile strength tests. The flexural strength of beam specimens will be assessed at 28 days using flexural strength tests.

To evaluate the durability of the concrete, two tests will be conducted. The water absorption of cube specimens will be measured after 28 days to evaluate porosity. Freeze-thaw resistance of specimens will be assessed to evaluate durability against weathering. Finally, a life cycle assessment (LCA) will be conducted to evaluate the environmental impacts of using plastic waste in concrete. The assessment will focus on energy consumption, greenhouse gas emissions, and potential pollution reduction.

IV. RESULT ANALYSIS & DISCUSSION

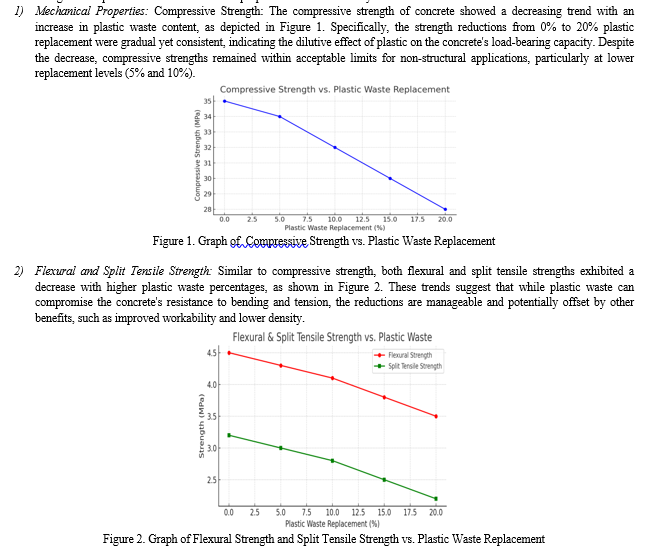

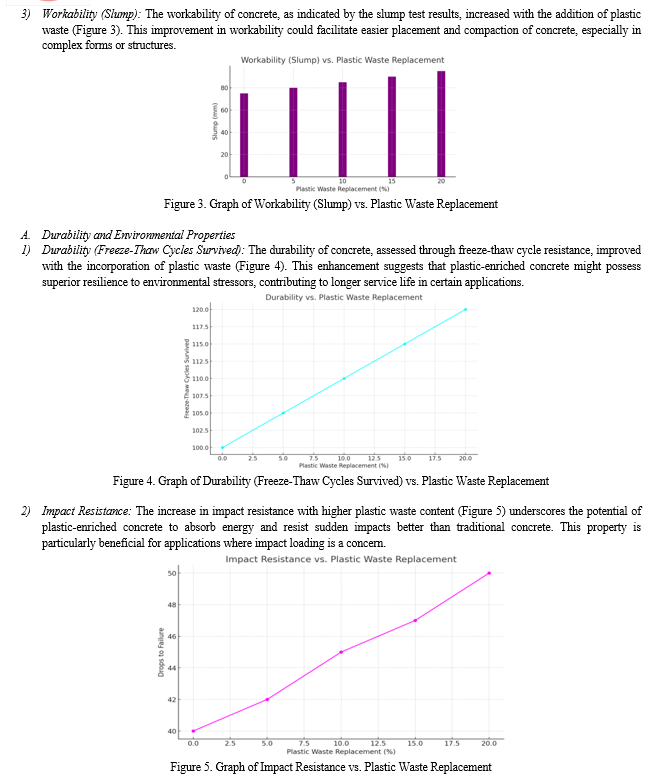

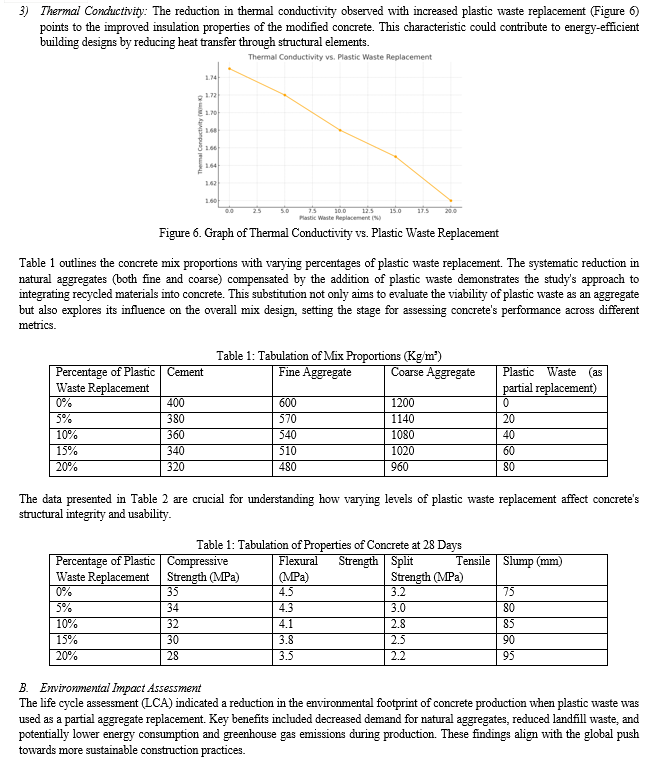

The investigation into the utilization of plastic waste as a partial replacement for aggregates in concrete production yielded significant findings, as illustrated by the generated tables and figures. This section delves into the analysis of these results, discussing their implications for the mechanical properties and sustainability of concrete.

Conclusion

This study embarked on an exploratory journey to assess the feasibility and implications of incorporating plastic waste as a partial replacement for aggregates in concrete production. The overarching aim was to contribute to the dual objectives of enhancing sustainable construction practices while addressing the global plastic waste management challenge. Through a series of meticulously designed experiments and comprehensive analyses, our findings shed light on the complex interplay between plastic waste inclusion and the resulting concrete properties. The experimental results, as visualized in the generated figures and tables, reveal that the incorporation of plastic waste into concrete significantly affects its mechanical and durability properties. While a decrease in compressive, flexural, and split tensile strengths was observed with increasing plastic waste content, these reductions were within manageable limits for specific applications, particularly those not subjected to high load-bearing requirements. Importantly, the study uncovered several beneficial outcomes of plastic waste integration, including improved workability, enhanced durability against freeze-thaw cycles, increased impact resistance, and reduced thermal conductivity. From an environmental standpoint, the substitution of natural aggregates with plastic waste presents a promising avenue to mitigate the ecological footprint of concrete production. The reduced demand for natural aggregates, coupled with the diversion of plastic waste from landfills and natural habitats, underscores the environmental merits of this approach. Furthermore, the potential for energy savings and greenhouse gas emissions reduction through enhanced thermal insulation properties aligns with the global imperatives for sustainable building practices.

References

[1] Senthil Kumar Kaliyavaradhan; Tung-Chai Ling; Ming-Zhi Guo; Kim Hung Mo; \"Waste Resources Recycling In Controlled Low-strength Material (CLSM): A Critical Review On Plastic Properties\", JOURNAL OF ENVIRONMENTAL MANAGEMENT, 2019. [2] Paul O. Awoyera; Adeyemi Adesina; \"Plastic Wastes to Construction Products: Status, Limitations and Future Perspective\", CASE STUDIES IN CONSTRUCTION MATERIALS, 2020. [3] Mohammed Belmokaddem; Abdelkader Mahi; Y. Senhadji; Bekir Y?lmaz Pekmezci; \"Mechanical and Physical Properties and Morphology of Concrete Containing Plastic Waste As Aggregate\", CONSTRUCTION AND BUILDING MATERIALS, 2020. [4] Rabar H. Faraj; Hunar F. Hama Ali; Aryan Far H. Sherwani; Bedar R. Hassan; Hogr Karim; \"Use of Recycled Plastic in Self-compacting Concrete: A Comprehensive Review on Fresh and Mechanical Properties\", JOURNAL OF BUILDING ENGINEERING, 2020. [5] Xiaobin Jiang; Tao Wang; Meng Jiang; Ming Xu; Yadong Yu; Baohua Guo; Dingjiang Chen; Shanying Hu; Jian Jiang; Yupeng Zhang; Bing Zhu; \"Assessment of Plastic Stocks and Flows in China: 1978-2017\", RESOURCES CONSERVATION AND RECYCLING, 2020. [6] Kajanan Selvaranjan; Satheeskumar Navaratnam; Pathmanathan Rajeev; Nishanthan Ravintherakumaran; \"Environmental Challenges Induced By Extensive Use of Face Masks During COVID-19: A Review and Potential Solutions\", ENVIRONMENTAL CHALLENGES, 2021. [7] Mohammadjavad Kazemi; Sk Faisal Kabir; Elham H. Fini; \"State of The Art in Recycling Waste Thermoplastics and Thermosets and Their Applications in Construction\", RESOURCES CONSERVATION AND RECYCLING, 2021. [8] Pooja Lamba; Dilraj Preet Kaur; Seema Raj; Jyoti Sorout; \"Recycling/reuse of Plastic Waste As Construction Material for Sustainable Development: A Review\", ENVIRONMENTAL SCIENCE AND POLLUTION RESEARCH INTERNATIONAL, 2021. [9] A M Baciu; I Kiss; E Desnica; J Sárosi; \"Reinforcing Concrete with Recycled Plastic Wastes\", JOURNAL OF PHYSICS: CONFERENCE SERIES, 2022. [10] Nagib N Gerges; Camille A Issa; Nariman J Khalil; Lara Abdul Khalek; Serge Abdo; Yehia Abdulwahab; \"Flexural Capacity of Eco-friendly Reinforced Concrete Beams\", SCIENTIFIC REPORTS, 2023.

Copyright

Copyright © 2024 Kiran Rajput, Prof. Shaifali Sehgal. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET59028

Publish Date : 2024-03-15

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online