Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Study of Compressive Strength of Glass Fiber Reinforced Concrete Cubes

Authors: A. S. Biradar, Dr. D. H. Tupe, Dr. G. R. Gandhe

DOI Link: https://doi.org/10.22214/ijraset.2024.64041

Certificate: View Certificate

Abstract

Nowadays, complex civil engineering work requires high-performance concrete materials. Researchers worked on reinforced concrete to provide sustainable solutions. Materials like carbon, glass, eggshell etc are used for reinforcement with concrete. While study of reinforced concrete cubes performance, compressive strength is an important parameter that need to be focused more. In this paper, experiments were carried out to study the influence of percentage glass fiber reinforcement in concrete on compressive strength. In order to evaluate Compressive Strength (N/mm2) obtained on CTM for GFRC cube of Size: 150x150x150 mm and the age of cube was kept 7 days, 14 days and 28 days. It was observed that maximum compressive strength can be achieved for glass fiber reinforcement of 10 % when age id cube is kept 28 days.

Introduction

I. INTRODUCTION

The demand for stronger, more durable and more environmentally friendly building materials is driving the evolution of the construction industry. While concrete's compressive strength makes it a valuable building material, in some situations it cannot withstand as much pressure or for as long. To exceed these restrictions, many impurities and reinforcements are being studied. Glass fiber, which is the ability to improve traction, resistance to corrosion, and to improve the mechanical characteristics of concrete, is one of these promising materials. The cement industry accounts for 5% of all carbon dioxide emissions. Due to its structural adaptability and aesthetic appeal, concrete is often used in the construction of small and large structures.

K K Annamaneni and K Pedarla (2023) investigated the characteristics of glass fibres reinforced concrete after 7 and 28 days of curing. It was observed the average compressive strength of GFRC after 28 days of curing was 72.06 MPa, indicating that GFRC responds well under loading conditions [1]. P Löber et. al. (2017) carried out experiments on Fibre reinforced concrete beams that have been subjected to bending and tested in cracked state under defined stress levels. Results show a dependence of residual strength and applied stress level. It turned out, that the beams failed due to tertiary creep at stress levels between 65 and 70% of residual crack load at 0.5 mm pre-crack deflection [2]. Sathish Kumar. V et. al. (2012) carried out experimental research to determine the mechanical properties of Geopolymer Concrete Composites (GPCC), which contains Fly ash (FA), alkaline liquids and glass fibres. Alkaline liquid to fly ash ratio was fixed as 0.4 with 100% replacement of OPC. Glass fibres were added to the mix in 0.01%, 0.02% and 0.03% by volume of concrete. It was observed that the Geopolymer concrete composites have relatively higher strength in short curing time (one day) than the Geopolymer concrete and ordinary Portland cement concrete. [3]. Abdelrahman Abushanab et. al. (2024) presented experimental and analytical investigations on the axial capacity of 12 heat-damaged glass fiber-reinforced polymer reinforced concrete columns. The columns were prepared with dimensions of 200 × 200 × 1000 mm and 3 replacement ratios of seawater for concrete mixing and curing (0%, 50%, and 100%). At the age of 3 months, the columns were subjected to an elevated temperature of 500 ?C for 30, 60, and 90 min and subsequently cooled and tested. The experimental results demonstrated that the compressive strength of concrete increased by 35% and 45% at seawater replacement ratios of 50% and 100%, respectively [4]. Geetinder Kaur and Dr. Bal krishan (2017) different tests performed on the materials used in making different mixes of concrete. study is made between the concrete with the addition of different ratios of glass fibre in the traditional concrete, so as to get a high and good quality mix because the strength, durability and other characteristics of concrete depend upon the properties of its ingredients, on the proportions of mix, the method of compaction and other controls during placing, compaction and curing. [5]. Md.Abid Alam et. al. (2015) studied alkali resistant glass fibres used in the concrete mixes. A total of 8 mixes were prepared by varying the percentages of glass fibres and grade of concrete mixes. Based on the laboratory results the compressive and tensile strength was reported to increase up to 26.19% and 25.4%. However, the workability of concrete mixes is not much affected by the addition of fibres. The tensile strength of concrete is improved which shows the use of glass fibres in concrete mixes may reduce its shortcoming of low tensile strength without affecting its workability and compressive strength.

The use of alkali resistant glass fibers significantly improves the compressive as well as tensile strength irrespective of affecting the workability of concrete mixes [6]. Sunil Thapa et. al. (2024) investigated how layer sequencing affects the compressive strength properties of SWSSC-filled hybrid glass-carbon FRP (HFRP) tubes under seawater exposure. It explores two different fibre orientations, namely cross-ply and hoop. One approach which has been used in this study involves constructing tubes where 50 % of the inner tube thickness comprises CFRP layers and 50 % of the outer tube thickness comprises GFRP layers, while another approach alternates carbon and glass layers throughout the tube thickness. Laboratory accelerated ageing tests involved three temperatures (25?C, 40?C, and 60?C) and three conditioning durations (30, 90, and 150 days). Arrhenius predictive models were used to predict the tubes’ long-term residual compressive strength. The results indicate that the 50 %-50 % layer configuration outperforms the layer-by-layer arrangement in cross-ply tubes, with a service life strength retention of 63.9 % in the 50 %-50 % layer configuration compared to 48.8 % in the layer-by-layer configuration. [7]. S. Srinivasan et. al. (2014) carried out experimental program on the mechanical properties of Fibre Reinforced Geopolymer Concrete (FRGPC) such as compressive strength, split tensile strength, flexural strength, and flexural behaviour of FRGPC beams. FRGPC contains flyash, alkaline liquids, fine aggregate, coarse aggregate and glass fibre. Alkaline liquid to fly ash ratio was fixed as 0.45 with 100% replacement of OPC. For alkaline liquid combination, ratio of sodium silicate to sodium hydroxide solution was fixed as 2.5. Glass fibre was added to the mix in volume fractions of 0.01%, 0.02%, 0.03% and 0.04% by volume of concrete. Specimens were subjected to 24 hours of Heat curing at 70°C in heat curing chamber. The effect of fibre content on the mechanical properties and flexural behaviour of FRGPC was studied and compared it with ordinary Geopolymer Concrete (GPC), Geopolymer concrete is an excellent alternative to Ordinary Portland Cement concrete [8]. M. Anil Kumar and V. Giridhar Kumar (2017) investigations conducted on Flexural behaviour of reinforced geopolymer concrete (GPC) and reinforced normally vibrated concrete (NVC) beams. A total of twelve beams were cast, in which six beams were of GPC beams and six beams were of NVC beams with varying percentages of glass fibres from 0,0.5,1,1.5,2 and 2.5 by weigh fraction of binder. This paper depicts the Load – deflection behaviour and Moment – Curvature behaviour of beam specimens. The Load carrying capacity of GPC beams are observed to be better than that of NVC beams [9]. Younes Nouri et. al. (2024) studied the behaviour of reinforced concrete beams with steel and GFRP reinforcement is numerically investigated, and the effect of steel percentage and GFRP percentage on the mechanical strength and energy response of the beam is determined using the Response Surface Methodology (RSM). Using the ABAQUS software, a widely used Finite-Element Analysis (FEA), the numerical modeling is first verified, and then targeted analyses are performed on the beam using the tests specified by the RSM. Then, based on the strength and energy of the beam, a two-variable Analysis of Variance (ANOVA) and two-objective optimization are performed to investigate the effect of changing each parameter of steel percentage and GFRP percentage on beam strength and energy. [10].

II. SAMPLE PREPARATION

The quality and characteristics of materials used in concrete are crucial for the performance and durability of the final product. Proper selection, testing, and quality control of cement, fine aggregates, coarse aggregates, and water, ensure that the concrete meets the desired specifications and standards. Understanding the roles and properties of these materials helps in designing and producing high-quality concrete for various construction applications. For sample preparation various tests were made are as discussed below. These tests help in determining whether the concrete meets the required specifications for the project, ensuring its durability and structural integrity.

A. Fineness Test

The fineness test of concrete typically refers to the fineness test of cement, which is an essential component of concrete. This test measures the particle size distribution of cement, which affects the rate of hydration, strength development, and workability of concrete.

Fig. 1 Fineness test

B. Normal Consistency of Cement

The normal consistency of cement refers to the amount of water required to make a cement paste of standard viscosity, which is neither too thick nor too thin. This consistency is important because it influences the workability of the cement and the hydration process, which directly affects the strength of the final concrete.

Fig. 2 Testing of Normal Consistency of Cement

C. Initial &Final Setting Time of Cement

The initial and final setting time tests of cement are crucial for determining how long it takes for cement to begin and complete the hardening process after mixing with water. These tests help ensure that the cement will provide adequate working time and develop sufficient strength within the expected time frame for construction.

a) b)

Fig. 3 Result of a) Initial Setting Time of Cement (35Min) 1mm Needle used b) Final Setting Time of Cement 580 min (5mm Sieve is Used)

D. Soundness Test of Cement

The soundness test of cement is conducted to determine the ability of cement to retain its volume after setting. This is crucial because any significant expansion after setting can lead to cracks, ultimately compromising the structural integrity of the concrete. The soundness test helps in identifying unsound cement, which could be due to excessive amounts of free lime (CaO) or magnesia (MgO) that can cause delayed expansion. The soundness test of cement is a vital quality control measure to ensure that the cement will perform reliably without causing expansion-related problems in the concrete. By preventing the use of unsound cement, this test helps in maintaining the durability and safety of constructed structures.

Fig. 4 Mould of Le Chatelier Apparatus is Filled with Cement Paste

- Slump Test

The slump test is a simple and widely used test to measure the workability or consistency of freshly mixed concrete. It assesses the ease with which concrete flows, which is important for ensuring that the concrete can be properly placed and compacted in forms without excessive effort or segregation.

Fig. 5 Filling of Slump Cone in 3 Layers (Each layer has 25 Times Tamping with 16mm Bar)

F. Compaction Factor Test

The Compaction Factor Test is a laboratory test used to measure the workability of concrete, particularly for mixes with low to medium workability where the slump test might not provide sufficient information. This test is especially useful for concrete mixes that are too stiff for a slump test, as it gives a more accurate measure of workability for these types of concrete.

Fig. 6 wt. of partially and fully compacted concrete

III. RESULT AND DISCUSSION

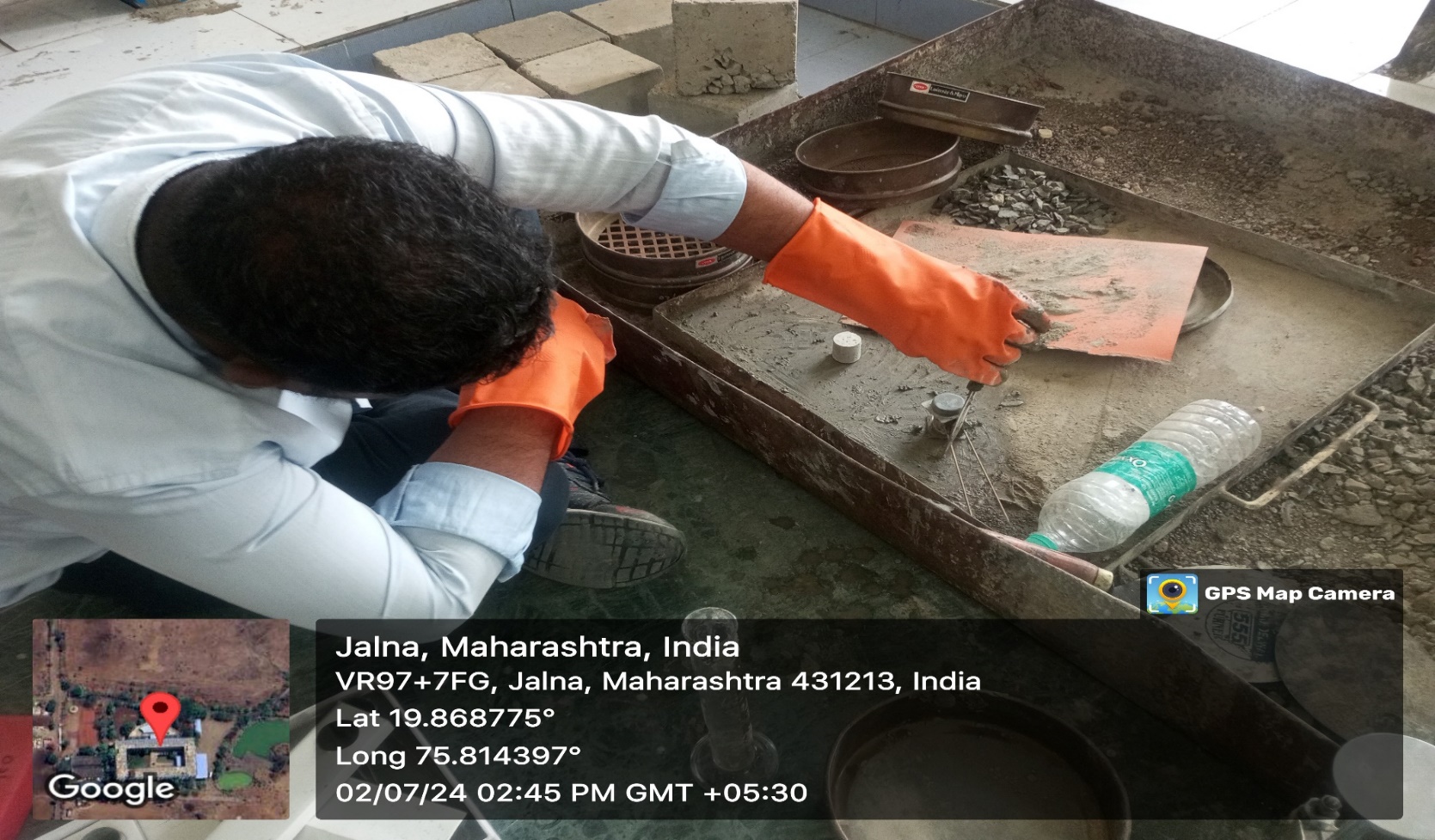

For experimentation Compressive Strength (N/mm2) obtained on CTM for GFRC cube of Size: 150x150x150 mm and the age of beam was kept 7 days, 14 days and 28 days. Figure 7 shows the casting of glass fiber reinforced concrete cube casting process. These cubes are prepared as per standards and then tested on CTM machine for compressive strength against the varying percentage of glass fiber reinforced concrete.

Fig. 7 Glass fiber reinforced Concrete Cube casting for experimentation

During experimentation compressive strength under the varying percentage of glass fiber was examined for 7 days, 14 days and 28 days as in table 1, table 2 and table 3 Glass fiber percentage was varied in the range of 0 ,5 and 10 % of concrete and for these samples force and compressive strength was studied.

TABLE I

COMPRESSIVE STRENGTH OF GFRC UNDER VARYING GLASS FIBER PERCENTAGE FOR AGE OF CUBE 7 DAYS

|

Sr No. |

Particulars |

0% Glass Fiber |

5% Glass Fiber |

10% Glass Fiber |

|

1 |

Load (KN) |

342.4 |

410.5 |

451.7 |

|

Compressive Strength (N/mm2) |

15.07 |

18.06 |

19.84 |

|

|

2 |

Load (KN) |

395.6 |

375.2 |

380.6 |

|

Compressive Strength(N/mm2) |

17.40 |

16.5 |

16.74 |

|

|

3 |

Load (KN) |

388.2 |

422.8 |

435.5 |

|

Compressive Strength(N/mm2) |

17.08 |

18.60 |

19.16 |

|

|

|

Average Compressive Strength |

16.51 |

17.72 |

18.58 |

TABLE III

COMPRESSIVE STRENGTH OF GFRC UNDER VARYING GLASS FIBER PERCENTAGE FOR AGE OF CUBE 14 DAYS

|

Sr No. |

Particulars |

0% Glass Fiber |

5% Glass Fiber |

10% Glass Fiber |

|

1 |

Load (KN) |

490.5 |

535.6 |

572.3 |

|

Compressive Strength (N/mm2) |

21.58 |

23.56 |

25.18 |

|

|

2 |

Load (KN) |

510.8 |

551.9 |

580 |

|

Compressive Strength(N/mm2) |

22.47 |

24.28 |

25.52 |

|

|

3 |

Load (KN) |

495.6 |

528.5 |

615.2 |

|

Compressive Strength(N/mm2) |

21.80 |

23.25 |

27.06 |

|

|

|

Average Compressive Strength |

21.95 |

23.69 |

25.92 |

TABLE IIIII

COMPRESSIVE STRENGTH OF GFRC UNDER VARYING GLASS FIBER PERCENTAGE FOR AGE OF CUBE 28 DAYS

|

Sr No. |

Particulars |

0% Glass Fiber |

5% Glass Fiber |

10% Glass Fiber |

|

1 |

Load (KN) |

650.5 |

730.6 |

855.8 |

|

Compressive Strength(N/mm2) |

28.62 |

32.144 |

37.65 |

|

|

2 |

Load (KN) |

668.7 |

729.5 |

783.6 |

|

Compressive Strength (N/mm2) |

29.228 |

32.098 |

34.47 |

|

|

3 |

Load (KN) |

598.8 |

724.5 |

839.5 |

|

Compressive Strength(N/mm2) |

26.34 |

31.87 |

36.93 |

|

|

|

Average Compressive Strength |

28.06 |

32.03 |

36.35 |

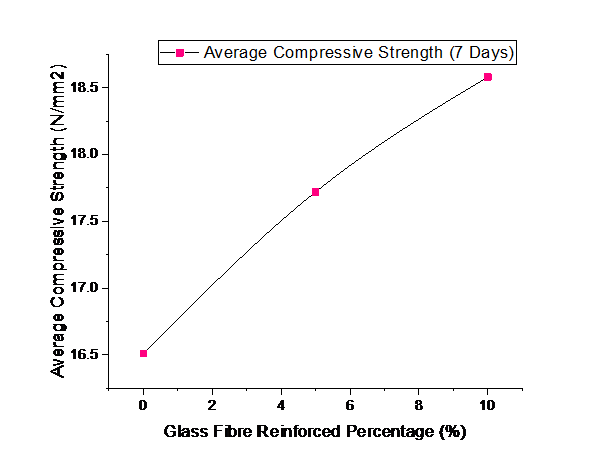

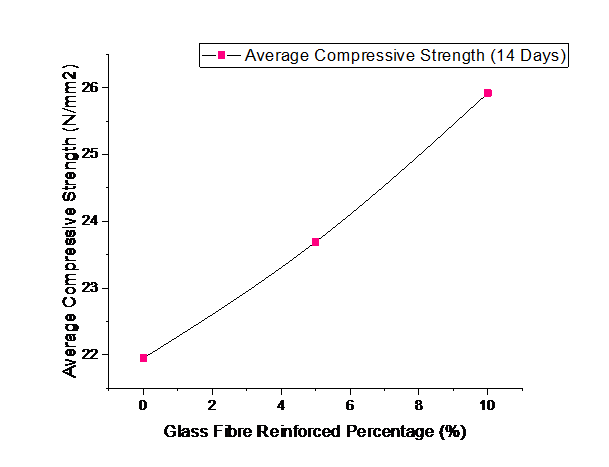

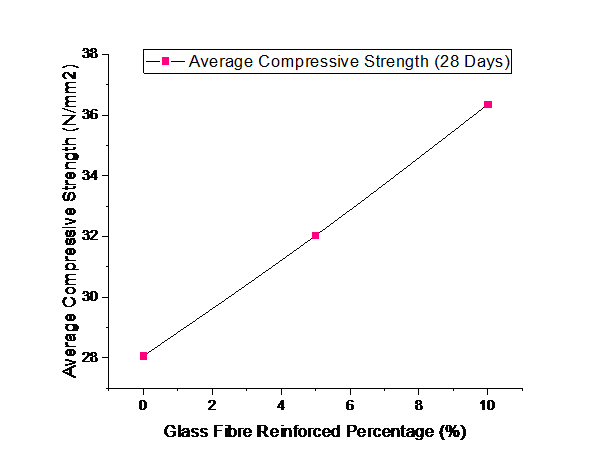

Individual graph related to Glass fiber reinforced Concrete percentage Vs Compressive Strength was plotted for 7 days, 14 days and 28 days. Figure 8, Figure 9, Figure 10 shows the graph of Glass fiber reinforced Concrete percentage Vs Compressive Strength for 0 %, 5 % and 10 % glass reinforced concrete; it shows increasing trend of Compressive Strength with respect to increase in Glass fiber reinforced Concrete percentage.

Fig. 8 Glass fiber reinforced Concrete percentage Vs Compressive Strength for 7 days

Fig. 9 Glass fiber reinforced Concrete percentage Vs Compressive Strength for 14 days

Fig. 10 Glass fiber reinforced Concrete percentage Vs Compressive Strength for 28 days

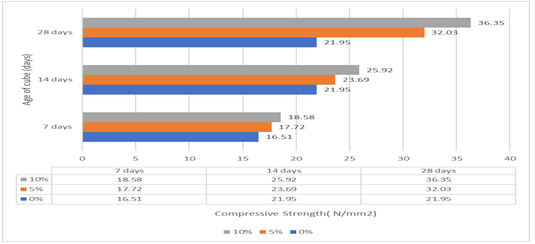

Figure 11 shows the graph for Glass fiber reinforced Concrete percentage Vs age of cube in days. Again, details are given for Compressive Strength for 0 %, 5 % and 10 % glass reinforced concrete with respective age of the cube. it shows increasing in compressive strength with increase in % glass fiber reinforcement. For 7 days age of cube and 10 % glass fiber reinforcement provided maximum compressive strength of 18.58 N/mm2. For 14 days age of cube and 10 % glass fiber reinforcement provided maximum compressive strength of 25.92 N/mm2. For 28 days age of cube and 10 % glass fiber reinforcement provided maximum compressive strength of 36.35 N/mm2.

Fig. 11 Glass fiber reinforced Concrete percentage Vs age if cube in days with varying glass fiber reinforcement percentage

Conclusion

Experiments were carried out to Compressive Strength (N/mm2) obtained on CTM for GFRC cube of Size: 150x150x550 mm and the age of beam was kept 7 days, 14 days and 28 days. The cubes are prepared as per standards and then tested on CTM for compressive strength against the varying percentage of glass fiber reinforced concrete. Following conclusions are drawn based on the observation and experimental data: Graph for Glass fiber reinforced Concrete percentage Vs age of cube in days. it shows increasing in compressive strength with increase in % glass fiber reinforcement. For 7 days age of cube and 10 % glass fiber reinforcement provided maximum compressive strength of 18.58 N/mm2. For 14 days age of cube and 10 % glass fiber reinforcement provided maximum compressive strength of 25.92 N/mm2. For 28 days age of cube and 10 % glass fiber reinforcement provided maximum compressive strength of 36.35 N/mm2. From the experiments it is clear that maximum compressive strength can be achieved for glass fiber reinforcement of 10 % when age id cube is kept 28 days.

References

[1] K K Annamaneni , K Pedarla “Compressive and flexural behavior of glass fiber-reinforced concrete” Journal of Physics: Conference Series 2423 (2023) 01 20-25. [2] P Löber, B Heiden and K Holschemacher “Creep behaviour of macro glass fibre reinforced concrete beams” IOP Conf. Series: Materials Science and Engineering 246 (2017) 01 20-28. [3] Sathish Kumar. V, Blessen Skariah Thomas, Alex Christopher “An Experimental Study on the Properties of Glass Fibre Reinforced Geopolymer Concrete” International Journal of Engineering Research and Applications (IJERA) Vol. 2, Issue 6, November- December 2012, pp.722-726. [4] Abdelrahman Abushanab, Usama Ebead, Magdy Genedy, Girgis Jacoup Ghattas “Behavior of reinforced concrete columns made with seawater and glass FRP bars and subjected to high temperatures” Results in Engineering 22 (2024) 102339. [5] Geetinder Kaur, Dr. Bal krishan “Strength properties of glass fibre reinforced concrete: a review” International Journal for Research Trends and Innovation 2017 IJRTI | Volume 2, Issue 8. [6] Md.Abid Alam, Imran Ahmad, Fazlur Rehman “Experimental Study on Properties of Glass Fibre Reinforced Concrete” International Journal of Engineering Trends and Technology (IJETT) – Volume 24 Number 6- June 2015. [7] Sunil Thapa , Zhongkuang Huang , Milad Bazli, Ali Rajabipour, Zhiqiang Dong , Reza Hassanli , Mehrdad Arashpour “Optimising compressive strength properties of seawater sea sand concrete-filled hybrid carbon-glass fibre-reinforced tubes: A study on the impact of layer sequencing” Construction and Building Materials 438 (2024) 137155. [8] S. Srinivasan, A. Karthik , DR. S. Nagan “An Investigation on Flexural Behaviour of Glass Fibre Reinforced Geopolymer Concrete Beams” International Journal of Engineering Sciences & Research Technology [1963-1968]. [9] M. Anil Kumar, V. Giridhar Kumar “Flexural Behaviour of Reinforced Geopolymer CONCRETE Beams with Glass Fibres” International Journal for Research in Applied Science & Engineering Technology (IJRASET) ISSN: 2321-9653. [10] Younes Nouri, Mohammad Ali Ghanbari, Pouyan Fakharian ” An integrated optimization and ANOVA approach for reinforcing concrete beams with glass fiber polymer” Decision Analytics Journal 11 (2024) 100479.

Copyright

Copyright © 2024 A. S. Biradar, Dr. D. H. Tupe, Dr. G. R. Gandhe. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64041

Publish Date : 2024-08-22

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online