Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Study of Mechanical Properties of Concrete using Recycled Aggregates

Authors: Mahima Modi, Dr. Madan Chandra Maurya

DOI Link: https://doi.org/10.22214/ijraset.2024.58422

Certificate: View Certificate

Abstract

The last few decades have seen a rapid increase in urbanisation, which has increased demand for building materials, particularly aggregates. The aggregate mining has put a burden on the environment and raised concerns about swift ecological harm. Lack of building aggregates is a severe issue that requires the use of alternative recycled aggregates in its stead. Old, abandoned building debris is used to create recycled aggregates (RA), which are then hauled to a landfill and disposed of there. In addition to pushing waste sites farther away, the decades-long urbanisation of the region has also increased the expense of moving these aggregates. Utilising them in place of natural aggregates in concrete mixtures is the solution. Here in this study some proportion of natural coarse aggregate is being replaced by the recycled aggregate and analysis of its effect on various mechanical properties of concrete is being done. The mechanical properties of concrete constitute Compressive Strength, Flexural Strength, Shrinkage, Creep and Modulus of Elasticity.

Introduction

I. INTRODUCTION

India has an extremely high rate of urbanisation growth as a result of industrialization. Quick infrastructure development necessitates a lot of building supplies, as well as the necessary land. Concrete is recommended for major construction projects due to its superior performance, longer lifespan, and lower maintenance costs. New buildings are built and smaller structures are dismantled in order to achieve the new infrastructure for economic growth. One fundamental element that is closely related to the survival of the human race is environmental protection. Modern construction criteria heavily effect factors like sustainable development, preservation of natural resources, and environmental consciousness. Modernization has resulted in the disposal of dismantled materials on land for no apparent use. This study deals with the experimental analysis of possibility of reusing of these aggregates in construction.

A. Scope of Problem

Aggregates comprise 70–75% of the materials needed to produce concrete. Of this, 33–40% is fine aggregate and 60–67% is coarse aggregate. If the current rate of use continues, all of the coarse aggregates are predicted to run out by 2050.Therefore, we need to consider various alternatives.

The idea behind this project is to use recycled aggregates in place of some natural coarse materials. Aggregates made from processing previously used building supplies, including masonry or concrete, are known as recycled aggregates. Hard graded pieces of inert mineral materials, such as sand, gravel, crushed stone, slag, rock dust, or powder, make up recycled aggregates. They are beneficial for environmental concerns and the materials of the future.

B. Scope for Solution

These recycled wastes come from concrete buildings that are either reinforced or unreinforced. Before using the old, destroyed concrete, it is crucial to remove any contaminants including plastics, metals, organic materials, and other contaminants. Following demolition, the concrete is run through a grading machine that divides the material into different sizes. Using demolished concrete reduces the cost of transportation since it is less expensive to transport to landfills than new concrete. The purpose of this research is to evaluate the feasibility of replacing coarse aggregates in structural concrete with recycled concrete aggregates in different ratios. Thereafter the mechanical properties of the concrete produced from these aggregates are tested for its suitability in construction. The mechanical properties of concrete constitute Compressive Strength, Flexural Strength, Shrinkage, Creep and Modulus of Elasticity.

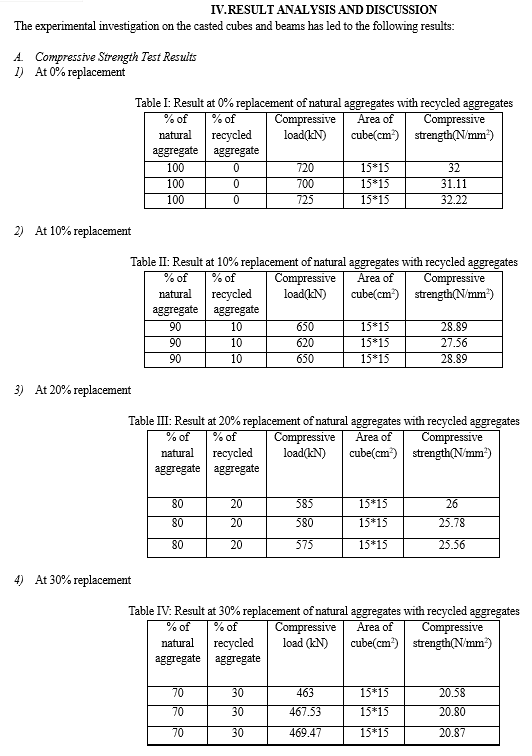

- Compressive Strength: The concrete's compressive strength is expressed in terms of the characteristic compressive strength of 150mm cubes that were tested after 28 days. Compressive strength is the most important property of concrete and gives a clear indication of the response of the hardened concrete when a compressive load is applied.

- Flexural Strength Test: Flexural strength of concrete is measure of tensile strength of concrete and is done by loading 150*150*700 mm concrete beam. Flexural strength, which is the amount of stress in the material just prior to its yielding in a flexure test. Other names for it include transverse rupture strength, bend strength, and modulus of rupture. The most popular test is the transverse bending test, which bends a specimen with a circular or rectangular cross-section until it fractures or gives using a three-point flexural test procedure. Flexural strength is a measure of the maximum stress a material can withstand before yielding.

- Shrinkage: Shrinkage is shortening of concrete due to drying and it does not depend on applied loads. It is determined by measuring the strain over time in an unloaded, unrestrained specimen at room temperature. Drying shrinkage is the reduction in volume of hardened concrete due to loss of moisture by evaporation. The factors that effect creep also effects shrinkage.

- Creep: Creep is time dependent deformation of concrete under constant loads (self-weight) and permanent displacement. Concrete instantly deforms when it experiences compressive force. We refer to this instantaneous deformation as instantaneous strain. Currently, the concrete experiences more deformations without an increase in load when the load is sustained for an extended period of time. We call this strain that varies with time "creep."

- Modulus of Elasticity: Modulus of Elasticity is the ratio of normal stress and normal strain. It is given by-

II. LITERATURE REVIEW

The utilization of waste materials in the construction industry has been gaining attention in recent years. Several studies have been conducted to investigate the potential of using various waste materials as partial replacements in the production of construction materials.

Katz [6] examined the characteristics of recycled aggregate used to make new concrete using partially hydrated old concrete and the attributes that resulted from using these recycled aggregates. The findings showed that, at the same water to cement ratio, concretes composed entirely of recycled aggregates performed worse than concretes constructed of natural aggregates. Regardless of the old concrete's crushing age, there was a 25% strength drop when the new concrete was created using the same kind of OPC and w/c as the old concrete. Similar patterns were seen in other characteristics like absorption, drying shrinkage, flexural and splitting strengths, and depth of carbonation.

Topcu and Sengel [8] examined the mechanical, physical, and freeze-thaw endurance of recycled aggregate concrete made from leftover concrete aggregate. In the course of testing with both fresh and hardened concrete, combinations including 30%, 50%, 70%, and 100% of recycled concrete aggregates were prepared. The findings demonstrated that RAs had a lower specific gravity than natural aggregates. Additionally, it was shown that recycled aggregates had a substantially greater water absorption ratio. Both the control concrete and the concrete with RA saw a drop in compressive strength parallel to the w/c ratio. The key finding of the paper was that when recycled aggregate content in the mix surpasses 30%, conventional concrete's capacity to retain the same slump without the need for admixtures is greatly reduced. This reduces the strength of concrete resulting in lower concrete strength.

Paul [13] also investigated the mechanical behaviour and durability performance of concrete with varying proportions of RA. At various ages, concrete samples with recycled aggregate replacement percentages of 0%,30%, and 100% to partially replace natural aggregate (NA) were examined. To examine the mechanical characteristics of RA, concrete with cube strength classes of 30 to 40 MPa was created. Additionally, the durability, shrinkage, and creep qualities of concrete with 0% and 30% RA replacement of NA were investigated. It was discovered that, when compared to concrete that contains 100% NA, RA substitution by 30% (RA30%) of NA did not significantly alter the concrete's strength or stiffness. Although there is a slight decrease in strength and stiffness after RA100% replacement, this is not very noticeable and can be made up for in conventional methods. Tests of the durability index showed that concrete with reasonable quality (RA30%) performed similarly to concrete with NA100% in terms of durability. However, RA30% showed increased creep, which structural designers must take into account.

Bhat [15] observed that the flexural strength, splitting tensile strength, and compressive strength of the normal-, medium-, and high-strength concrete were not significantly impacted by the parent concrete's grade on providing RA. All of these mentioned characteristics fell short of those of the initial concrete that included solely NA. When RA was created using high-strength parent concrete, its mechanical characteristics outperformed those of RA built with normal and medium strength parent concrete. The investigation's findings show that recycled aggregate concrete with a lower grade strength should ideally be produced using high-strength parent concrete.

The literature shows that recycled concrete waste can be effectively used to replace conventional aggregates in various proportions. As noted, different sources of waste aggregates produce different results; The purpose of this research is to find out the optimal replacement percentage of old recycled concrete in the production of new construction concrete.

III. PROPOSED METHODOLY AND EXPERIMENTATION

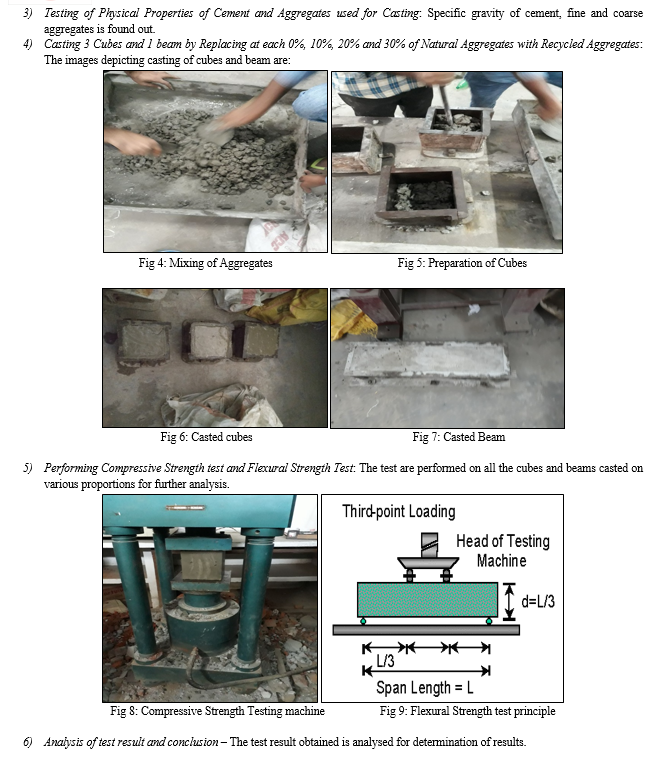

The methodology for this study involves preparation of M25 cubes and a beam for testing compressive strength and flexural strength of concrete. The casting is done by replacing some proportion of natural aggregate by the recycled aggregates in concrete. Here in this study, 0%, 10%, 20% and 30% of natural aggregates are being replaced by recycled aggregates and at each proportion 3 cubes and 1 beam was casted. The preparation of sample is done in following steps:

1) Procurement of used Aggregates from a Demolished Building: The recycled aggregates used here in this study is taken from demolished building of Raj theatre which was situated near Vijay Chowk in Gorakhpur, Uttar Pradesh. This was a 50 year old cineplex in Gorakhpur city. The below images shows the demolished site.

Conclusion

Conclusion - From the analysis of result it is found that on 22% replacement of natural coarse aggregate with recycled aggregate, the concrete cubes gives the desired compressive strength and thus the same % of coarse aggregate can be replaced with recycled aggregates. It was also found that on 24% replacement of natural coarse aggregate with recycled aggregate, the concrete beam of M25 gives the desired flexural strength and thus the same % of coarse aggregate can be replaced with recycled aggregates. Thus, it can be concluded that the average value i.e. 23% of natural coarse aggregate can be replaced with recycled aggregate for the desired strength of the construction. Future Scope - It is definite that recycled aggregates are the ‘Materials of Future’ and should be adopted on large scale in construction. The future scope of this study involved testing the cubes and beams of other grades of concrete at different proportions of replacement of recycled aggregates with natural aggregates. Cost estimate of a building made with recycled aggregates can be done and compared with cost estimate of a building made with only natural aggregates. Moreover, microscopic study of chemical reactions occurring on combining recycled aggregates with cement can also be done.

References

[1] Hansen, T.C. (1990): Recycling of Demolished Concrete and Masonry, Rilem Report No. 6, CRC Press. [2] Topcu, I.B.; Guncan, F. (1995): Using waste concrete as aggregate. Cement and Concrete Research, 25(7), pp-1385-1390. [3] Topcu, I.B. (1997): Physical and mechanical properties of concrete produced with waste concrete, Cement and Concrete Research, 27(12), pp. 1817-1823. [4] Grubl, P.; Nealen, A.; Schmidt, N. (1998): Concrete made from recycled aggregate: Experiences from the building project Waldspirale, Vilbelerbeg Project, Berlin, Germany. [5] Bodin, F.; Buyle, K.: Zaharieva, R.H.(2002): Influence of industrially produced recycled aggregates on flow properties of concrete, Materials and Structures, 35, pp. 504-509. [6] Katz, A. (2003): Properties of concrete made with recycled aggregate from partially hydrated old concrete, Cement and Concrete Research, 33 (5), pp. 703-711. [7] Yong-Huang, L.; Yaw-Yauan, T.; Ta-Peng, C.; Chang-Chin-Yung (2003): An assessment of optimal mixture for concrete made with recycled concrete aggregates, Cement and Concrete Research, 34, pp. 1373-1380. [8] Topcu, I.B.; Sengel S.; (2004): Properties of concretes produced with waste recycled aggregates, Cement and Concrete Research, 34, pp. 1307-1312. [9] Xiao, J., Li J., Zhang Ch.(2004).”Mechanical properties of recycled aggregate concrete under uniaxial loading”, Elsevier, Cement and concrete research 35(2005) 1187-1194. [10] Khaldoun, R.; (2007): Mechanical properties of concrete with recycled coarse aggregate, Building and Environment, 42, pp. 407-415. [11] Tsung-Yuhe, T.; Yuen-Yuen, C.; Chau-Lung, H. (2006), Properties of HPC with recycled aggregates, Cement and Concrete Research, 36 (5), pp. 943-940. 13. Etxeberria, M.; Vazquez, E.; Mari, A.; Barra, M. (2007), Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete, Cement and Concrete Research, 37 (5), 735-742. [12] S R Yadav, S R Pathak, Use of recycled aggregate concrete in making concrete – An overview 34th Conference on our world in concrete & structures: 16 – 18 August 2009, Singapore [13] Paul, S.; Gideon P.A.G van Zijl; (2013): Mechanical behavior and durability performance of concrete containing RCA, International Journal of Sustainable Construction Engineering and Technology, 4(1), pp. 89-103. [14] IS 383-1970 2002 Specification for Coarse and Fine Aggregates from Natural Sources for Concrete Bureau of Indian Standards (BIS) New Delhi [15] Bhat, J.A., 2021. Effect of strength of parent concrete on the mechanical properties of recycled aggregate concrete. Materials Today: Proceedings, 42, pp.1462-1469.

Copyright

Copyright © 2024 Mahima Modi, Dr. Madan Chandra Maurya. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET58422

Publish Date : 2024-02-13

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online