Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Experimental Investigation into Super Finishing of Nickel Alloy A-286 Hole Surface Using Extrusion Honing Process

Authors: Sreenivasa Murthy B P, Prasad P, Thimmegowda M B

DOI Link: https://doi.org/10.22214/ijraset.2024.66110

Certificate: View Certificate

Abstract

Extrusion Honing (EH) is also known as Abrasive flow machining (AFM) is a fine finishing process mainly applicable for difficult to reach internal surfaces and components with intricate geometries finished through the action of extrusion, where abrading action of the polymer media laden with abrasive particles machines the component surface. The EH processes is an advanced finishing techniques widely used as finishing machining process a solution to produce parts with high surface properties that mainly used in high-end industries like aerospace, automobile, medical, tool and die, and prosthetic. EH processes is mainly used for finishing operations namely polishing, de-burring, removal of cast layers, radiusing and finishing of intricate shapes by flowing abrasive laden viscoelastic media over the surfaces to be finished. Although EH have a wide range of applications and could be used in every shop floor as a finishing solution, their usage is limited owing to high initial and running costs associated with them. In this work, the experiment is conducted using a one way extrusion honing machine and the process is carried out on Nickel Alloy A-286 specimens, a super alloy having high hardness and high strength properties which is machined to get good surface finishing. In this paper a thorough research is done on how the EH parameters impacts on surface parameters of Nickel Alloy A-286. The results obtained are measured and extruded surface is analysed with the help of surface roughness measuring instrument.

Introduction

I. INTRODUCTION

The Extrusion Honing (EH) or Abrasive Flow Machining (AFM) is one of the non-conventional finishing processes build to enhance the surface characteristics of hard to cut materials carrying difficult to reach geometries / shapes. This process consists of machine, tooling and media. The process works by utilising the visco-elastic property of Silicone polymer and abrading characteristics of abrasive particles coupled together that act as a working media and this media is made to pass through the extrusion passage of the workpiece under high pressure making the media to act as a tool. The process can be equated to grinding machining operation. As media passes through the confined space of workpiece, it exerts force onto the workpiece surface and abrades it. Thus, the media behaves like grinding tool with abrasives in it working as cutting edges. However, the tool in EH remains a flexible one. Through EH/AFM, polishing, de-burring, removing recast layers and to remove stress raisers on the surface.

AFM produces an accurate, repeatable and reliable surfaces with a yielding of 90% enhancement in surface finish with reduced burden on overhead costs involving finishing operation [1]. Material removed and surface finish achieved under AFM process is greatly influenced by media viscosity and within first few cycles of the process most part of the surface finish is achieved. Through their study they found that with the number of strokes surpassing the critical threshold level, stock of dynamic active grains plummets in the media indicating more abrasives has entered into the media due to breakage of large grains [2]. Loveless studied the effects of AFM on surfaces produced by various machining operations namely; turning, milling, grinding and WEDM. All signs of turning and milling found to be removed successfully from the surface, leaving behind only fewer deeper cracks; indicating the superficial nature of machining. Initial irregular and uneven flow lines becomes straight indicating media flow path thereby enhancing surface characteristics [3]. Extrusion pressure and media concentration affects the surface parameters and MMR. With increased extrusion pressure and concentration, increases the active grain density and radial force, as a results the percentage reduction of Ra increases with high material removal [4]. From the experiment they observed that, the hardness of material and its initial surface roughness found to control the material removal rate and surface finish achieved, with softer material yielding better results than harder one.

Higher the mesh number of abrasives used, lesser the material removal rate with decrease in ΔRa values [5]. The surface parameters found to improve greatly in early phases of honing process this is due to removal of dominant surface asperities, followed by progressive improvement owing to crest flattening with deterioration of surfaces in later stages. The out of roundness appears to decrease with AFM process. They also concluded that surface finish due to extrusion honing is better along exit side of the specimen than the entry side. [6-8]. Their experimental studies have shown to remove the tool marks and replaces uneven surface lay marks on the surface with a uniform lay one along with improved in overall surface parameters [9-10].

In the present study, extrusion honing operations were conducted on Nickel Alloy-286 at laboratory using an indigenously designed and fabricated EH set up. A selected grade polymeric material as carrier with silicon carbide (SiC) as abrasives particles owing to its high hardness have been used in developing media for conducting honing operations. The extruded honed surface of Nickel Alloy-286 have been studied in terms of surface finish parameters and the results show positive response.

II. EXPERIMENTATION

The fabrication of hole, preparing working media and precision finishing of hole using a one-way extrusion honing system constitutes the present experimental study. The surface roughness parameters of specimens were evaluated after each trials and SEM images were used to analyse the effect of honing on surface texture.

A. Workpiece Material

Super alloy A286 is an iron-based high temperature and high strength alloy and corrosion resistance up to 1300°F (704°C). The following datasheet provides an overview of super alloy A286.

Applications of Nickel Alloy A - 286

- In offshore oil and gas components.

- Jet engines and after burner parts and fasteners.

- Used in Springs and flanges equipments.

- Exhaust parts, turbines and Nozzles in the oil industry.

- Moderate corrosion applications in aqueous solutions.

- Non - magnetic cryogenic equipment.

B. Experimental Setup

This experimental set up is a one way type Extrusion Honing process, i.e. the media flows only in one direction. It consists of an abrasives media cylinder connected to a hydraulic cylinder and to control the actuation, suitable directional control valve has been utilized. Abrasive media cylinder is a piston - cylinder arrangement with an end cap and the whole assembly acts as a tooling that helps to confine and directs the media flow through the desired path of specimens. During experimentation, the end cap of the cylinder arrangement is removed to fill the abrasives media into the cylinder and later the end cap is replaced. This end cap also has the fixture arrangement to hold the specimen during the experimentation. Abrasives media enters the specimen from the one side and extrude out at another side. The extruded abrasives media is collected in the collector.

Fig 1: One - Way type extrusion honing Machine.

C. Experimental Procedure

- Preparation of test specimens.

- Preparation of the abrasive media.

- Performing the extrusion honing trails.

- Measuring surface parameters at different locations of the specimen using surface roughness measuring instrument (Surfcom 130A). ex Ra, Rz, Rt and Rpk.

- Tabulation of results.

D. Chemical Composition

The chemical composition of Nickel alloy 286 or INCOLOY alloy 286 is given in the following table.

Table 2.1: Chemical Composition

|

Element |

Content (%) |

|

Nickel, Ni |

24.0-27.0 |

|

Iron, Fe |

54 (Balance) |

|

Chromium, Cr |

14.8 (13.5-16.0) |

|

Titanium, Ti |

2.13 (1.90-2.35) |

|

Molybdenum, Mo |

1.30 (1.0-1.5) |

|

Manganese, Mn |

1.0 (2.0max) |

|

Silicon, Si |

0.50 (1.0max) |

|

Vanadium, V |

0.30 (.10-.050) |

|

Aluminum, Al |

0.18 (0.35max) |

|

Carbon, C |

0.040 (0.08max) |

|

Phosphorous, P |

0.020 |

|

Sulphur, S |

0.015(0.030max) |

|

Boron, B |

0.0060(0.001-.01) |

E. Physical and Mechanical Properties

Table 2.2: Physical properties

|

Properties |

Metric |

|

Density |

7.94 gm /cm3 |

|

Melting point Range |

1370-1430oC |

|

Specific Gravity |

7.94 |

|

Specific Heat |

419 j/kg0C |

|

Young’s Modulus |

201Gpa |

Table 2.3: Mechanical properties

|

Properties |

Metric |

|

Tensile strength |

1035 MPa |

|

Yield strength (@strain 0.200%) |

759 MPa |

|

Elongation at break |

25% |

|

Reduction of area |

40% |

|

Hardness, Brinell (estimated from Rockwell C value for Brinell test with 3000 kg load/10 mm dia ball) |

304 |

|

Hardness, Knoop (estimated from Rockwell C value) |

330 |

|

Hardness, Rockwell C value |

36 |

|

Hardness, Vickers (estimated from Rockwell C value) |

318 |

F. Media Preparation

The most important aspect in Extrusion Honing is the preparation of working media. In this study, the working media is developed by using a select grade polymer carrier and silicon carbide (SiC) abrasive particles of 36 grit size. Abrasives with volume fraction (50%) of base polymer, were mixed thoroughly using an in-house fabricated silicone media mixer.

G. Specimen Preparation

Test specimens of Nickel Alloy-286 possessing Ø 25 mm and length 12 mm were prepared from its stock. These specimens were initially drilled for holes of diameters 6 mm, 8 mm and 10 mm using a carbide drill bit. Before conducting trials, initial surface roughness parameters of specimens were measured using Surfcom 130 roughness measuring instrument.

H. Experimental Trials

For the present study, a laboratory fabricated extrusion Honing system was used. The system is a one-way Extrusion Honing machine where the media is extruded in one direction. The system consists of a media chamber attached to a hydraulic cylinder and direction control valve. The media chamber is a piston cylinder configuration, where piston movement is actuated hydraulically. An end cap is used to close the open end of media chamber and it also acts as tolling helping in channelizing the media to the extrusion region. Provision is made on the end cap surface to hold the fixture carrying test specimens rigidly. As piston performs forward stroke, the flexible media enters the specimen from one side, hones the surface that comes in contact to it and leaves the specimen on the other side. This extruded media is collected using a collector. Each individual specimen was honed for 10 passes under constant experimentation conditions. Table 2.4 illustrates the machining parameters of present EH process. The surface roughness parameters were evaluated for each pass after cleaning the specimen surface with acetone and evaluations were done at three distinct locations on both entry and exit sides of the specimen.

Table 2.4: Extrusion Honing Process Parameters

|

Parameters |

Details |

|

Number of passes |

10 |

|

Hole diameter (mm) |

6, 8 and 10 |

|

Abrasive mesh size |

36 |

|

Volume fraction of Abrasive (in %) |

50 |

|

Pressure(bar) |

60 |

|

Temperature |

Ambient |

|

Stroke length |

600 mm |

III. RESULTS AND DISCUSSION

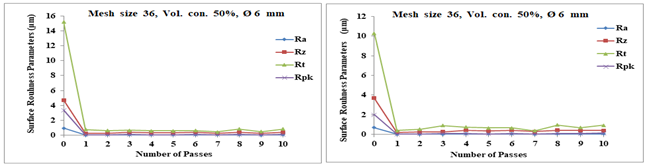

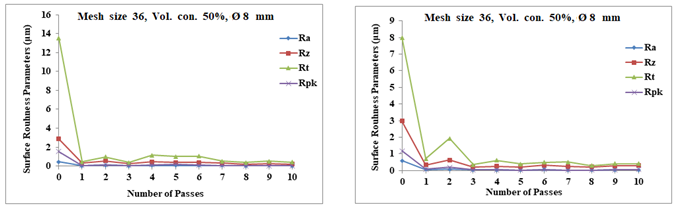

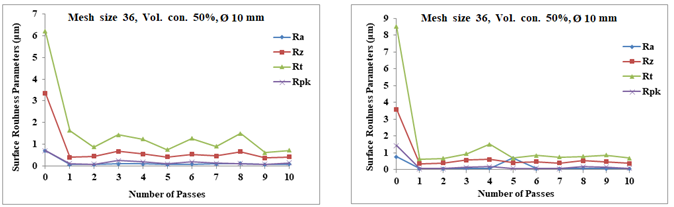

The main purpose of this work is to eliminate surface unevenness by applying extrusion honing process and to achieve a fine surface finish on Nickel Alloy-286. After each finishing process, the honed surface of specimens was evaluated in terms of its surface finish parameters (Ra, Rt, Rz and Rpk). Graphs were plotted for the parameters obtained after each experimental for hole diameter of 6 mm, 8 mm and 10 mm specimens.

A. Observation on surface roughness

- (b)

Fig 3.1: Surface roughness parameters v/s number of passes for Ø 6 mm; (a) Entry side (b) Exit side

(a) (b)

Fig 3.2: Surface roughness parameters v/s number of passes for Ø 8 mm; (a) Entry side (b) Exit side

(a) (b)

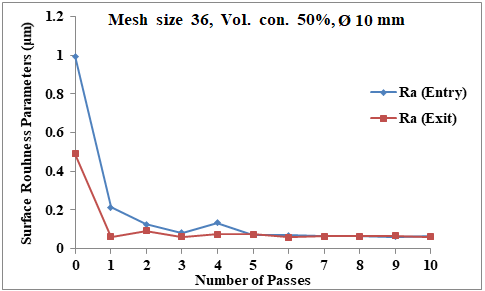

Fig 3.3: Surface roughness parameters v/s number of passes for Ø 10 mm; (a) Entry side (b) Exit side

Fig 3.1, 3.2 and 3.3 shows the working of honing on the surface roughness parameters on both entry and exit sides respectively. From the figures, it is observed that, there exhibits a drastic reduction in surface roughness parameters after 1st pass followed by a progressive reduction afterwards and attains core roughness between 3th to 6th pass, in later passes, surface deterioration sets in.

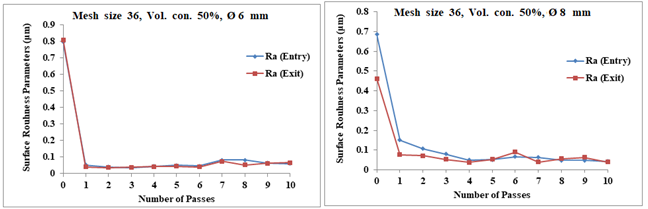

(a) (b)

(c)

Fig 3.4: Surface roughness (Ra) at Entry and Exit side v/s number of passes; (a) Ø 6 mm, (b) Ø 8 mm and (c) Ø 10 mm

Fig 3.4 compares the surface roughness (Ra) achieved on both entry and exit side of the specimens. It can be seen that, Ra along exit side of the media is better than the entry side.

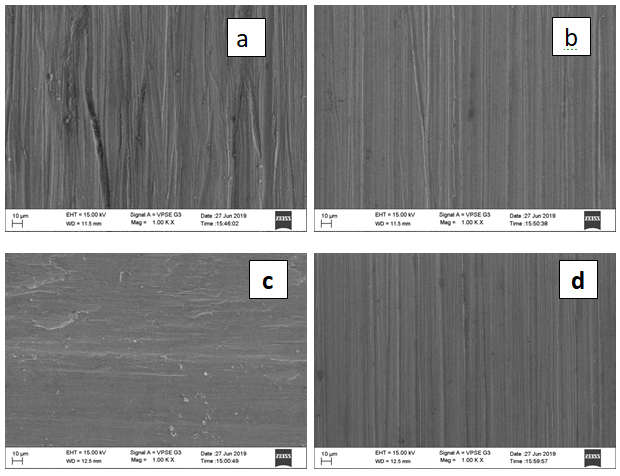

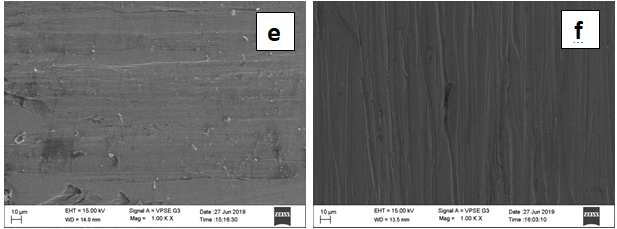

B. Scanning Electron Macrograph (SEM) Images Observation

Fig 3.5: SEM images for 1000 magnification; (a) Ø 6 mm, Zero pass (b) Ø 6 mm, Ten Passes (c) Ø 8 mm, Zero pass (d) Ø 8 mm, Ten Passes (e) Ø 10 mm, Zero pass (f) Ø 10 mm, Ten Passes

From the above SEM images (fig: 3.5), it can be seen that the uneven initial tool feed marks and macro surface irregularities of drilling operation have been effectively removed and replaced with a fine surface having a uniform lay.

Conclusion

In the present experimentation, Extrusion Honing was carried on Nickel Alloy-286 using a select grade silicone polymer and silicon carbide (SiC) abrasive particles. The extrusion Honed surface of Nickel Alloy-286 were measured at three distinct positions on both entry and exit side of the abrasive media flow. From the present experimentation results, following conclusion could be drawn, 1) The experimental conditions with select grade silicone polymer and SiC abrasives is capable of producing a good surface finish on Nickel Alloy-286. 2) Surface finish increases substantially after first pass followed by a progressive improvement and once the surface attains core roughness, surface starts to deteriorate. 3) Surface finish of specimen at media exit side is better than the media entry side. 4) The uneven lay pattern of drilling got replaced with a uniform lay as verified in SEM images.

References

[1] L.J. Rhoades, Abrasive flow machining: a case study, Journal of Material Processing Technology 28 (1991) 107–116. [2] R.E. Williams, K.P. Rajurkar, Stochastic modelling and analysis of abrasive flow machining, Transactions of the ASME, Journal of Engineering for Industry 114 (1992) 74–81. [3] T.R. Loveless, R.E. Willams, K.P. Rajurkar, A study of the effects of abrasive flow finishing on various machined surfaces, Journal of Material Processing Technology 47 (1994) 133–151. [4] V.K. Gorana, V.K. Jain, G.K. Lal, On the effect of cutting forces and active grain density on surface roughness in abrasive flow machining, Int. J. Mach. Tool Manuf. 44 (2004) 201–211. [5] Jain V.K., Adsul S.G., Experimental investigations into abrasive flow machining, International Journal of Machine tool and Manufacturer, 40 (2002), pp.1003-1021. [6] Raju H P, Narayanasamy K, Srinivasa Y G and Krishnamurthy R “Characteristics of extrude honed SG iron internal primitives” Journal of Materials Processing Technology 166 (2005), pp 455–464. [7] Devadath, V R, Raju H P, A study of the effect of extrusion honing on Hastealloy c 22 using abrasives of different mesh sizes, international journal of current research in life sciences, Vol, 07, No 02, pp.1029-1035, February,2018. [8] N.L. Murali Krishna and H. P. Raju, Extrusion Honed Surface Characteristics of Inconel 625 Fabricated by EDM for Square Shape, Int. Journal of Engineering Research and Applications, June 2014, pp.68-72. [9] Raju H P, Sreenivasa Murthy B P “Investigation into the Super Finishing of Hole Surface of Titanium Grade-2 using One-Way Extrusion Honing Process” IJRASET, Volume 7, Issue VII, July 2019. [10] Raju H P, Sachin N “Experimental Studies on Surface Roughness of Nickel Alloy-286 by Extrusion Honing Process” IJRASET, Volume 7, Issue VII, July 2019.

Copyright

Copyright © 2024 Sreenivasa Murthy B P, Prasad P, Thimmegowda M B. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET66110

Publish Date : 2024-12-25

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online