Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Challenges and Opportunities in Supply Chain Management for Public Building Projects

Authors: Mukesh Kumar, Niharika Patel

DOI Link: https://doi.org/10.22214/ijraset.2025.66844

Certificate: View Certificate

Abstract

Inefficient management in construction projects can have severe consequences, including low productivity, cost and schedule overruns, conflicts, disputes, and prolonged legal proceedings. Previous research suggests that optimizing construction logistics can enhance productivity, while effective supply chain management can reduce costs, minimize delivery times, lower inventory levels, and improve reliability—ultimately strengthening an organization\'s competitive position. This study evaluates the perceptions of construction industry stakeholders regarding the necessity and significance of supply chain management in selected public building construction projects. It also investigates current practices and challenges within the supply chain management process. The research focuses on active public projects overseen by the Ministry of Urban Development and Housing. Data collection methods include questionnaires and desk research to assess past efforts and identify key challenges in supply chain management. The study employs frequency analysis and the Relative Importance Index (RII) to analyze questionnaire responses, with findings presented through charts and tables. The results indicate that industry stakeholders recognize the benefits of supply chain collaboration in enhancing quality assurance and profitability. Critical success factors for effective collaboration include improved customer service, increased profitability, and enhanced quality assurance. However, challenges such as delayed or incorrect payments, inaccurate data, and unsuitable engineering drawings hinder effective supply chain management. Additionally, the findings reveal that most stakeholders do not implement an integrated supply chain management approach.

Introduction

I. INTRODUCTION

Numerous researchers argue that the construction industry continues to face performance challenges, despite some indications of improvement (Egan, 1998; Cox et al., 2002; Vrijhoef et al., 2000; Love et al., 2004). To enhance quality, time, and cost efficiency, construction firms must adopt new tools and technologies to optimize their supply chains. Consequently, the importance of supply chain management remains significant.

As construction processes become increasingly complex, various management systems and methodologies have been developed through academic research and successfully implemented in industry practices. Among these, supply chain management has gained widespread attention, particularly in the context of broader collaboration, vertical disintegration, and the concept of a networked supply chain within the construction industry (Vrijhoef et al., 1999).

Efforts to optimize material consumption, streamline project structures, and organize deliveries efficiently can significantly improve project performance (Czarnigowska et al., 2005). With contractors sourcing materials globally, the supply process begins with design and engineering at manufacturing facilities and extends through multiple stages of transportation to the construction site. Effective planning of this extensive supply chain requires a thorough evaluation of time and cost at each stage (Wegelius-Lehtonen et al., 1996). One of the primary causes of delays in major industrial construction projects is the late delivery of materials and components. Ensuring the timely arrival of construction materials is therefore crucial for meeting project completion deadlines (Fallahnejad, 2013).

In Ethiopia, public construction projects are a key component of the country’s development strategy, consuming a substantial portion of its limited financial resources. The construction sector receives the largest share of the government’s budget as part of its national development program. Previous estimates indicate that public construction projects account for approximately 58.2% to 60% of the government's annual capital budget (MoUDHC, 2006; Wubishet, 2004).

However, many public projects continue to experience significant time and cost overruns. Despite this, no comprehensive study has specifically identified the key supply chain management challenges contributing to these issues. This research aims to examine current practices and identify the critical challenges affecting supply chain management in the construction sector.

II. RESEARCH MOTIVATION

The primary motivation for this research stems from the observation that many projects are being executed with technical specifications that deviate from those outlined in the contract documents. This not only leads to dissatisfaction among project owners but also results in cost escalations, schedule delays, conflicts, disputes, and prolonged legal claims. Beyond these industry challenges, there is a noticeable gap in the available literature on the current supply chain practices in Ethiopia’s construction sector. This lack of documented research, combined with firsthand experiences and observations of existing practices, further inspired this study. Additionally, this research is undertaken as part of the partial fulfillment of a master’s program in Construction Technology and Management. By conducting this study, the aim is to enhance the understanding of construction managers and planners regarding logistics activities and their associated costs. Furthermore, the findings can help improve bid competitiveness and increase the likelihood of project success by optimizing construction logistics costs and minimizing inefficiencies.

III. LITERATURE REVIEW

It is often stated that the construction industry differs significantly from other industries and therefore requires unique approaches and solutions to enhance performance and efficiency. Construction is typically characterized by distinct features such as one-of-a-kind products, temporary project-based organizations, and on-site production, which hinder the achievement of streamlined workflows comparable to those in manufacturing (Koskela, 1992). For instance, the primary construction company overseeing a project directly executes only a small portion of the final product using its own workforce and facilities. Instead, a significant share—approximately 75% or more—of the project's value is realized through suppliers and subcontractors (Dubois et al., 2002). Advancements in construction are often associated with mitigating these industry-specific challenges, such as transitioning from site-based production to industrialization or replacing custom-built solutions with pre-engineered components.

The concept of supply chain management (SCM) in construction emerged in response to the industry's inherent challenges. Many researchers argue that the high degree of fragmentation in the construction sector has contributed to various inefficiencies, including low productivity, cost and time overruns, conflicts, disputes, and protracted legal claims (Latham, 1994; Egan, 1998). To address this fragmentation, there is a growing recognition of the need to integrate various disciplines and stakeholders involved in a project, including all members of the supply chain (Anumba et al., 2002).

The necessity for substantial improvements in project performance and profitability has gradually become apparent within the construction industry (O’Brien et al., 2000; Bankvall et al., 2010), prompting discussions on refining supply chain management practices (Agapiou, 1998). However, despite efforts to adapt SCM principles from other industries, the construction sector has yet to fully realize its potential. The implementation of SCM remains fragmented and slow, with attempts often lacking effectiveness and yielding only partial success (Akintoye et al., 2000; Love et al., 2004; Lönngren et al., 2010). Practitioners have applied SCM principles selectively, sometimes focusing on the supply chain, other times on-site operations, or a combination of both, depending on project-specific circumstances (Vrijhoef et al., 2000).

It is widely believed that unstructured collaborative relationships lead to increased costs for clients, whereas effective supply chain management can enhance value and reduce expenses. The integration of SCM, particularly through information and communication technologies, has the potential to address industry fragmentation and improve overall construction performance. However, its application in the sector remains in the early stages (Saad et al., 2002). Nevertheless, there is a growing awareness within the industry of the urgent need to reform current work practices and the mindsets they reflect (Pearson, 1999; Pryke, 2009).

IV. RESEARCH METHODOLOGY

A. Research Elements

The primary research instrument utilized in this study is a structured questionnaire survey, which consists mainly of closed-ended questions. Surveys are widely regarded as the preferred method for research in logistics and supply chain management (Kotzab, 2005). While questionnaires have inherent limitations, they are particularly valuable in supply chain research as they facilitate the collection of detailed insights into real-world supply chain dynamics, enabling the development of more comprehensive and well-founded theories (Eisenhardt, 1989; Yin, 2003).

To effectively interpret and present respondents' perspectives in a clear and meaningful manner, the collected data is organized into thematic categories aligned with the research objectives. The key themes include:

Part I: General Information

Part II: Perception of Construction Stakeholders on the Benefits of SCM

Part III: Current Practices and Challenges in SCM

Part IV: Approach to Supply Chain Management

Part V: Solutions for Challenges in the Supply Chain Network

The identification of potential suppliers for the study was conducted after gathering responses from public agencies and contractors.

B. Area of study

The study focused on relevant public construction projects in Addis Ababa, primarily those managed by the Ministry of Urban Development and Housing (MoUDH). Since supply chain management is a relatively new conceptual framework and is implemented at higher management levels, the selected respondents included project managers, contract managers, resident engineers, and supply managers.

C. Analysis techniques used

The study employed descriptive statistics to analyze the survey responses numerically. Percentages were used to present the findings, as they offer a clearer and more intuitive interpretation by expressing results as proportions of the total. To enhance comprehension, the findings are displayed in tables and charts.

Given the relatively small sample size, the analysis combined responses from all groups of participants, including clients, consultants, and contractors, to ensure meaningful results. The study also applied the Relative Importance Index (RII) method to rank variables based on their significance and level of agreement. The RII was calculated following the approach outlined by Aibinu and Jagboro (2002).

V. RESULTS & DISCUSSIONS

A. General response

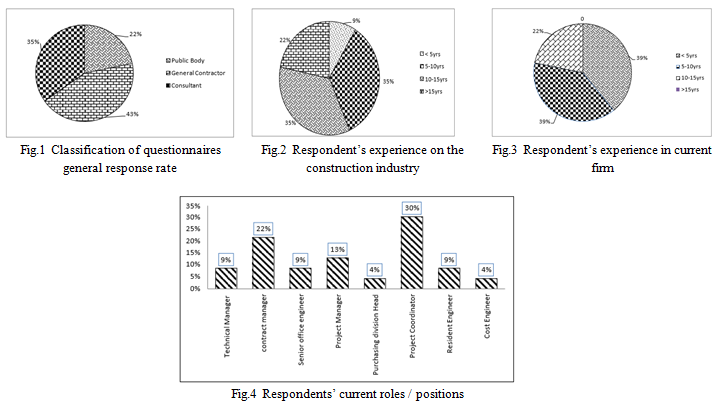

In this study, a total of 34 questionnaires were distributed to clients, contractors, and consultants, yielding 23 responses, resulting in a return rate of 67.65%. The distribution of respondents is as follows: contractors (43%), consultants (35%), and clients (22%). Additionally, potential suppliers were identified based on the responses received from public agencies, contractors, and consultants. To gather supplier-specific insights, 20 questionnaires were distributed to suppliers, of which only eight were returned.

B. Perception of stakeholders

As shown in the table below, the most important factors for supply chain collaboration, as identified by public bodies, contractors, and consultants, include:

- Enhanced quality assurance

- Increased profitability

- Improved customer service

- Cost reductions within the organization

- Benefits to the client

Table 1 highlights the five key factors that are considered crucial for supply chain collaboration from the suppliers' perspective, which include:

- Improved customer service

- Achievement of company goals and objectives

- Increased profitability

- Enhanced quality assurance

- Increased market competitiveness

Clearly, improved quality assurance, enhanced customer service, and increased profitability are recognized as shared priorities for successful supply chain collaboration across these organizations.

TABLE I RII analysis on the importance of supply chain management collaboration

|

|

Public body, Contractor and Consultant response |

Suppliers' response |

||||||||||

|

Factors |

Likert Scale |

wi |

frequency (fi) |

|

23 ∑ ???????? * ???????? ????=1 |

RII |

Rank |

frequency (fi) |

|

8 ∑ ???????? * ???????? ????=1 |

RII |

Rank |

|

Improved customer service |

Unimportant |

1 |

0 |

0 |

102 |

89% |

2 |

0 |

0 |

40 |

35% |

1 |

|

Less important |

2 |

0 |

0 |

0 |

0 |

|||||||

|

Somewhat important |

3 |

2 |

6 |

0 |

0 |

|||||||

|

Important |

4 |

9 |

36 |

0 |

0 |

|||||||

|

Very important |

5 |

12 |

60 |

8 |

40 |

|||||||

|

Overall supply chain reduction |

Unimportant |

1 |

2 |

2 |

84 |

73% |

9 |

1 |

1 |

29 |

25% |

10 |

|

Less important |

2 |

1 |

2 |

0 |

0 |

|||||||

|

Somewhat important |

3 |

8 |

24 |

3 |

9 |

|||||||

|

Important |

4 |

4 |

16 |

1 |

4 |

|||||||

|

Very important |

5 |

8 |

40 |

3 |

15 |

|||||||

|

Increased profitability |

Unimportant |

1 |

0 |

0 |

102 |

89% |

2 |

0 |

0 |

38 |

33% |

3 |

|

Less important |

2 |

0 |

0 |

0 |

0 |

|||||||

|

Somewhat important |

3 |

1 |

3 |

0 |

0 |

|||||||

|

Important |

4 |

11 |

44 |

2 |

8 |

|||||||

|

Very important |

5 |

11 |

55 |

6 |

30 |

|||||||

|

Reducing bureaucracy/ paperwork |

Unimportant |

1 |

1 |

1 |

91 |

79% |

6 |

0 |

0 |

31 |

27% |

9 |

|

Less important |

2 |

1 |

2 |

0 |

0 |

|||||||

|

Somewhat important |

3 |

6 |

18 |

2 |

6 |

|||||||

|

Important |

4 |

5 |

20 |

5 |

20 |

|||||||

|

Very important |

5 |

10 |

50 |

1 |

5 |

|||||||

|

Increased market competitiven ess |

Unimportant |

1 |

0 |

0 |

91 |

79% |

6 |

0 |

0 |

35 |

30% |

5 |

|

Less important |

2 |

2 |

4 |

0 |

0 |

|||||||

|

Somewhat important |

3 |

6 |

18 |

0 |

0 |

|||||||

|

Important |

4 |

6 |

24 |

5 |

20 |

|||||||

|

Very important |

5 |

9 |

45 |

3 |

15 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Public body, Contractor and Consultant response |

Suppliers' response |

||||||||||

|

Factors |

Likert Scale |

wi |

frequency (fi) |

|

23 ∑ ???????? * ???????? ????=1 |

RII |

Rank |

frequency (fi) |

|

8 ∑ ???????? * ???????? ????=1 |

RII |

Rank |

|

Cost reductions within your organization |

Unimportant |

1 |

0 |

0 |

94 |

82% |

4 |

0 |

0 |

34 |

30% |

6 |

|

Less important |

2 |

0 |

0 |

0 |

0 |

|||||||

|

Somewhat important |

3 |

7 |

21 |

0 |

0 |

|||||||

|

Important |

4 |

7 |

28 |

6 |

24 |

|||||||

|

Very important |

5 |

9 |

45 |

2 |

10 |

|||||||

|

Benefits to the client |

Unimportant |

1 |

0 |

0 |

94 |

82% |

4 |

0 |

0 |

33 |

29% |

7 |

|

Less important |

2 |

0 |

0 |

0 |

0 |

|||||||

|

Somewhat important |

3 |

8 |

24 |

3 |

9 |

|||||||

|

Important |

4 |

5 |

20 |

1 |

4 |

|||||||

|

Very important |

5 |

10 |

50 |

4 |

20 |

|||||||

|

Benefits to your supplier |

Unimportant |

1 |

0 |

0 |

82 |

71% |

10 |

0 |

0 |

32 |

28% |

8 |

|

Less important |

2 |

3 |

6 |

0 |

0 |

|||||||

|

Somewhat important |

3 |

10 |

30 |

3 |

9 |

|||||||

|

Important |

4 |

4 |

16 |

2 |

8 |

|||||||

|

Very important |

5 |

6 |

30 |

3 |

15 |

|||||||

|

Improved quality assurance |

Unimportant |

1 |

0 |

0 |

105 |

91% |

1 |

0 |

0 |

38 |

33% |

3 |

|

Less important |

2 |

0 |

0 |

0 |

0 |

|||||||

|

Somewhat important |

3 |

0 |

0 |

0 |

0 |

|||||||

|

Important |

4 |

10 |

40 |

2 |

8 |

|||||||

|

Very important |

5 |

13 |

65 |

6 |

30 |

|||||||

|

achievement of company goals and objectives |

Unimportant |

1 |

0 |

0 |

91 |

79% |

6 |

0 |

0 |

39 |

34% |

2 |

|

Less important |

2 |

0 |

0 |

0 |

0 |

|||||||

|

Somewhat important |

3 |

9 |

27 |

0 |

0 |

|||||||

|

Important |

4 |

6 |

24 |

1 |

4 |

|||||||

|

Very important |

5 |

8 |

40 |

7 |

35 |

|||||||

Conclusion

1) Importance of Supply Chain Management (SCM): The study highlights that awareness of SCM in the construction industry improves quality assurance, increases profitability, enhances customer service, reduces organizational costs, and benefits clients. Trust, reliable supply, mutual interest, standardized processes, and strong supplier relationships are key to successful supply chain collaboration. 2) Challenges in Construction Supply Chain: The research identifies several issues affecting construction projects, including late payments, design/engineering interface problems, changes in client requirements, and material management challenges such as incomplete contracts, incorrect materials, and inappropriate storage. 3) Supply Chain Integration: The study suggests that construction supply chains should focus on integrated management, incorporating both site production and SCM. Unlike other industries, construction relies on pooled and reciprocal interdependencies, which requires synchronized management across multiple supply chains. 4) Measures to Improve Supply Chain Efficiency: Actions to address material delivery issues include better coordination between stores and construction teams, minimizing design changes, and ensuring accurate specifications. Improvements in Just-In-Time delivery, supplier relationships, vertical integration, and strategic planning are also recommended for better SCM.

References

[1] Agapiou A., Flanagan, R., Norman, G., Notman, D. The changing role of builders merchants in the construction supply chain [Book]. - [s.l.]: Construction Management and Economics, 1998. [2] Agyerum K. Minimizing Materials Wastage at The Construction Stage of a Project through the implementation of lean construction [Report]. - [s.l.]: Kwame Nkrumah University of Science and Technology, 2012. [3] Akintoye A., McIntosh, G., and Fitzgerald E. A survey of supply chain collaboration and management in the UK construction industry [Journal]. - [s.l.]: European Journal of Purchasing and Supply Management, 2000. - Vol. 6. [4] Ali Gohari Supply Chain Management in Construction Industry [Journal] // Advances In Management. - 2014. [5] Anumba C.J. and Ruikar K., Electronic commerce in construction—trends and prospects [Journal]. - [s.l.] : Automation in Construction, 2002. - Vol. 11. [6] Arditi D. and Gunaydin H.M. Total quality management in the construction process [Journal] // International Journal of Project Management. - 1997. [7] Arlbjorn J.S. and Halldorsson A. Logistical Analysis: A Search for a Contingency Theory Ph.D. thesis [Book]. - Odense : Odebse University Press, 2002. [8] Atkin B., Flanagan R. and Marsh A., Agapiou, A. Improving Value for Money in construction: Guidance for Chartered Surveyors and their Clients [Journal]. - London : Royal Institution of Chartered Surveyors, 1995. [9] Ayers J. Handbook of supply chain management [Journal] // St. Lucie Press and APICS. - 2006. [10] Babbar S., and Prasad S. International purchasing, inventory management and logistics research: An assessment and agenda [Journal]. - [s.l.]: International Journal of Operations and Production Management, 1998. - 1 : Vol. 18. [11] Baiden B.K., Price, A.D.F. and Dainty A.R.J. The extent of team integration within construction projects [Journal]. - [s.l.]: International Journal of Project Management, 2006. - 1 : Vol. 24. [12] Bankvall L., Bygballe, L.E., Dubois, A. and Jahre M. Interdependence in supply chains and projects in construction [Journal] // Supply Chain Management: An International Journal. - 2010. - pp. Vol. 15 No. 5, pp. 394-403.. [13] Bechtel C. and Jayaram J. Supply chain management: A strategic perspective [Report]. - [s.l.]: The International Journal of Logistics Management, 1997. [14] Belay Mengistu Challenges of Supply Chanin Managment and their relation with the competitive Position of Cement Industries in Ethiopia [Report]. - [s.l.] : DR. DOUGLAS BOATENG (FIoD, FCILT, FCMI, FIBC, FIOM), 2011. [15] Berry Leonard L. and Parasuraman A. Marketing to Existing Customers? in Marketing Services: Competing through Quality, [Book]. - New York, NY : [s.n.], 1991. [16] Blanchard D. Supply Chain Management Best Practices [Book]. - New Jersy : John Wiley & Sons, Inc., 2010. - Vol. 2.

Copyright

Copyright © 2025 Mukesh Kumar, Niharika Patel. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET66844

Publish Date : 2025-02-05

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online