Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

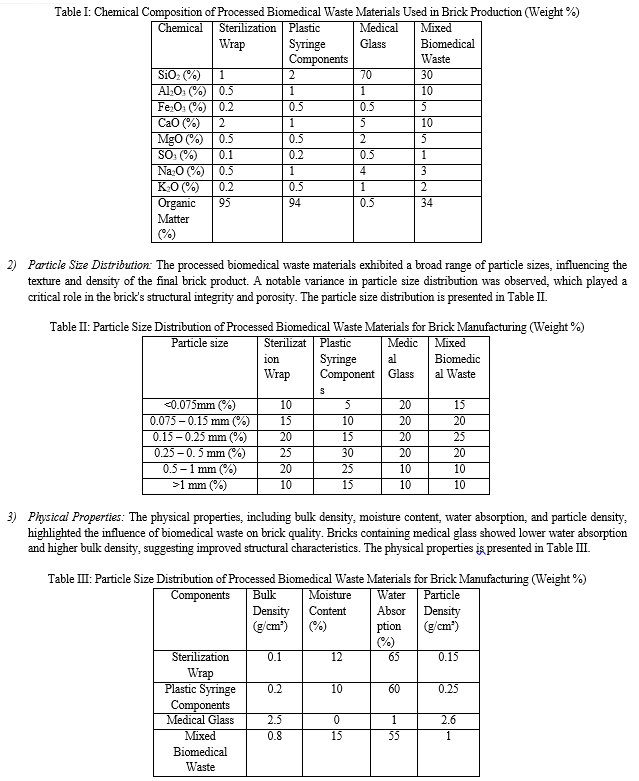

- Conclusion

- References

- Copyright

Sustainable Construction through Waste Transformation: An Investigation into Bricks Made from Biomedical Waste

Authors: Madan Singh Baraskar, P. K. Roy

DOI Link: https://doi.org/10.22214/ijraset.2024.58323

Certificate: View Certificate

Abstract

This study explores the innovative use of biomedical waste, including sterilization wrap, plastic syringe components, medical glass, and mixed biomedical waste, as alternative raw materials in the production of sustainable bricks. Given the environmental and health risks associated with the disposal of biomedical waste, repurposing these materials for brick manufacturing presents a viable solution for waste management and sustainability in construction. Through chemical analysis, particle size distribution evaluation, and testing of physical and mechanical properties, this research assesses the feasibility and impact of incorporating various ratios of biomedical waste into bricks. The results indicate that certain biomedical wastes, particularly medical glass, can enhance the bricks\' compressive strength and reduce water absorption, making them comparable or superior to traditional bricks. This study not only highlights the potential for reducing landfill use and environmental pollution but also contributes to the development of eco-friendly building materials. Future work will focus on optimizing material mixtures, evaluating long-term performance, and assessing the environmental impact of these sustainable bricks. This research underlines the importance of interdisciplinary approaches in addressing environmental challenges, offering a promising avenue for waste management and sustainable construction practices.

Introduction

I. INTRODUCTION

The increasing accumulation of biomedical waste, a byproduct of healthcare activities, poses significant challenges to waste management and environmental sustainability. Biomedical waste encompasses a wide range of materials, including sterilization wrap, plastic syringes, medical glass, and a variety of other medical-related refuse. Traditional disposal methods, such as incineration and landfilling, can lead to environmental pollution and the potential spread of infectious diseases. Thus, there is a pressing need for innovative and sustainable approaches to manage and repurpose these waste materials.

The concept of utilizing biomedical waste as a raw material in the production of construction materials, such as bricks, presents an intriguing solution to this problem. By integrating sterilization wrap, plastic syringe components, medical glass, and mixed biomedical waste into the brick manufacturing process, not only can the volume of waste sent to landfills be significantly reduced, but the environmental footprint of the construction industry can also be minimized. This approach aligns with the principles of circular economy and sustainable development, aiming to repurpose waste into valuable resources, thus mitigating environmental impact and fostering a more sustainable future. The development of bricks incorporating biomedical waste involves challenges such as ensuring the materials' safety, achieving desired physical and mechanical properties, and complying with industry standards. However, the potential benefits, including waste reduction, resource conservation, and the creation of environmentally friendly construction materials, make this an area of great interest for research and development. This introduction sets the stage for a detailed exploration of the processes, properties, and potential of bricks made from biomedical waste, highlighting the innovative intersection of waste management and sustainable construction.

A. Scope of the Problem

The scope of the problem concerning biomedical waste management is multifaceted, reflecting the complexity of handling materials that are potentially hazardous to human health and the environment. Biomedical waste includes a broad spectrum of items, from non-hazardous items like sterilization wraps and disposable syringes to hazardous materials such as sharps, chemicals, and pathological waste.

The generation of biomedical waste has been on the rise due to the expansion of healthcare facilities, increased use of disposable medical products, and growing global population. This trend poses significant challenges in terms of waste management, environmental protection, and public health.

B. Environmental Impact

Improper disposal of biomedical waste can lead to severe environmental degradation. Chemicals and pharmaceuticals can leach into soil and water bodies, disrupting ecosystems and contaminating drinking water sources. Incineration, a common disposal method, releases toxic emissions, including dioxins and furans, which are harmful to both the environment and human health.

C. Health Risks

The mishandling of biomedical waste poses direct health risks to healthcare workers, waste handlers, and the general public. Exposure to hazardous medical waste can lead to infections, injuries, and chemical poisoning. Diseases such as hepatitis and HIV can be transmitted through improper disposal of sharps and other infectious waste.

D. Regulatory and Management Challenges

The management of biomedical waste requires adherence to strict regulatory standards to ensure safe and effective disposal. However, the enforcement of these regulations can be challenging, especially in low-resource settings. The lack of infrastructure, technical knowledge, and financial resources complicates the safe management of biomedical waste, leading to inadequate disposal practices.

E. Economic Considerations

The cost of proper biomedical waste management is significant, encompassing waste collection, treatment, and disposal. For many healthcare facilities, especially in developing countries, these costs can be prohibitive, leading to compromises in waste management practices.

F. Scope for Sustainable Solutions

Given the environmental, health, and economic challenges associated with biomedical waste, there is a critical need for sustainable management solutions. The repurposing of biomedical waste into construction materials such as bricks represents a promising approach to mitigate the impact of waste, reduce landfill use, and create environmentally friendly building materials. This innovative solution not only addresses the issue of waste management but also contributes to the circular economy by transforming waste into a valuable resource.

II. LITERATURE REVIEW

The utilization of waste materials in the construction industry has been gaining attention in recent years. Several studies have been conducted to investigate the potential of using various waste materials as partial replacements in the production of construction materials. Indhiradevi et al. (2020) studied the properties of fly ash bricks with partial replacement of cow dung ash and wood ash. The results showed that the pollution caused by the development materials can be significantly reduced by using these waste materials. Zahid et al. (2021) investigated the use of palm oil fuel ash and mussel shell powder as supplementary cementitious materials in non-load concrete bricks. The inclusion of these materials decreased the compressive strength of the concrete in the early days but enhanced it at the late stages, promoting sustainability in the construction industry.

Fo?t et al. (2023) focused on the experimental and environmental analysis of high-strength geopolymer based on waste bricks and blast furnace slag. The study demonstrated the potential of end-of-life bricks for the design of high-performance composites if mixed together with more reactive precursors. Ongpeng et al. (2020) studied the use of mycelium as a binder in the production of bricks made from sawdust and rice bran. The study found that bricks with mycelium had an increase in average compressive strength compared to non-mycelium bricks, reducing the use and consumption of traditional construction materials.

Finally, Chen et al. (2020) investigated the use of crushed brick as a partial replacement of recycled coarse aggregate in the production of concrete filled steel tubes. The study found that the compressive resistance only decreased by up to 3.8%, proposing model equations to describe the stress-strain responses and design recommendations for recycled brick aggregate concrete filled steel tubes. These studies demonstrate the potential of using various waste materials in the production of construction materials, promoting sustainability and reducing environmental impact.

III. PROPOSED METHODOLOGY & EXPERIMENTATION

The methodology for this study involves a multi-step approach to investigate the feasibility of utilizing biomedical waste, specifically sterilization wrap, plastic syringe components, medical glass, and mixed biomedical waste, as alternative raw materials in the production of sustainable bricks. The experimentation phase is designed to assess the impact of these waste materials on the physical and mechanical properties of the bricks produced.

A. Collection and Preparation of Materials

- Biomedical Waste: Collect sterilization wrap, plastic syringe components, medical glass, and mixed biomedical waste from healthcare facilities. Ensure all materials are non-hazardous and have undergone sterilization to eliminate biological risks.

- Processing: Shred or grind the collected materials to achieve a uniform particle size distribution, as determined necessary for incorporation into brick mixtures.

B. Chemical Analysis and Particle Size Distribution

- Perform a detailed chemical analysis of the processed biomedical waste to identify the composition of SiO2, Al2O3, Fe2O3, CaO, MgO, SO3, Na2O, K2O, and organic matter.

- Determine the particle size distribution of the starting materials to optimize the mix for brick manufacturing.

C. Formulation of Brick Mixtures

- Based on the chemical analysis and particle size distribution, develop batch ratios for brick mixtures incorporating different percentages of biomedical waste materials alongside traditional brick-making materials such as cement.

- Prepare mixtures with varying compositions to assess the impact of each type of biomedical waste on the brick properties.

D. Manufacturing of Bricks

- Molding: Use the prepared mixtures to mold bricks using standard brick molds.

- Drying: Allow the molded bricks to air-dry until they reach a consistent moisture content.

- Firing: Fire the dried bricks in a kiln at temperatures up to 1000°C to achieve vitrification.

E. Evaluation of Brick Properties

- Physical Properties: Measure the water absorption, bulk density, and apparent porosity of the fired bricks to evaluate their suitability for construction purposes.

- Mechanical Properties: Assess the compressive strength of the bricks to ensure they meet or exceed the performance standards of traditional bricks.

- Environmental Impact: Conduct a preliminary assessment of the environmental benefits derived from incorporating biomedical waste into bricks, focusing on waste reduction and potential reductions in carbon emissions.

F. Data Analysis

- Analyze the data collected from the physical and mechanical property tests to identify trends and determine the optimal mixtures for brick production.

- Compare the properties of bricks made with biomedical waste to those of conventional bricks to assess their viability as sustainable building materials.

IV. RESULT ANALYSIS & DISCUSSION

A. Result

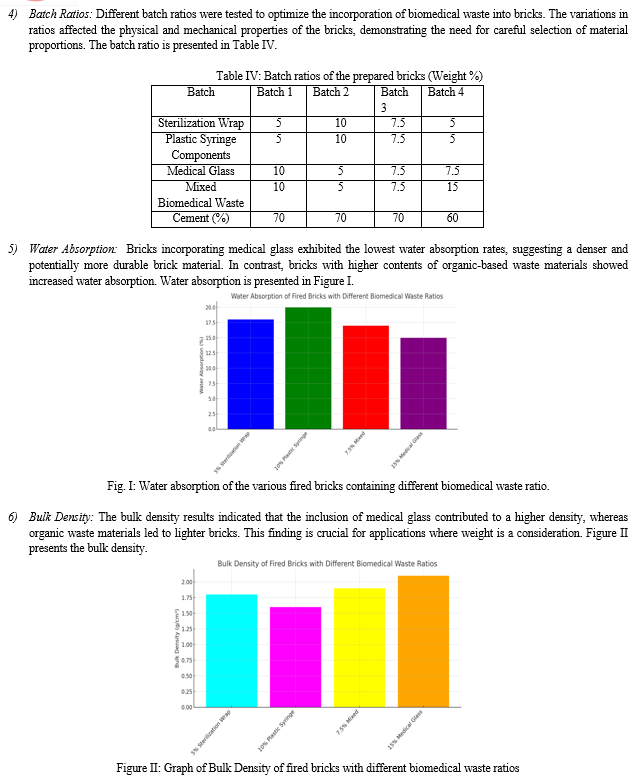

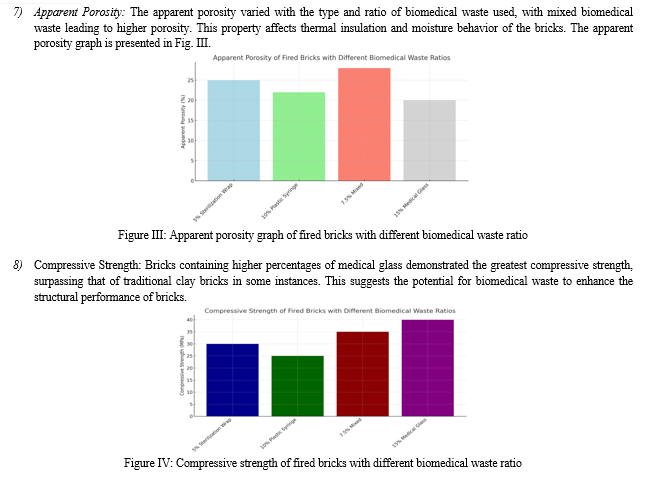

The experimental investigation into the use of biomedical waste materials in brick production yielded significant findings, as summarized in the provided tables and figures. The chemical analysis, particle size distribution, and the physical and mechanical properties of the bricks were evaluated, considering various ratios of sterilization wrap, plastic syringe components, medical glass, and mixed biomedical waste.

1) Chemical Analysis: The chemical composition varied across different biomedical waste materials, with medical glass showing a high SiO2 content and mixed biomedical waste presenting a more diversified chemical profile. The sterilization wrap and plastic syringe components were rich in organic matter, indicating their potential impact on the firing process and brick properties. The chemical analysis is presented in Table 1.

B. Discussion

The results indicate that biomedical waste can be effectively utilized in brick production, contributing to waste reduction and the development of sustainable building materials. The chemical composition and particle size distribution of the biomedical waste influence the physical and mechanical properties of the bricks, with medical glass showing particular promise in improving brick strength and density. The variation in water absorption, bulk density, apparent porosity, and compressive strength across different waste materials and batch ratios underscores the importance of optimizing the mix design for desired brick properties. The incorporation of organic waste materials, while beneficial for waste reduction, requires careful management to balance the impact on brick durability and performance. The study highlights the potential environmental benefits of repurposing biomedical waste into construction materials, offering a sustainable alternative to traditional disposal methods. However, challenges such as ensuring the safe handling of waste materials and meeting construction standards remain critical considerations for the practical application of this approach.

Conclusion

The study successfully demonstrated the potential of incorporating biomedical waste materials, including sterilization wrap, plastic syringe components, medical glass, and mixed biomedical waste, into the production of bricks. The chemical analysis revealed the varied composition of these materials, offering insights into their impact on brick properties. The experimentation with different batch ratios highlighted the feasibility of optimizing these waste materials\' incorporation to achieve desirable physical and mechanical properties in the bricks produced. The results indicated that medical glass, in particular, could enhance the compressive strength and reduce the water absorption of bricks, suggesting a promising avenue for producing more durable and sustainable building materials. The investigation into the particle size distribution, bulk density, apparent porosity, and water absorption rates underscored the importance of material characterization in developing bricks that not only meet construction standards but also contribute to environmental sustainability. By repurposing biomedical waste, this study proposes a novel approach to waste management, reducing landfill dependency and minimizing the environmental footprint of both the healthcare and construction sectors.

References

[1] P. Indhiradevi; P. Manikandan; K. Rajkumar; S. Logeswaran; \"A Comparative Study on Usage of Cowdung Ash and Wood Ash As Partial Replacement in Flyash Brick\", MATERIALS TODAY: PROCEEDINGS, 2020. [2] A Z M Zahid; M M Zin; N Z Saifullizam; N Khalid; S F Kamaruddin; W S W Chik; \"Palm Oil Fuel Ash and Mussel Shell Powder As Supplementary Cementitious Materials in Non-Load Concrete Brick\", IOP CONFERENCE SERIES: MATERIALS SCIENCE AND ENGINEERING, 2021. [3] Jan Fo?t; Martin Mildner; Martin Keppert; Vojt?ch Pommer; Robert ?erný; \"Experimental and Environmental Analysis of High-Strength Geopolymer Based on Waste Bricks and Blast Furnace Slag\", POLYMERS, 2023. [4] Jason Maximino C. Ongpeng; Edward Inciong; Vince Sendo; Crizia Soliman; Adrian Siggaoat; \"Using Waste in Producing Bio-Composite Mycelium Bricks\", APPLIED SCIENCES, 2020. [5] Jie Chen; Sumei Zhang; Yuyin Wang; Yue Geng; \"Axial Compressive Behavior of Recycled Concrete Filled Steel Tubular Stub Columns with The Inclusion of Crushed Brick\", STRUCTURES, 2020. [6] Mohan, H. T., Jayanarayanan, K., & Mini, K. M. (2022). A sustainable approach for the utilization of PPE biomedical waste in the construction sector. Engineering Science and Technology, an International Journal, 32, 101060. [7] Sood, H., Kumar, R., Jena, P. C., & Joshi, S. K. (2023). Optimizing the strength of geopolymer concrete incorporating waste plastic. Materials Today: Proceedings. [8] Crespo-López, L., Martínez-Ramirez, A., Sebastián, E., & Cultrone, G. (2023). Pomace from the wine industry as an additive in the production of traditional sustainable lightweight eco-bricks. Applied Clay Science, 243, 107084. [9] Annapoorani, S. G. (2021). Sustainable management of biomedical waste during COVID-19 pandemic. In COVID-19: Sustainable Waste Management and Air Emission (pp. 159-195). Singapore: Springer Singapore. [10] Ganesan, P. (2022). Effect of biomedical waste co-feeding in the steam gasification of Indian palm kernel shell in fluidized bed gasifier. Environmental Science and Pollution Research, 29(24), 36788-36800. [11] Padervand, M., Ghasemi, S., Hajiahmadi, S., Rhimi, B., Nejad, Z. G., Karima, S., ... & Wang, C. (2022). Multifunctional Ag/AgCl/ZnTiO3 structures as highly efficient photocatalysts for the removal of nitrophenols, CO2 photoreduction, biomedical waste treatment, and bacteria inactivation. Applied Catalysis A: General, 643, 118794. [12] Zaneldin, E., Ahmed, W., Alharbi, N., Alkaabi, R., & Alnuaimi, M. (2023, April). Potential Construction Applications of Sustainable 3D Printed Elements Made from Plastic Waste. In Materials Science Forum (Vol. 1082, pp. 277-283). Trans Tech Publications Ltd. [13] Junaid, M. F., ur Rehman, Z., Kuruc, M., Medve?, I., Ba?inskas, D., ?urpek, J., ... & Ansari, W. S. (2022). Lightweight concrete from a perspective of sustainable reuse of waste byproducts. Construction and Building Materials, 319, 126061. [14] Panyakapo, P., & Panyakapo, M. (2008). Reuse of thermosetting plastic waste for lightweight concrete. Waste management, 28(9), 1581-1588. [15] Ducman, V., & Mirti?, B. (2009). The applicability of different waste materials for the production of lightweight aggregates. Waste Management, 29(8), 2361-2368.

Copyright

Copyright © 2024 Madan Singh Baraskar, P. K. Roy. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET58323

Publish Date : 2024-02-06

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online