Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Sustainable Municipal Solid Waste Management in India by Biomethanation Process

Authors: C. Devoor, A. K. Nema

DOI Link: https://doi.org/10.22214/ijraset.2024.64331

Certificate: View Certificate

Abstract

Due to the recent population expansion, fast industrialization, and urbanisation, garbage generation has dramatically increased both globally and in India. This waste has huge potential for material and energy recovery. There are numerous waste-to-energy (WtE) technologies available, such as gasification, pyrolysis, incineration, biomethanation etc. that can offer dual benefit of combating the nuisance created by the waste as well support the energy needs of the country. Of these technologies, biomethanation are one of the most used technology to tap energy (gas/electricity) and procure compost (digestate).There are numerous municipal solid waste based biomethanation plants operating in India. The aim is to identify the key challenges that the MSW based biomethanation plants are facing and provide possible recommendations for improving their performance and making them successful. The research outcome could be beneficial in helping regulatory authorities, plant operators, technology providers and other stakeholders in facilitating the conducive environment for the success of bio-methanization as energy recovery facilities.

Introduction

I. INTRODUCTION

The world population has more than doubled since 1960 and it is estimated that there will be rise in urban population from 4.2 billion with an addition of 2.5 billion in 2050 resulting in 6.7 billion. India’s population has grown to 1.35 billion which is more than three times since independence and has reached 34% in 2018 which is nearly twice the level of urbanization then [1].

Owing to quick population progression, urbanization, economic development and industrialization, the quantity of solid waste generated has augmented since past few years [8, 9].

Waste generation all over the world (2.24 billion tonnes/year in 2020) and India (71.01 million tonnes/year in 2021) has increased drastically over last few decades. In Indian cities, the waste generation per capita varies from 200 gms - 600 gms per day [3]. In 2023, urban India is generating 154.09 KT/d waste every day and by 2030 it is projected to generate 165 million tonnes and by 2050, 436 million tonnes will be generated.

All the Indian cities produce significant amounts of solid waste, and poor waste management puts public health at risk, has detrimental effects on the environment, and causes a host of socioeconomic problems [5, 12].

More than 80% of generated solid waste in the cities/urban local bodies (ULB) is disposed of in an unscientific and unhygienic manner at the solid waste dump yards by the municipal bodies [16]. Many studies disclose unscientific disposal of solid waste generated in non-engineered landfills and dump sites which creates environmental and public health complications causing damage to local inhabitants [15].

As per the Annual report 2018-19 of MSW by CPCB, the collection efficiency of the generated solid waste is 98.4%. This shows the improvement in collection. As per this report, generation of solid waste is around 1.48 lakh Tonne per day, out of which 0.55 lakh TPD is treated and 0.50 lakh TPD is going to landfills. It also lays out strategy for proper implementation of the SWM Rules 2016, by emphasizing creation of State level time targeted action plan, handholding etc. In spite of all the efforts, the report submitted by CPCB in August 2019 to NGT regarding the data on dumpsites, shows that there are more than 3153 dumpsites across India, of which only 37 have been reclaimed/capped and 9 have been converted into sanitary landfill. This clearly shows that, the only solution to the solid waste management issue at ULB level, is source segregation followed by processing and controlling all the waste going into the landfill.

TABLE I: Solid Waste Collection, Processing and Disposal Data (Source: CPCB, 2018-19)

|

States |

Collected (TPD) |

Treated (TPD) |

Landfill (TPD) |

|

Andaman Nicobar |

117 |

65.1 |

37.9 |

|

Andhra Pradesh |

6140 |

548 |

203 |

|

Arunachal Pradesh |

215 |

Nil |

Nil |

|

Assam |

1119.37 |

. |

. |

|

Bihar |

Yes |

. |

no |

|

Chandigarh |

458.52 |

150 |

361.28 |

|

Chhattisgarh |

1386 |

1271 |

115 |

|

Daman Diu |

94.5 |

5 |

89.5 |

|

Delhi |

10614 |

5714 |

5225 |

|

Goa |

235.9 |

154.71 |

1.49 |

|

Gujarat* |

11119 |

1127 |

9992 |

|

Haryana |

4430.25 |

815.93 |

3614.32 |

|

Himachal Pradesh |

340 |

150 |

190 |

|

Meghalaya |

170.63 |

8.72 |

161.91 |

|

Telangana |

8360 |

5747 |

869 |

|

Jharkhand |

1043.4 |

836.69 |

0 |

|

Jammu & Kashmir |

1452.86 |

. |

. |

|

Karnataka |

10011 |

4515 |

|

|

Kerala |

742.23 |

437.74 |

. |

|

Lakshadweep |

18 |

18 |

. |

|

Madhya Pradesh |

7500 |

6100 |

1400 |

|

Maharashtra |

23675.7 |

12623.33 |

11052.37 |

|

Manipur* |

126.63 |

80 |

46.63 |

|

Mizoram |

213.07 |

29.22 |

. |

|

Nagaland |

216.9 |

135.8 |

33.95 |

|

Orissa |

2255.32 |

91.63 |

2163.69 |

|

Punjab |

4574.93 |

917.56 |

3657.37 |

|

Pondicherry |

505 |

24 |

481 |

|

Rajasthan |

6475.39 |

780.18 |

4187.16 |

|

Sikkim |

67.1 |

13.05 |

51.4 |

|

Tamil Nadu |

12850 |

7196 |

5654 |

|

Tripura |

389.46 |

150.1 |

239.36 |

|

Uttarakhand |

1437.4 |

524 |

. |

|

Uttar Pradesh |

17329.4 |

4615 |

0 |

|

West Bengal |

13064.63 |

916 |

334 |

Swachh Bharat Mission-Urban was launched by Ministry of Housing & Urban Affairs (MoHUA), Government of India in 2014 with an objective of 100% scientific collection and disposal of solid waste including door to door collection, segregation at source, storage, transportation, processing and disposal of municipal solid waste. According to an annual exercise ‘Swachh Survekshan’ conducted under SBM-U, during 2019-2020, a total of 1.45 lakh TPD of MSW was generated and0.11 kg/capita/day was the average per capita waste generated in India. Out of this, it is estimated that around 1.11 lakh TPD (76.65%) was segregated at source, 1.40 lakh TPD (96.65%) of waste is collected through door to door collection and 0.97 lakh TPD (67%) is processed or treated respectively.

II. COMPOSITION & CHARACTERISTICS OF MUNICIPAL SOLID WASTE

The municipal solid waste varies with respect to composition and characteristics across the globe and from one region to an area to any place. India is a land of diversity with respect to physical features, social customs, economic status, geographical locations and climatic conditions coupled with lot of etymological diversity. Owning to such diversity, the culture and food habits change from even city to city, resulting in diverse characteristic (physical and chemical) of waste generated.

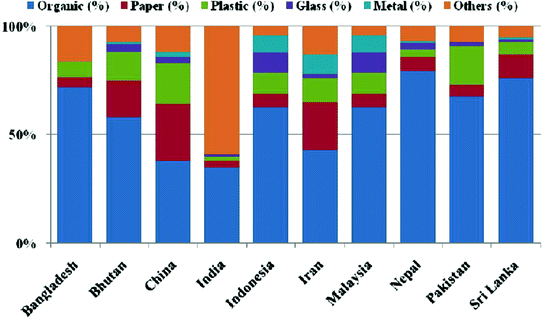

Fig 1: Composition of municipal solid waste of few developing countries (Source: Report by World Bank)

As per CPHEEO Solid Waste Manual, 2013, the average biodegradable composition varies between 42 - 47%. The physical analysis of the solid waste indicates 40% – 60% compostable matter, 10% – 25% recyclable fraction, 30% – 60% moisture content and 20 – 40 C/N ratio.

TABLE II: COMPOSITION OF INDIAN WASTE

|

Sl NO |

Composition |

Percentage fraction |

Reference |

|

1 |

Compostable/biodegradable fraction or wet waste |

40%–60% |

Sharma, 2019; CPCB |

|

42-47% |

MoHUA, 2013 |

||

|

53.7% |

CPCB |

||

|

2 |

Recyclables |

Less than 1% of plastic, glass and metal, paper (3%–6%); |

Gupta et al., 2015 |

|

10%–25% |

MoHUA, 2013 |

||

|

10% |

CPCB |

||

|

10%–30% |

Sharma ,2019 |

||

|

3 |

Inert segment |

30%–50% |

Sharma, 2019 |

|

Ash and fine earth (30%–40%); |

Gupta et al., 2015 |

||

|

37.25% |

CPCB |

The waste consists of various different types of materials from different types of activities including paper, plastics, rubber, metal, synthetics, glass etc. which vary in physical and chemical characteristics. The organic content of the solid waste samples on a dry weight basis ranges between 20 to 40%. Nitrogen, carbon, calorific value, phosphorus, pH, potassium, C/N ratio etc. determine the Chemical characteristics of solid waste. The nitrogen, phosphorus and potassium (N-P-K) content of the municipal solid waste ranges between 0.5 to 0.7%, 0.5 to 0.8% and 0.5 to 0.8% respectively. The calorific value ranges between 800-1000 kcal/kg. Carbohydrates, fibre, proteins etc. determine the bio-chemical characteristics and the presence of pesticides, insecticides, heavy metals etc. determine the toxicological characteristics of the solid waste. It is essential to have knowledge of the physical and chemical characteristics of any kind of solid waste are in determining the efficacy of any treatment process.

III. STATUS & CURRENT PRACTICES OF MSW MANAGEMENT IN INDIA

Augmented population, urbanization, industrialization, unabated intake of raw materials etc. are few of the major reasons for increase of waste and it is estimated that in three decades from now, there will be threefold increase in generation of waste in India. In large urban areas, waste collection efficiency ranges from 70% to 95%, whereas it is less than 50% in a number of smaller communities [6].

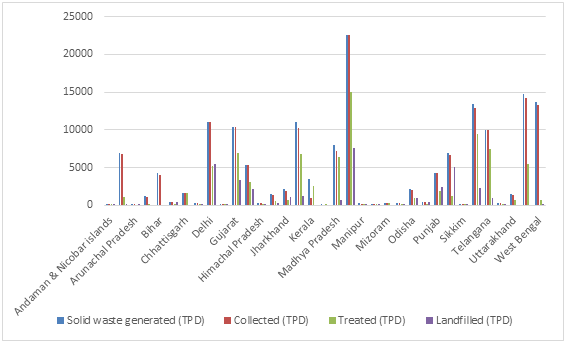

According to the CPCB's Annual Report for 2020–21 on MSW, the total amount of waste generated in the India is 160038.9 TPD, of which 152749.5 TPD is collected, 79956.3 TPD is treated or processed and around 29427.2 TPD is landfilled. This clearly shows that, the only solution to the solid waste management issue at ULB level, is source segregation followed by appropriate processing technology and controlling all the waste going into the landfill. Maharashtra state alone is producing 22632.7 TPD of waste, which accounts to 14% of waste generated in India followed by states like Uttar Pradesh (14710TPD), West Bengal (13709TPD), Tamil Nadu (13422TPD) etc.

100% collection of waste is observed in Delhi, Chandigarh, Chhattisgarh, Dadra Diu Daman Nagarhaveli, Sikkim and Telangana. Chhattisgarh is the only state having 100% treatment. Highest percentage of landfilling the generated waste is seen in Chandigarh (86.55%) and Puducherry (88.40%). Five States/UTs Chhattisgarh, Dadra Diu Daman Nagarhaveli, Andaman & Nicobar Islands, Tripura and Goa have achieved 100% source segregation.

After taking into account all of the MSWM strategies available, landfilling is a necessary component of any planned MSWM system. However due to scare land resource, source segregation must be practiced in which most of the dry waste & recyclables are removed from the waste stream and wet waste is processed, leaving a small chunk of waste to be landfilled.

Fig 2 : Solid waste collected, treated and landfilled data (Source: CPCB, 2020-21)

In India, there is a large difference ranging from 0% to 100% in collection of solid waste, its treatment, and disposal by landfilling among all the States. This shows solid waste management is challenging and not uniform and have challenges like poor technical know-how, low financial capacity, land use and infrastructure, deficiency of compliance with rules, lack of coordination amongst all the departments/authorities, inadequate guidelines and in deficit political priority [11]. Many cities/towns lack the necessary equipment and tools for managing such a large volume of unorganized garbage [2].

Review of literature on SWM highlights inadequate management of generated solid waste among various towns and cities of developing countries. Municipal solid waste (MSW) management practices of this nature not only harm the environment, but also put the public's health at danger and cause other socioeconomic problems. Therefore, it is imperative to improve garbage collection, segregation, and safe disposal as soon as possible [12].

Environmental degradation and climate change are examples of local, regional, or even global repercussions of poor waste management [6]. Many researchers have described that India lack of technical knowhow due to varied composition of waste generated in India, institutional/financial issues at cities/states etc. are few of the most important factors which limit any progress in municipal solid waste management. Therefore, considerably better medium-term planning is immediately required at the local and state levels in order to create and implement considerably accurate investment predictions [5] and with appropriate energy recovery technologies from waste wherein energy can be recovered and also the menace of the solid waste can be addressed with least negative environmental impact.

With the onset of missions like Swachh Bharat Mission-Urban (SBM-U) which aims at 100% scientific processing of solid waste was launched in October 2014. After this mission was implemented by Government of India, door to door collection and segregation have been encouraged. As on 01.08.2023, all 89,997 wards across urban India have achieved door-to-door collection, of which 83,747 wards (93%) are segregating their waste. However, the configuration of mixed waste provides an enormous challenge for implementation of suitable technology for environmentally safe disposal and also recovers energy from MSW. But all efforts are to be made to encourage for the energy recovery from the wet waste and also select appropriate recovery mechanism for recyclable waste & reuse technology for dry waste.

IV. POTENTIAL FOR ENERGY RECOVERY FROM MSW

Rapid garbage generation results in a large amount of rubbish that is typically dumped in the least sanitary way possible. It consumes resources and necessitates spending as well. This may result in a nation's decline and the collapse of its economy. Therefore, turning waste into energy is a modern option that not only aids in waste management but also contributes to energy security for countries. Energy recovery from the trash created is a challenging yet inventive technique. Due to factors including a deficiency in policy framework, sustainable planning, lack of infrastructure, limited financing sources, low technical improvements, India has historically lagged behind in this area [15]. The country hasn't given up and is still actively experimenting with ways to get electricity out of its massive garbage stockpile. There are numerous waste-to-energy initiatives running state-by-state across India [7].

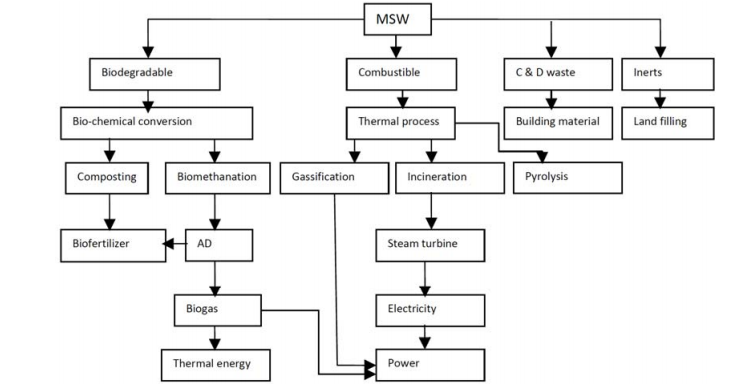

Municipal Solid Waste (MSW) is chiefly made up of inert fractions, C&D trash, non-biodegradable combustible fractions, and biodegradable organic fractions. Energy recovery technologies like gasification, pyrolysis, biomethanation, incineration etc. will carefully and sustainably transform MSW into an appropriate form of usable energy i.e., heat and electricity. The most appealing approach to address the problem of MSW management is by using WtE technologies.

In any of the waste to energy technology, the energy produced is dependent on particular process of treatment that is employed. It is also dependent on Quantity and Quality of the waste. Therefore, detailed information on these characteristics is crucial in comprehending the potential for solid waste energy recovery. To get more accurate energy recovery estimate, then information on percentage variations of various characteristics with respect to time like daily variation or depending on seasons like summer, monsoon, winter etc. are necessary.

Fig 3: Various municipal solid waste treatment technologies (Source: Begum et al., 2017)

Currently, South East Asia's landfill biogas plants, incinerators, and other waste-to-energy techniques have a combined capacity of about 323 MW. By 2022, this capacity is anticipated to quadruple [17]. By 2030, the Indian government intends to have installed a total of 50% of its electric power from non-fossil fuel sources. The Ministry of New and Renewable Energy (MNRE) has launched the Waste to Energy Programme within the National Bio Energy Programme (FY 2021-22 to 2025-26) to promote Energy from Urban Waste. According to SWM rules, 2016, waste must be transferred to treatment facilities like refuse-derived fuel (RDF), incinerators, biomethanation, and others instead of burning [10]. There is a potential for around 1700 MW from urban waste (1500 MW from MSW and 225 MW from sewage) and approximately 1300 MW from industrial waste, according to the Ministry of New and Renewable Energy (MNRE). The ministry provides incentives and subsidies for waste-to-energy initiatives. According to the Indian Renewable Energy Development Agency (IREDA), the nation has so far only utilized only 2% of its potential for waste-to-energy. There are many commercial scale plants operational worldwide based on these technologies, however only few of them are functioning successfully in the India. Due to the limited knowledge and experience in waste to energy sector in, it becomes essential for identification of success stories, challenges, operating mechanism for supporting waste to energy technologies to make them viable and affordable[19]. For WtE selection technology, separate collection of high-quality waste streams is just as crucial as the availability of recycling facilities and the market for the recovered products. There are numerous technological options are available for energy recovery, like gasification, Refuse Derive Fuel (RDF), pyrolysis, incineration, biomethanation, composting etc. which are developed and studied for recovery of energy from the municipal solid waste. However, most preferred one and considered green technology is Biomethanation. The implementation of biogas technology considerably aids the region's economic growth [14]. Additionally, it has also become a viable renewable technology to turn other wastes like horticultural, animal wastes, municipal etc. into electricity. The quantity and contents of generated waste determines the best waste to energy technology under the prescribed environmental condition. The biodegradable or organic portion of municipal solid waste, primarily consists of cooked and uncooked kitchen waste, makes up around 40–70% of the MSW composition. With such a high percentage of biodegradable wastes, methods for turning waste into energy, such composting and biomethanation, might be tested. By adopting any of the suitable processing and treatment technology, the latent energy can be recovered which is present the biodegradable portion of the solid waste and utilized effectively. Due to the properties of waste from household kitchen and vegetable markets, biomethanation is a profitable technique for the creation of bioenergy and manure. It is a tried-and-tested process for disinfecting and deodorizing industrial sludge, farmyard manures, animal slurries, and sewage sludge. In addition to producing compost or sludge, it also results in the production of biogas and electricity. The technology of anaerobic digestion and biomethanation appears to be more stable and promising. It is estimated that one tonne of municipal solid waste has a potential to produce 2-4 times more methane through controlled anaerobic digestion in 3 weeks when compared to 1 tonne of landfill waste which releases equivalent amount of methane in 6–7 years.

There are many commercial scale plants operational worldwide based on these technologies, however only few of them are functioning successfully in the India. Due to the limited knowledge and experience in waste to energy sector in, it becomes essential for identification of success stories, challenges, operating mechanism for supporting waste to energy technologies to make them viable and affordable [19]. Anaerobic digestion could provide a critical answer to the growing garbage problems while also reducing the external energy requirements when applied to the organic waste produced in metropolitan settings. As landfills around Canada and the rest of the world reach their capacity, it is important to carefully consider a carbon-neutral technique that can locally create power and heat while providing up to 50% volatile solid reduction. The most popular technological solution for recovering energy from organic waste among the several alternatives is anaerobic digestion/biomethanation. It is one of the most reliable, promising, attractive, eco-friendly, economic, less labor intensive and efficient waste to energy technologies available [18, 13]. It lessens usage of fossil fuels and reduces climate change and global warming by avoiding the release of greenhouse gases. Due to its advantages for the economy and ecology, it is also advantageous for the community and society [18] and can be used for treating solid waste and other kinds of organic discards. Though statistics show that this technology has been commercialized since 1980s and is not considered very new, it has not been used extensively for energy recovery from municipal solid waste, which may be attributed due to uncertainty in quality and quantity of methane produced caused due to various issues related to waste quality, process instability and operation & maintenance [15].

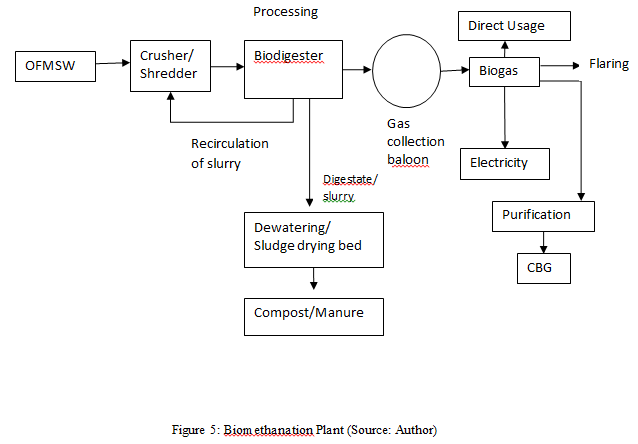

V. BIOMETHANATION

A. The Process

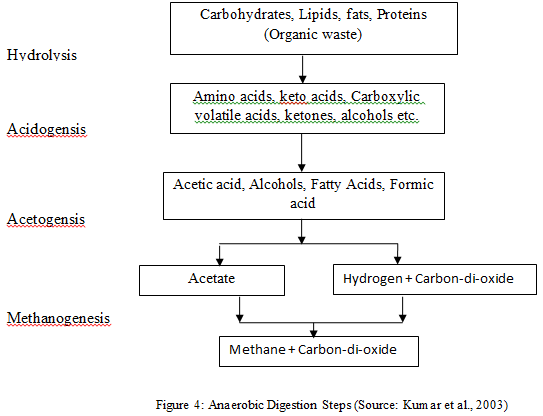

Biomethanation is an advanced approach for the bio-chemical conversion of the organic part of municipal solid waste by bacteria in the absence of oxygen [7]. The four key stages of this process are, Hydrolysis, Acidogenesis, Acetogeneis and Methanogenesis. Overall chemical reaction is represented as below,

C6H12O6 → 3CH4 + 3CO2

1) Hydrolysis: It is the first stage in which carbohydrates, proteins and lipids (insoluble complex organic matter) are converted into amino acids, sugars and long chain fatty acids (soluble simple matter) by enzymes called as hydrolase which are produced by hydrolytic bacteria like Clostridium, bacillus, peptococcus, vibrio, bacteroides, staphylococcus etc. It can be expressed as

(C6H10O5) n+ n H2O → n C6H12O6+nH2

2) Acidogenesis: It is the second stage of anaerobic digestion process in which soluble molecules that are produced in previous stage are converted into volatile fatty acids, alcohols, lactate, and carbon dioxide by fermentative bacteria like Lactobacillus, Streptococcus, saccharomyces, Clostridium etc. It can be expressed as

C6H12O6 ↔ 2 CH3CH2OH + 2 CO2

C6H12O6 + 2 H2 ↔ 2 CH3CH2COOH + 2 H2O

C6H12O6 → 3 CH3COOH

3) Acetogeneis: It is the third stage in which volatile fatty acids (VFAs) and alcohols are converted into acetate, H2, and CO2 by acetate-forming fermentative bacteria like Clostridium aceticum, Syntrophobacter wolinii, Sporomusa, Acetobacterium, Pelotomaculum thermopropionicum, etc.

CH3CH2COO− + 3 H2O ↔ CH3COO− + H+HCO3− + 3 H2

C6H12O6 + 2 H2O ↔ 2 CH3COOH + 2 CO2 + 4 H2

CH3CH2OH + 2 H2O ↔ CH3COO− + 3 H2 + H

4) Methanogenesis: In this last stage of digestion process, methane gas is formed from acetate and molecular hydrogen by methanogens.

2CH3CH2OH + CO2 → CH4 + 2 CH3COOH

CO2 + 4 H2 → CH4 + 2 H2O

CH3COOH → CH4 + CO2

This process is used to process wide variety of organic wastes like biodegradable wet waste like vegetable, fruit, flowers, poultry & meat market wastes, Horticulture, garden waste and food waste collected from households, restaurants, hotels, canteens etc. Some of the waste other than municipal solid waste which uses anaerobic digestion for processing are animal dung from dairies, animal shelter, agriculture waste, food processing industry waste, sludge from wastewater treatment plants.

It produces biogas, which contains traces of various gases but majorly carbon dioxide and methane [14]. It can be used for cooking or heating applications as conventional fuel, CNG, LPG, Compressed Biogas (CBG), or for generating electricity. At the end of the process, liquid slurry is produced which can be used in agriculture as compost or manure after dewatering or drying. Therefore, biomethanation has dual benefit of not only generating energy but also producing compost that can be used as soil conditioner [16].

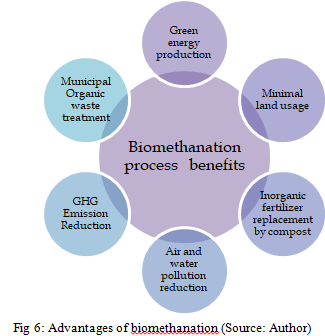

B. Advantages of Biomethanation

The recovery of energy from wastes through anaerobic digestion/biomethanation offers innumerable benefits as follows:

- The cost of collection of garbage, transportation, storage, treatment and final disposal is decreased by using biomethanation to process the organic component of domestic municipal solid waste, particularly if the material must be carried to far-off landfill sites.

- The demand for land for landfilling of waste is drastically reduced, which is already scarce, expensive and challenging to find in cities.

- Contrary to composting, biomethanation is an energy-producing process. The energy-intensive process of composting uses 50–75 kWh of electricity for every tonne of garbage but in contrast, biomethanation generates 75–150 kWh of power from the same amount of garbage.

- Due to anaerobic digestion in an enclosed digester, leachate handling is not present, thereby eliminating nuisance caused due to odour and other air pollutants.

- There is drastic reduction in environmental pollution due to reduction in GHG emissions and decomposition of biodegradable waste caused by prolonged collection, storage, transportation and disposal from point of generation. Due to this, soil, water, air and vegetation can be protected from the environmental damage caused due indiscriminate disposal of waste.

- It promotes the creation of renewable energy sources, such as biogas, and earns revenue through the sale of carbon credits, electricity, and biogas. Additionally, it prevents the loss of fossil fuel supplies.

C. Types of Biogas Digesters

There are many kinds of biogas digesters available based on the mode of operation, operating conditions, feeding system, moisture content, operating stages, processing methods etc. [20]. They are discussed as below,

Based on feeding system, it is categorized into Batch Digester and Continuous Digester. A batch biogas digester is operated by filling the digester completely and after a fixed retention time, it is emptied completely. A Continuous Digester is filled and emptied regularly on daily basis, then it is called as Continuous digester.

Based on operating moisture content, it is categorized as Wet Digester and Dry Digester. A wet digester is a stirred tank that processes the feed having low solids (<15%) or having high moisture content (> 80%). A dry digester processes the feed having higher solids (>15%) or low moisture content (< 80%). Typically, slurry is poured into the digester tank as the feedstock for such a digester.

Based on the rate of digestion, it is categorized as high rate and low rate digestor. The manure which is the main source of methane-forming microorganisms flows through the digester in low rate digestor and in high rate digestor, microorganisms that form methane are confined in the digester to boost productivity.

Based on operating stages, it is categorized in to Single stage and Two-stage or Multistage Digester. In single stage digester, complete process of digestion occurs in a solo vessel. There are two different vessels in two-stage digesters wherein the1st&2ndphases of the digestion takes place. Multi-stage digesters are having more than two stages in which digestion takes place. For MSW, typically single stage digesters used and rarely constitute to two stages.

Based on design of the digester, it is categorized into floating drum type, fixed-dome type and tubular type. A floating-drum type consists of a digester which is cylindrical in shape placed under the ground and a floating type movable type gasholder (drum) which is generally situated above the ground. The digester is in dome shape and not movable, and a gas-holder is also immovable in a fixed-dome type digester. A tubular biogas or bag type digester plant: It comprises of rubber or plastic bag that is all weather and heat resistant in which the inlet and outlet, both are attached to it. It is longitudinal in shape that serves as both digester and gas holder.

D. Operational parameters

The characteristics of the input waste, the process parameters like pH, temperature, etc. inside the digester, kind of digester, sort of microorganisms developed inside the digester, retention time of solids and microbes etc. affect the performance of the biomethanation plants. Some of the most important operational parameters are as follows,

Table III: Factors Affecting Anaerobic Digestion (Source: ODCMOW ADVISORY, MOHUA, 2018)

|

Sl. No. |

Factors |

Optimal range for various types of digesters |

Remarks |

||

|

High-solids |

Low solids |

||||

|

Stackable |

Slurry |

||||

|

1. |

Moisture content |

Less than 60% |

Between 60 to 80% |

Greater than 80% |

The designed system will not work if the moisture content is not in the right range. |

|

2. |

pH |

(i)6.0 to 7.0a (single stage) (ii) 5.0 to 6.0(1st stage) and 6.5 to 8 (2nd stage) |

Low pH slows down the process and may lead to the death of microorganisms. |

||

|

3. |

Alkalinity |

More than 100 mg/L |

Even a little alkalinity will make acidogenic stage faster than the methanogenic stage, which can lead to process upsets. |

||

|

4. |

Volatile Fatty Acids (VFAs) |

Less than 4000 mg/L |

Higher concentrations of VFAs can be toxic to the microorganisms in the digester. |

||

|

5. |

Temperature |

Mesophilic digesters: 30 to 38°C Thermophilic digesters: 50 to 60°C |

Thermophilic breakdown proceeds much faster than mesophilic. Therefore, thermophilic reactor can yield a higher rate of biogas in a shorter period of time. |

||

|

6. |

Retention time (SRT) |

14 to 40 days |

If the SRT is too short, full degradation will not be achieved. It the SRT is too long, biogas recovery efficiency suffers, and the digester vessel will not be efficiently used. |

||

|

7. |

C:N ratio |

30:1 |

Excess nitrogen can lead to the accumulation of ammonia in the digester. Lower nitrogen can affect the cell growth of microorganisms. |

||

|

8. |

Ammonia |

200 mg/L |

Excess ammonia leads to substrate/product toxicity and hampers the digestion process. |

||

|

9. |

Sulphide |

Less than 50 mg/L |

Presence of high sulphide (as H2S) levels inhibits methane generation, which is most likely due to high loading of Sulphur compounds, including proteins. |

||

Notes:

aTypical range for single-stage digester. In two-stage digesters, typical range is 5.0 to 6.0 in hydrolysis/acid-forming stages (first digester) and 6.5 to 8.0 in methanogenic stage (second digester).

b Depends strongly on technology;

VI. STATUS OF BIOMETHANATION PLANTS IN INDIA

As per the Consolidated Annual Review Report (2020–21) published by Central Pollution Control Board, prepared in accordance with Section 8(2) of the MSW Rules, 2016, there are 21 States/UTs in which Biomethanation Plants are present. In Kerala, there are 287 and 21550 Community Level and 287 Household level biogas plants respectively.

After the implementation of SWM Rules 2016,and launch of missions by Government of India like Swachh Bharat (Rural & Urban) by Government of India, the status of house to house collection, source segregation, scientific processing and disposal of the MSW has improved as compared to before. 100% scientific solid waste processing in all statutory towns across the nation is one of the objectives of Swachh Bharat Mission-Urban and numerous biomethanation plants with compressed biogas are being set up in the country under this programme.

Fig 7 : Status of the presence of biomethanation plants in states of India (Source: CPCB Report, 2020-21)

A Thiruvananthpuram-based biogas technology company called Biotech has built 20,000 home biogas systems, diverting 2.5 percent organic waste from landfills. By this, Thiruvananthpuram and Kochi ULBs spare an annual transportation expense of INR 225 million. Additionally, these units help prevent 7000 t of CO2 equivalent year [2]. In Chandigarh, there is a biomethanation plant for processing the waste collected from poultry, fruit, vegetable, fish, flower, meat market etc.

Overall there is not much data available on technical, administrative, managerial and financial information which will provide details about performance of the plant, Operation and management aspects, cost effectiveness of the system etc. Only general data about the location and capacity is present with Central Pollution Control Board (CPCB), Ministry of Environment, Forest and Climate Change of India (MoEF & CC). With this data, it is difficult to access the performance or the status of biomethanation plants available in India.

VII. KEY OBSERVATIONS & RECOMMENDATIONS

- All the cities shall carry out the study on classification of generated municipal solid waste & based on the composition will arrive at the best suitable technology to manage their waste including adoption of biomethanation as processing technology because the effectiveness of biomethanation technology is reliant on the input waste.

- Resource mapping of the segregation of waste and pre-feasibility studies may be carried out the Authorities in collaboration with Academic Institutes in bigger cities for wider adoption of biomethanation plants.

- The city shall ensure that the segregated waste reaches the biomethanation plant and there is feedstock security so that plant is operated for the design capacity to avoid repeated breaks in Supply Chain.

- There is a need to develop standard design parameters for biomethanation plant by studying various biomethanation plants working in the country.

- The plant operators shall develop data format to capture all the data related to the biomethanation plant like operational parameters (pH, temperature, HRT), biogas yield, electricity generated, quantity and quality of the compost produced, breakdowns, manpower etc. on daily basis.

- State PCBs//ULBs shall develop strict monitoring mechanism to ensure all the biomethanation plants maintain data and submit to authorities on at least biannual basis.

- There is no database of the biomethanation plants at State or Central Government level other than generic data maintained by CPCB, MoEF & CC, which is collected from all the State PCBs as a part of their Annual report. A national data base has to be created to maintain the data on the biomethanation plants. The information on the biomethanation plants needs to be strengthened and updated frequently to have robust database.

- The financial feasibility study has to be carried out to understand about the capital cost and payback period. Subsidies from Government and other funding from PPP have to explored and encouraged by Authorities and regulatory bodies to make biomethanation plants as viable option.

- The final disposal of the solids after dewatering needs attention and there is no mechanism of selling of biomethanation plant output products (slurry, compost, gas) or revenue generated. The market for Biogas/Bio CNG, organic manure has to be increased.

- Key performance parameters that affect the performance of the plants have to be developed to understand the efficiency of biogas generation in the biomethanation plant and feasibility of making them profitable.

- The plant operators have to be skilled to understand the process and operate the plant. Therefore adequate training and capacity building has to be present to ensure good operation and maintenance without plant failure/stoppage.

Conclusion

Although anaerobic digestion/biomethanation technology has a number of advantages over other methods for processing and treatment of municipal solid waste, there are numerous uncertainties regarding the techno-economics of the technology because the quantity and category of solid waste generated differ based on location or city. The biomethanation plants have to comply and operate as per their design, which cannot be ascertained due to many challenges like lack of required data to be maintained in the field, required amount of waste reaching the plant, source segregation, etc. Given the benefit of literature from other parts of the world as well as from India itself, there are many lab scale studies on biomethanation plants done till now. It\'s time to transfer the findings of lab-scale research to a full-scale manufacturing facility so they may be made accessible and practical. This causes a significant gap between the theory and practice of anaerobic digestion, which opens up several opportunities for the plant\'s process development. There is lot of barriers and its type varies from plant to plant, location to location. The kind and significance of obstacles differ widely between different systems due to the difference in availability & quality feedstock, public awareness level, policy & programmes of government, financial support, maturity of technology, decisions of regulatory & implementing authorities etc. It can be concluded that Biomethanation requires extensive planning to process the organic portion of urban solid wastes, including design, construction, and operation as well as financial viability for institutionalising the idea of integrated solid waste management, without which it will not be a practical choice.

References

[1] A report on World Urbanization Prospects, United Nations 2018. [2] Annepu, R. K. (2012). biomethanation solid waste management in India. Columbia University, New York, 2(01), 1-89. [3] CPCB. Consolidated Annual Review Report prepared in compliance to the provision 8(2) of the MSW Rules, 2000. Central Pollution Control Board, Annual report (2020–11) [4] CPCB. Environmental Guidelines for Compressed Biogas Plant (CBG)/Bio-CNG Plants. Available ”https://cpcb.nic.in/uploads/Categorization_Environmental_26102023.pdf [5] Gupta, N., Yadav, K. K., & Kumar, V. (2015). A review on current status of municipal solid waste management in India. Journal of environmental sciences, 37, 206-217.https://doi.org/10.1016/j.jes.2015.01.034. [6] jurnalSharma, K. D., & Jain, S. (2019). Overview of municipal solid waste generation, composition, and management in India. Journal of Environmental Engineering, 145(3), 04018143.https://doi.org/10.1061/(ASCE)EE.1943-7870.0001490. [7] Kalyani, K. A., & Pandey, K. K. (2014). Waste to energy status in India: A short review. Renewable and sustainable energy reviews, 31, 113-120.https://doi.org/10.1016/j.rser.2013.11.020. [8] Kaushal, R. K., Varghese, G. K., & Chabukdhara, M. (2012). Municipal solid waste management in India-current state and future challenges: a review. International Journal of Engineering Science and Technology, 4(4), 1473-1489. [9] Kumar, A., & Agrawal, A. (2020). Recent trends in solid waste management status, challenges, and potential for the future Indian cities–A review. Current Research in Environmental Sustainability, 2, 100011.https://doi.org/10.1016/j.crsust.2020.100011. [10] Kumar, A., & Samadder, S. R. (2020). Performance evaluation of anaerobic digestion technology for energy recovery from organic fraction of municipal solid waste: A review. Energy, 197, 117253.https://doi.org/10.1016/j.energy.2020.117253. [11] Kumar, K. N., & Goel, S. (2009).Characterization of municipal solid waste (MSW) and a proposed management plan for Kharagpur, West Bengal, India. Resources, Conservation and Recycling, 53(3), 166-174. [12] Malav, L. C., Yadav, K. K., Gupta, N., Kumar, S., Sharma, G. K., Krishnan, S., ...& Bach, Q. V. (2020). A review on municipal solid waste as a renewable source for waste-to-energy project in India: Current practices, challenges, and future opportunities. Journal of Cleaner Production, 277, 123227. [13] Panigrahi, S., & Dubey, B. K. (2019). A critical review on operating parameters and strategies to improve the biogas yield from anaerobic digestion of organic fraction of municipal solid waste. Renewable Energy, 143, 779-797.https://doi.org/10.1016/j.renene.2019.05.040. [14] Rasimphi, T. E., Tinarwo, D., Sambo, C., Mutheiwana, M. A., & Mhlanga, P. (2022). Decentralized biogas plants: status, prospects, and challenges. Handbook of Biofuels, 473-484. https://doi.org/10.1016/B978-0-12-822810-4.00024-5 [15] Sharholy, M., Ahmad, K., Mahmood, G., & Trivedi, R. C. (2008). Municipal solid waste management in Indian cities–A review. Waste management, 28(2), 459-467.https://doi.org/10.1016/j.wasman.2007.02.008. [16] Solid Waste Management in India - An Assessment of Resource Recovery and Environmental Impact Isher Judge Ahluwalia, Utkarsh Patel, April 2018 http://hdl.handle.net/10419/203690. [17] Tun, M. M., Palacky, P., Juchelkova, D., & Sí?a?, V. (2020). Renewable waste-to-energy in southeast Asia: Status, challenges, opportunities, and selection of waste-to-energy technologies. applied sciences, 10(20), applied.https://doi.org/10.1016/j.techfore.2008.04.004. [18] Vaish, B., Sarkar, A., Singh, P., Singh, P. K., Sengupta, C., & Singh, R. P. (2016).Prospects of biomethanation in Indian urban solid waste: stepping towards a sustainable future. In Recycling of Solid Waste for Biofuels and Bio-chemicals (pp. 1-29). Springer, Singapore.DOI:10.1007/978-981-10-0150-5_1. [19] (2014) Report of the Task Force on Waste to Energy (Online). Available: http://swachhbharaturban.gov.in/writereaddata/Task_force_report_on_WTE.pdf [20] (2015) Energypedia. Types of biogas digesters and plants (Online). Available: https://energypedia.info/wiki/Types_of_Biogas_Digesters_and_Plants [21] (2018) Swachh Bharat Mission–Urban. Advisory on On-Site and Decentralized Composting of Municipal Organic Waste. (Online). Available: https://sbmurban.org/storage/app/media/pdf/Advisory%20on%20decentralised%20composting.pdf [22] (2021) Circular Economy in Municipal Solid and Liquid Waste (Online). Available: https://mohua.gov.in/pdf/627b825fd31b3Circular-Economy-in-waste-management-FINAL.pdf

Copyright

Copyright © 2024 C. Devoor, A. K. Nema. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64331

Publish Date : 2024-09-24

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online