Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Steady & Transient Thermal Analysis Comparison of Square & Round Shaped Engine

Authors: Pramod Sonkar, Vijaykant Pandey

DOI Link: https://doi.org/10.22214/ijraset.2023.57696

Certificate: View Certificate

Abstract

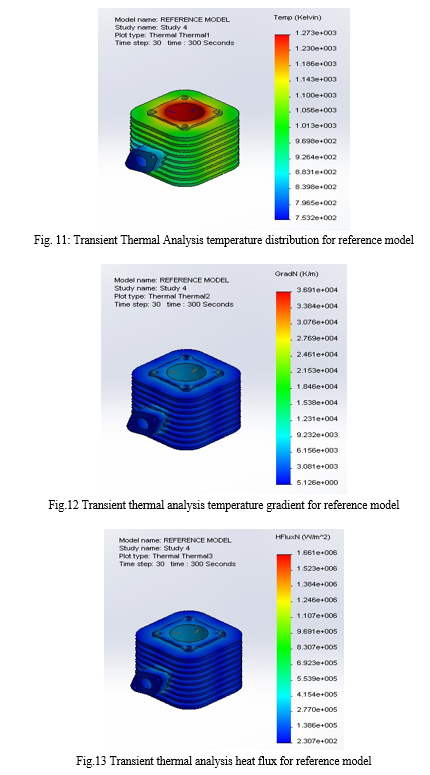

The engine block is the primary support structure for the other components of the engine. When the heat dissipation of the engine block deteriorates, excessive thermal expansion and frictional wear occur in various parts of the engine, which reduces the lubricating power of the engine oil. Therefore, the design of the engine block must be changed to improve its efficiency. In this analysis, a two-stroke gasoline engine block was initially used as a reference model for the development of the modified model. The two models were modeled using SolidWorks simulation software and thermal and computational fluid dynamics (CFD) analyzes were performed. The thermal analysis results show that the maximum temperature gradient and heat flux obtained in steady state and transient thermal analysis. The results show that the modified model has improved heat dissipation rate than the reference model. CFD analysis shows that the reference model experiences higher pressure and air resistance than the modified model. This increases the drag force acting on the reference model. The improved model has increased air flow speed around the engine block compared to the reference model. This is due to changes in the fins of the improved model. As a result, engine block models have lower air restrictions. Here, we recommend performing further validation to determine the effectiveness of the modified model. The performance of the modified model can also be improved by converting the fins to a triangular fin shape.

Introduction

I. INTRODUCTION

In an combustion chamber of internal combustion engine, combustion occur at high temperature and pressure due to which chances of piston seizure , overheating, chances of piston ring, compression ring, oil ring etc can be affected . Excess temperature can also damage the cylinder material. Due to overheating chances of pre-ignition also occurs. In Air cooled motorcycle engines heat release to the atmosphere through forced convection. The rate of heat transfer depends upon the wind velocity, geometry of engine surface, external surface area and the ambient temperature. In this work analysis is done on engine block fins considering temperature inside by means of conduction and convection, air velocity is not consider in this work. Motorbikes engines are normally designed for operating at a particular atmosphere temperature, however cooling beyond optimum limit is also not considered because it can reduce overall efficiency. Thus it may be observed that only sufficient cooling is desirable. Inside the cylinder the temperature of gases will be around 2000 celsius . This is very high temperature and may result into burning of oil film between the moving parts this temperature must be reduced to about 150-200 at which engine will work more efficiently. The internal combustion engine is a type of engine in which a fuel is burned with an oxidizer (usually air) in a combustion chamber. The expansion of high-temperature and high-pressure gases produced by combustion gives direct force to a few components of an internal combustion engine, such as pistons, turbine blades, or a nozzle. This force propels the aspect forward, generating valuable mechanical electricity. Most modern-day internal combustion engines are cooled using a closed circuit of liquid coolant flowing through channels within the engine block, where the coolant absorbs warmth, to a warmth exchanger or radiator, where the coolant releases warmth into the air.

As a result, even though they are ultimately cooled by air, they are referred regarded as water-cooled due to the liquid-coolant circuit. In comparison, heat created by an air-cooled engine is released directly into the air. Typically, this is helped by metallic fins overlaid on the exterior of the cylinders, which increase the surface area on which air may act. In all combustion engines, a large proportion of the heat generated (approximately 44%) leaves via the exhaust, not via a liquid cooling mechanism or the metallic fins of an air-cooled engine (12%). Approximately 8% of the heat electricity finds its way into the oil, which, while generally intended for lubrication, also plays a role in heat dissipation via a cooler.

There are three types of heat transmission. The first is conduction, which is defined as heat transmission via a medium.

Without bulk motion of the substance, intervening should be counted. A stable has two floors, one at high and one at low temperatures. This type of heat conduction can occur in a jet engine, for example, through a turbine blade. The outside floor, which is exposed to gases from the combustor, is hotter than the inside floor, which has cooling air following it. Convection, or heat switch due to a flowing fluid, is the second heat transmission system. The fluid can be a gas or a liquid, and both have uses in aircraft generation. The warmth is transferred by bulk transfer of a non-uniform temperature fluid in a convection warmness switch. The 0.33 process involves the transport of electrical through space without the presence of matter. Radiation is the most effective heat switch technique in the area. Even when there is an intervening medium, radiation can be critical; a common example is heat transfer from a gleaming piece of metal or from a fireplace.

Convective heat transfer between surfaces and surrounding fluid can be improved by introducing slender strips of metallic known as fins. Extended surfaces are another name for fins. When available surfaces are insufficient to transmit the needed amount of heat, fins can be employed. Fins are synthetic and come in a variety of sizes and shapes depending on the use. Air cooling for an integrated circuit The engine is a well-known example of an air cooling system in which air serves as a medium. Heat generated in the cylinder can be dissipated into the environment via conduction mode via the fins or extended surfaces used in this device, which can be included around the cylinder.

II. LITERATURE REVIEW

Pulkit Agarwal etc. [1] simulated the heat transfer in motor cycle engine fan using CFD analysis. It is observed that ambient temperature reduces to the very low value; it results in over cooling and poor efficiency of the engine. They have concluded that over cooling also affects the engine efficiency

Magarajan U et.al. [2] have studied heat release of engine cylinder cooling fins with six numbers of fins having pitch of 10 mm and 20 mm, and are calculated numerically using commercially available CFD tool Ansys Fluent. The engine was at 150 C and the heat release from the cylinder was analyzed at a wind velocity of 0 km/h. Their CFD results were mostly same as that of the experimental results. So, they concluded that, it is possible to modify the fin geometry and predict those results, changes like tapered fins, providing slits and holes in fins geometry can be made and the optimization of fins can be done. A.K. Mishra et.al. [3] carried out transient numerical analysis with wall cylinder temperature of 423 K initially and the heat release from the cylinder is analyzed for zero wind velocity. The heat release from the cylinder which is calculated numerically is validated with the experimental results. To increase the cylinder cooling, the cylinder should have a greater number of fins. However, the cylinder cooling may decrease with an increased number of fins and too narrow a fin pitch.

G. Babu and M. Lavakumar [4] analyzed the thermal properties by varying geometry, material and thickness of cylinder fins. The models were created by varying the geometry, rectangular, circular and curved shaped fins and also by varying thickness of the fins. Material used for manufacturing cylinder fin body was Aluminum Alloy 204 which has thermal conductivity of 110-150W/mk and also using Aluminum alloy 6061 and Magnesium alloy which have higher thermal conductivities. They concluded that by reducing the thickness and also by changing the shape of the fin to curve shaped, the weight of the fin body reduces thereby increasing the efficiency. The weight of the fin body is reduced when Magnesium alloy is used and using circular fin, material Aluminum alloy 6061 and thickness of 2.5mm is better since heat transfer rate is more and using circular fins the heat lost is more, efficiency and effectiveness is also more. S.S. Chandrakant et.al.[5] conducted experiments for rectangular and triangular fin profiles for air velocities ranging from 0 to 11 m/s. Experimental and CFD simulated result proves that annular fins with rectangular fin profiles are more suitable for heat transfer enhancement as compared to triangular fin profiles. Surface temperature of triangular fin profile is higher than rectangular fin profile at different air velocity. Heat transfer coefficient increase with increases with increases in velocity in both profiles. In comparison of both profile rectangular fin profile have higher heat transfer coefficient than triangular fin profile.

III. CFD

Computer primarily based simulation is mentioned during this chapter. procedure simulation is technique for examining fluid flow, heat transfer and connected phenomena like chemical reactions. This project uses CFD for analysis of flow and warmth transfer. CFD analysis accepted go in the various industries is employed in R&D and producing of craft, combustion engines and in powerhouse combustion similarly as in several industrial applications.

A. Why Computational Simulation

Three-dimensional (3D) numerical analysis of whorled coil tubes is dispensed by victimization business CFD tool ANSYS 18.2. this can become troublesome and time overwhelming, if this analysis is dispensed by experimentation. Experimental setup is extremely expensive that's why in my work I take facilitate of CFD to create it easier and fewer time overwhelming.

B. Computational Fluid Dynamics

Computational fluid dynamics, because the name implies, could be a subject that deals with procedure approach to fluid dynamics by means that of a numerical resolution of the equations that cause the fluid flow and though it's known as procedure fluid dynamics; it doesn't simply wear down the equations of the fluid flow, it's conjointly generic enough to be ready to solve at the same time along the equations that direct the energy transfer and similarly the equations that verify the chemical process rates and the way the chemical process takings and mass transfer takes place; of these things may be tackled along in a regular format. So, this define permits America to wear down a really complicated flow circumstances in fairly quick time, specified for a specific set of conditions, associate degree engineer would be ready to simulate and see however the flow is happening and what quite temperature distribution there's and what quite product area unit created and wherever they're fashioned, in order that {we can|we will|we area unit able to} build changes to the parameters that area unit below his management to switch the approach that these items are happening. So, therein sense procedure fluid dynamics or CFD becomes a good tool for a designer for associate degree engineer. it's conjointly a good tool for associate degree associate degreealysis for associate degree examination of a reactor or an instrumentality that isn't functioning well as a result of in typical industrial applications, several things is also happening associate degreed what a designer has had in mind at the time of fabricating or coming up with the instrumentality won't be really what an operator of the instrumentality introduces into the instrumentality at the time of operation, perhaps once 5 years or 10 years changes might need taken place in between; and in such a case, the presentation of the instrumentality won't be up to the quality and you'd wish to modify it in such some way that you just will restore performance. So, the question is then, what this can managed to the autumn within the performance associate degreed what quite measures we are able to build while not creating an overall adjustment within the finish of apparatus. Is it potential to urge improved performance from the equipment? Is it potential to extend the productivity? If you wish to appear on of these analysis, then procedure fluid dynamics is employed.

IV. METHODOLOGY

- Stage 1: Aggregation data and information identified with cooling blades of IC motors.

- Stage 2: A parametric model of the motor square with balance is made in SolidWorks.

- Stage 3: Model got in Step an attempt of is investigated utilizing ANSYS, to get the warmth or warmth rate, warm angle and nodal temperatures.

- Stage 4: Manual computations are finished.

- Stage 5: Finally, we will in general will in general check the outcomes got from ANSYS and manual calculations for totally unique material, shapes and thickness.

A. Transient Thermal Analysis

Transferring different temperatures after a while is desirable for some applications such as cooling electronic packages and final heat treatment inspection. The temperature cycle is fascinating together, involving a hot load that can cause frustration. In such cases, temperatures from transient or unsteady thermal studies are used as a data source or used as initial test start conditions for thermo-baric valuation. Temporal hot probes are performed using ANSYS or Samcef problem solvers.

Intermittent hot testing is involved in many hot motion applications such as heat treatment issues, electronic package fashions and styles, fountains, motor squares, pressure vessels, and fluid structure related issues.

VI. RESULT & DISCUSSION

The reference model has high total pressure and dynamic pressure than the modified model. This increase in pressure, increases the drag force acting on the engine. This shows the modified model has high air flow velocity than the reference model. This is due to the fins modification round the engine block. This makes the engine block model to have low air restriction on the surface of the engine block. The high velocity shown by the modified model would reduce the drag coefficient and reduce the power required to overcome the drag force. The CFD results shows that the reference model has high temperature than the modified model. This agreed with the results obtained earlier during the thermal analysis of the engine blocks. Meanwhile, heat is transferred from a region of higher temperature to a region of lower temperature. During the simulation, the surrounding air of the modified model has low fluid thermal conductivity, specific heat, and fluid density. This is as the result of the heat transfer enhancement by the fins in the modified model. While the high fluid thermal conductivity, specific heat, and fluid density shown by the reference model, implies that some amount heat are retained in the engine block.

Conclusion

This study presents thermal and aerodynamics analysis of a two stroke spark ignition engine block. The modified model shows uniform fins arrangement round the engine cylinder in order to enhance its strength and its heat dissipation. The low temperature shown by the modified model with high temperature gradient and heat flux, indicates that, the modified model has high heat dissipation rate than the reference model, which will subsequently improve the engine efficiency. The CFD analysis shows that, the reference model has high total pressure and dynamic pressure than the modified model. This increase in pressure, increases the drag force acting on the model. While the modified model has high air flow velocity than the reference model; due to its fins modification. This made the modified model to have low air restriction. The CFD results also shows that the reference model has higher temperature than the modified model. This agreed with the results obtained earlier during the thermal analysis of the engine blocks.

References

[1] Pudiri Madhu and N. Sateesh., An experimental investigation into the Modeling and Simulation of Fins for 150cc Engine, SAE paper R. Caves, Multinational Enterprise and Economic Analysis, Cambridge University Press, Cambridge, 1982. International Journal of Recent Development in Engineering and Technology. [2] D. Merwin Rajesh and K Suresh Design and thermal analysis of cylinder fins by varying its geometry and material, IJME International Journal, ISSN NO: 2348- 4845 (2014) [3] Thornhill D. and May A., An Experimental Investigation into the Cooling of Finned Metal Cylinders in a free Air Stream, SAE Paper 1999-01-3307 (1999) [4] Gibson H., The Air Cooling of Petrol Engines, Proceedings of the Institute of Automobile Engineers, Vol.XIV, 243-275 (1920) [5] Biermann E. and Pinkel B., Heat Transfer from Finned Metal Cylinders in an Air Stream, NACA Report No. 488 (1935) [6] Masao Yoshida, Soichi Ishihara, Yoshio Murakami, Kohei Nakashima and Masago Yamamoto, Air-Cooling Effects of Fins on Motorcycle Engine, JSME International Journal, Series B, 49(3), (2006) [7] Zakhirhusen, Memon K., Sundararajan T., Lakshminarasimhan V., Babu Y.R. and Harne Vinay, Parametric study of finned heat transfer for Air Cooled Motorcycle Engine, SAE Paper, 2005-26-361, (2005) [8] Zakirhusen, Memon K. and Sundararajan T., Indian Institute of Technology Madras, V. Lakshminarasimhan, Y.R. Babu and Vinay Harne, TVS Motor Company Limited, Simulation and Experimental Evaluation of Air Cooling for Motorcycle Engine, 2006-32-0099 / 20066599 (2006) [9] Pathak Sunil, Turbo charging and oil techniques inlight motor vehicles, Res.J. Recent Sci, 1(1), 60-65 (2012) [10] Dev Nikhil, Attri Rajesh, Mittal Vijay, Kumar Sandeep, Mohit, Satyapal, Kumar pardeep, Thermodynamic analysis of a combined heat and power system, Res.J. Recent Sci, 1(3), 76-79 (2012) [11] G.Raju, et al. (2012). \"Optimal Design of an I.C. Engine Cylinder Fin Arrays Using a Binary Coded Genetic Algorithms.\" International Journal of Modern Engineering Research (IJMER) 2(6): 4516-4520. [12] U. Magarajan, et al. (2012). \"Numerical Study on Heat Transfer of Internal Combustion Engine Cooling by Extended Fins Using CFD.\" International Science Congress Association 1(6): 32-37. [13] A. Mishra, et al. (2012). \"Heat Transfer Augmentation of Air Cooled Internal Combustion Engine Using Fins through Numerical Techniques.\" Research Journal of Engineering Sciences ISSN 2278:9472. [14] J.A. Paul, et al. (2012). \"Experimental and Parametric Study of Extended Fins in the Optimization of Internal Combustion Engine Cooling Using CFD.\" International Journal of Applied Research in Mechanical Engineering (IJARME) 2(1). [15] G. Babu and M. Lavakumar (2013). \"Heat Transfer Analysis and Optimization of Engine Cylinder Fins of Varying Geometry and Material.\" IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE) 7(4): 24-29. [16] S.S.Chandrakant, et al. (2013). \"Numerical and Experimental Analysis of Heat Transfer through Various Types of Fin Profiles by Forced Convection.\" International Journal of Engineering Research & Technology (IJERT) 2(7). [17] A.R. Kumar, et al. (2013). \"Heat Transfer Analysis in the Cylinder Head of a Four-Stroke SI Engine.\" International Journal of Engineering Research & Technology (IJERT) 2(5). [18] R.P. Patil and P. H. M. Dange (2013). \"Experimental and Computational Fluid Dynamics Heat Transfer Analysis on Elliptical Fin by Forced Convection.\" International Journal of Engineering Research & Technology (IJERT) 2(8). [19] N.P.R. Rao and T. V. Vardhan (2013). \"Thermal Analysis of Engine Cylinder Fins By Varying Its Geometry and Material.\" International Journal of Engineering 2(8). [20] S. Wange and R. Metkar (2013). \"Computational Analysis of Inverted Notched Fin Arrays Dissipating Heat by Natural Convection.\" International Journal of Engineering and Innovative Technology (IJEIT) 2(11). [21] V. GANESAN, (2008). I C Engines, McGraw-Hill Education (India) PVT Limited.

Copyright

Copyright © 2023 Pramod Sonkar, Vijaykant Pandey. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET57696

Publish Date : 2023-12-23

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online