Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Use of Waste Rubber Material as Crumb on Road Construction

Authors: Abhishek Das, Ahad Abbasi, Julius Koushik Ranjan Deka, Heri Tado, Prastuti Talukdar, Palash Protim Borah, Rupjyoti Bordoloi

DOI Link: https://doi.org/10.22214/ijraset.2024.58747

Certificate: View Certificate

Abstract

The growth rate of vehicles is the backbone of economic development of any country. India is the second fast growing automobile industry in the world. In today’s era, solid waste management is the thrust area. On the other side, the traffic intensity is also increasing. As a result, amount of waste tyres is also increasing. The increasing consumption of waste tire has generated many problems such as increasing landfill space, environmental pollution and causing health hazards. Parallel to this is the increasing of roads construction because of heavy traffic on roads. This study reviews to the use of crumb rubber (waste tires in powder form) in bitumen using the wet process. The study focuses on the crumb rubber as a replacement to the total weight of bitumen. The design or life span for all highways and urban roads is 10 – 20 years. Unfortunately, damages or distresses on pavements are still occurring before reaching the maximum period of the designed road serviceability. Among the major influencing factor that is contributing to this distress is the repeated heavy traffic loading on the road surfaces. Moreover, the use of waste crumb rubber in road construction as a pavement surface has a better skid resistance, fatigue crack resistance and increased rut resistance. The review includes physical tests that are used to determine the physical properties of bitumen and modified crumb rubber mix. The physical tests involve penetration test, softening point test, and ductility test. The expectations from the study are to develop bitumen with waste crumb rubber that would minimize the costs of bitumen and providing better physical properties compared to the convention bitumen based on the tests that was conducted.

Introduction

I. INTRODUCTION

In India, over 15 million waste tires are generated annually. Not only are these tire mounds eyesores, they are also environmental and health hazards. The little pools of water retained by whole waste tires create an ideal breeding ground for mosquitoes. Aside from the persistent annoyance, mosquitoes have been shown to spread various dangerous diseases. Equally hazardous are tire fires, which pollute the air with large quantities of carbon smoke, hydrocarbons, and residue. These fires are virtually impossible to extinguish once started. Currently, the only large-scale methods to use waste tires are through burning for electric power generation, production of cement in cement kilns, energy to run pulp and paper mills, and recycling at tires-to-energy facilities. In 1990, the Environmental Protection Agency (EPA) estimated that out of the 242 million waste tires generated that year, 78% of the tires were either stockpiled, a land filled, or illegally dumped. While some states burn waste tires this is only a temporary solution because of the tires, in many cases, tend to float back up to the surface. Land filling waste tires has also become more and more expensive as landfill space has decreased. To overcome the above problems, we can use tyre in road construction. Bituminous mixes are used widely for paving applications in India and worldwide. Currently, the road projects in India are taken up under Design, Build Operate and Transfer (DBOT) basis. The highway designer and the agency have to ensure satisfactory performance of the pavement during the design life to meet the contractual obligations. The selection of appropriate paving binders duly considering the climatic and loading conditions and the scientific design of the thicknesses of various pavement layers dictate the serviceability of the bituminous pavements during the design life. The mechanical properties of bituminous mixes depend to a large extent on the type, quality and quantity of binder used. Defects in flexible pavements such as rutting, crack initiation and propagation occur are not only due to traffic loads but also due to the thermal susceptibility of bituminous binders.

The materials that gain prominence in the area of improved pavement performance are modified bituminous binders. Modifiers in the form of polymers, natural rubber, fillers etc., are added to virgin bitumen in an attempt to improve its mechanical and thermodynamic properties. To understand the applicability and performance of these modified bituminous binders, traditional specifications based on measurements of viscosity, penetration, ductility, softening point and elastic recovery are generally not adequate.

In order to relate the properties of the binder to the properties of the bituminous mixes and later to the field pavement performance, it is necessary to carry out investigations and understand the rheological behaviour of the bituminous mixes with modified bituminous binders. Investigations on the performance of bituminous mixes with different modified bituminous binders will provide the much-needed information on the longevity of modified bituminous binders over conventional bitumen under different traffic, climate and environmental conditions.

A. Hazards of Tyre Waste

- This waste tyres are produced carbon by burning process.

- This number of tyres is very large manner, so it becomes dangerous as well as uncomfortable to placing, because of Land problems to our country.

- Potentially harmful substances were found exposed to highly acidic solutions.

- Aside from the persistent annoyance, mosquitoes have been shown to spread various dangerous diseases.

- Equally hazardous are tyre fires, which pollute the air with large quantities of carbon smoke, hydrocarbons, and residue.

II. LITERATURE REVIEW

Many types of research were carried out by many scholars and professors of civil engineering in this field, to find the ways and crumb rubber mix in conventional bitumen to improve in engineering properties of bitumen.

Nabin Rana Magar, (2014) investigates the performance of crumb rubber modified bitumen by varying the sizes of crumb rubber. The test results of common laboratory test on plain bitumen and crumb rubber modified bitumen shows that the penetration values and softening points of plain bitumen can be improved significantly by modifying it with the addition of crumb rubber which is a major environmental pollutant. The best size to be used for crumb rubber modification is suggested as (0.3-0.15mm) size for commercial production of CRMB.

Siddharth Rokade, (2012) The Crumb Rubber was added to 60/70 grade bitumen in varying percentage. The mix was prepared with 5 % bitumen and the varying percentages of Crumb Rubber. The bitumen, when mixed with Crumb Rubber, is termed as Crumb Rubber Modified Bitumen (CRMB). The results observed that the Marshal Stability Value is increased from 4% to 12% Crumb Rubber and then it is decreased 15% of Crumb Rubber of the weight of bitumen is the optimum dose for getting enhanced strength characteristics of the mix.

Nuha S.Mashaan, (2012) In their study presented the application of crumb rubber modifier in the asphalt modification of flexible pavement. From the results of the previous study, it aspires to consider crumb rubber modifier in hot mix asphalt to improve resistance to rutting and produce pavement with better durability by minimizing the distresses caused in hot mix asphalt pavement. Hence, road user would be ensured of safer and smoother roads.

Mashaan et al, (2011a) The penetration is a measure of hardness or softness of bitumen binder which shows an effect by adding crumb rubber to bitumen binder; it decreases as rubber content is increased. The penetration shows lower values as rubber content increases at different mix conditions of rubberized bitumen binder, indicating that the binder becomes stiff and more vicious The softening point refers to the temperature at which the bitumen attains a particular degree of softening. The use of crumb rubber in bitumen modification leads to an increase in the softening point and viscosity as rubber crumb content increases.

Becker et al, (2001) claimed that blend properties will be influenced by the amount of crumb rubber added to the bitumen. Higher amounts indicated significant changes in the blend properties. As rubber content generally increases, it leads to increased viscosity, increased resilience, increased softening point and decreases penetration at 25°C.

Abedlrahman and Carpenter, (1999) From the study he determines that the various properties of CRMB vary with blending temperature and blending time. The optimum blending temperature and blending time found out 175ºC and 45 minutes respectively for preparing high-quality CRMB.

III. METHODOLOGY

The purpose of this study was to investigate the effects of rubber waste on bitumen. This report discusses several tests that will be conducted to achieve the objectives of the study. In order to evaluate the quality of rubber waste on road asphalt, laboratory experiments have to be done to identify the performance of the modified bitumen with rubber waste compared to the unmodified bitumen. All the laboratory experiment is based on the standard specification on ASTM and AASHTO. Study will be carried out by using experimental methods to evaluate the quality of rubber waste and its suitability in road pavement. The sample testing on rubber waste as modifier in bitumen is carried out through the bitumen tests.

Testing on bitumen have to be carried out is Ductility Test, Penetration Test and Softening Point Test and Specific Gravity test in order to ensure it performs well on the specification. The available waste was checked regarding its quantity and dumping. Then followed the samples collection, treatment and cleaning to remove organic and inorganic impurities like grasses, mud, etc. The tire rubber waste was cut and heated, and then mixed with bitumen under partial replacement of 5%, 10%, 15%, and 20% bitumen weight. These percentages were selected as practical values to make more feasible the measurement of the portion.

IV. MATERIALS USED

This chapter provides a background on the materials used in road construction and how to use the waste tyre in road construction as a base to reduce cost of construction and to enhance speed of construction techniques in civil engineering.

A. Bitumen

Bitumen is a black, highly viscous and very sticky liquid or semi-solid, found in some natural deposits. It is also the by-product of the fractional distillation of crude petroleum. Generally, in India bitumen used in road construction of flexible pavement is of grades 60/70 or 80/100 penetration grade.

B. Crumb Rubber

The major component of crumb rubber modifier (CRM) is scrap tire rubber which is primarily natural and synthetic rubbers and carbon black. Automobile tires have more synthetic rubber than truck tires. Truck tires contain a higher percentage of nature rubber than automobile tires. Advances in tire manufacturing technology have decreased the difference in chemical composition between the types of tire rubber. The typical bulk CRM produced in today’s market is uniform in composition. The average car tire contains ten types of synthetic rubber, four types of natural rubber, four types of carbon black, steel cord, bead wire, and 40 kinds of chemicals, waxes, oils, pigments, etc.

- Advantages of Crumb Rubber: 1. Lower susceptibility to daily & seasonal temperature variations 2. Higher resistance to deformation at elevated pavement temperature 3. Better age resistance properties 4. Higher fatigue life of mixes 5. Better adhesion between aggregate & binder 6. Prevention of cracking & reflective cracking 7. Overall improved performance in extreme climatic conditions & under heavy traffic condition.

- Experimental mixing of Crumb Rubber with Bitumen: In preparing the modified binders, about 500 gm of the bitumen was heated to a fluid condition in a 1.5- litre capacity metal container. For the blending of crumb rubber with bitumen, it was heated to a temperature of 160 °C and then crumb rubber was added. For each mixture sample 5%, 10%, 15%, 20% of crumb rubber by weight is used. The blend is mixed manually for about 3-4 minutes. The mixture is then heated to 160 °C and the whole mass was stirred using a mechanical stirrer for about 50 minutes. Care is taken to maintain the temperature between 160 °C to 170 °C. The contents are gradually stirred for about 55 minutes. The modified bitumen is cooled to room temperature and suitably stored for testing.

- Desirable Properties of Bituminous Mix: Adequate stability of the mix to withstand the stresses and deformation due to the repeated application of the wheel loads; this may be achieved by selecting a suitable type and gradation of aggregates, appropriate binder and its proportion. Adequate flexibility of the mix to withstand fatigue effects and the development of cracks during service life of the pavement to be achieved by the selection of proper mix of aggregates and binder. Adequate resistance to permanent deformation such as rutting due to movement of heavy wheel loads during hot weather; this may be achieved by selection of good quality of aggregates, ensuring its appropriate gradation and densification of the mix during compaction. Possess adequate resistance to low-temperature cracking under traffic movement, this may be achieved by selection of suitable type and grade of bituminous binder.

C. Description of Natural Rubber

Natural rubber is made up of long isoprene polymer chains, loosely connected. The chains reattach themselves when pulled apart; this gives rubber its elasticity. As opposed to synthetic rubbers, which are made from petrochemicals, natural rubber is made from the latex sap of rubber trees (although other plants also produce latex, rubber trees are the most efficient at producing rubber, making them the suppliers of latex for 99% of natural rubber).

- Effect of Temperature on Natural Rubber: 1. At-10°C - brittle and opaque 2. At 20°C - soft, resilient, and translucent 3. At 50°C - plastic and sticky 4. At 120°C -160 C - vulcanized when agents like sulphur are added 5. At 180°C - break down as in the masticator 6. At 200°C – decomposes.

- Vulcanization of Rubber: Raw dry rubber is heated with sulphur (3%-5% based on the requirement), zinc oxide (a filler, 5%) and accelerator (0.5% - 1%) at 125’ C-165’ C for about half an hour. As the sulphur quantity increases, the rubber becomes tougher. 50% sulphur gives ebonite (vulcanite). An accelerator containing nitrogen, sulphur or both is used to increase the reaction rate and for vulcanization to occur at room temperatures.

|

Serial No. |

Raw Natural Rubber |

Vulcanized Natural Rubber |

|

1. |

Soft and sticky |

Comparatively hard and non-sticky |

|

2. |

Low tensile strength and not very strong |

High tensile strength and very strong |

|

3. |

Low elasticity |

High elasticity |

|

4. |

Can be used over a narrow range of temperatures from 10 to 60 degrees centigrade |

Can be used over a wide range of temperatures from -40 to 100 degrees centigrade |

|

5. |

Absorbs a large amount of water |

Absorbs a small amount of water |

|

6. |

Soluble in solvents like ether, carbon disulphide, carbon tetrachloride, petrol and turpentine |

Insoluble in all the usual solvents |

|

7. |

Low abrasion resistance |

High abrasion resistance |

Table 1. Difference between natural and vulcanised rubber

V. EXPERIMENTAL TESTS PERFORMED

A. Experiment No.1

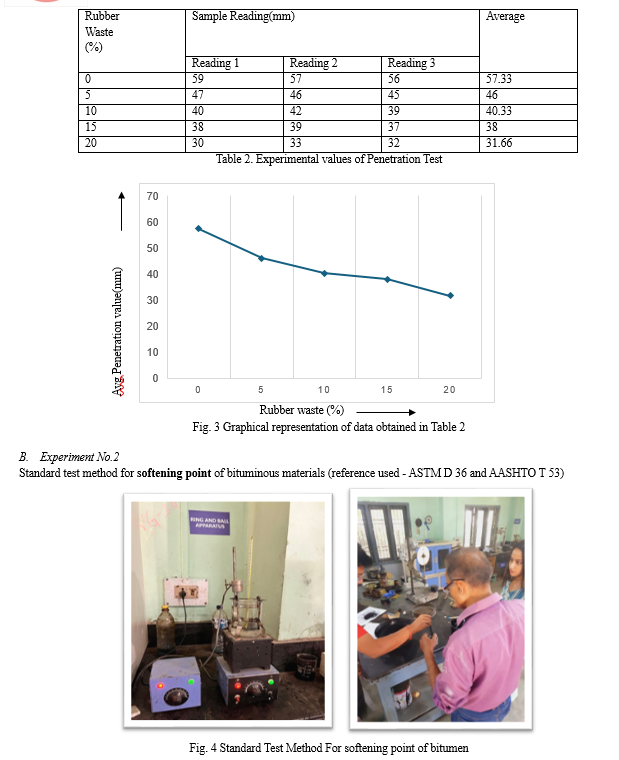

Standard test method for penetration of bituminous materials (reference used - ASTM D5 and AASHTO T49)

\

\

Conclusion

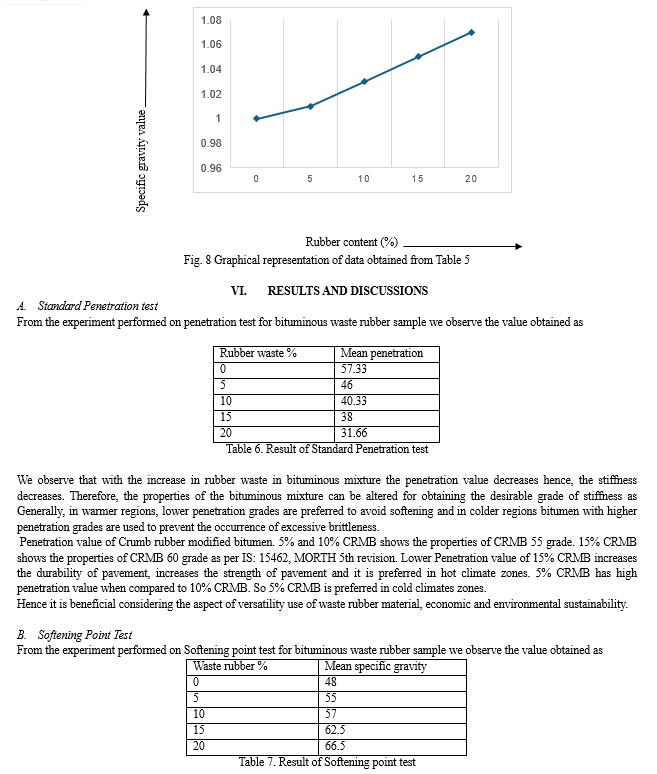

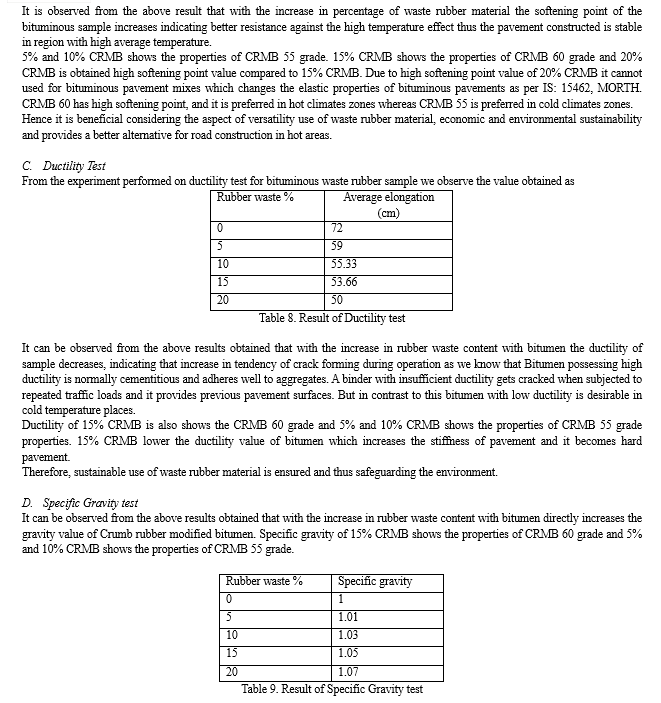

Use of waste rubber material with bitumen for road construction is proven to be more convenient than the regular use of bitumen. This adoption of practice mitigates and aid for the problem faced in solid waste management and thus converting the concern of bulk waste generation due to the booming of the industrial sector and transportation sector into a sustainable alternate. For carrying out the physical test of this thesis, the rubber waste which was chosen as tube sample was shredded into small sections and was brought into powdered form by means of treating it on extreme temperature and added in small percentage by the weight of the bitumen. Four tests are performed namely: Penetration test, soft point test, ductility test and specific gravity test. The penetration test indicating the gradation of bitumen has obtained better results for the bitumen with waste rubber material with mixture than bitumen alone. As penetration test indicates the hardness or softness of a bitumen by measuring the depth in tenths of a millimeter to which a standard loaded needle will penetrate vertically in 5 seconds under specified, load, temperature, and duration of loading. After mixing the rubber waste the value of penetration decreases which is beneficial for road construction. Softening point test which helps us to know the temperature up to which a bitumen binder should be heated for various use applications has also shown better results for bitumen with waste rubber material as a mixture. The resistance against temperature will increase, that is the road will resist higher temperature impact. So, using rubber waste in bitumen will be beneficial for us. Ductility test which gives information about the tensile strength and ductility grade of material is also seen to give better results for bitumen with waste rubber material. Poor adequacy of ductility results in the cracking of pavement. Ductility test result shows that the rubber waste added will harden the bitumen. The bitumen becomes more viscous and harden, which would be useful to obtain stiffer bitumen asphalt. Specific gravity test performed to determine the workability of the bitumen binder has also given better result for bitumen with waste rubber material.it helps us to know whether the mix is lighter or heavier than water. `Waste rubber also causes many problems in the environment. The heavy metals and chemicals they contain leach into the environment as they slowly decompose in contact with other liquids in the landfill. The leachate contains harmful and carcinogenic substances and contaminates the soil, groundwater, and farmland.From the consideration of above observation and test it can be concluded that bitumen when mixed with waste rubber material in small percentage by weight results in better physical properties than the convention method and is more desirable economically, environmentally and sustainably. Based on above observations, it is concluded that 5% and 10% CRMB shows the properties of CRMB 55 grade and 15% CRMB shows the properties of CRMB 60 grade. 5% CRMB is recommended in cold climate zones due to its high penetration value and 15% CRMB is recommended in hot climate zones due its lower ductility and higher stiffness of pavements. The properties of 20% CRMB are failed due to high content of waste rubber and could not able to obtain any grade as per specifications of IS: 15462 hence not used for flexible pavement mixes.

References

[1] J. L. McQuillen, H. B. Takallou, R. Gary Hicks, and D. Esch, “Economic analysis of rubber-modified asphalt mixes,” Journal of Transportation Engineering, vol. 114, no. 3, pp. 259–277, 1988. [2] W. C. Vonk and A. L. Bull, “Phase phenomena and concentration effects in blends of bitumen and cariflex TR,” in Proceedings of the 7th International Roofing Congress, Munich, Germany, 1989. [3] T. C. Billiter, J. S. Chun, R. R. Davison, C. J. Glover, and J. A. Bullin, “Investigation of the curing variables of asphalt rubber binder,” Petroleum Science and Technology, vol. 15, no. 5-6, pp. 445–469, 1997. [4] M. Attia and M. Abdelrahman, “Enhancing the performance of crumb rubber-modified binders through varying the interaction conditions,” International Journal of Pavement Engineering, vol. 10, no. 6, pp. 423–434, 2009. [5] J. Peralta, H. M. R. D. Silva, A. V. Machado, J. Pais, P. A. A. Pereira, and J. B. Sousa, “Changes in rubber due to its interaction with bitumen when producing asphalt rubber,” Road Materials and Pavement Design, vol. 11, no. 4, pp. 1009–1031, 2010. [6] D. Lo Presti, G. Airey, and P. Partal, “Manufacturing terminal and field bitumen-tyre rubber blends: the importance of processing conditions,” Procedia, vol. 53, pp. 485–494, 2012.

Copyright

Copyright © 2024 Abhishek Das, Ahad Abbasi, Julius Koushik Ranjan Deka, Heri Tado, Prastuti Talukdar, Palash Protim Borah, Rupjyoti Bordoloi. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET58747

Publish Date : 2024-03-03

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online