Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Weight Monitoring System for Truck Load

Authors: Mr. Manjunatha Prabhu, Omprakash SM, Raghavan A, Shobharaj C, Vinay Kumar KM

DOI Link: https://doi.org/10.22214/ijraset.2024.58400

Certificate: View Certificate

Abstract

For cargo to be moved safely and effectively, a truck load weight monitoring system is required Overloading of trucks not only poses a risk to road safety but also causes excessive wear and tear on the vehicle, resulting in higher maintenance costs and reduced fuel efficiency. To address these challenges, an advanced weight monitoring system has been developed to measure and monitor the weight of truck loads using HX711 loadcell. When it comes to monitoring and managing the weight of truck loads. Overloading of trucks has been a longstanding issue in the industry. It not only compromises road safety but also has detrimental effects on the vehicles themselves. Excessive weight can lead to increased braking distances, compromised steering control, and increased risk of tire blowouts, all of which contribute to higher accident rates. This system utilizes advanced technologies and sensors to accurately measure and monitor the weight distribution of cargo carried by trucks. By providing real-time weight information using GPS and GSM modules, operators and fleet managers can make informed decisions to ensure compliance with weight regulations and prevent overloading

Introduction

I. INTRODUCTION

The weight-in-motion (WIM) system, the bridge weigh-in-motion system, the portable scale, and the stationary truck weigh station comprise the current system. Although they can measure the load, the first two are trustworthy. Measurements from the weight in motion system enable a continuous recording of vehicles as they weigh the axle length or wheel weights. The weight monitoring system typically consists of load sensors. The data from these sensors is then collected by data acquisition units, which convert analog signals into digital data for further processing. These units are equipped with microcontrollers or specialized signal processing circuits to ensure real-time data acquisition and transmission. The acquired data is then sent to the central monitoring system for analysis and display. The acquired weight data is transmitted to a central monitoring system, which serves as the control centre for the weight monitoring system. This system provides a user-friendly interface for operators to visualize and manage the weight information. It displays real-time weight distribution, alerts the operator in case of overloading, and stores historical data for analysis and reporting purposes.

II. LITERATURE SURVEY

B.Vishnupriya , M.Susmitha , S.Valarmathi , S.Dheenathayalan and R.Rajakumari published paper “ Load Detection And Monitoring System” in theyear 2020 under the international journal of scientific & technology It states that there is currently no way to check a vehicle's weight at the tollgate. This work will be implemented on the tollgate area to use a weight sensor to detect the load carried by the vehicle. Determining whether the vehicle is overloaded is the primary goal of this work. The vehicle's load will be displayed on the display screen, and the weight will be compared to a database that contains the legal maximum weight for each kind of vehicle. An alert is generated in the event that the vehicle's capacity is exceeded. Because it prevents accidents by preventing the vehicle from carrying an excessive load and because it prolongs life, this work is regarded as protected work. time of the road. Hope that if it comes in practice, it will play a major role in government sector.

M.Lakshmi and K.Hariprasad published paper “ Automatic Weight Monitoring Using Rfid and Load Cell” in the year 2016 under journal It claims that new scientific and technological innovations are thriving throughout the world. In our nation, the transportation of heavy vehicles is very important. Owners and operators of heavy vehicles in our nation risk fatalities, serious injuries, and lost cargo. The primary causes of traffic accidents are goods theft and the mid-stream addition of drugs. In our project, tollgate-based RFID technology is being used to gather sensor data. Two corners of the field will have sensors installed in order to position the vehicle and obtain load weight data through a load cell. Once the vehicle is in position, a camera will be activated, capturing a front image of the vehicle and storing data such as load weight, vehicle details, and image data for mailing., with the data client can cross verify the details regarding the transportation.

III. PROBLEM STATEMENT

The current methods of weight monitoring for truck loads are manual and prone to errors, leading to noncompliance with weight regulations, increased safety risk. It often difficult for drivers and owner to accurately estimate the weight of their loads, especially when loads are constantly changing. This can lead truck being overloaded, variety of problem and decrease in the efficiency. To ensure theft of load in truck.

IV. NEW APPROACH

In order to prevent load theft and manage load-related issues, this paper proposes an integrated system that also helps to provide real-time feedback from the load cell and GSM module.

V. OBJECTIVES

- To provide real time feedback to the owner or central dispatch system.

- To ensure that truck is not overloaded. To provide easier convenience to the owner.

- By ensuring that trucks are not overloaded, the system can help improve safety on the roads by reducing the risk of accidents caused by overloaded trucks.

- To avoid the theft load in truck

VI. BASIC WORKING PRINCIPLE

Whenever the truck is loaded, we cannot monitor the weight continuously so we have proposed weight monitoring system for truck load. It typically involves measuring and tracking the weight of the load carried by a truck throughout its journey. This is important for various reasons such as ensuring compliance with legal weight limits, preventing overloading.

The HX711 load cell, which we utilized in our model, amplifies the low electric output. The amplified signal is then digitally converted and fed into the Arduino to determine the weight. It comes with a small breakout board that houses a dual-channel, 24- bit precision A/D weight pressure sensor load cell amplifier. For ease of interface, the board has pinouts for the microcontroller and load cell in two different directions. The LCD (liquid crystal display) shows the weight. Through Arduino we have connected GPS and GSM module. It facilitates keeping track of and monitoring the truck's weight. GPS is a navigation system that is based on satellites and offers precise timing and location data.

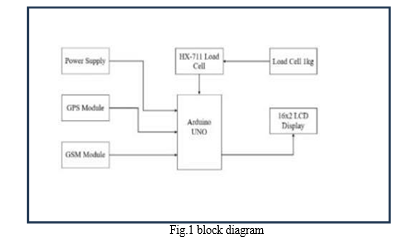

In a weight monitoring system for truck loads, GPS can be used to track the location of the truck and monitor its movement. The GPS receiver receives signals from at least four satellites and calculates its precise location based on the time delay of the signals. This location information is then transmitted to a central monitoring station or server via a communication network (such as GSM or internet). By integrating GPS and GSM technologies, the weight monitoring system can not only track the location and movement of the truck but also transmit weight-related data to a central monitoring station in real-time. This enables remote monitoring, data analysis, and timely decision-making regarding the truck's load status, route optimization, and compliance with weight regulations. Figure 1 shows the block diagram of proposed method of our project.

D. Arduino (UNO)

Arduino is an open-source electronics platform featuring user-friendly hardware and software components. It includes a programmable microcontroller equipped with digital and analog input/output pins, making it versatile for a wide range of applications. Its simplicity, coupled with the Arduino IDE and a simplified version of C++ programming language, makes it accessible to beginners and hobbyists interested in electronics and programming. Arduino finds applications in diverse fields such as robotics, home automation, art installations, and scientific research. With a vibrant community of users, Arduino encourages collaborative learning and innovation by facilitating the sharing of projects, code, and knowledge. This open approach has democratized electronics, empowering enthusiasts, students, and professionals to create interactive and intelligent projects effortlessly.

VIII. RESULT AND DISCUSSION

Table 8.1 Weight Regulation of the model

|

Weight of the load is more than 800 gram |

Weight of the load is less than 800 gram |

|

Truck load is more with how much extra weight it is carrying in gm and with location of the truck |

Truck load is less with how much extra weight it is carrying in gm and with location of the truck |

Table 8.1 gives the data of our model in which we have taken 1kg load cell to calculate the weight of the truck load where we have set 800gm has constant value in which if the load is above the normal weight we get the information of the increased weight and live location of the truck if the weight is less than the normal weight then also same procedure follows.

IX. ACKNOWLEDGMENT

We would like to thank our guide, Prof. Mr. Manjunatha Prabhu P, Assistant Professor, Department of EEE, PESITM, Shivamogga, for his invaluable guidance, encouragement, and support throughout the project. We also thank Dr. Om Prakash Yadav, Head of the Department, EEE, PESITM, Shivamogga, for his assistance and encouragement. We thank Dr. Chaitanya Kumar M V, Principal, PESITM, Shivamogga, for providing this opportunity to further our knowledge. We thank the management, all of the faculty members, and the lab staff members of the department for their consistent support and cooperation. Finally, we cannot forget the support we received from our family and friends.

Conclusion

In conclusion, the weight monitoring system for truck loads is a valuable tool for tracking and managing the weight carried by trucks. However, it is important to be aware of its limitations. The system\'s accuracy depends on proper calibration and maintenance of the weighing equipment. External factors like road conditions and temperature can also impact the accuracy of weight measurements. Furthermore, the system may face challenges in measuring dynamic loads and detecting certain types of load tampering. By acknowledging these limitations and taking appropriate measures to address them, the weight monitoring system can be effectively utilized to enhance truck load management and ensure compliance with weight regulations.

References

[1] B. Vishnupriya , M.Susmitha , S.Valarmathi ,S.Dheenathayalan and R.Rajakuma published paper “ Load Detection And Monitoring System” volume 9, February(2020)- international journal of scientific & technology. [2] AMOL SHENDE , PRANIL RAMTEKE , ANKITA KADU , RUPALI RAUT and ROSHNI BHAVE - “ Truck Load and Monitoring Analysis for Vehicle Routing System” volume 1, March(2018) under the IRE journal. [3] M.Lakshmi and K.Hariprasad published paper “ Automatic Weight Monitoring Using Rfid and Load Cell” - (2016). [4] Sravanthi Alamandla, Kishore Putha and Sai Prasad R L N ,”FBG sensing system to study the Bridge weighin-motion for measuring the vechicle parameters”(2018). [5] K.Balamurugan,Dr.R.Mahalakshmi, Dr.S.Elangovan and R.Pavithra “Automatic check-post and fast track toll system”(2017). [6] Akshay Bhavke and Sadhana Pai “Smart weight based toll collection vechicle detection during collision using RFID”(2017). [7] Rakesh Kumar Giri, “An Itinerant GPRS-GPS and Sensors Integration Atmospheric Effluence Screening “International Journal of Technology And Engineering System (IJTES): Jan –March2016- Vol.2.No. [8] Bonde, D.1.; Shende, R.S.; Gaikwad, K.S.; Kedari, AS.; Bhokre, AU., \"Automated car parking system commanded by Android application,\" in Computer Communication and Informatics(ICCCI), International Conference on, vol., no., pp.l-4, 3-5 [9] Zantout R, Fleet management automation using the global positioning system, Conference at Al Ain, IEEE- 2016, ISBN:9781- 4244-5698-7 ThuongLeTien, Vu Phung, Vietnam “Routing and Tracking System for Mobile Vehicles in Large Area” IEEE 2010. [10] Andrew Jason Tickle, Proof-of-Concept Development for a Weight-to-Speed System on Heavy Goods Vehicles, 2012. [11] K. Ertugay and S. Duzgun, “GIS-based stochastic modeling of physical accessibility using GPS-based floating car data and Monte Carlo simulation,” International Journal of Geographical Information Science, vol. 25, no. 9, pp. 1491-1506, 2011 [12] Farhad Ismail, Development of a Model for Electronic Toll Collection System, IEE Sensors Applications Symposium (SAS), 2015. [13] Mehran Safdar, A Mobile Vehicle Weight Sensor and its Application in Transportation, Trends cogn.sci, 4(3), 2000, 91-99. [14] Nemoto T, Measurement by load cells of impact force which a human body receives by external force, Journal of Software Engineering, 2009. [15] C. C. Cheong and L.Nadiah, “Transport policies and patterns: A comparison of five Asian cities,” JOURNEYS, September 2013 [16] K. Ertugay and S. Duzgun, “GIS-based stochastic modeling of physical accessibility using GPS-based floating car data and Monte Carlo simulation,” International Journal of G eographical Information Science, vol. 25, no. 9, pp. 1491-1506, 2011 [17] J. Pei, Z.-Q Hu, and J. Zhang, “High dynamic carrier phase locked loop design and performance analysis,” Science of Surveying and Mapping, no. 3, pp. 147-149, 2012. [18] J. Li, C. Li, and Z. Yin, “ArcGIS based kriging interpolation method and its application,” Science of Surveying and Mapping, no. 9, pp. 87-97, 2013. [19] BMB. Li and L. Wu, “Simulation system design and application of traffic capacityof urban main roadways network based on ArcGIS engine,” Journal of Chongqing Jiaotong University (Natural Science), S1, pp. 555-559, 2012. [20] Yanling Liu and Zhenhua Liu “An optimized method for dynamic measurement of truck loading capacity”(2018). [21] MohamedRehan Karim, Nik Ibtishamiah Ibrahim, Ahmad Abdullah Saifizul and Hideo Yamanaka “Effectiveness of vehicle weight enforcement in a developing country using weigh-in- motion sorting system considering vehicle”(2018). [22] inxinqiao, Yidingzhao “Vehicle overload detection system based on magnetoresistance sensor.(2018). [23] Xueyun Hua “The development of vehicle load detection system based on the deformation of shock” (2016). [24] Yiding Zhao “The Study of Vehicle Load Monitoring System Applied Mechanics and Materials” (2014).

Copyright

Copyright © 2024 Mr. Manjunatha Prabhu, Omprakash SM, Raghavan A, Shobharaj C, Vinay Kumar KM. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET58400

Publish Date : 2024-02-12

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online